Patents

Literature

367 results about "Photonic crystal fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

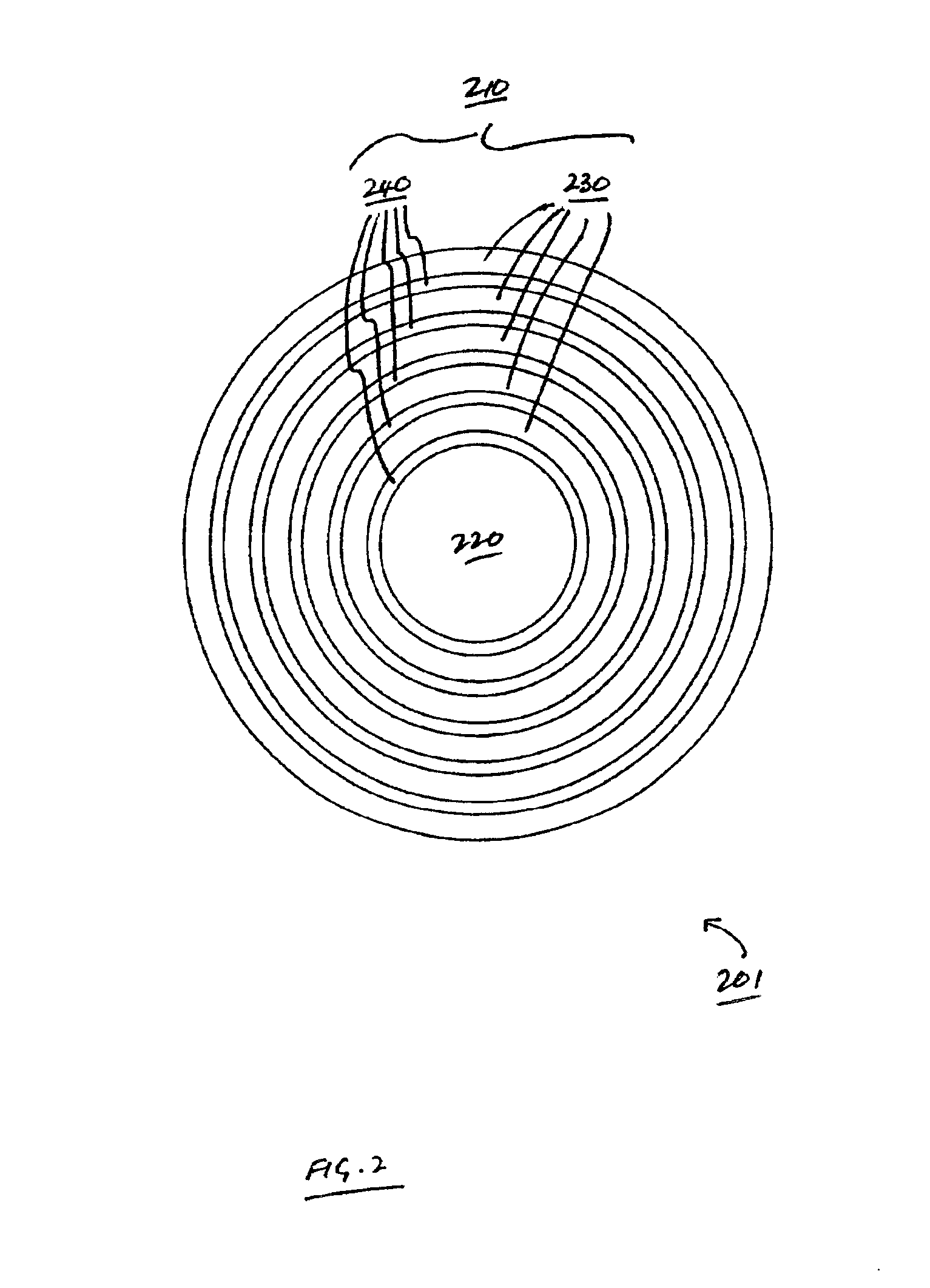

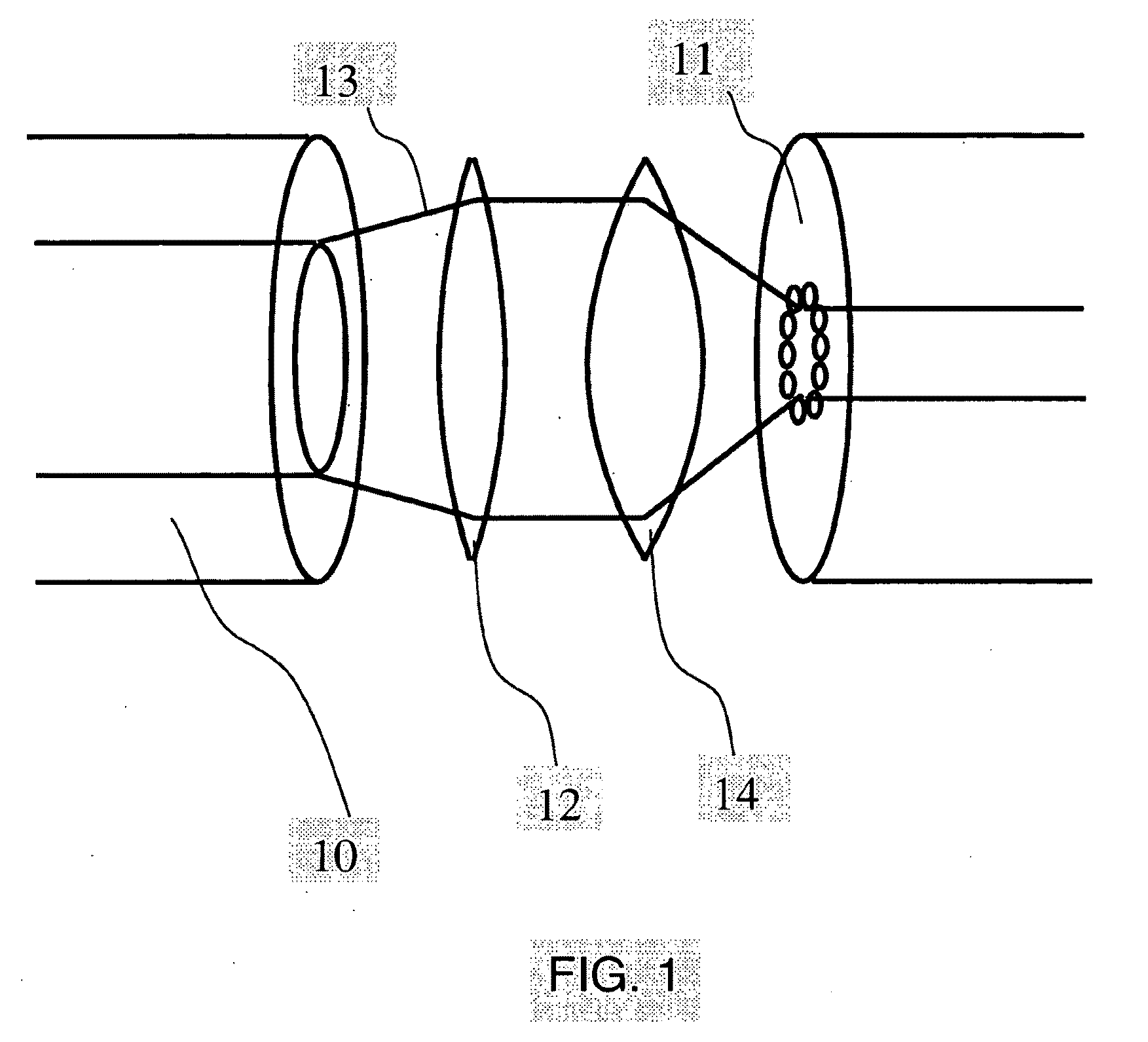

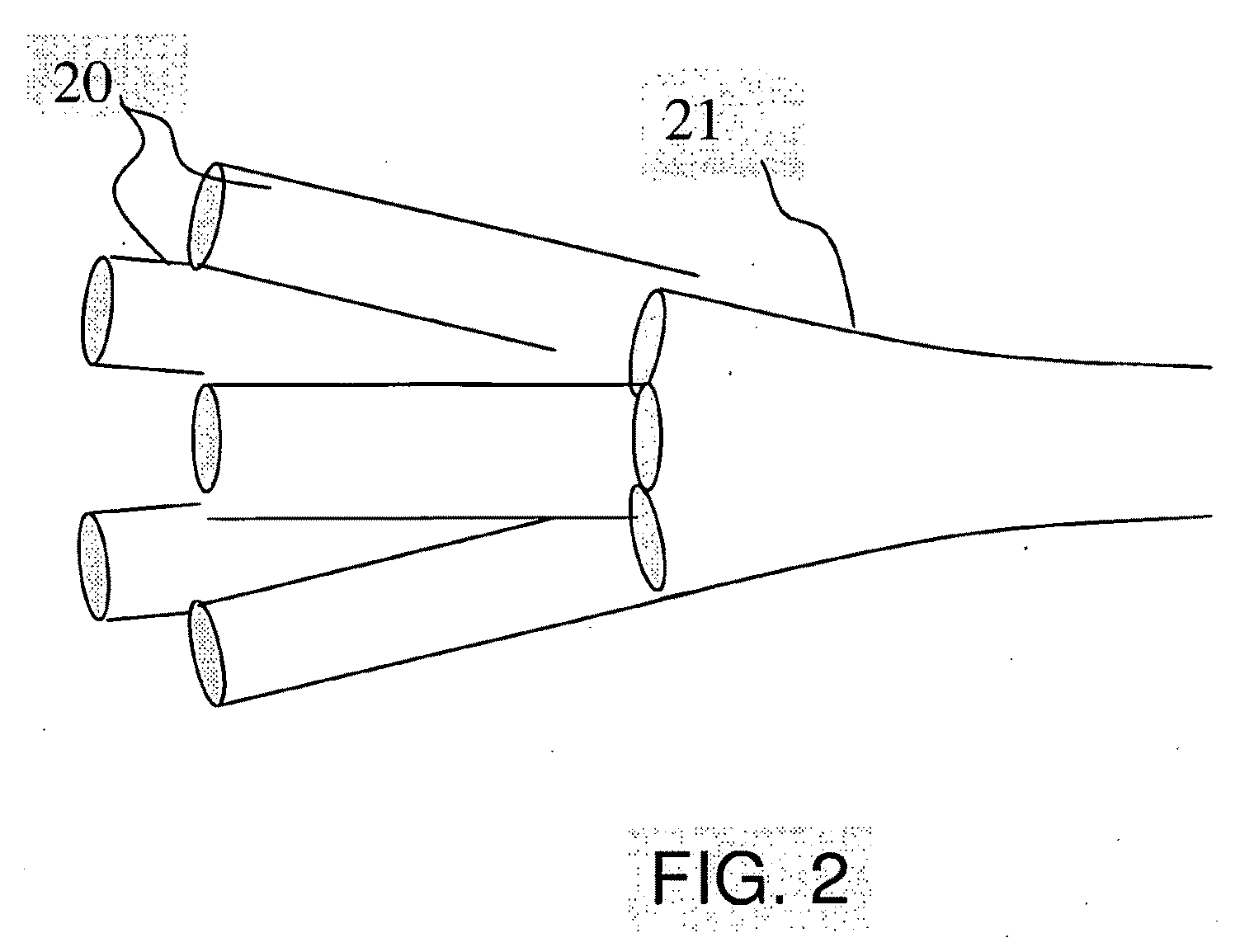

Optical Coupler Devices, Methods of Their Production and Use

InactiveUS20070237453A1Laser using scattering effectsOptical fibre with multilayer core/claddingDouble-clad fiberWaveguide

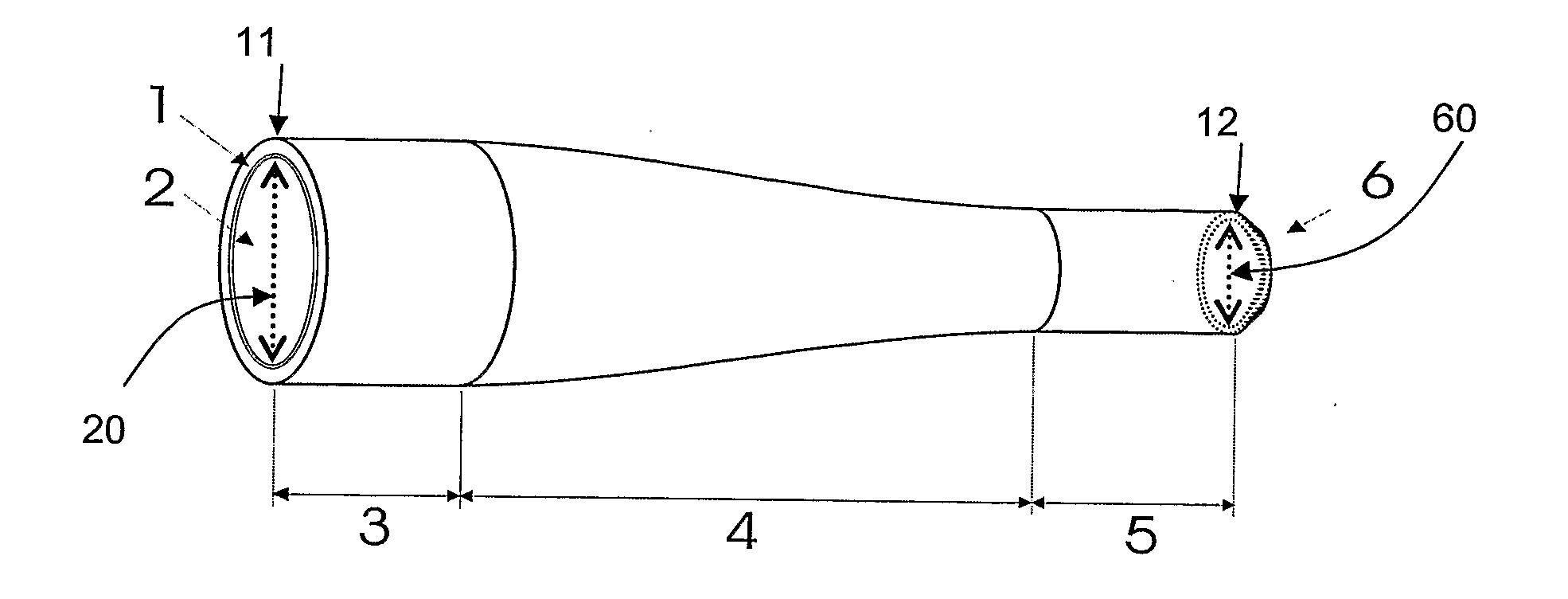

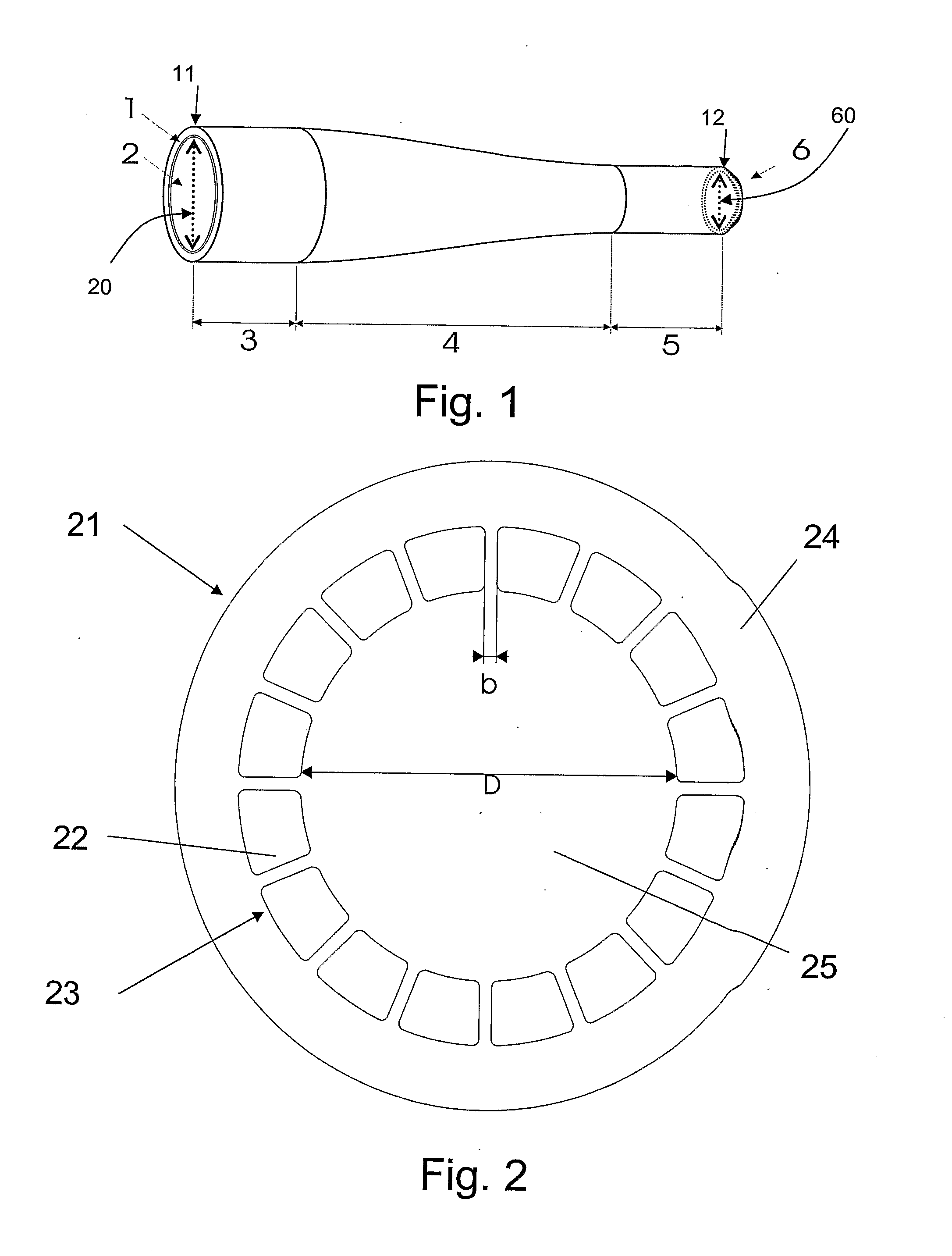

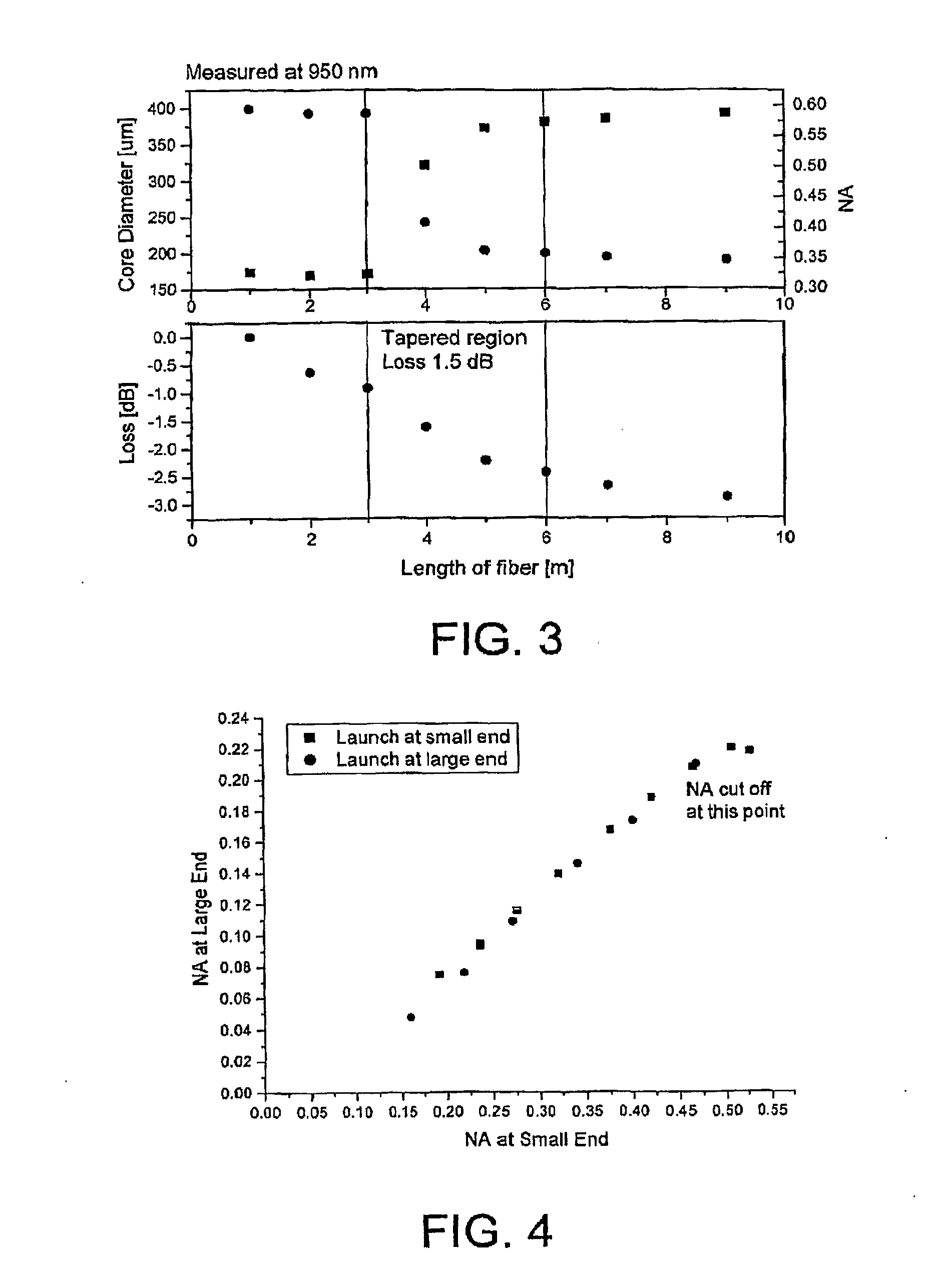

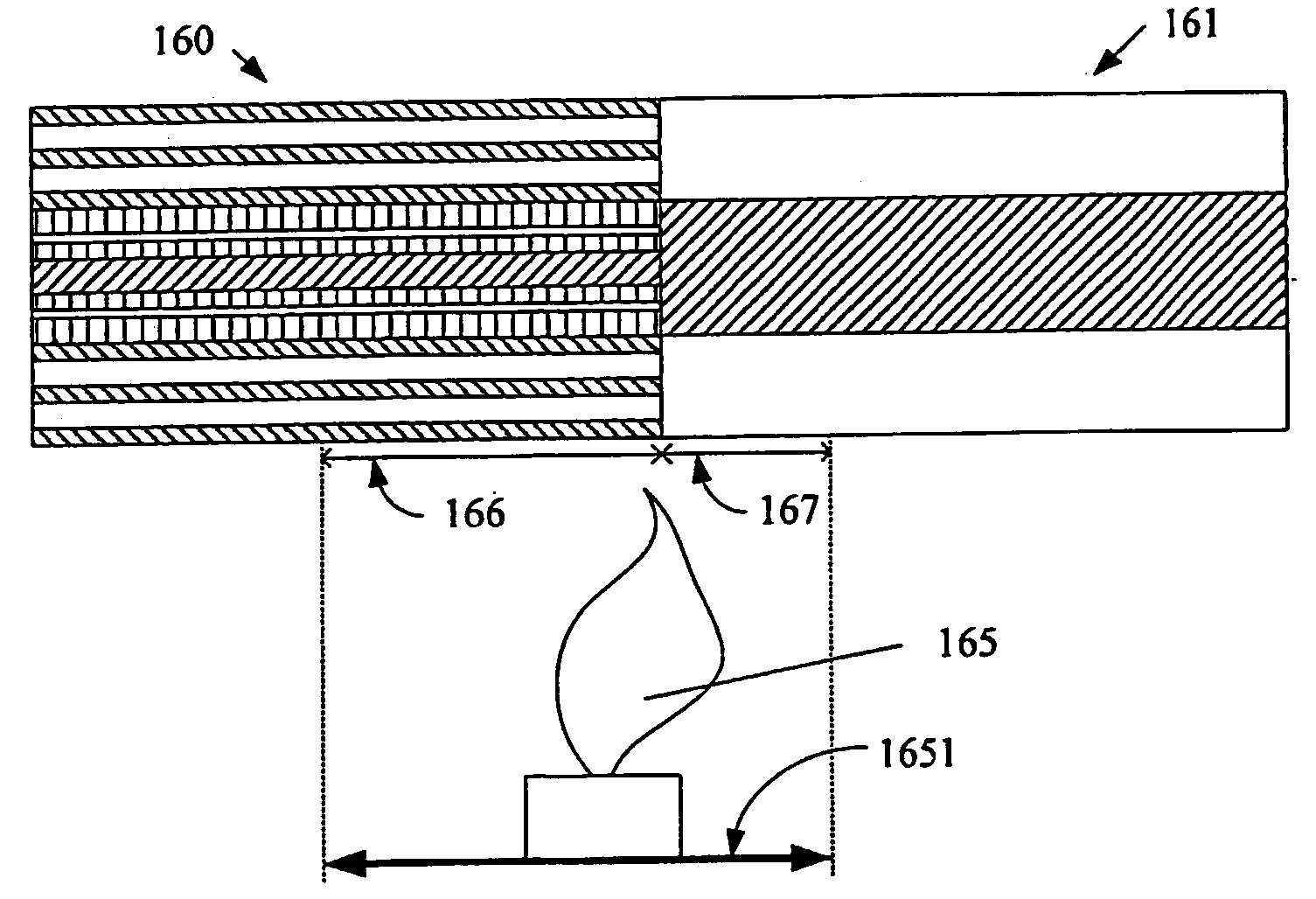

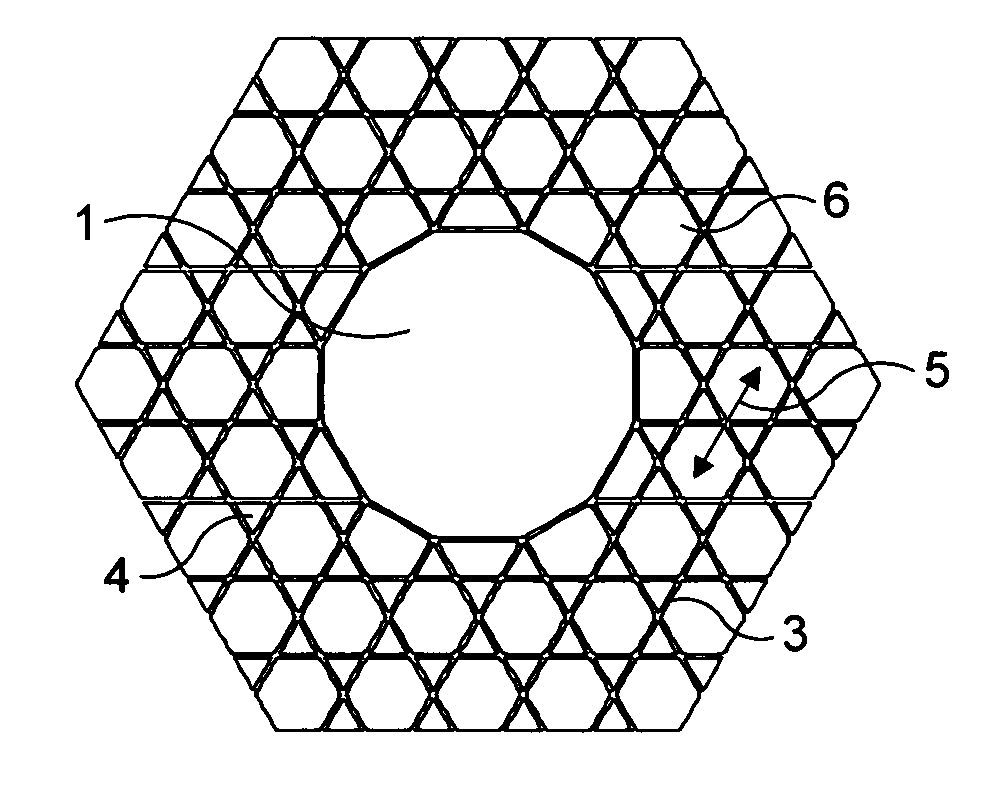

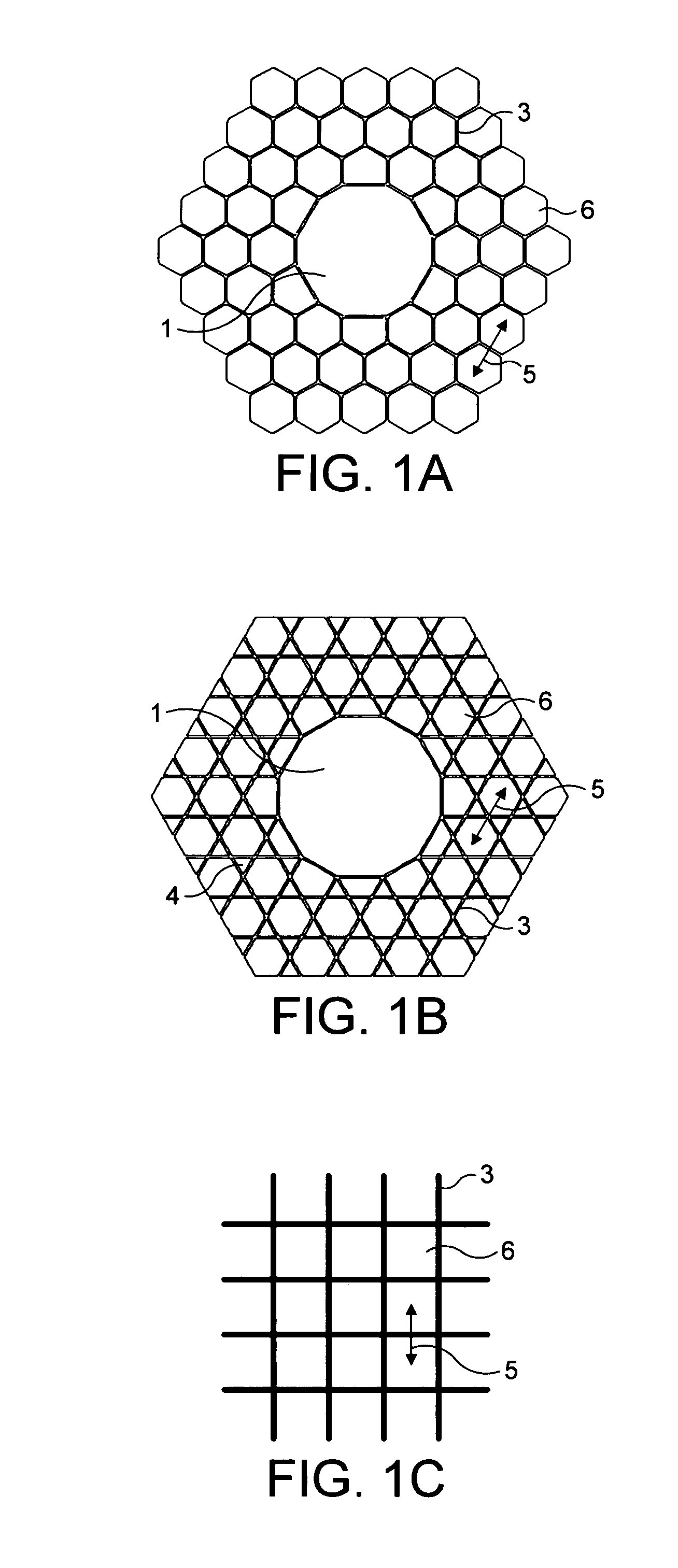

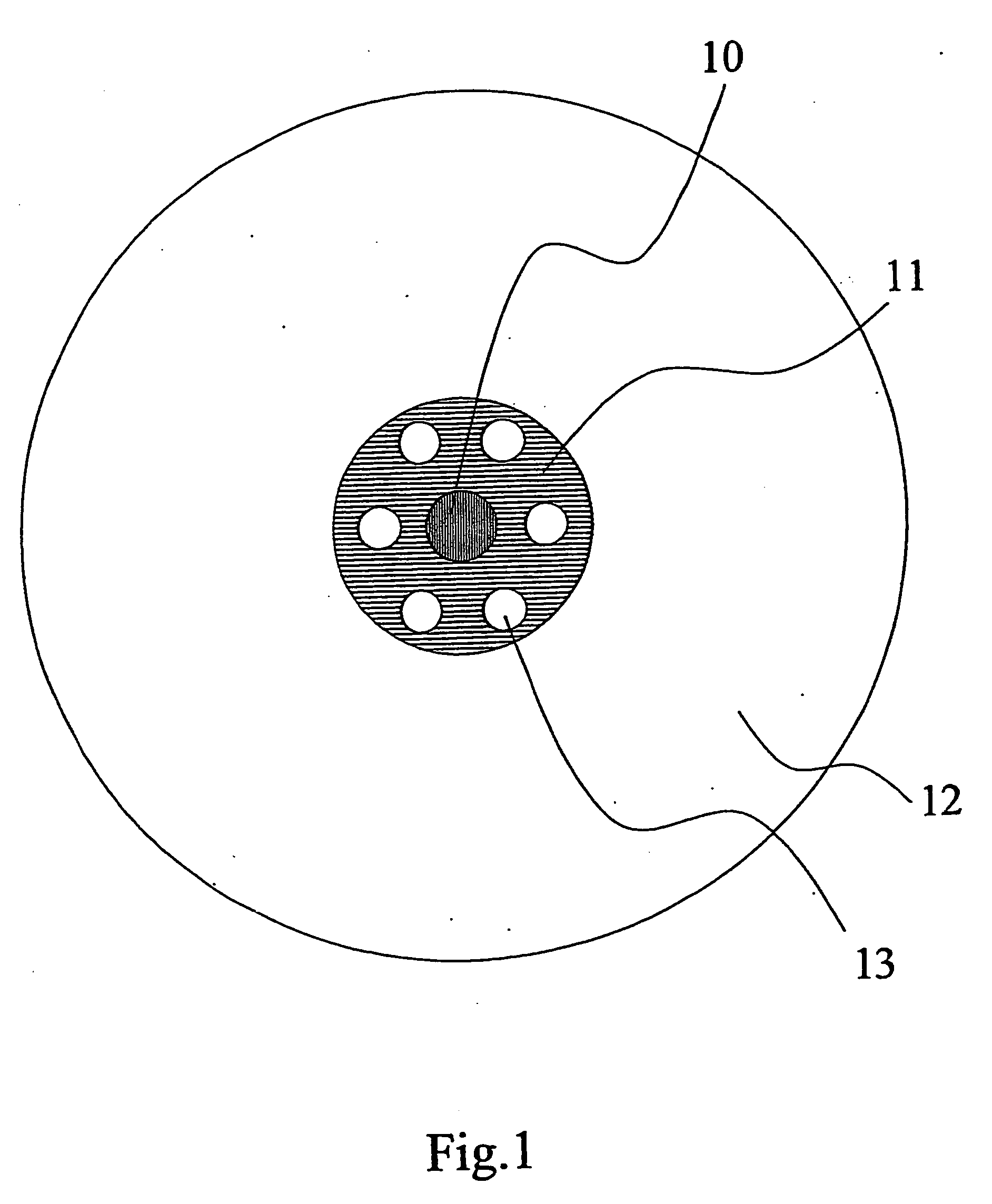

The present invention relates in general to coupling of light from one or more input waveguides to an output waveguide or output section of a waveguide having other physical dimensions and / or optical properties than the input waveguide or waveguides. The invention relates to an optical component in the form of a photonic crystal fibre for coupling light from one component / system with a given numerical aperture to another component / system with another numerical aperture. The invention further relates to methods of producing the optical component, and articles comprising the optical component, and to the use of the optical component. The invention further relates to an optical component comprising a bundle of input fibres that are tapered and fused together to form an input coupler e.g. for coupling light from several light sources into a single waveguide. The invention still further relates to the control of the spatial extension of a guided mode (e.g. a mode-field diameter) of an optical beam in an optical fibre. The invention relates to a tapered longitudinally extending optical waveguide having a relatively larger cross section that over a certain longitudinal distance is tapered down to a relatively smaller cross section wherein the spatial extent of the guided mode is substantially constant or expanding from the relatively larger to the relatively smaller waveguide cross section. The invention may e.g. be useful in applications such as fibre lasers or amplifiers, where light must be coupled efficiently from pump sources to a double clad fibre.

Owner:CRYSTAL FIBRE AS

Splicing and connectorization of photonic crystal fibres

InactiveUS20060067632A1Reduce lossReduce couplingCladded optical fibreCoupling light guidesPhotonic crystalCoupling

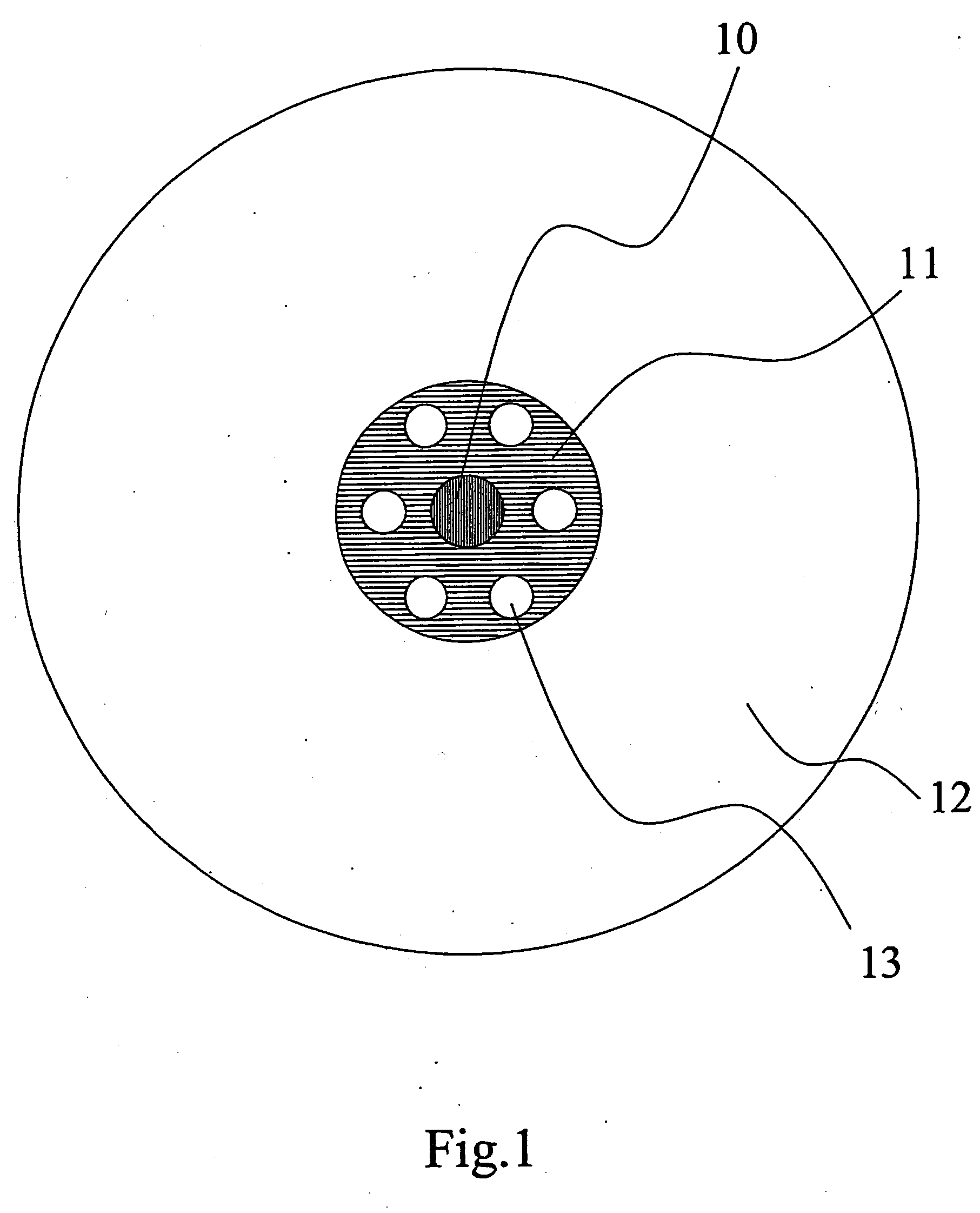

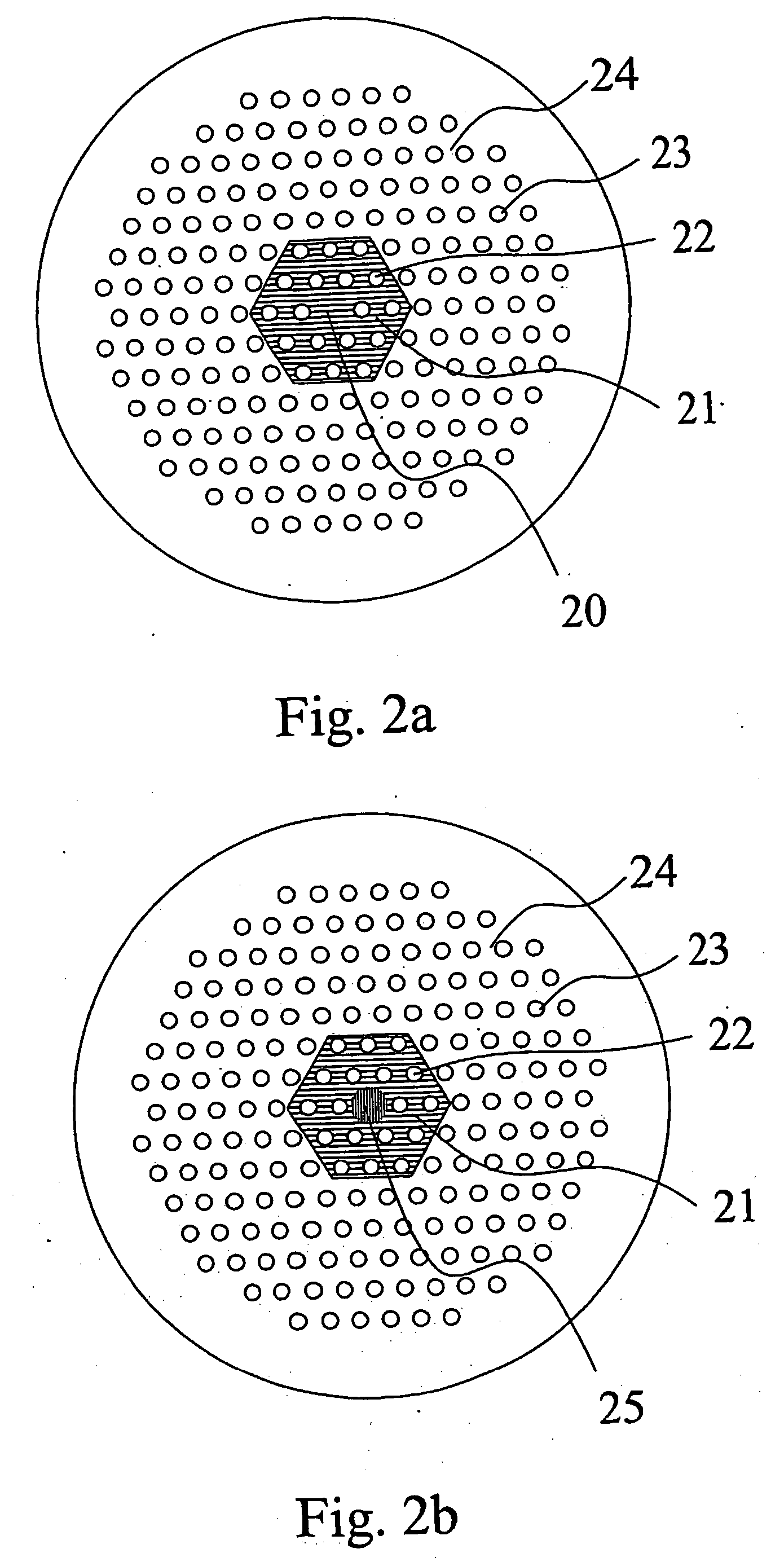

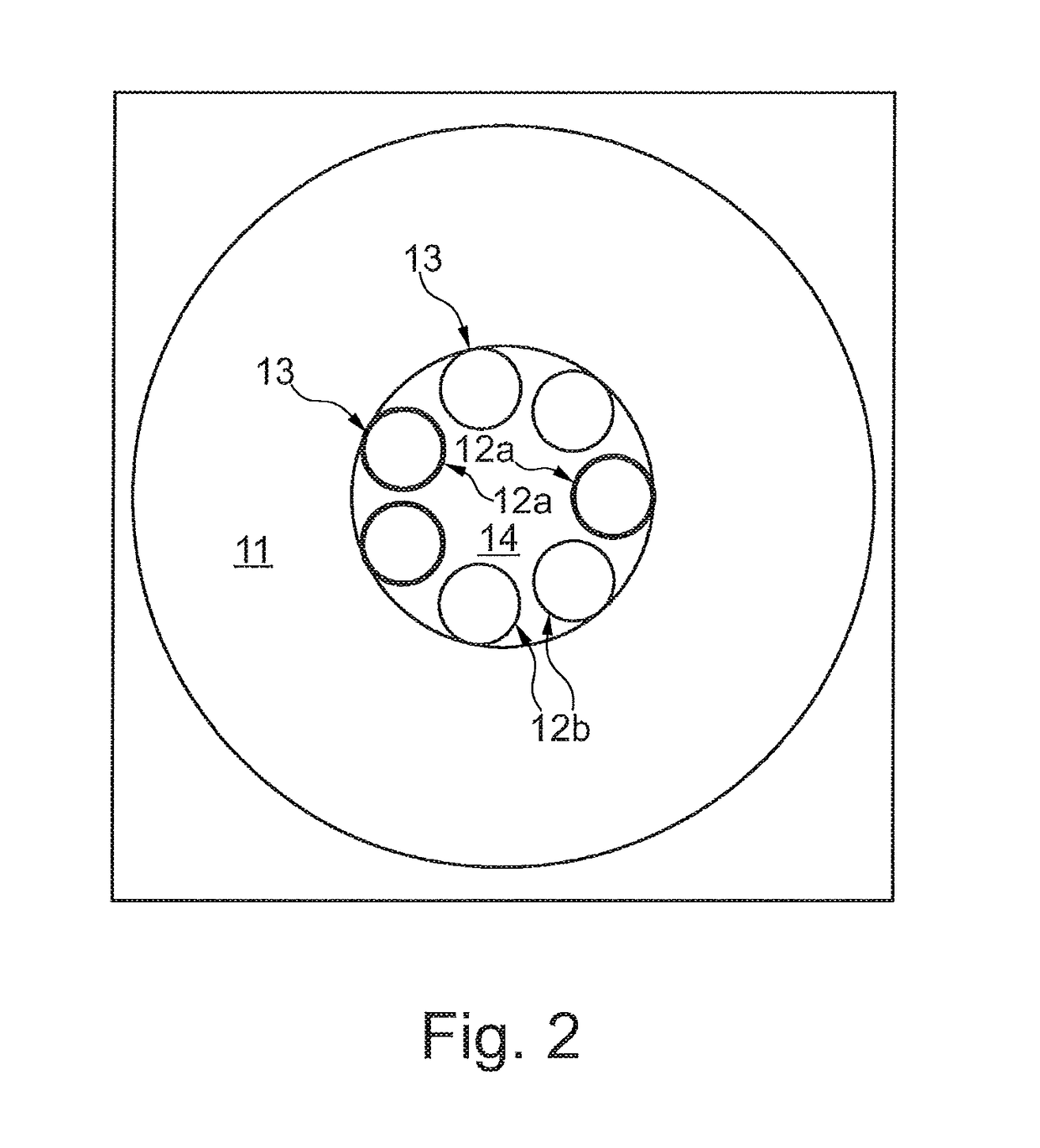

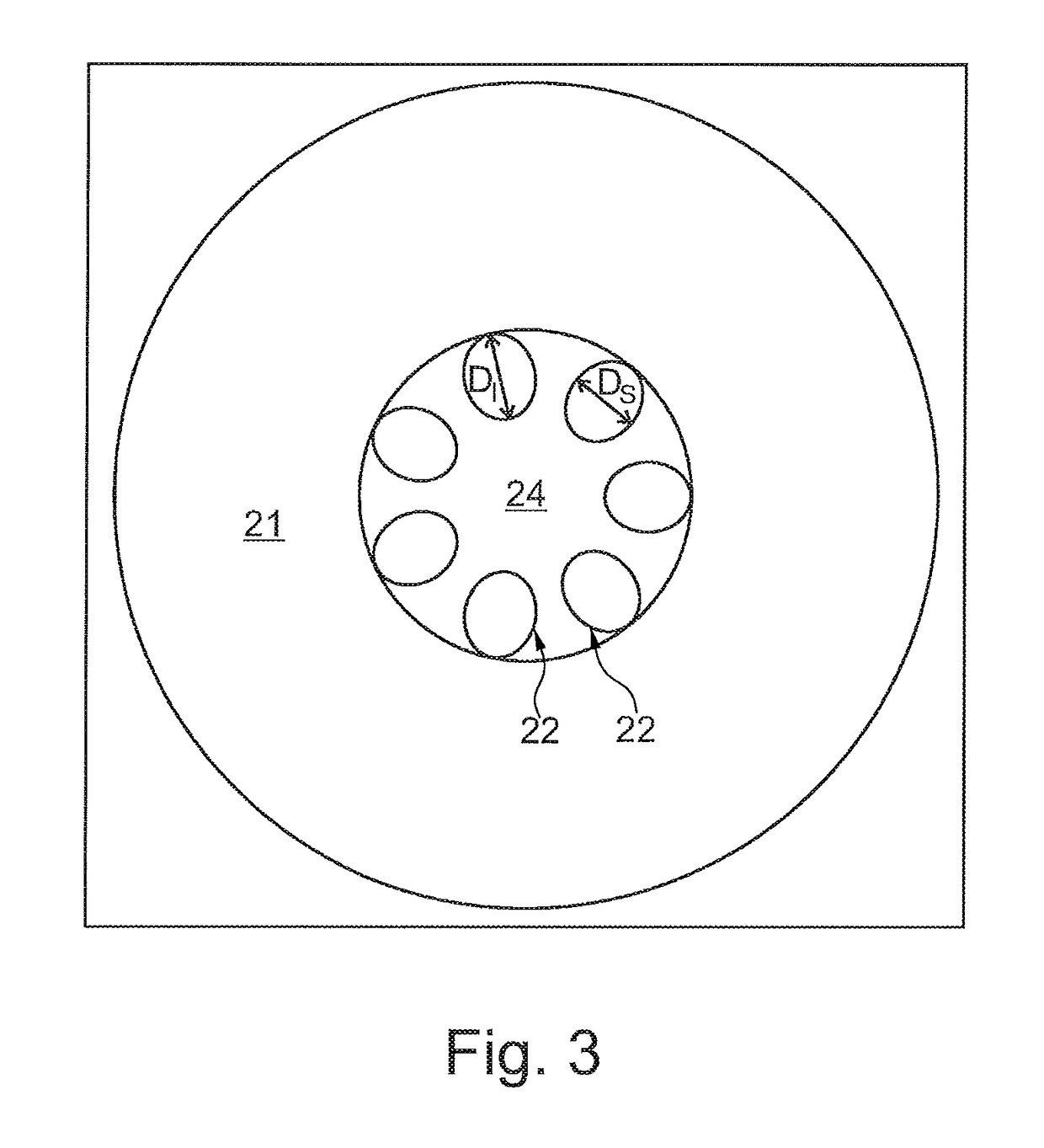

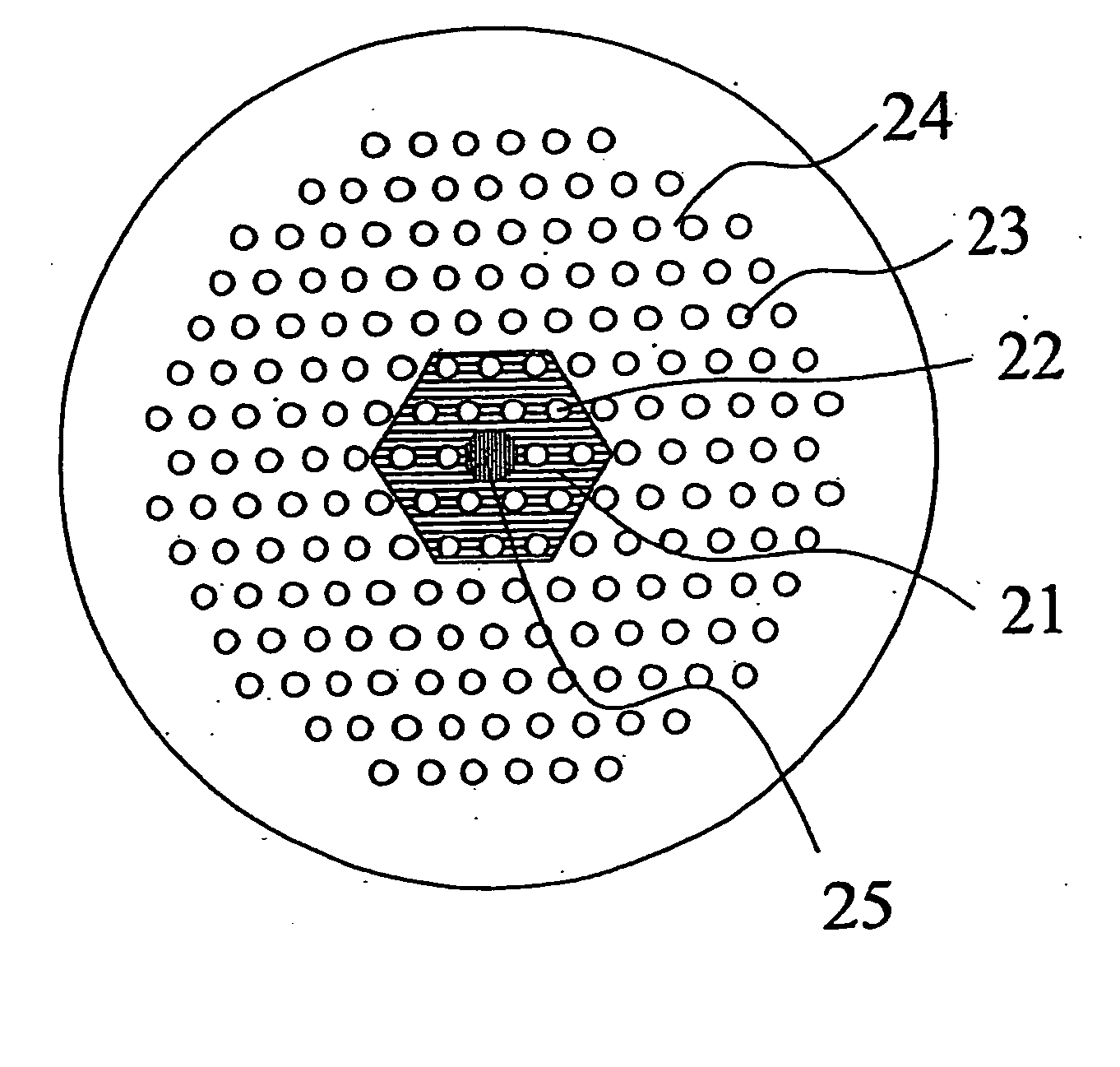

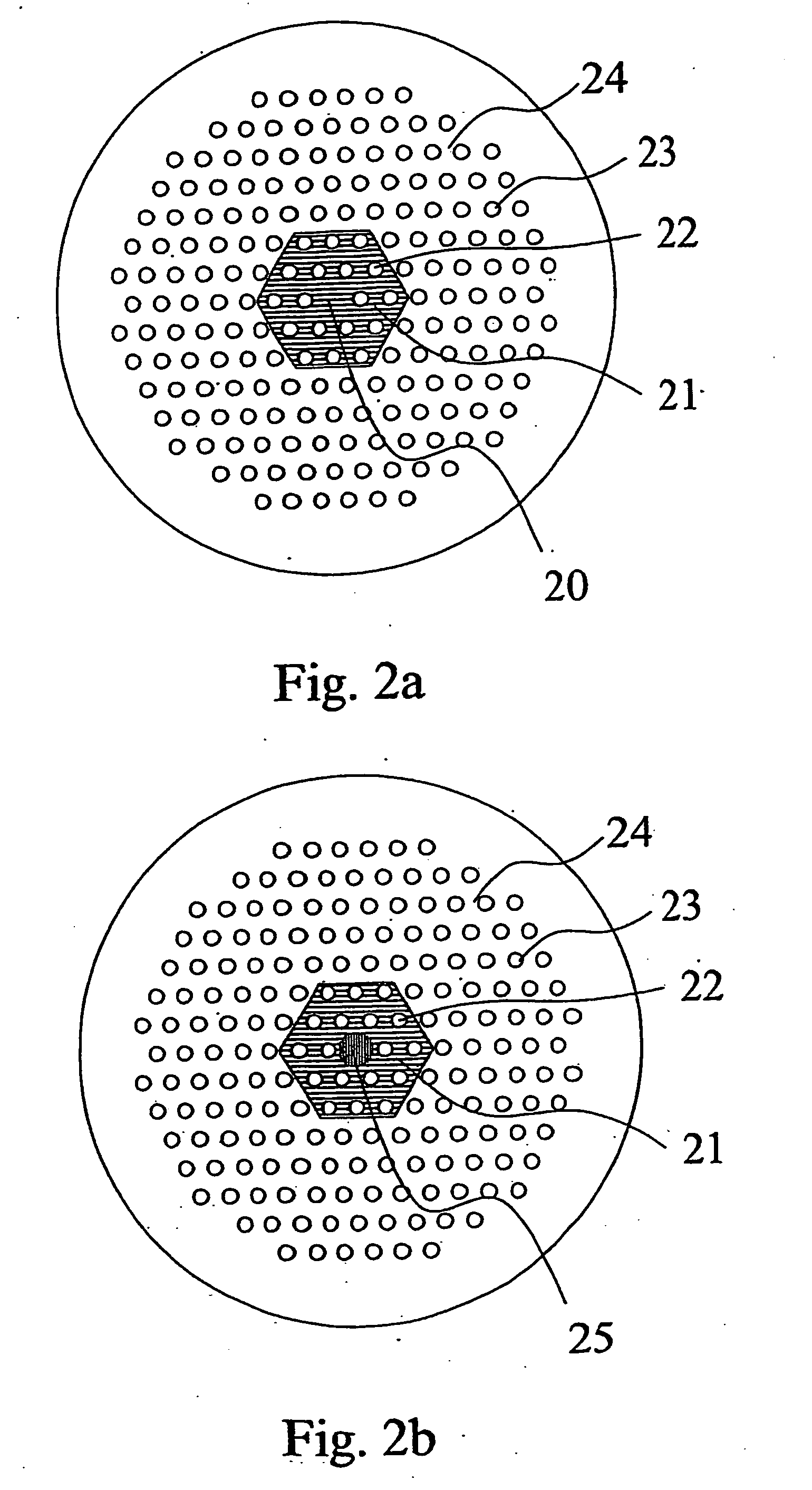

A method of coupling a spliceable optical fibre for transmission of light in its longitudinal direction to an optical component, the method comprising (A) providing the spliceable optical fibre, said spliceable optical fibre comprising: (a) a core region (10, 20, 25, 30, 110); and (b) a microstructured cladding region, said cladding region surrounding said core region and comprising: (b1) an inner cladding region with inner cladding features (13, 22, 112) arranged in an inner cladding background material (11, 21, 111) with a refractive index n1, said inner cladding features comprising thermally collapsible holes or voids, and (b2) an outer cladding region with an outer cladding background material (12, 24, 114) with a refractive index n2; said spliceable optical fibre having at least one end; (B) collapsing said thermally collapsible holes or voids by heating said least one end of said spliceable optical fibre; and (C) coupling said collapsed spliceable optical fibre end to the optical component. A spliceable optical fibre; a preform for producing a spliceable optical fibre; a method of producing a spliceable optical fibre comprising drawing of the preform; a heat-treated spliceable optical fibre; an article comprising a spliceable optical fibre is further disclosed.

Owner:CRYSTAL FIBRE AS

Optical waveguide monitoring

InactiveUS6879386B2Cladded optical fibreMaterial analysis by optical meansPhotonic crystalEngineering

Owner:OMNIGUIDE

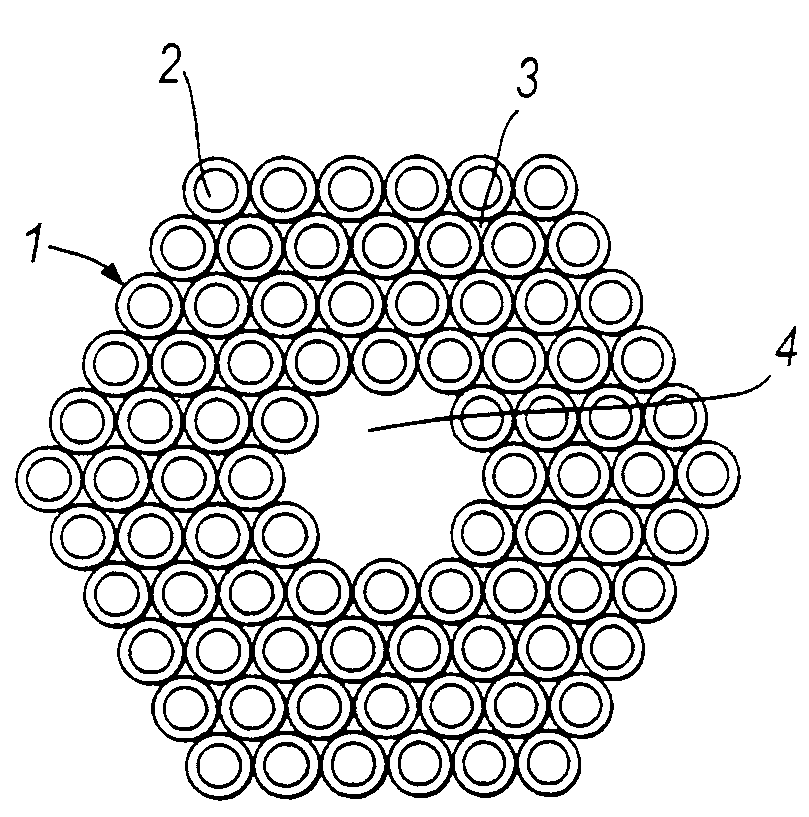

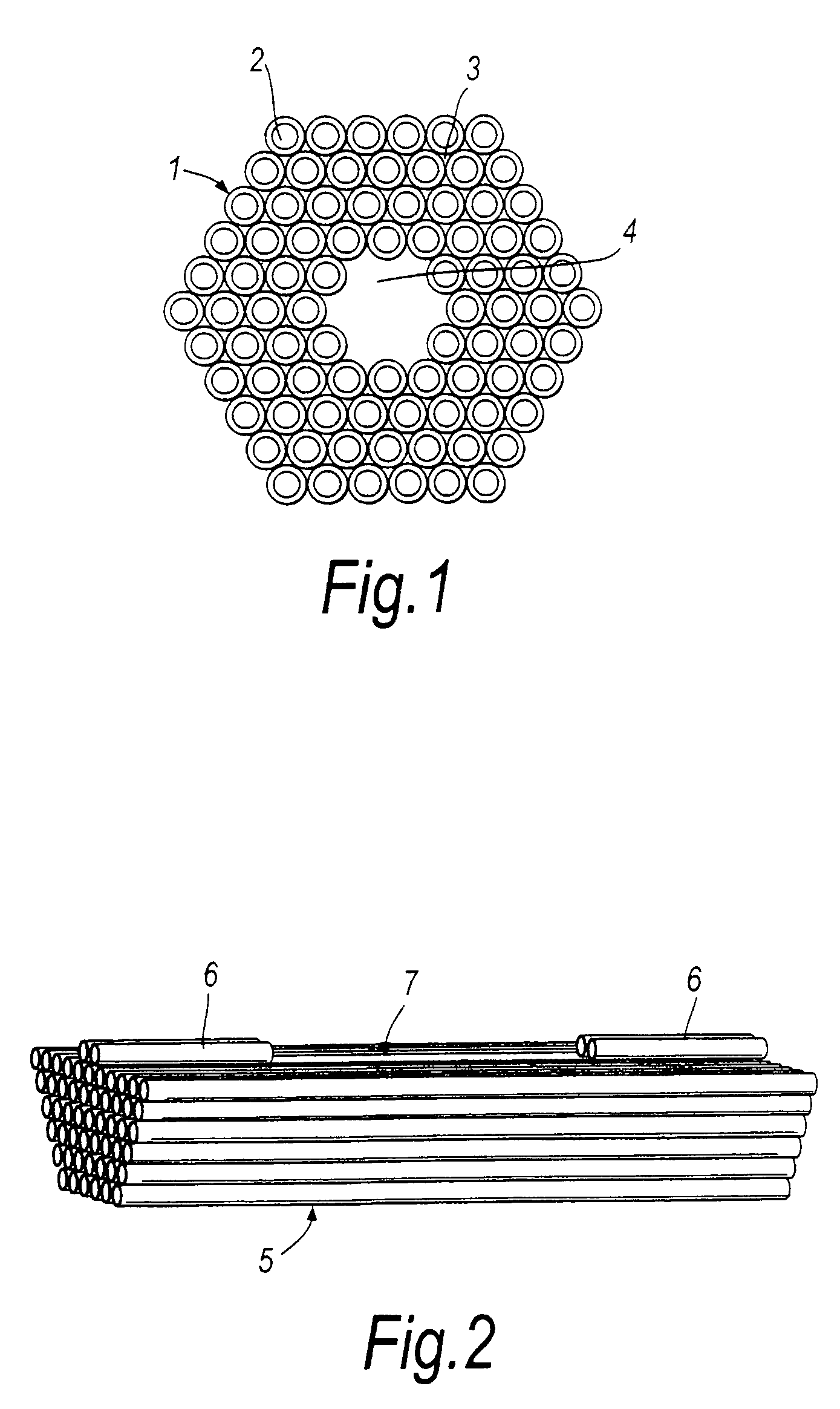

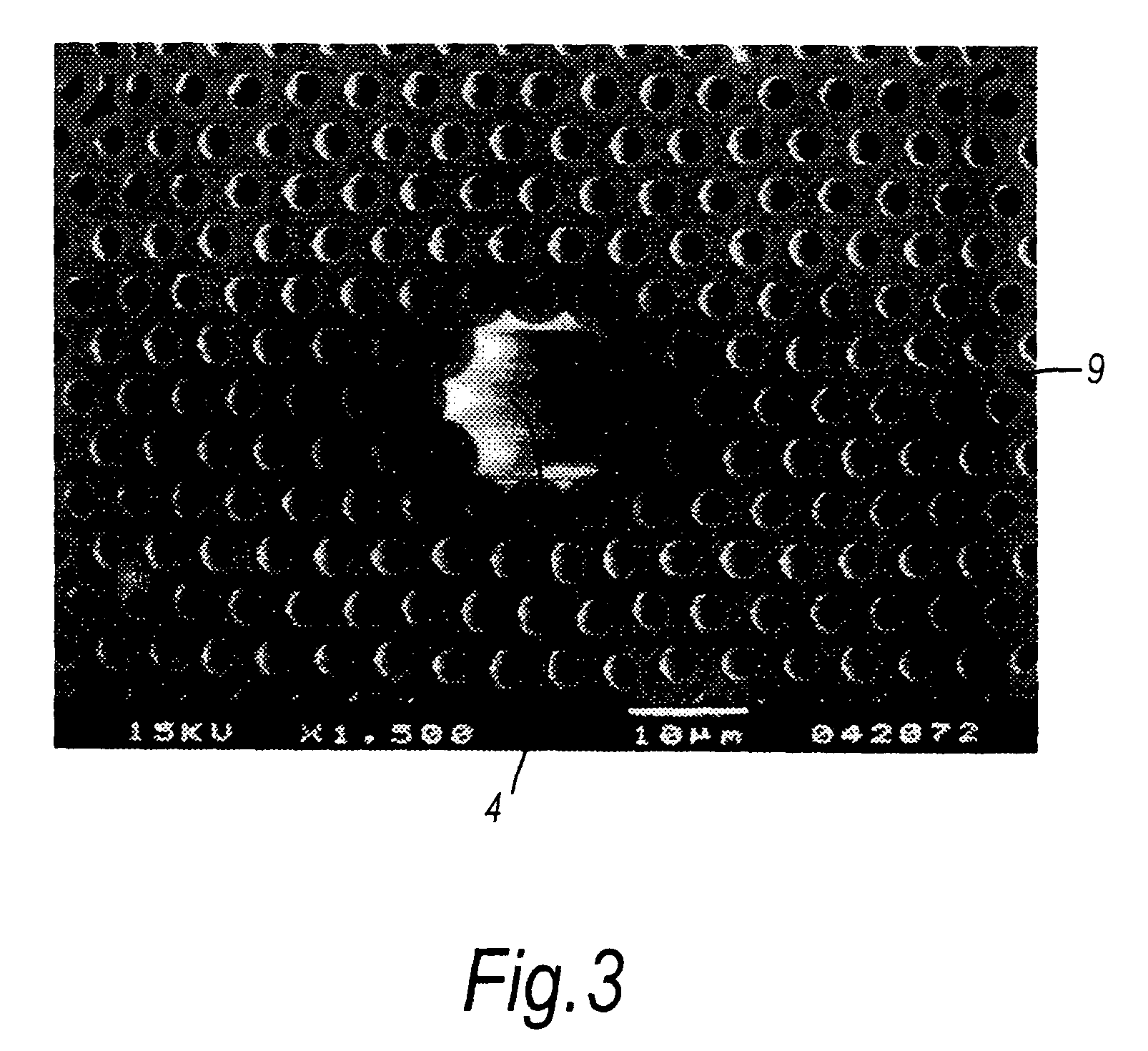

Photonic crystal fibre and a method for its production

InactiveUS6985661B1Reduce lossIncrease powerGlass making apparatusOptical fibre with graded refractive index core/claddingTelecommunications networkRefractive index

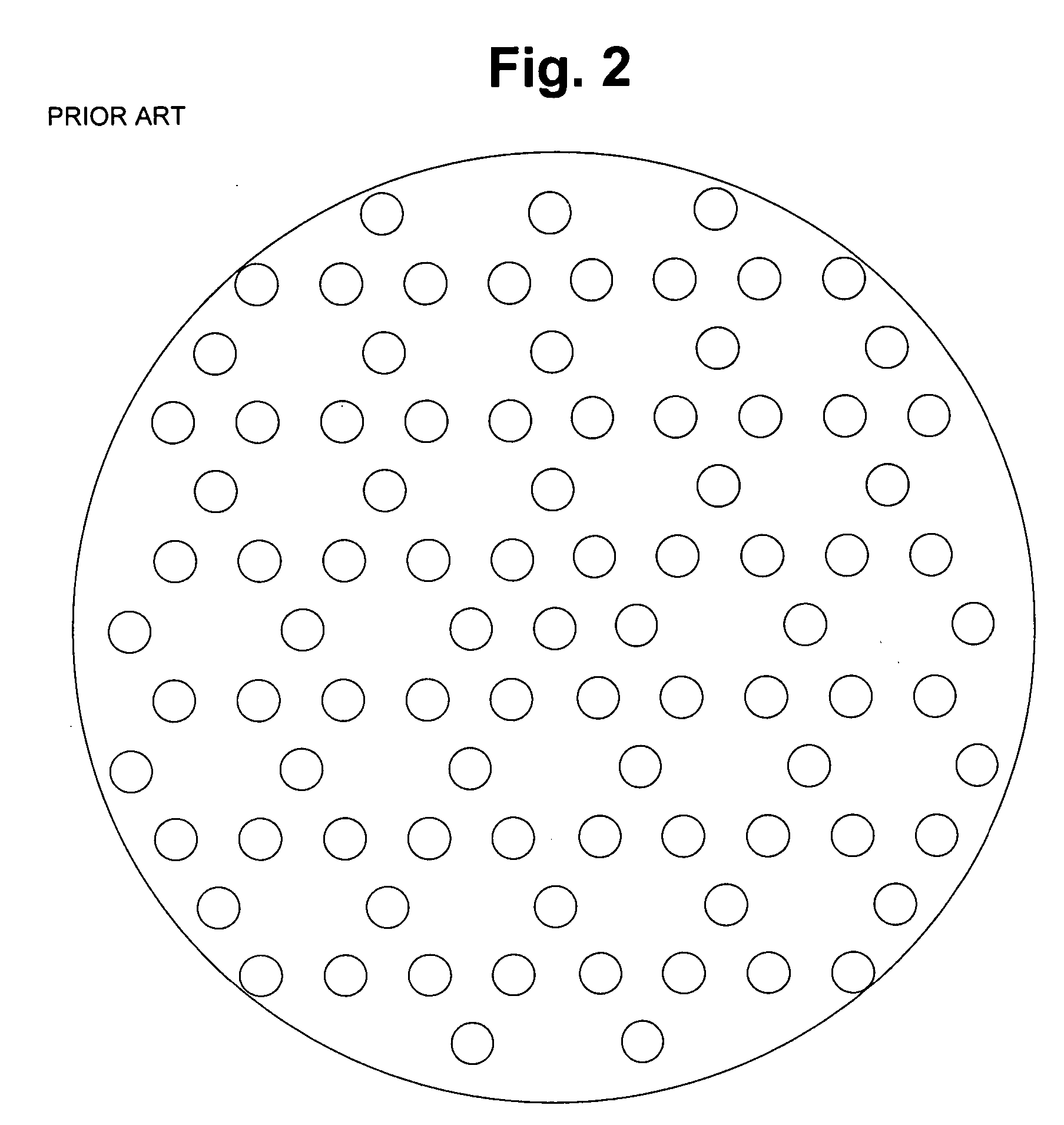

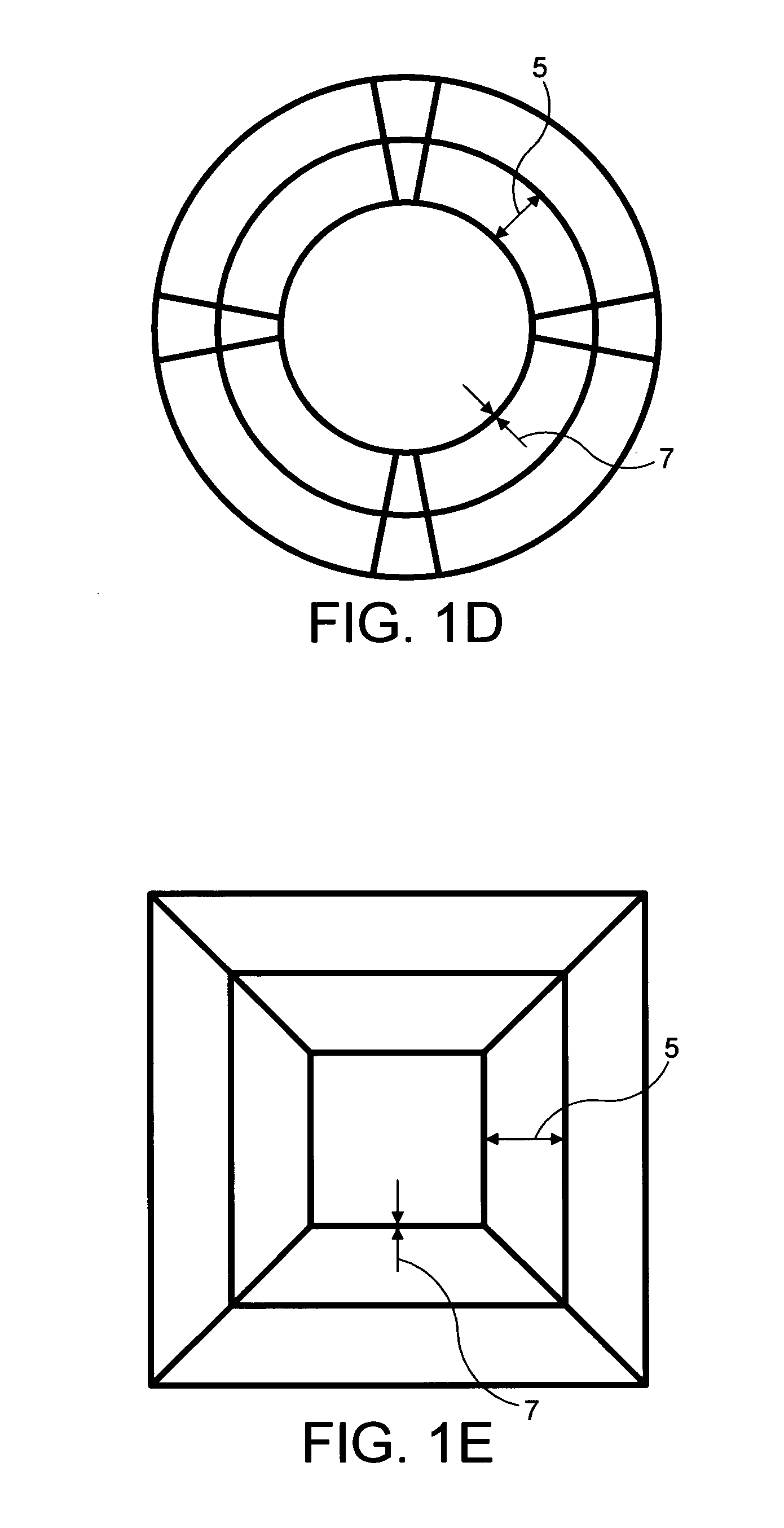

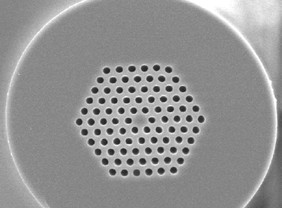

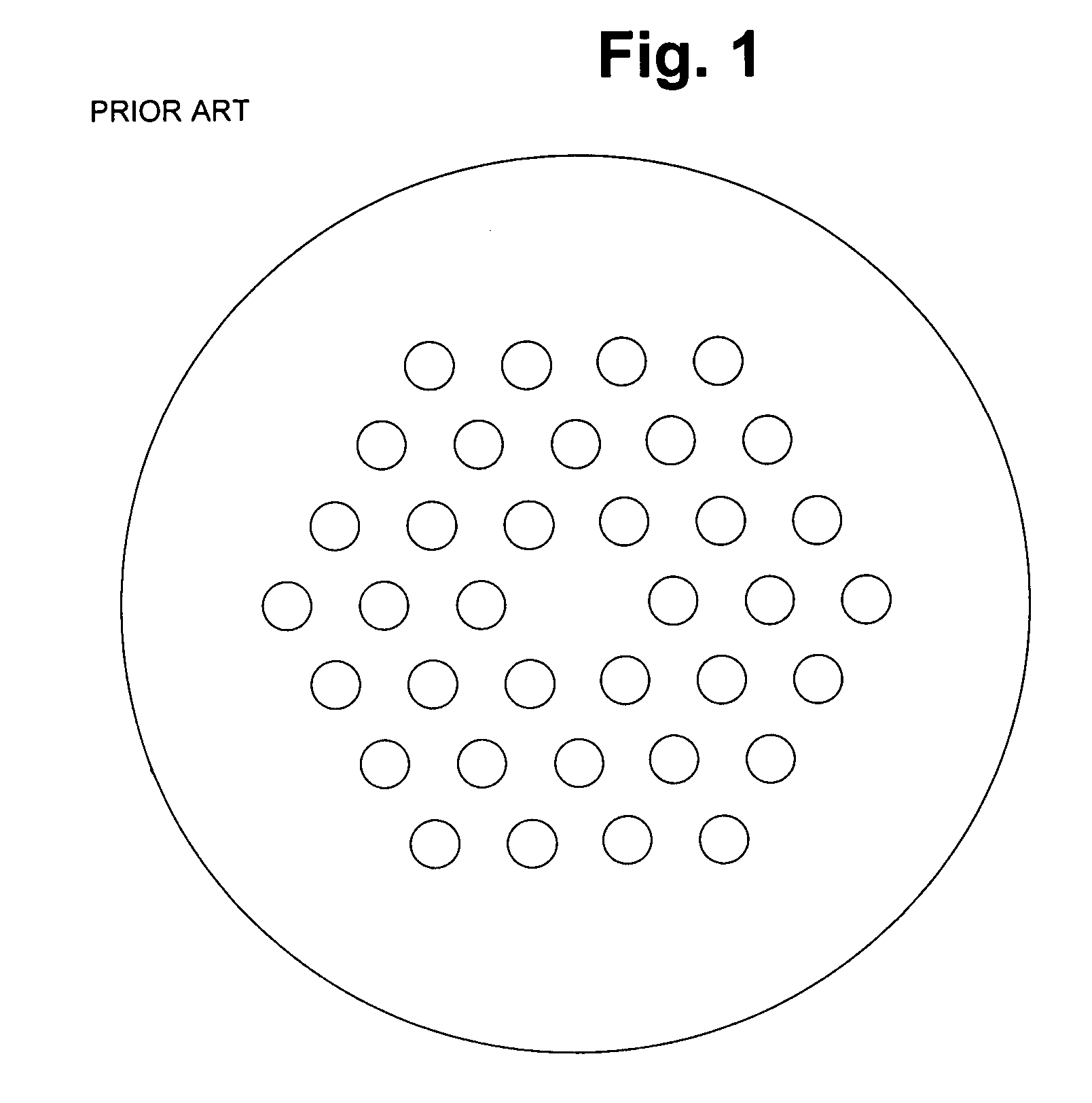

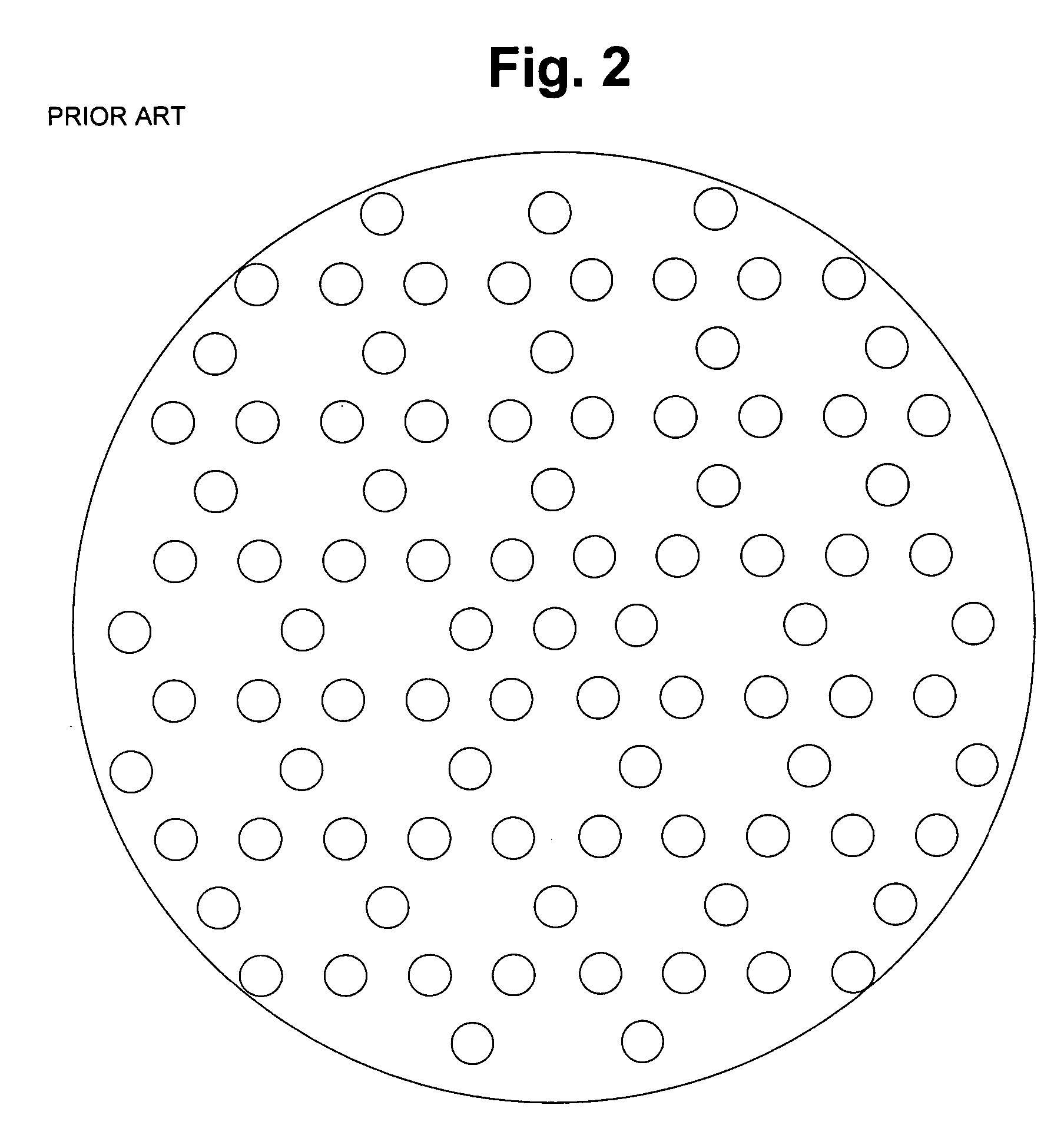

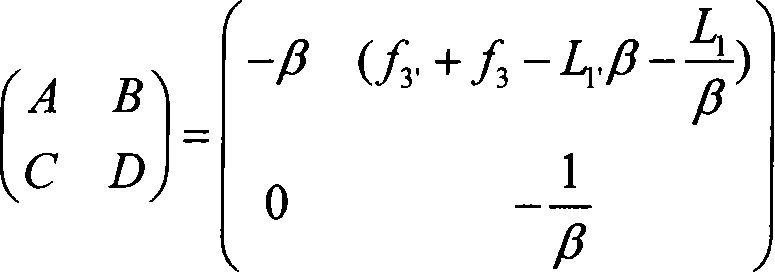

This invention relates to an optical fibre that comprises a core (4) of lower refractive index that is surrounded by a cladding which includes regions of a higher refractive index and is substantially periodic, where the core (4) has a longest transverse dimension that is longer than a single, shortest period of the cladding. In a fibre of this type light is substantially confined to the core area by virtue of the photonic band gap of the cladding material. The invention also relates to a method of manufacturing such an optical fibre, comprising the steps of forming a stack of canes (5), the stack (5) including at least one truncated cane (6) that defines an aperture (7), and then drawing the stack (5) into a fibre having an elongate cavity. The fibre is suitable for high power uses, but is equally suitable for other areas, e.g. optical amplifiers, spectral filters, lasers, gas sensors and telecommunications networks.

Owner:NKT RES & INNOVATION

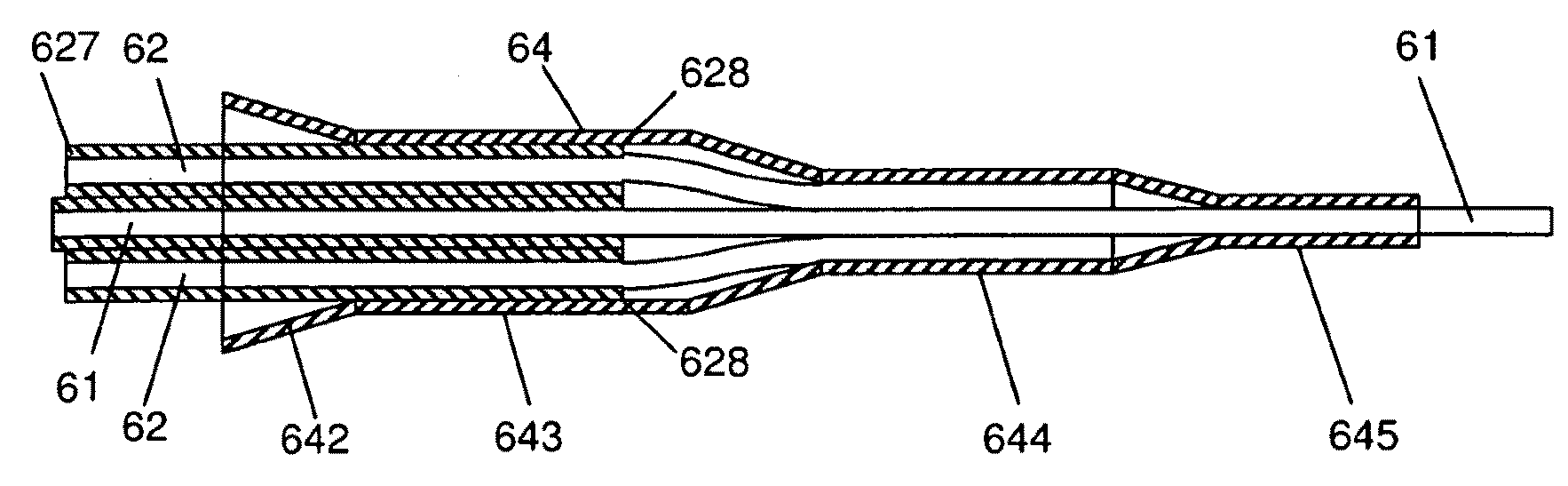

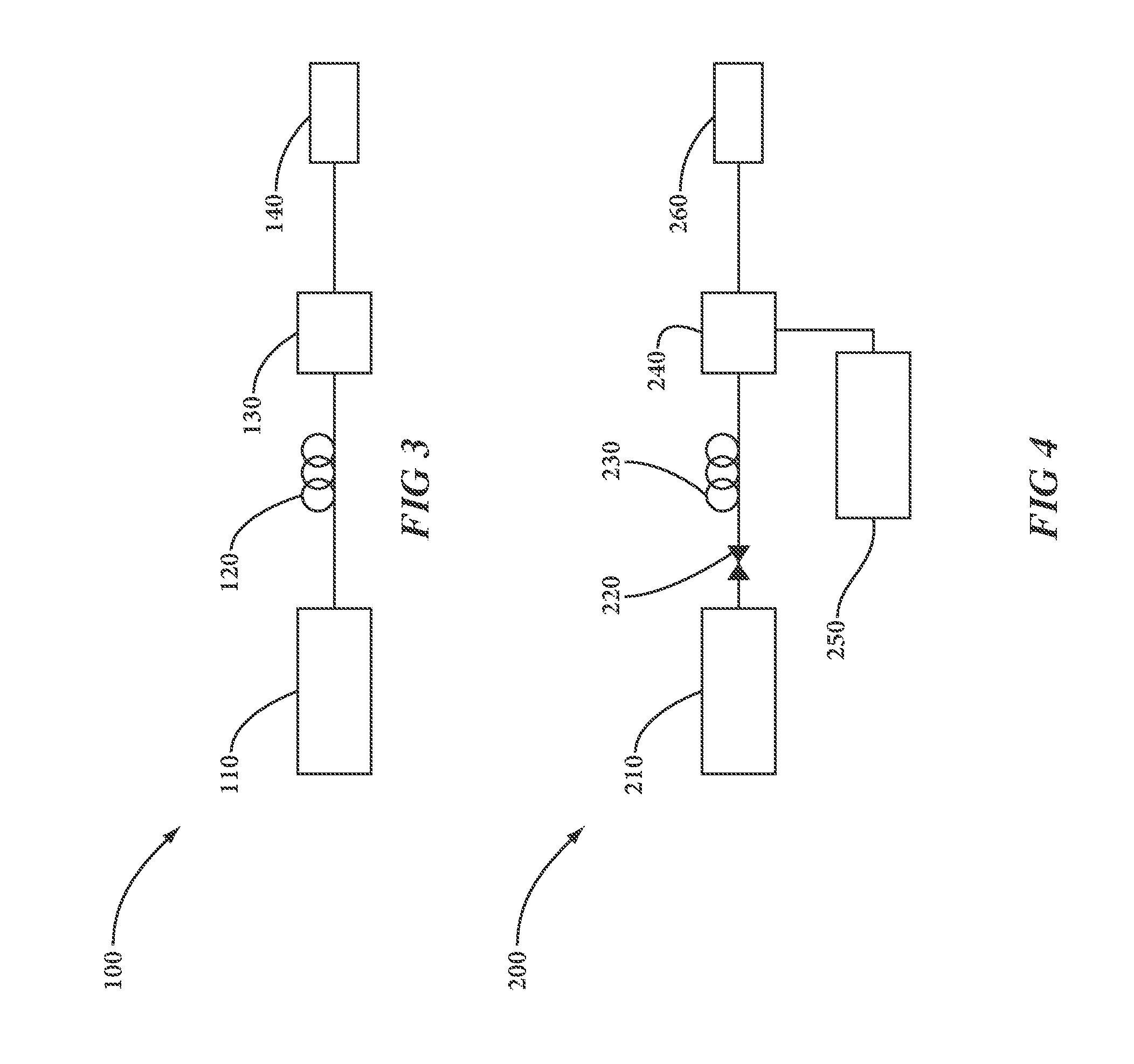

Optical coupler devices, methods of their production and use

InactiveUS20090080469A1Difficult to packageLess fragileLaser using scattering effectsOptical fibre with graded refractive index core/claddingDouble-clad fiberAudio power amplifier

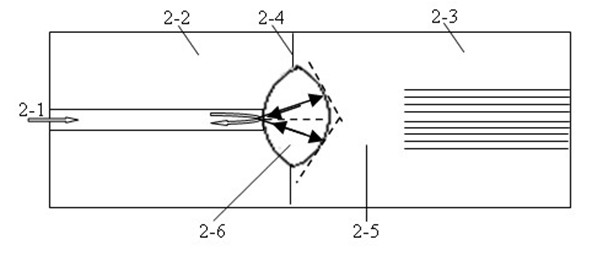

The present invention relates to an optical component comprising an acceptance fibre, e.g. a photonic crystal fibre, for propagation of pump and signal light, a number of pump delivery fibres and a reflector element that reflects pump light from the pump delivery fibres into the acceptance fibre. It is an object of the invention to provide a fibre coupler for coupling two or more light sources into a multi-clad (e.g. double clad) optical fibre, which has practical advantages with respect to handling, loss and back reflection. An object of the invention is achieved by an optical component comprising a) a first fibre having a pump core with an NA1, and a first fibre end; b) a number of second fibres surrounding said pump core of said first fibre, at least one of said second fibres has a pump core with an NA2 that is smaller than NA1, said number of second fibres each having a second fibre end; and c) a reflector element comprising an end-facet with a predetermined profile for reflecting light from at least one of said second fibre ends into the pump core of said first fibre. The invention further relates to articles comprising the optical component (e.g. a laser or amplifier), to methods of its production and use. The invention further relates to a rod-type optical fibre with optimized stiffness to volume ratio. The invention may e.g. be useful in applications such as fibre lasers or amplifiers, where light can be coupled efficiently from pump sources to an acceptance fibre, e.g. a double clad fibre, using the optical component. The invention specifically addresses optical fibre amplifiers where pump light and signal light are propagating in different directions (counter-propagating pump) within a double-clad optical fibre.

Owner:NKT PHOTONICS

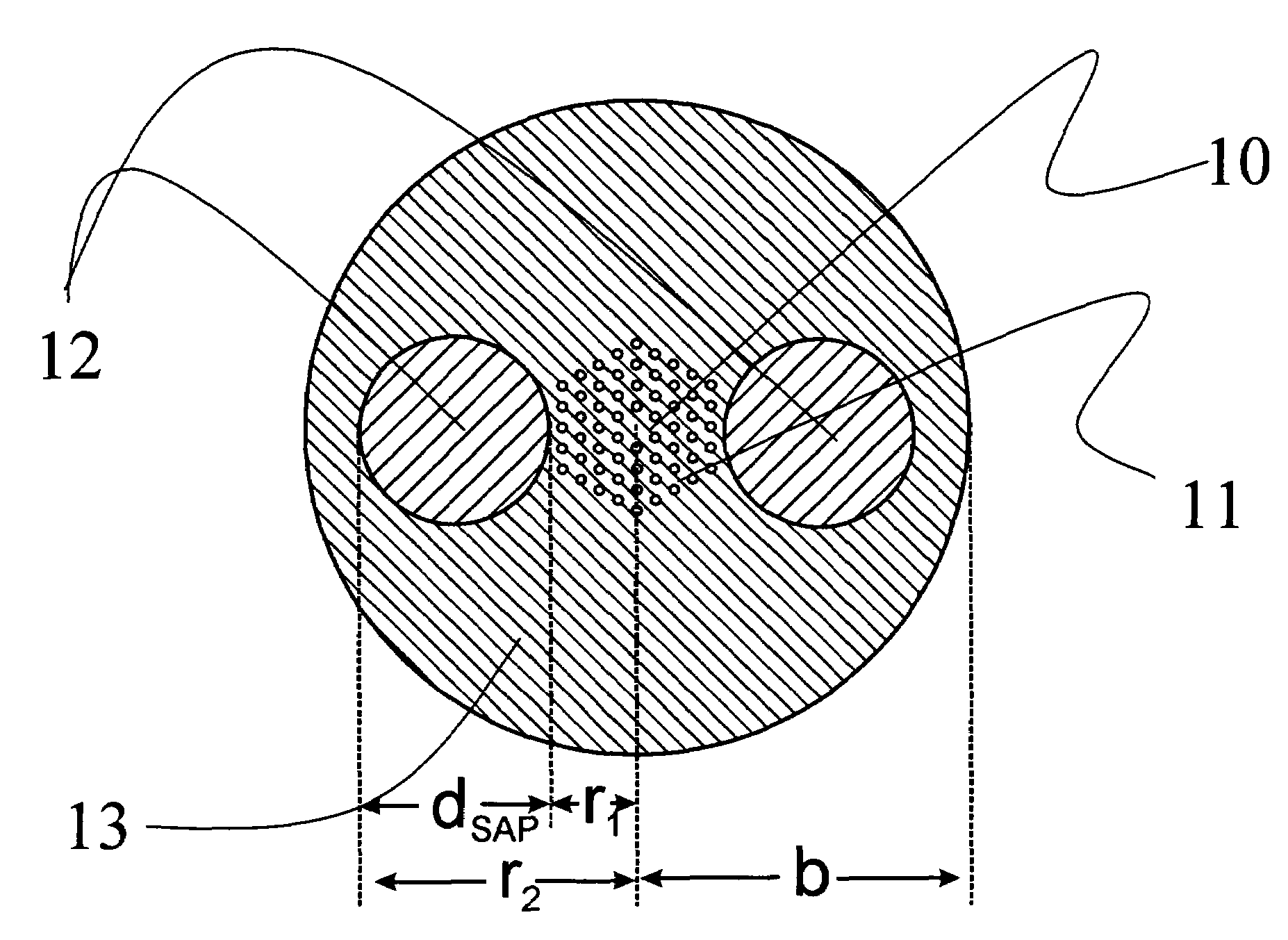

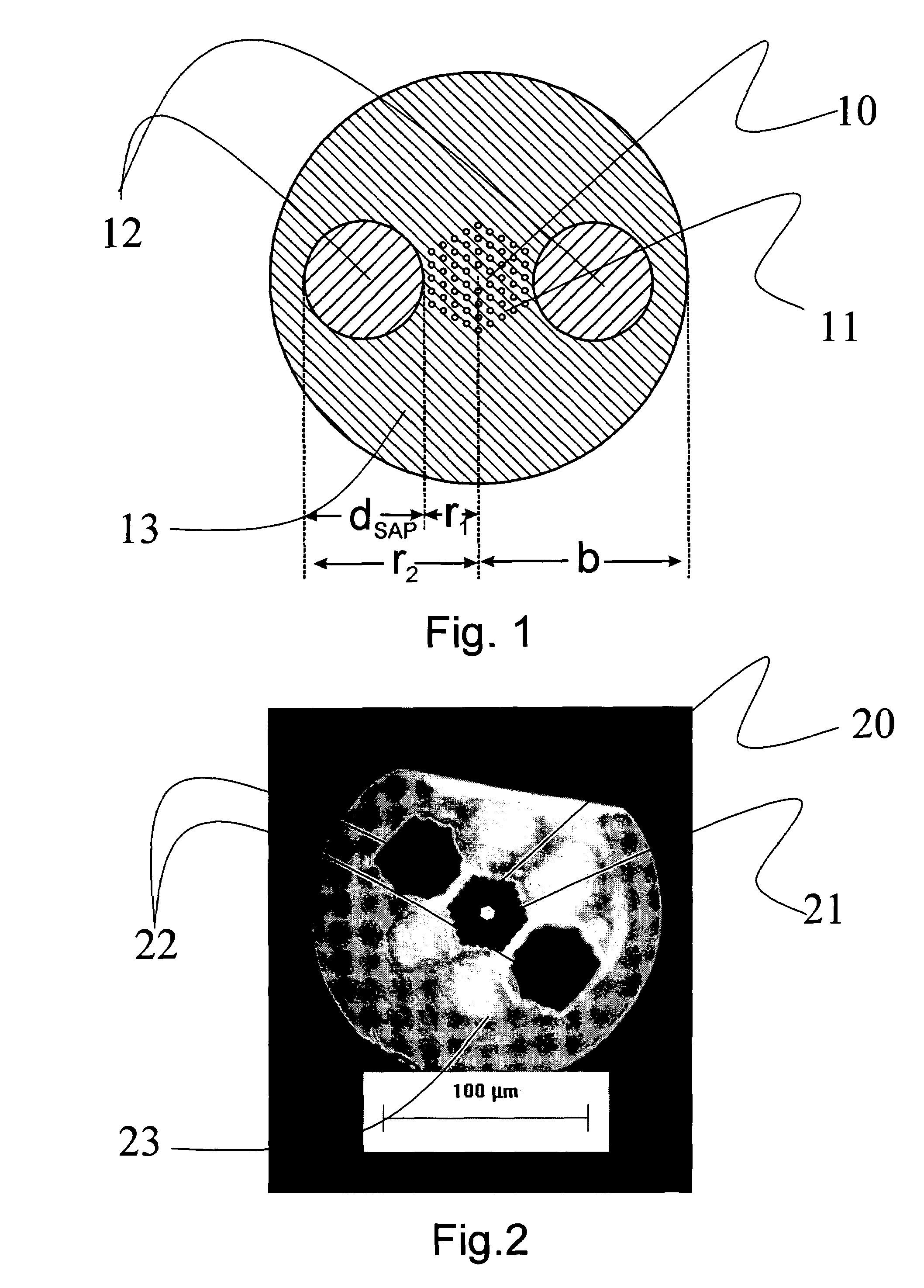

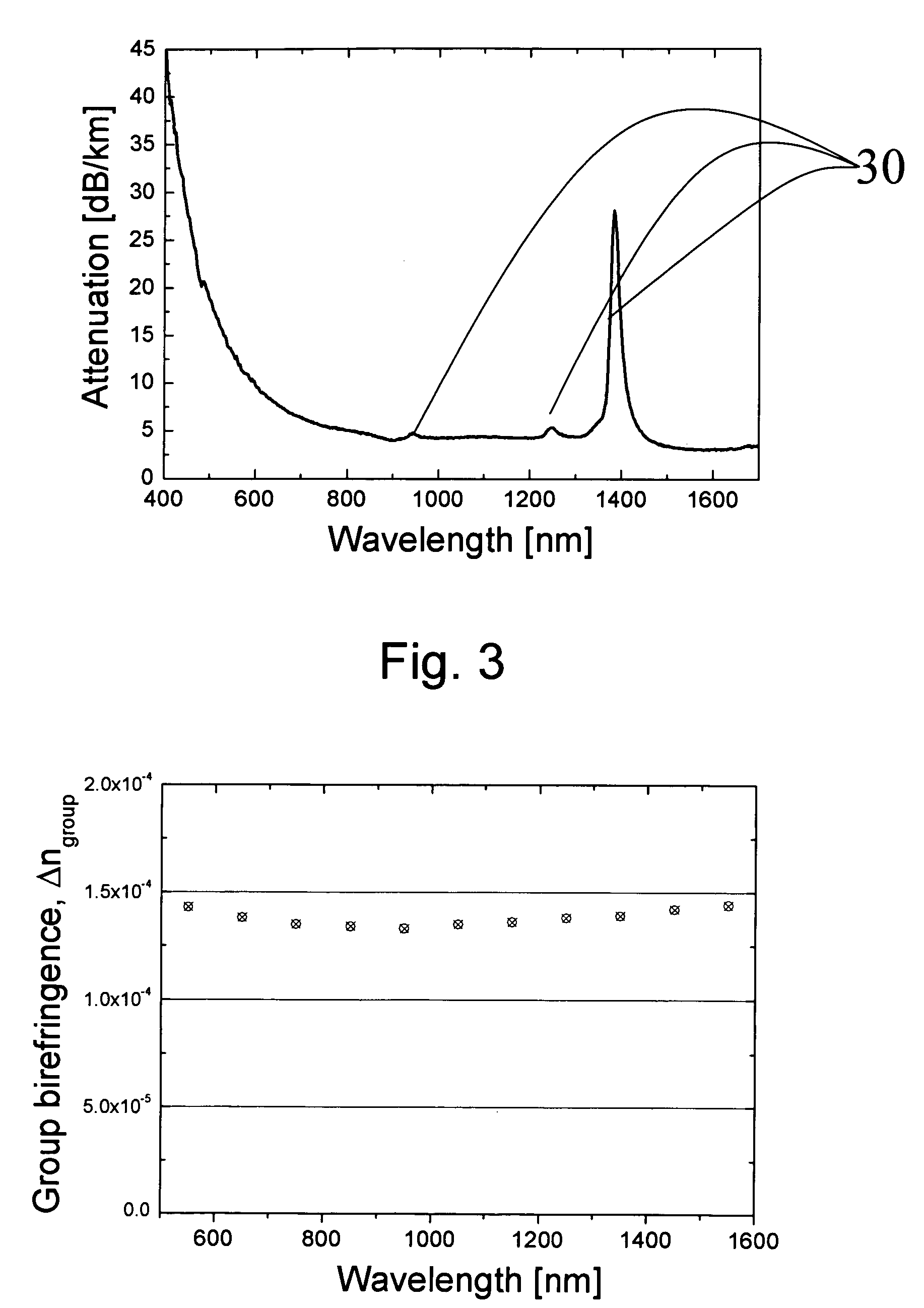

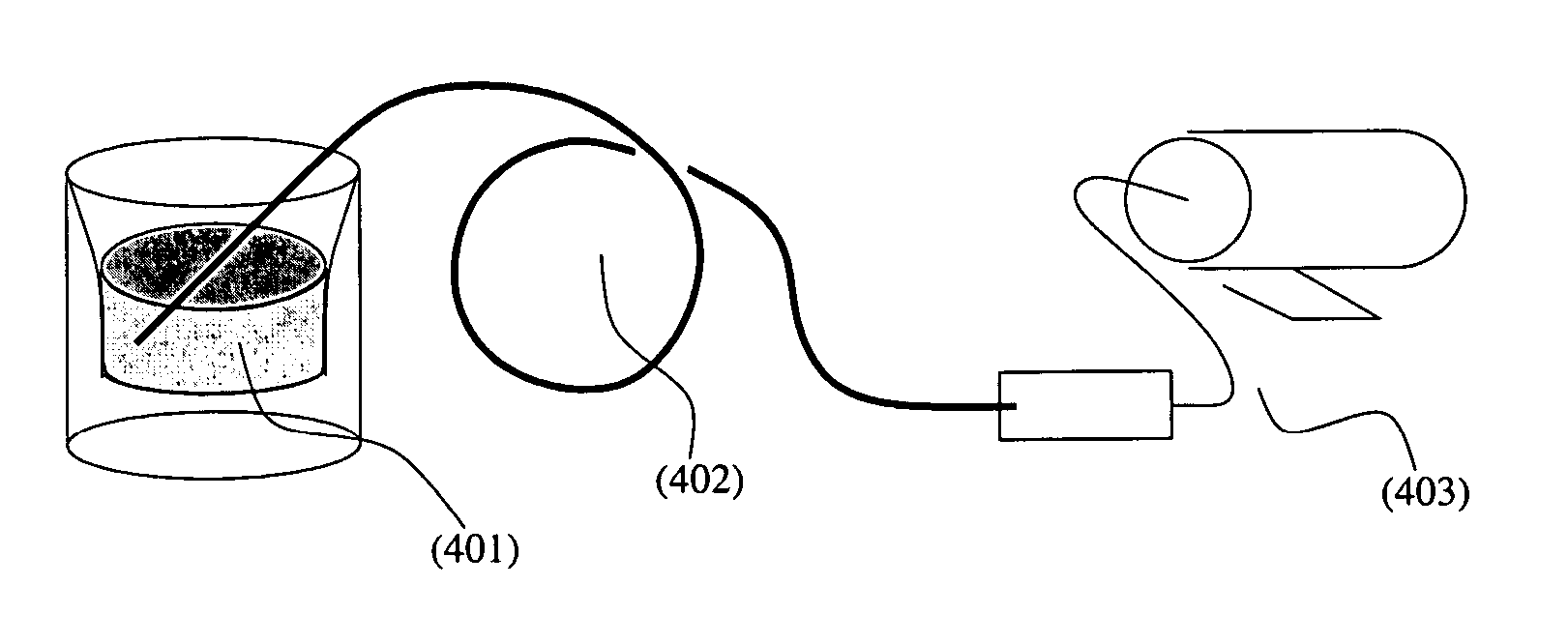

Photonic crystal fibres comprising stress elements

ActiveUS7289709B2Constant birefringenceSimple and economic wayGlass making apparatusOptical fibre with polarisationStress inducedPhotonic crystal

A photonic crystal fiber includes a core region for propagating light in a longitudinal direction of the fiber, a cladding region surrounding the core region, the cladding region including micro-structural elements extending in the longitudinal direction. The cladding region further includes at least one stress element having a coefficient of thermal expansion αT,SAP and extending in the longitudinal direction of the photonic crystal fiber, the stress element(s) being located in a cladding background material having a coefficient of thermal expansion αT,cladback different from αT,SAP. The location of the at least one stress element relative to the core region and the micro-structural elements and the coefficients of thermal expansion αT,SAP and αT,cladback are adapted to provide a stress induced birefringence in the core region of the photonic crystal fiber. An article includes a photonic crystal fiber, a method of manufacturing and the use of a photonic crystal fiber are furthermore provided.

Owner:CRYSTAL FIBRE AS

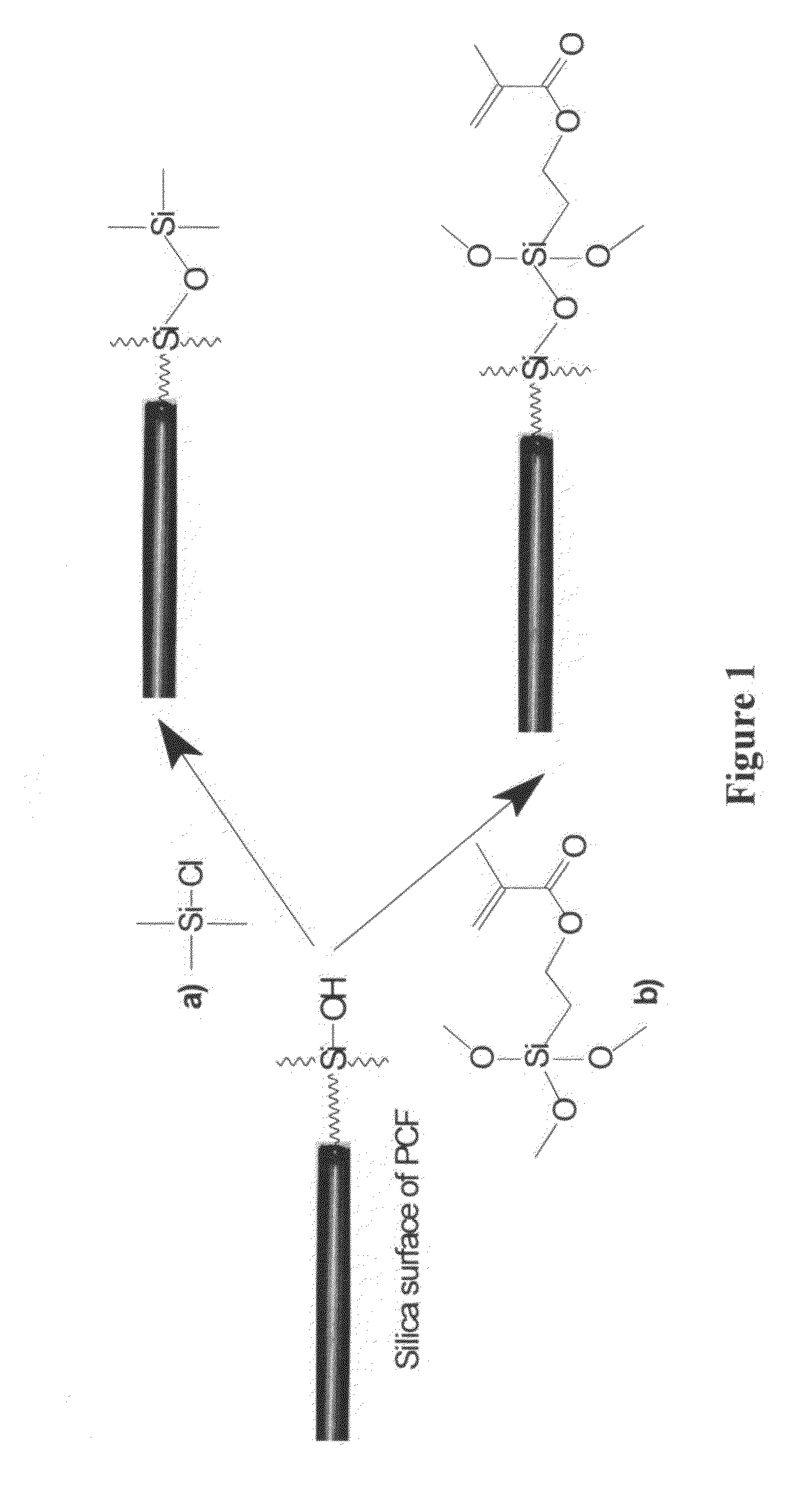

Composite material photonic crystal fibres, method of production and its use

InactiveUS20050111804A1High temperature dependenceHigh viscosityOptical fibre with multilayer core/claddingOptical waveguide light guideFiberPhotonic crystal

An optical fibre for transmission of light at a predetermined wavelength, the fibre having a core region, an inner cladding region and an outer cladding region, the inner cladding region having spaced apart voids, at least some of which are at least partly filled with a fluid substance to modify a refractive index in the cross-section of the fibre. The fluid substance may be introduced by preparing and fixing the fiber ends, identifying the voids to be filled and infusing the fluid therein while masking openings in the remaining voids. By selective heating of parts of the fibre, the location of the fluid substance in the void may be controlled to extend over only a fraction of the length of a void that extends the length by the fibre.

Owner:CRYSTAL FIBRE AS

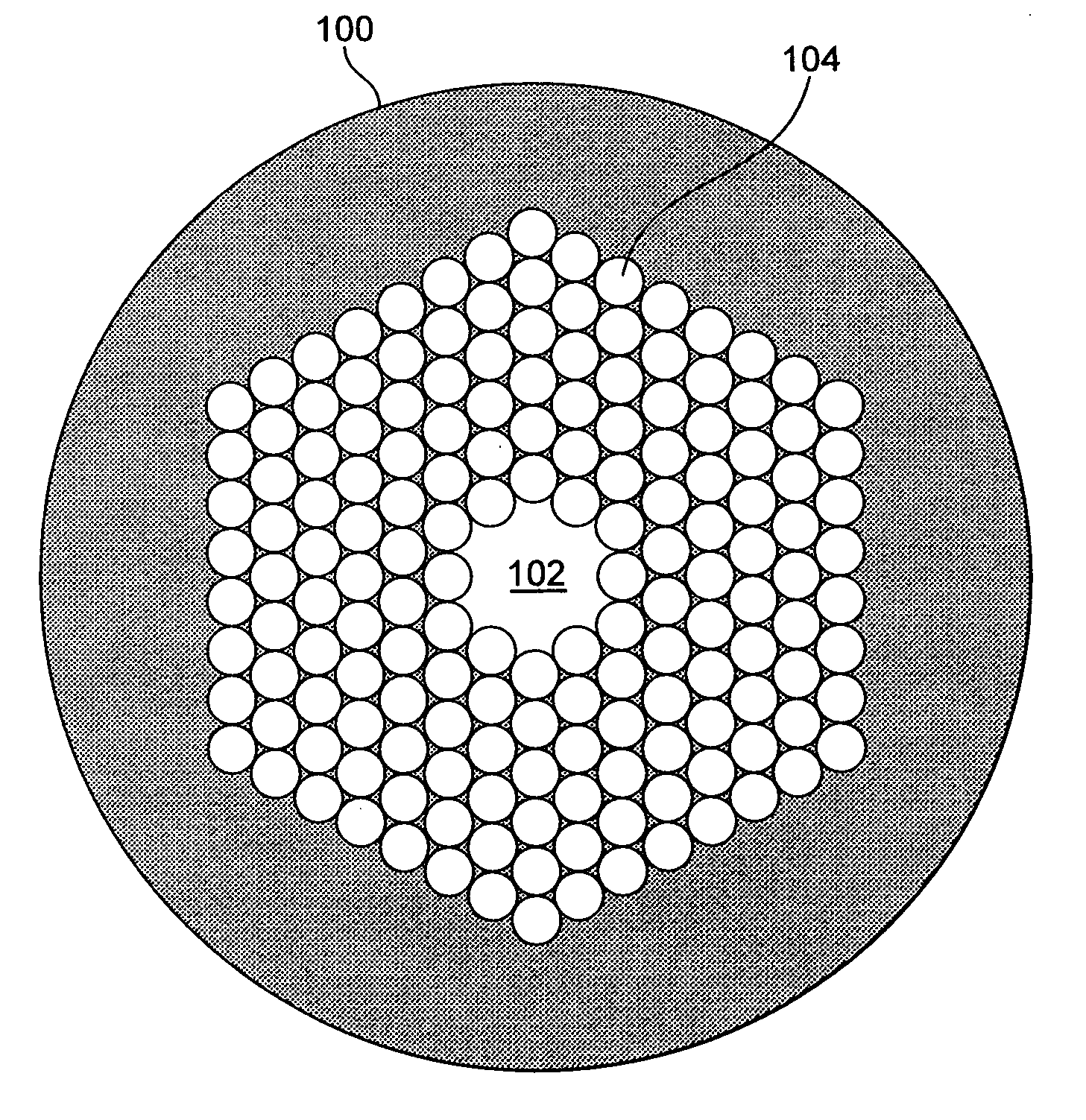

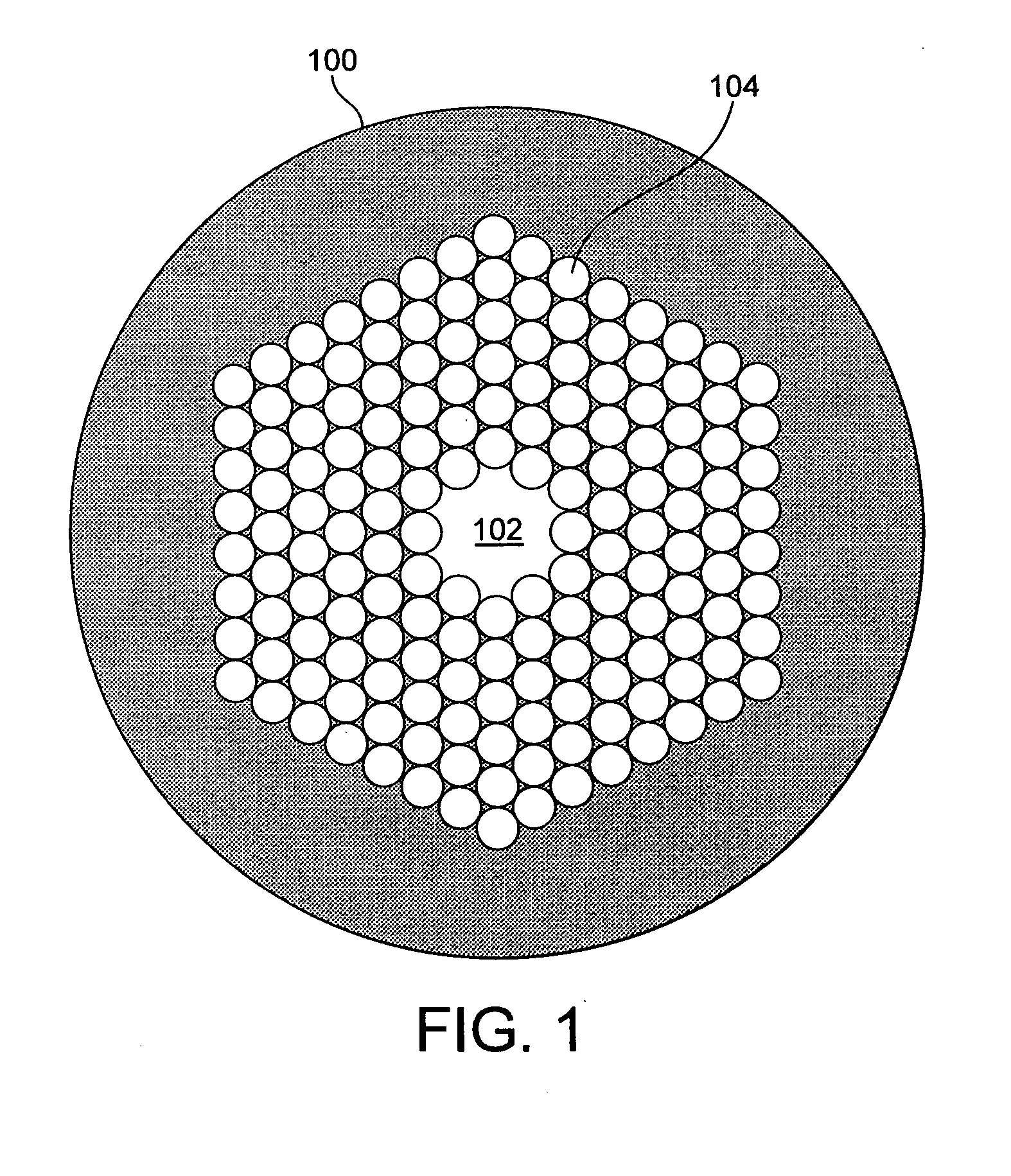

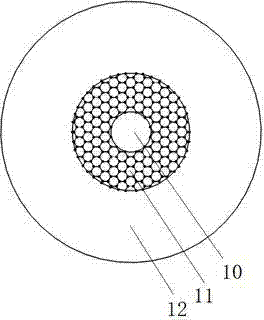

Hollow-core photonic crystal fibre

ActiveUS8306379B2Easy to makeWide transmission regionGlass making apparatusRadiation pyrometryRefractive indexLength wave

A hollow core photonic crystal fiber (HCPCF) having a wavelength of operation, the HCPCF comprising: a core region having a first refractive index; a cladding region surrounding the core region and comprising a plurality of microcapillaries arranged in a transverse structure having a pitch, the pitch of the structure being at least five times larger than the wavelength of operation, the cladding region having a second refractive index higher than the first refractive index.

Owner:GLOPHOTONICS

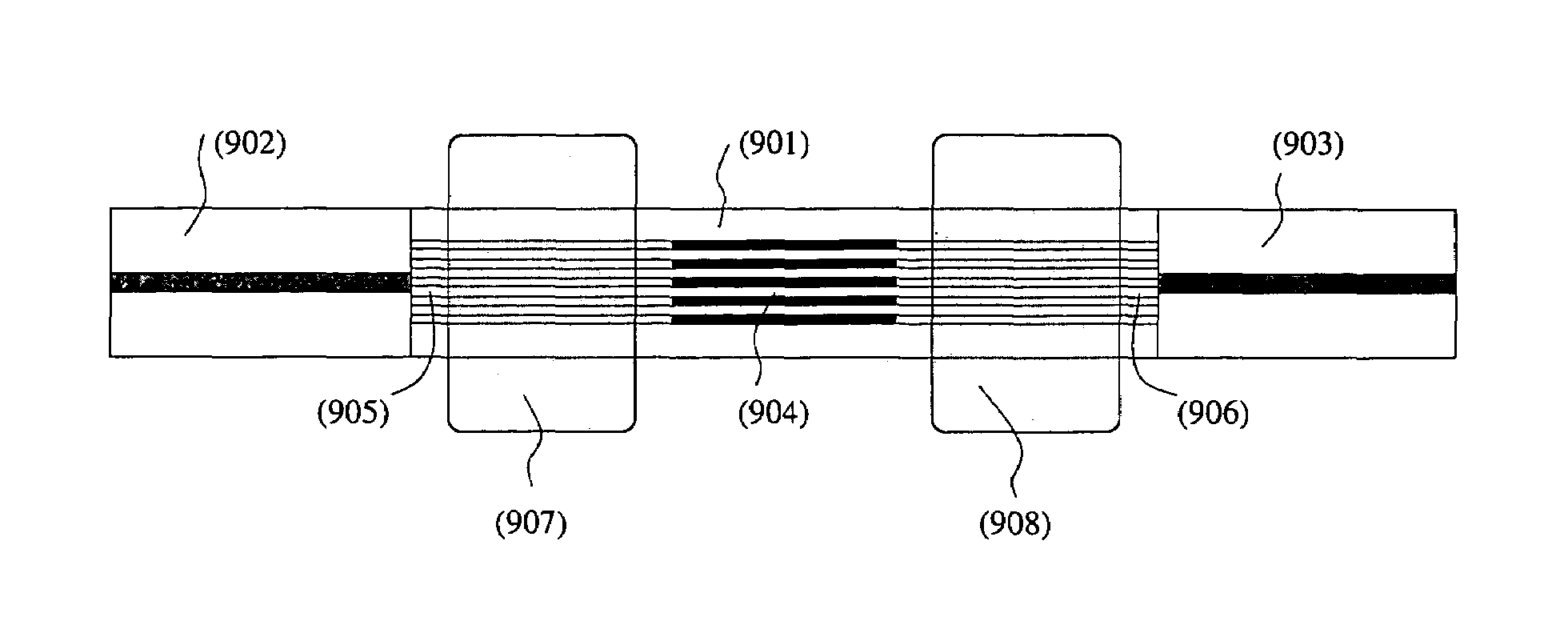

A Fabry-Perot interference sensor based on solid-core photonic crystal fiber and its manufacturing method

InactiveCN102261924ASimple structureSmall sizeCoupling light guidesConverting sensor output opticallyThermal dilatationInterferometric sensor

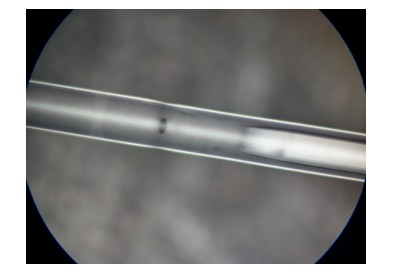

The invention provides a Fabry-Perot interferometric sensor based on a photonic crystal fiber and a manufacturing method thereof. The sensor is composed of a conventional communication single-mode fiber and a solid photonic crystal fiber, wherein the conventional communication single-mode fiber and the solid photonic crystal fiber are welded by using a certain welding method. Because air holes ona cladding of the photonic crystal fiber collapse, an air cavity (namely, an F-P cavity) is formed between the two fibers, and the two end faces (namely, the front and rear surfaces of the air cavity) of the photonic crystal fiber and the single-mode fiber are two reflecting surfaces of the F-P cavity. The solid photonic crystal fiber is made of a single material, and does not cause the mismatching of thermal expansion coefficients of materials in the process of temperature variation, thereby ensuring that the influence of temperature variation on the interferometric sensor is small; in the manufacturing process, only a fiber cutting and welding process is used, therefore, the preparation process is simple; by using the sensor, high-fineness and high-contrast interference fringes can be obtained, therefore, the sensor has a great application potential in large-capacity and quasi-distributed sensing systems; and the sensor is in an all-fiber structure, and has the advantages of small volume, good robustness and low cost.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Hollow core optical fiber and a laser system

ActiveUS20190011634A1High spectral transmissionEnhanced inhibitory effectGlass making apparatusLaser detailsHollow corePhotonic-crystal fiber

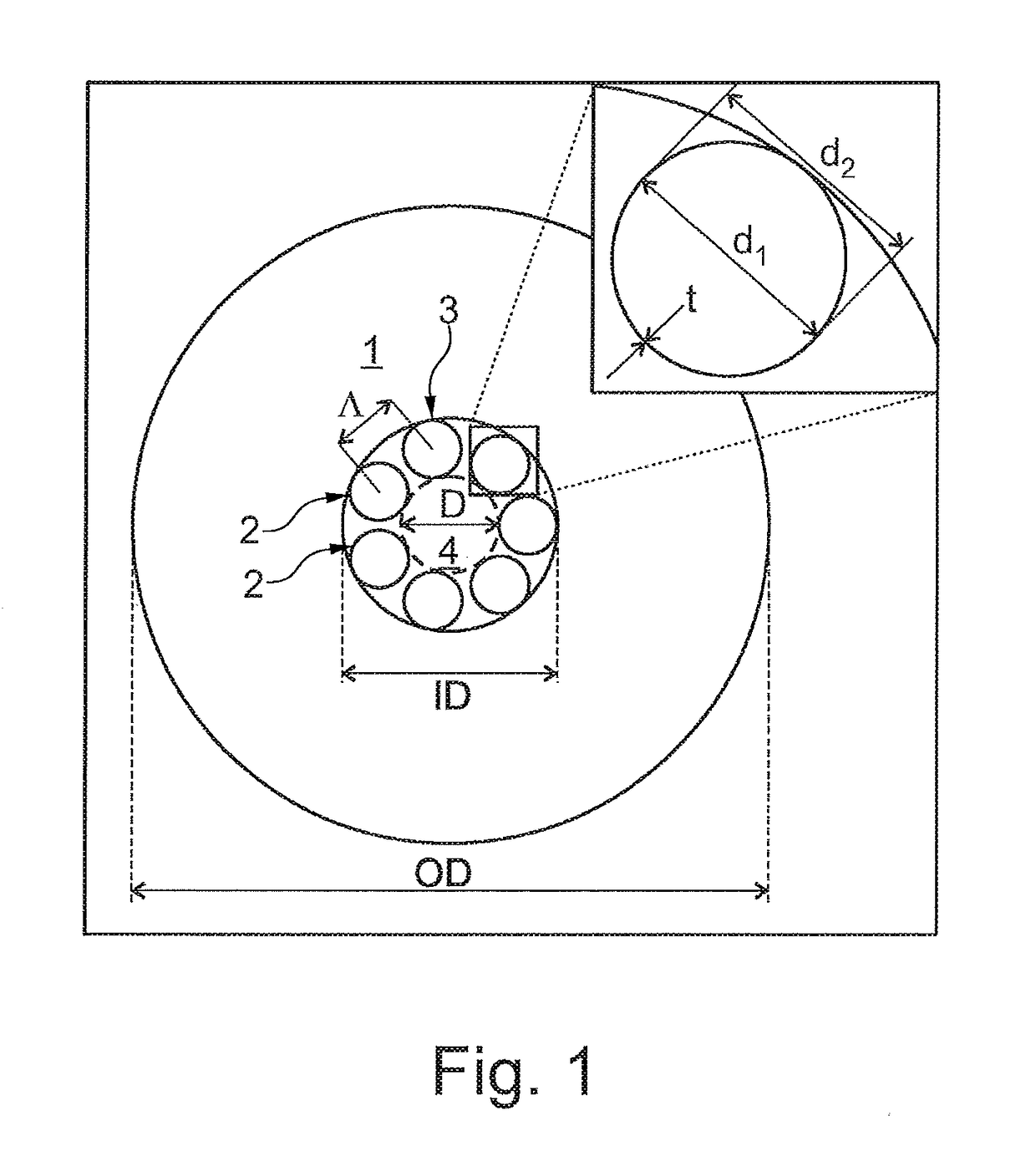

A hollow core photonic crystal fiber (PCF) comprising an outer cladding region and 7 hollow tubes surrounded by the outer cladding region. Each of the hollow tubes is fused to the outer cladding to form a ring defining an inner cladding region and a hollow core region surrounded by the inner cladding region. The hollow tubes are not touching each other, but are arranged with distance to adjacent hollow tubes. The hollow tubes each have an average outer diameter d2 and an average inner diameter d1, wherein d1 / d2 is equal to or larger than about 0.8, such as equal to or larger than about 0.85, such as equal to or larger than about 0.9.Also a laser system is disclosed.

Owner:NKT PHOTONICS

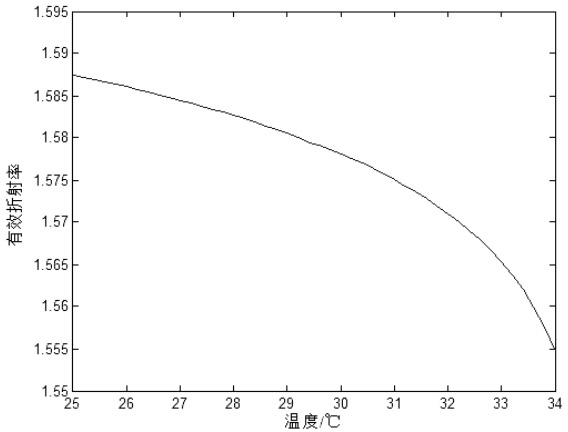

Adjustable photonic crystal optical fiber terahertz waveguide

InactiveCN102162876ANo need to change geometryChange transfer characteristicsCladded optical fibreOptical waveguide light guideLiquid crystallineFiber

The invention relates to an adjustable photonic crystal optical fiber terahertz waveguide, which comprises a coating consisting of a plastic material and air holes formed in a triangular period. The air hole in the center of the coating is used as a fiber core. The radius of the fiber core is greater than the radii of the other air holes in the coating. Nematic liquid crystals sensitive to the temperature are filled in the fiber core. The refractive index of the liquid crystals is greater than the refractive index of the coating. The refractive index of the liquid crystals can be changed by controlling the temperature of the working environment of the liquid crystals, so that a propagation mode, an effective mode field area and a zero dispersion range of an optical fiber are flexibly controlled. The defect that when the conventional photonic crystal optical fiber waveguide is produced, the optical properties and the transmission characteristics of the conventional photonic crystal optical fiber waveguide cannot be changed is overcome. A structure parameter of a photonic crystal optical fiber for the terahertz waveguide is at the millimeter order of magnitude. Compared with a visible light or infrared band photonic crystal optical fiber, the photonic crystal optical fiber for the terahertz waveguide is easier to prepare.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

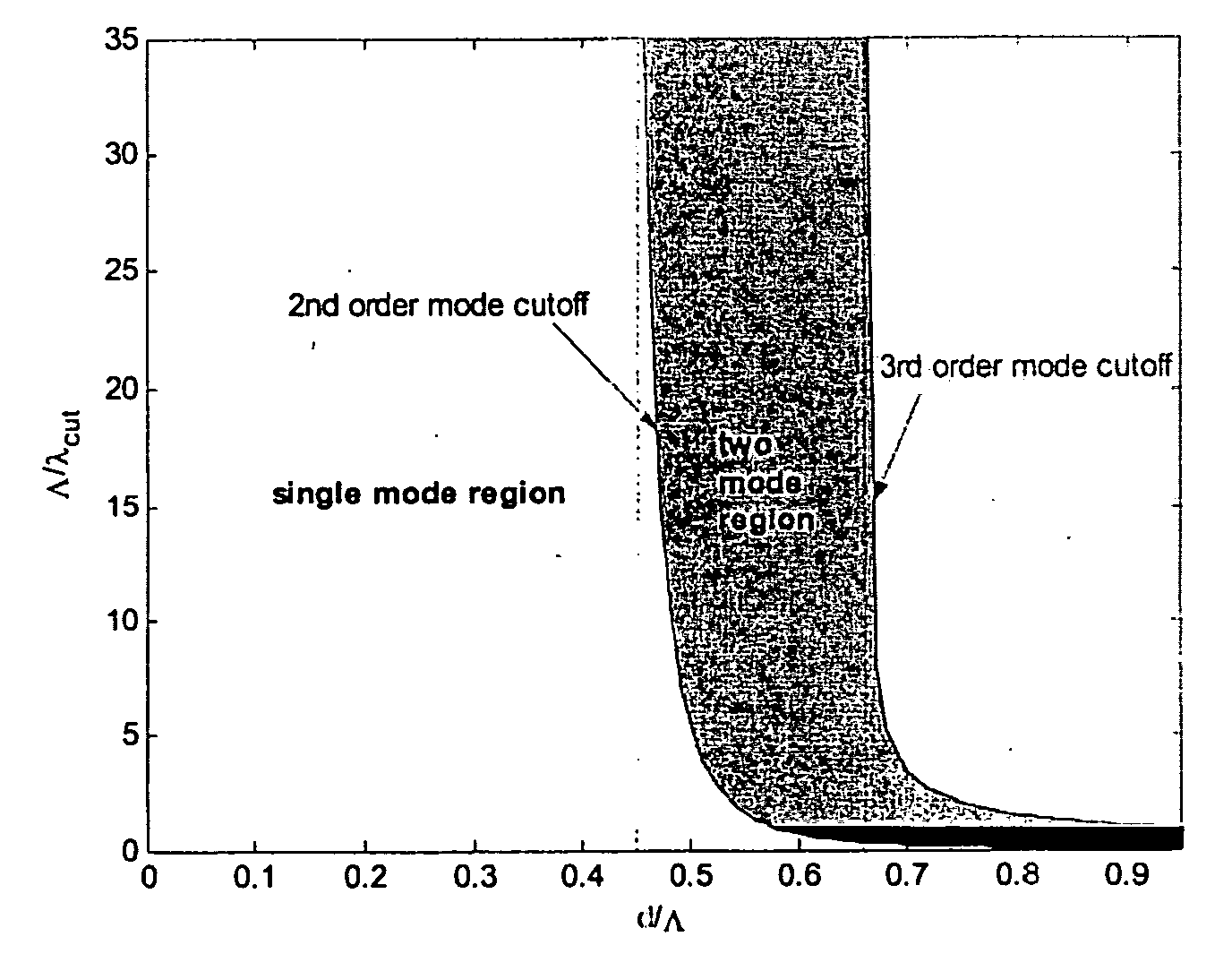

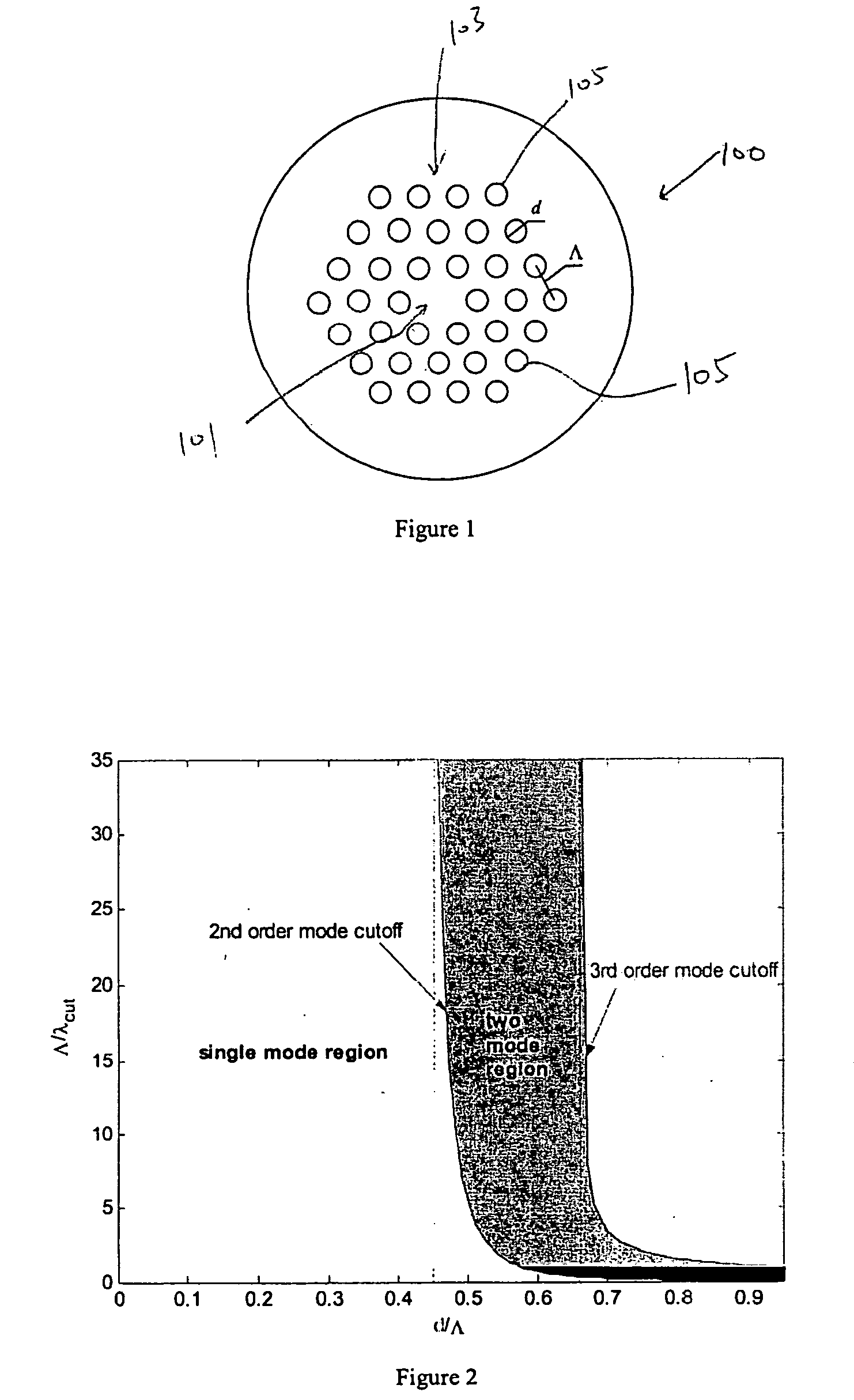

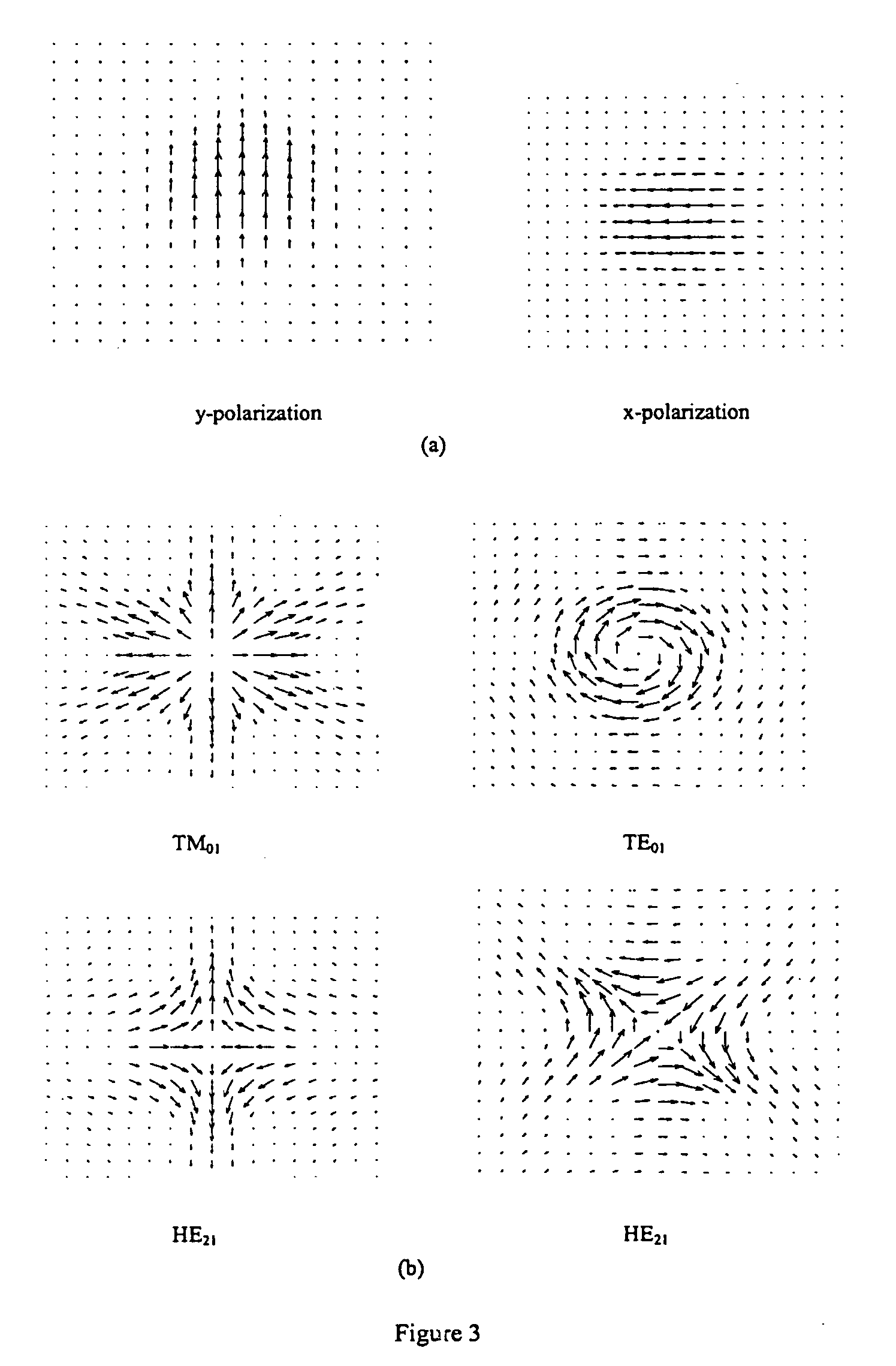

Two-mode photonic crystal fibre and applications thereof

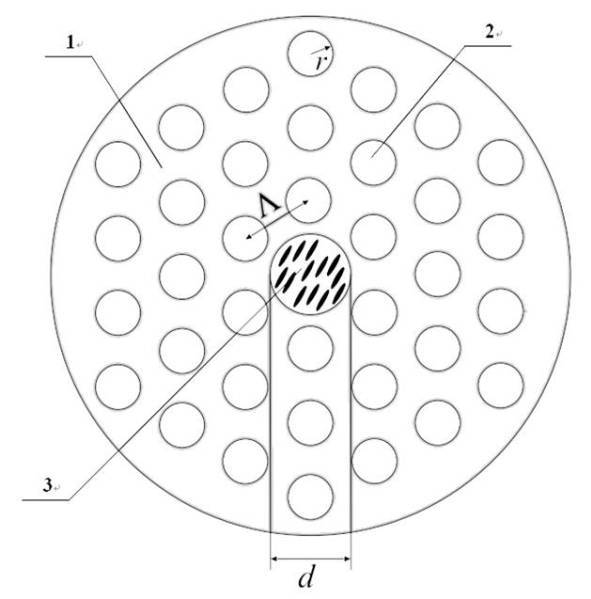

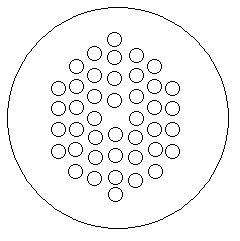

A two-mode photonic crystal fiber includes a core of a substantially transparent core material. The core material has a core refractive index and a length, and has a core diameter. The fiber also includes a cladding region surrounding the length of core material. The cladding region has a first substantially transparent cladding material, having a first refractive index. The first substantially transparent cladding material has embedded along its length a substantially periodic array of holes, having a diameter, d, and being spaced apart by a pitch, Λ. The holes have a second refractive index, which is less than the first refractive index. The dimensions of the hole diameter, d, and the pitch, Λ, co-operate to give two modes propagation within the photonic crystal fiber independent of input radiation wavelength for any value of the pitch, Λ, for a substantially fixed d / Λ ratio within a range of approximately 0.45-0.65.

Owner:THE HONG KONG POLYTECHNIC UNIV

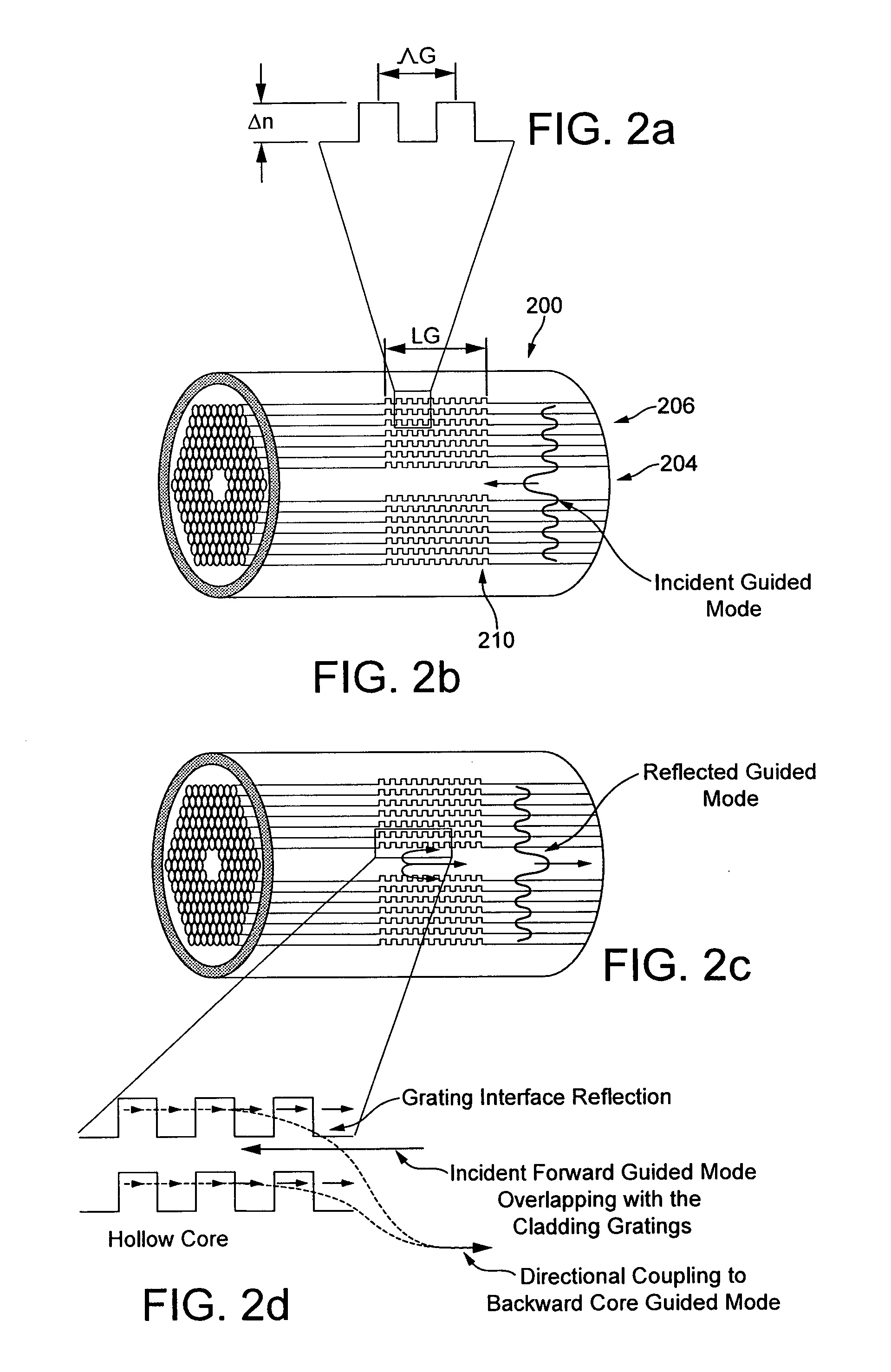

Hollow Core Photonic Crystal Fibre Comprising a Fibre Grating in the Cladding and Its Applications

InactiveUS20110267612A1Improve reflectivityLarge finesseRadiation pyrometryOptical fibre with graded refractive index core/claddingOptical propagationFiber

An optical fibre is provided having a fibre cladding around a longitudinally extending optical propagation core. The cladding has a reflection region of a varying refractive index in the longitudinal direction.

Owner:GLOPHOTONICS

Composite material photonic crystal fibres, method of production and its use

InactiveUS7062140B2High strengthAvoid couplingOptical fibre with multilayer core/claddingCoupling light guidesFiberPhotonic crystal

An optical fibre for transmission of light at a predetermined wavelength, the fibre having a core region, an inner cladding region and an outer cladding region, the inner cladding region having spaced apart voids, at least some of which are at least partly filled with a fluid substance to modify a refractive index in the cross-section of the fibre. The fluid substance may be introduced by preparing and fixing the fibre ends, identifying the voids to be filled and infusing the fluid therein while masking openings in the remaining voids. By selective heating of parts of the fibre, the location of the fluid substance in the void may be controlled to extend over only a fraction of the length of a void that extends the length by the fibre.

Owner:CRYSTAL FIBRE AS

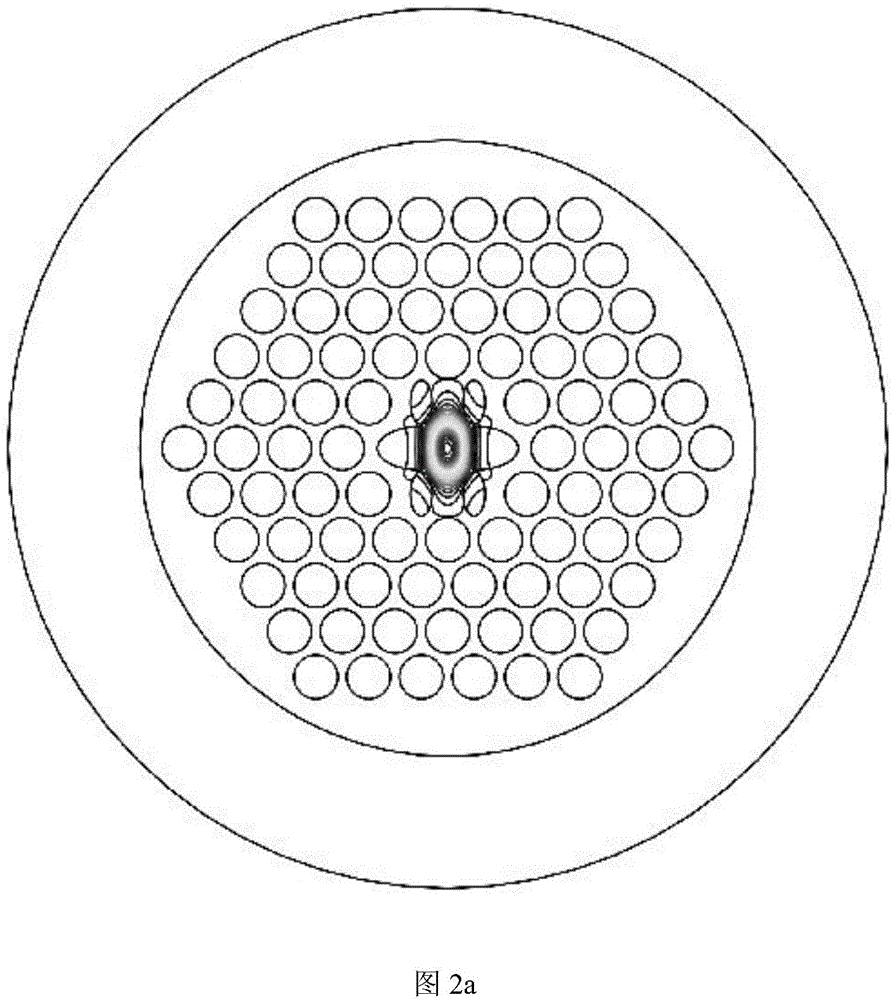

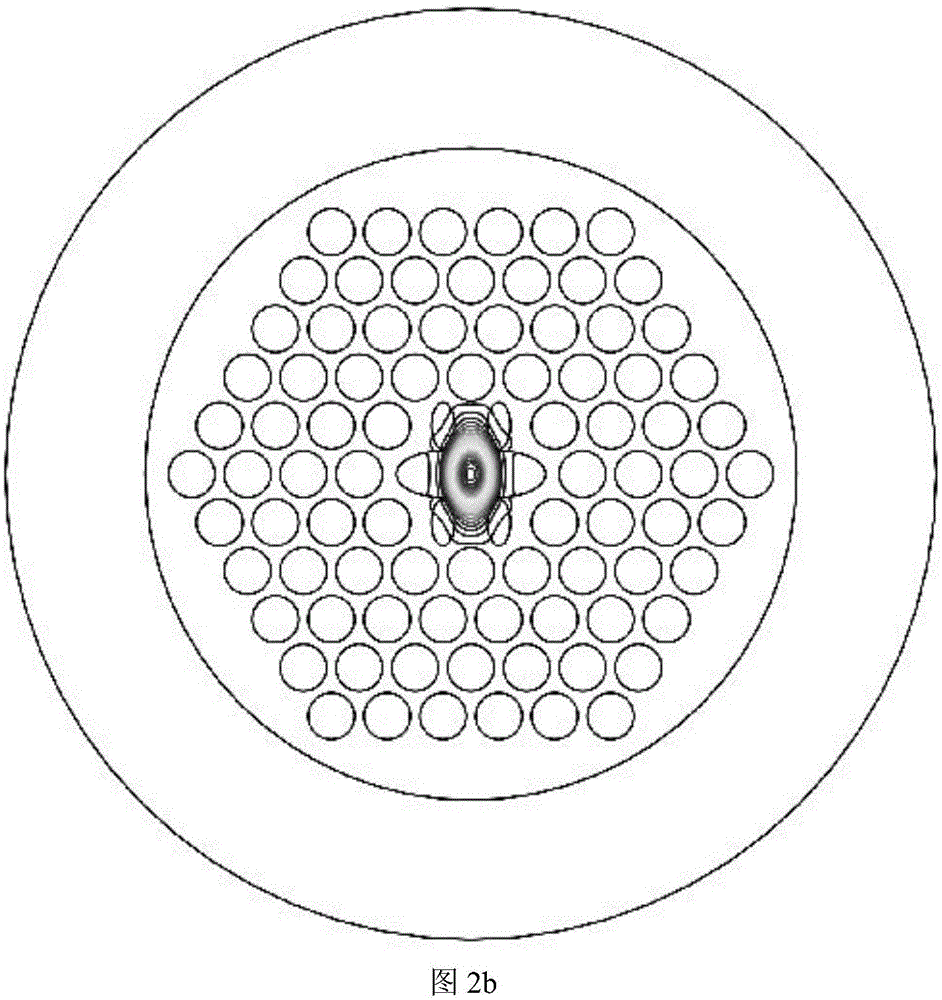

Refractive index and temperature sensor of photonic crystal fiber, manufacturing method and measuring system

InactiveCN102778306AEasy to detectImprove detection accuracyThermometers using physical/chemical changesPhotonic crystalRefractive index

The invention discloses a refractive index and temperature sensor of a photonic crystal fiber, a manufacturing method and a measuring system. The refractive index and temperature sensor comprises an optical signal input-output fiber made of a single mode fiber, a sensor probe made of a photonic crystal fiber, and an ellipsoid air cavity formed by sunk air holes of a cladding layer of the photonic crystal fiber; and a composite Fabry-Perot cavity is formed by the air cavity and the sensor probe. With the adoption of the refractive index and temperature sensor of the photonic crystal fiber and the measuring system, the fiber does not need to be corroded or photo-etched, so the manufacturing is convenient, a sensor system is free from the affect of stray lights; the refractive index and the temperature are measured synchronously, the signal noise is low, the system sensitivity is high, and the reliability is high.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

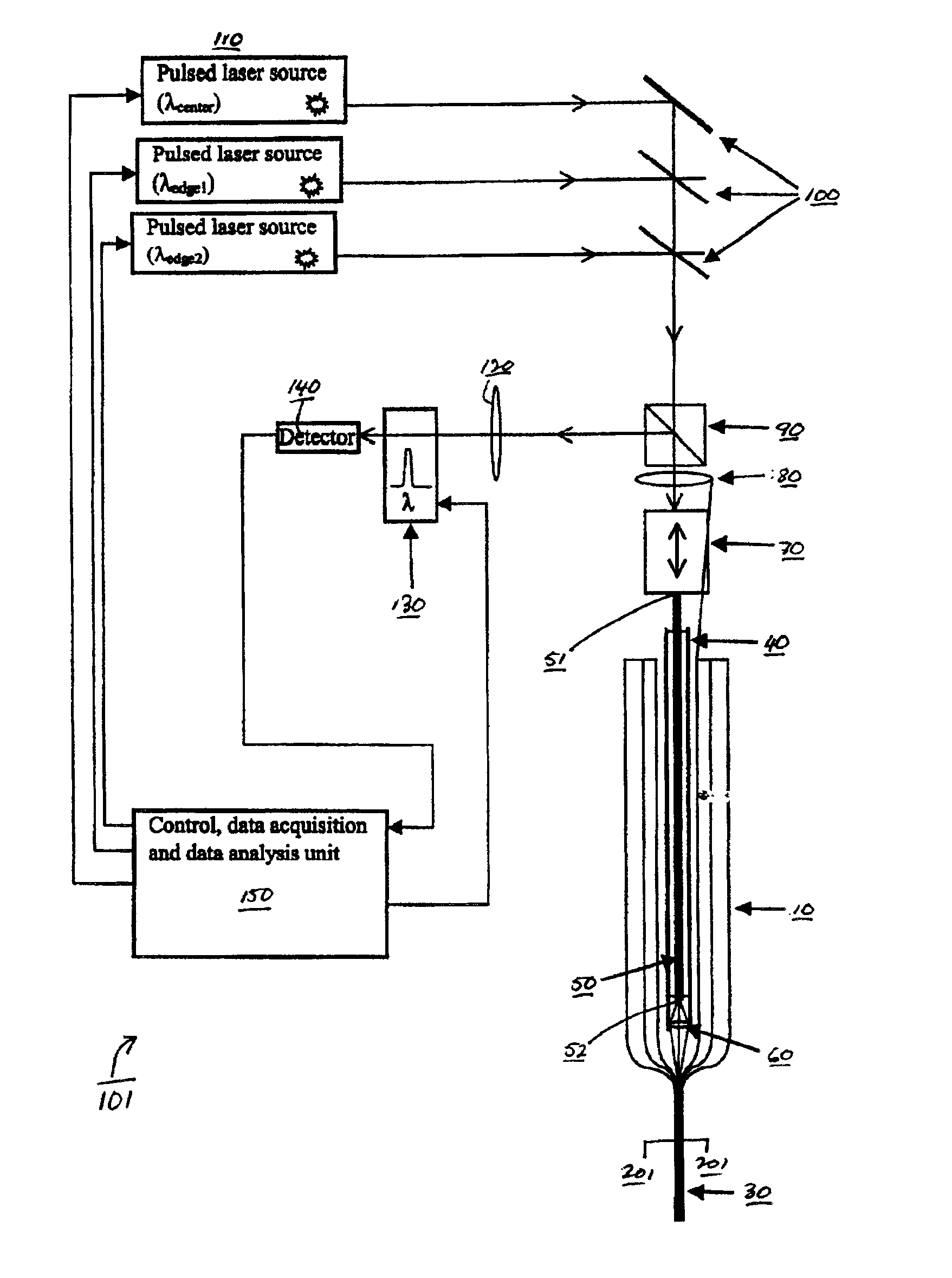

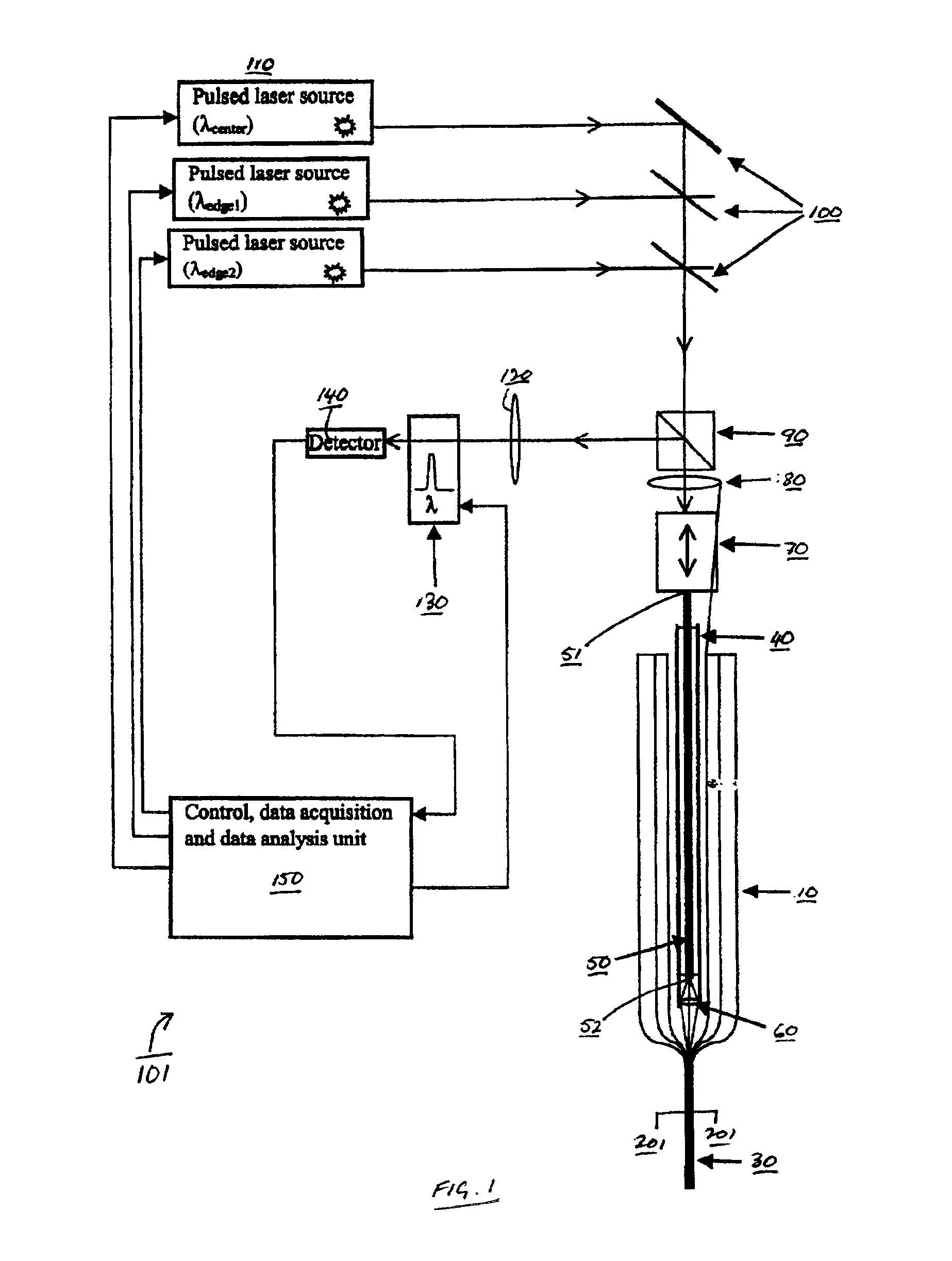

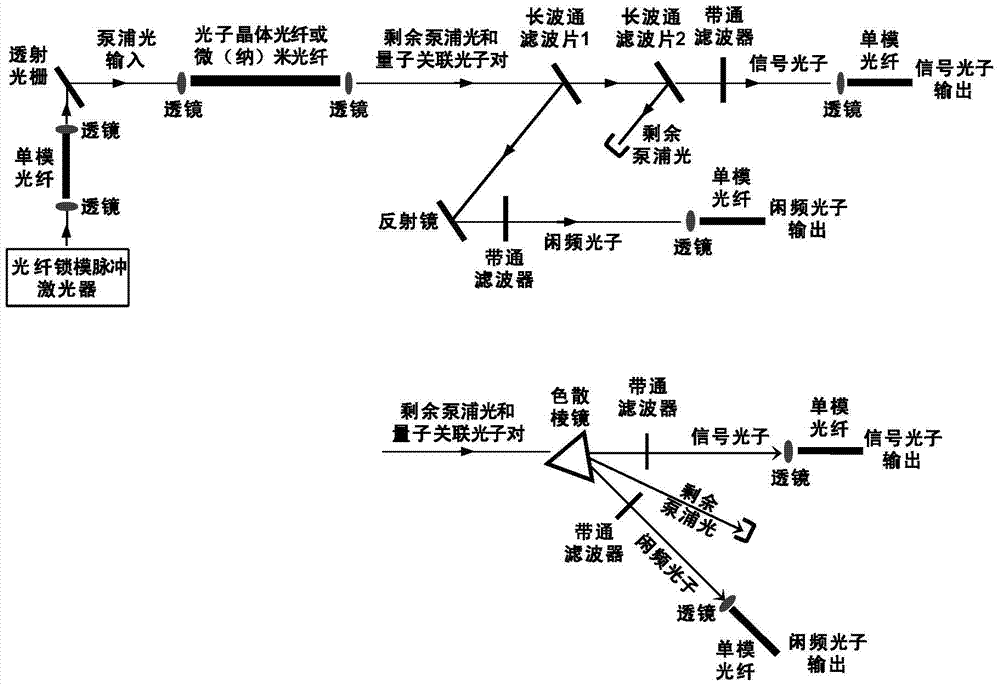

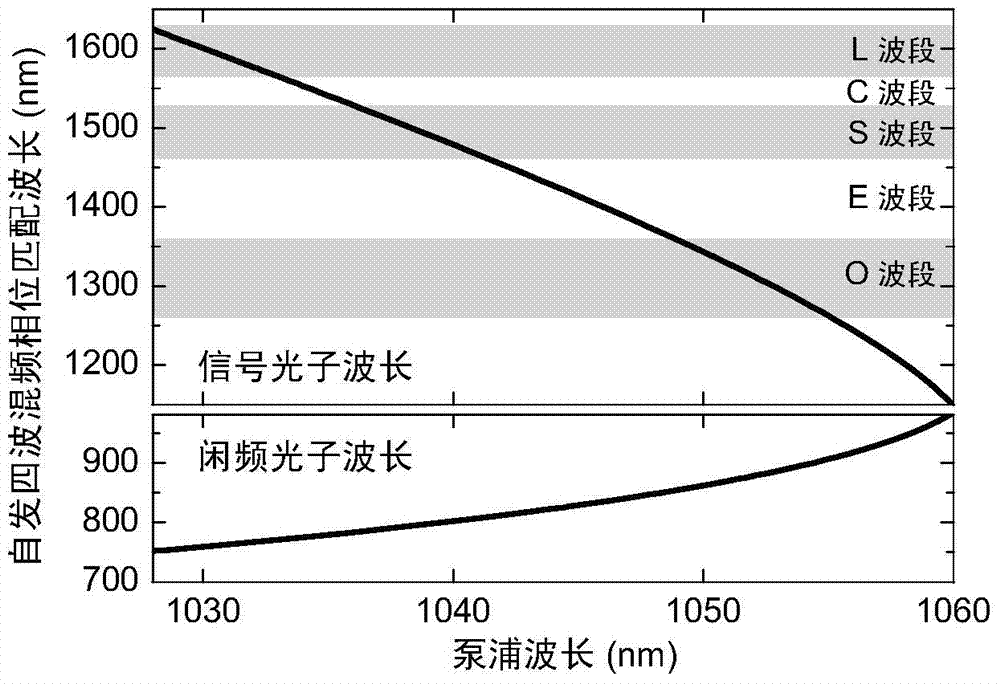

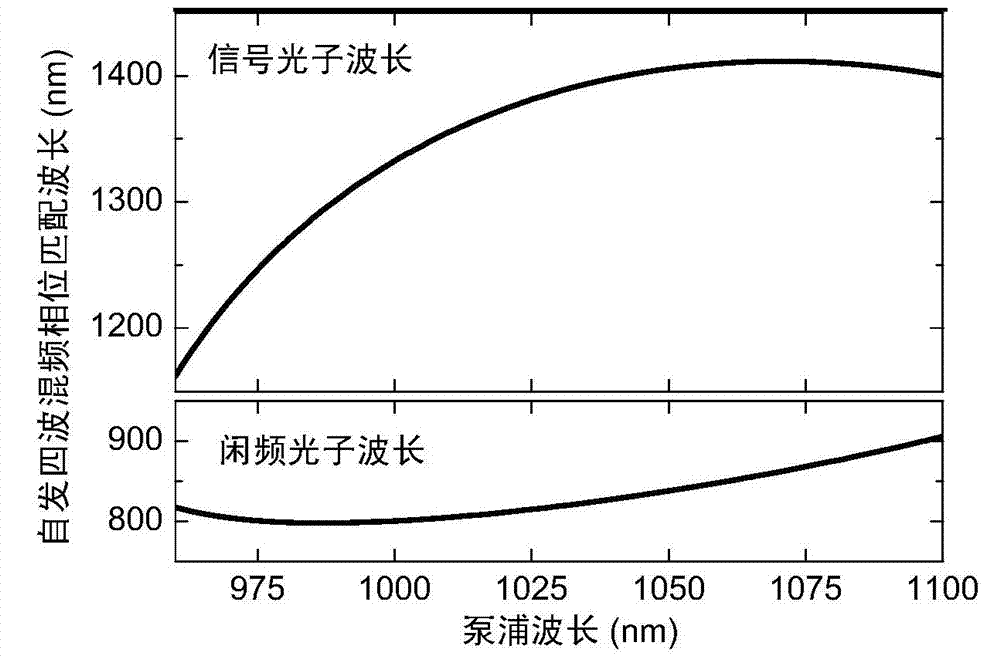

Mini-type quantum relevancy photon pair source with adjustable wavelength and controllable frequency spectrum and generating method

InactiveCN103901700AAchieve wavelength tuningAchieve Spectrum ControlNon-linear opticsMicro structureQuantum technology

The invention belongs to the technical field of quantum, and provides a quantum relevancy photon pair source with the adjustable wavelength and the controllable frequency spectrum, and the quantum relevancy photon pair source has the advantages of being small, low in cost and high in purity. According to the technical scheme, a pulse laser with the tunable central wavelength and bandwidth in a wave band ranging from 950 nm to 1150 nm serves as a pumping light; a photonic crystal fiber with specific micro-structure parameters or a micro-nanofiber is selected to serve as a nonlinearity medium, and a quantum relevancy photon pair with the adjustable wavelength and the controllable frequency spectrum is generated by tuning the central wavelength and bandwidth of the pumping light through the spontaneous four-wave mixing process of the nonlinearity medium. The method is mainly applied to quantum technology occasions.

Owner:TIANJIN UNIV

Splicing and connectorization of photonic crystal fibers

InactiveUS20070122095A1Reduce couplingReduce the overall diameterOptical fibre with multilayer core/claddingCoupling light guidesPhotonic crystalRefractive index

A method of coupling a spliceable optical fibre for transmission of light in its longitudinal direction to an optical component, the method comprising (A) providing the spliceable optical fibre, said spliceable optical fibre comprising: (a) a core region; and (b) a microstructured cladding region, said cladding region surrounding said core region and comprising: (bI) an inner cladding region with inner cladding features arranged in an inner cladding background material with a refractive index n1, said inner cladding features comprising thermally collapsible holes or voids, and (b2) an outer cladding region with an outer cladding background material with a refractive index n2; said spliceable optical fibre having at least one end; (B) collapsing said thermally collapsible holes or voids by heating said least one end of said spliceable optical fibre; and (C) coupling said collapsed spliceable optical fibre end to the optical component. A spliceable optical fibre; a preform for producing a spliceable optical fibre; a method of producing a spliceable optical fibre comprising drawing of the preform; a heat-treated spliceable optical fibre; an article comprising a spliceable optical fibre is further disclosed.

Owner:NKT PHOTONICS

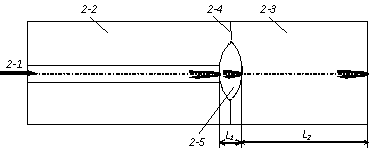

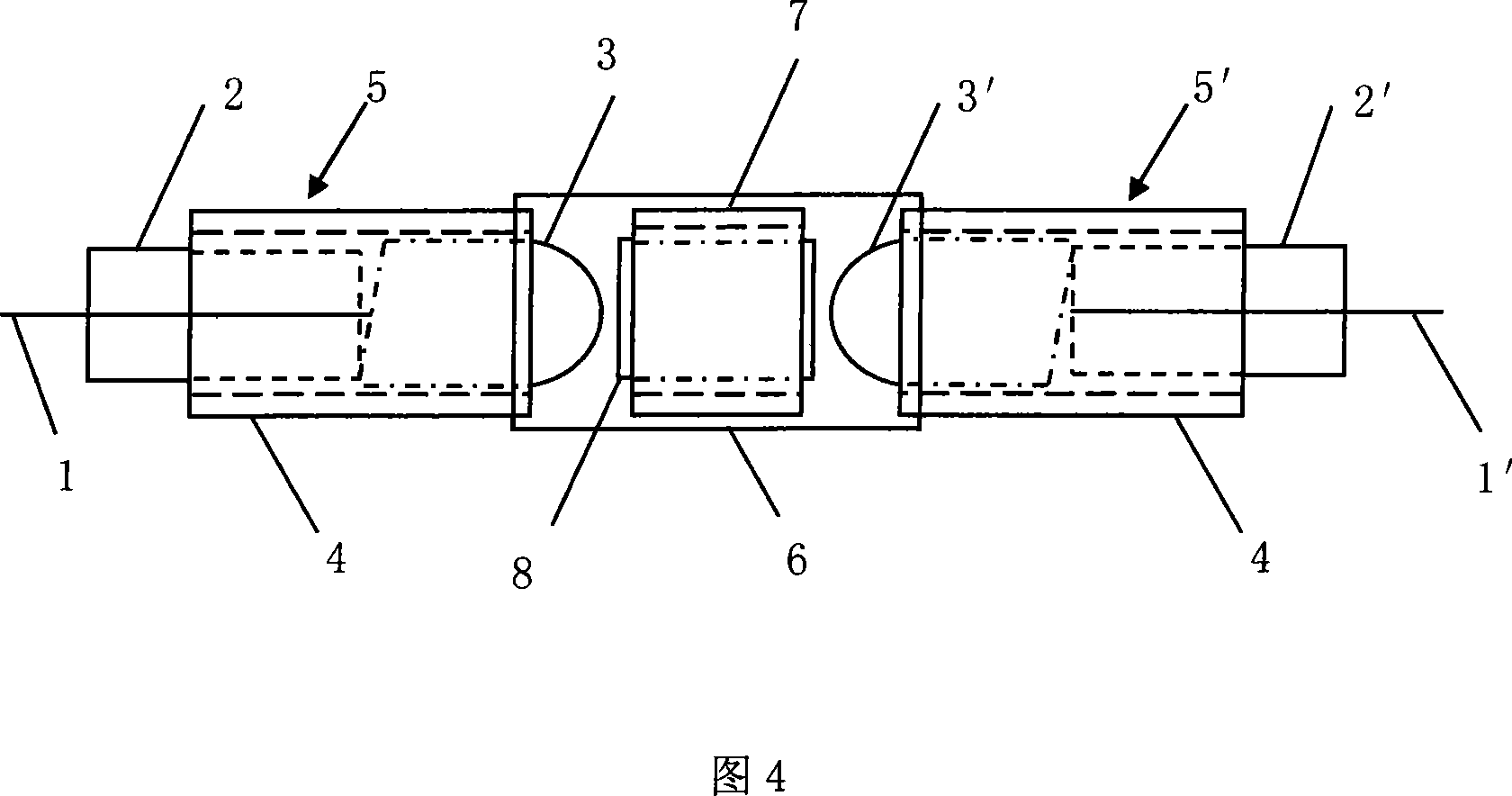

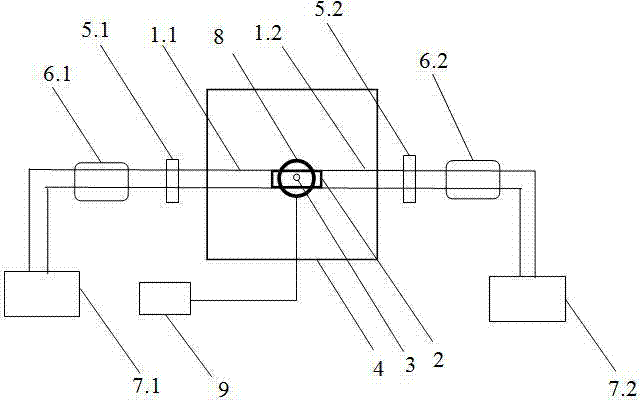

Photon crystal optical fibre coupling method and its coupling apparatus

InactiveCN101216577AReduce lossFirmly connectedCladded optical fibreCoupling light guidesPhotonic crystalUltimate tensile strength

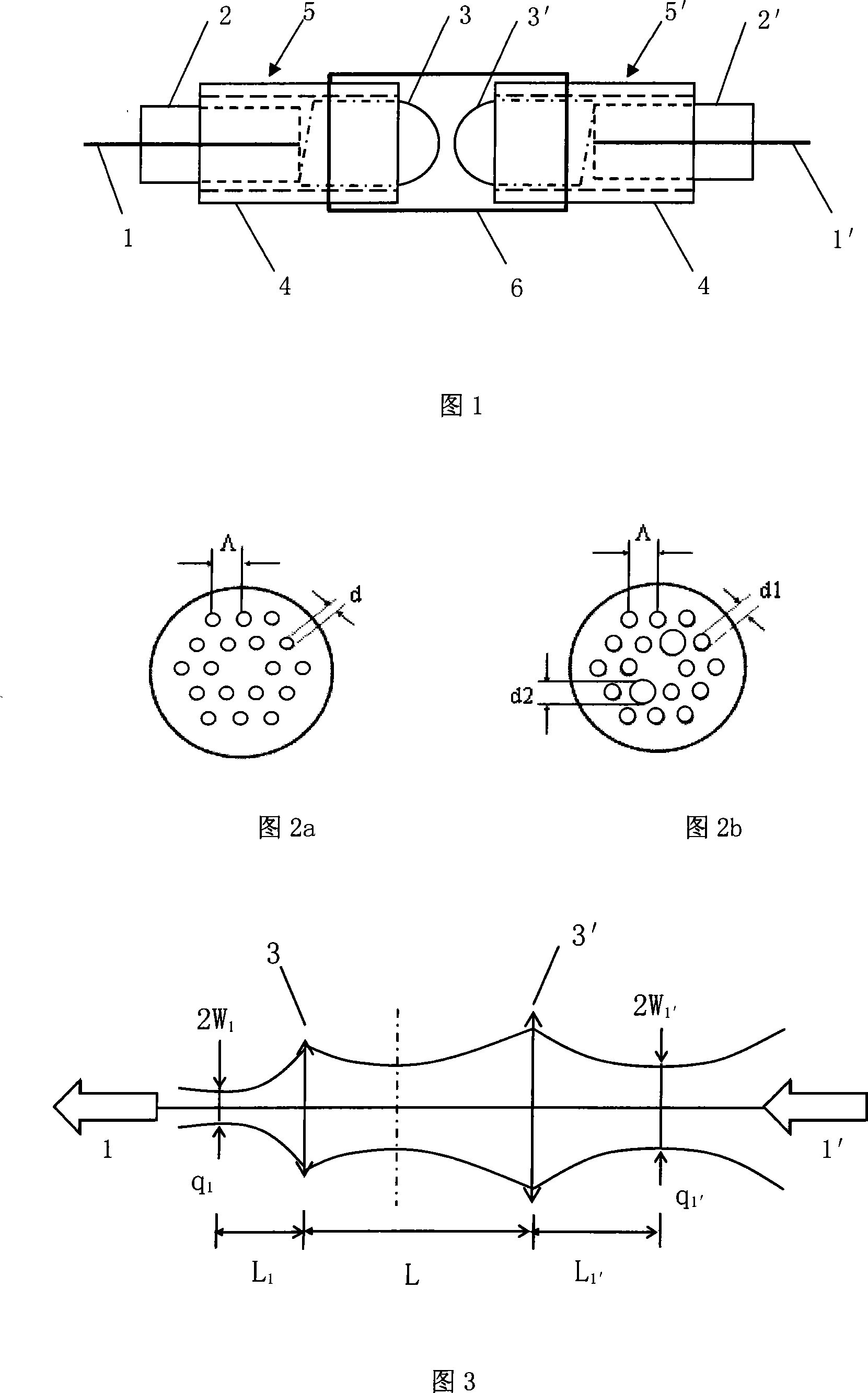

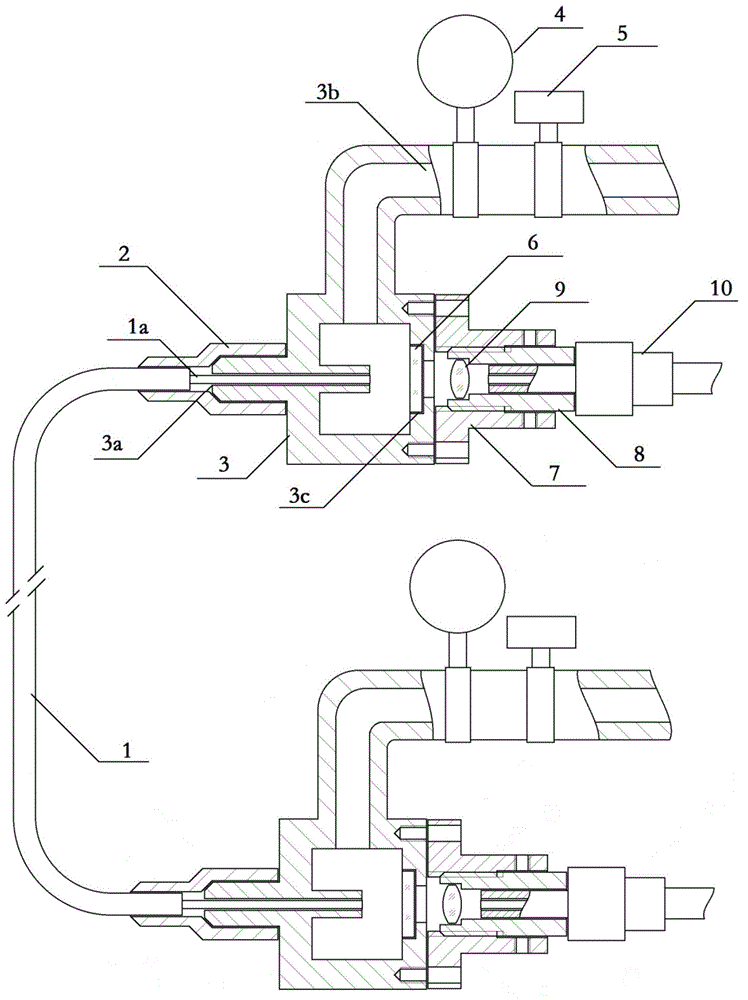

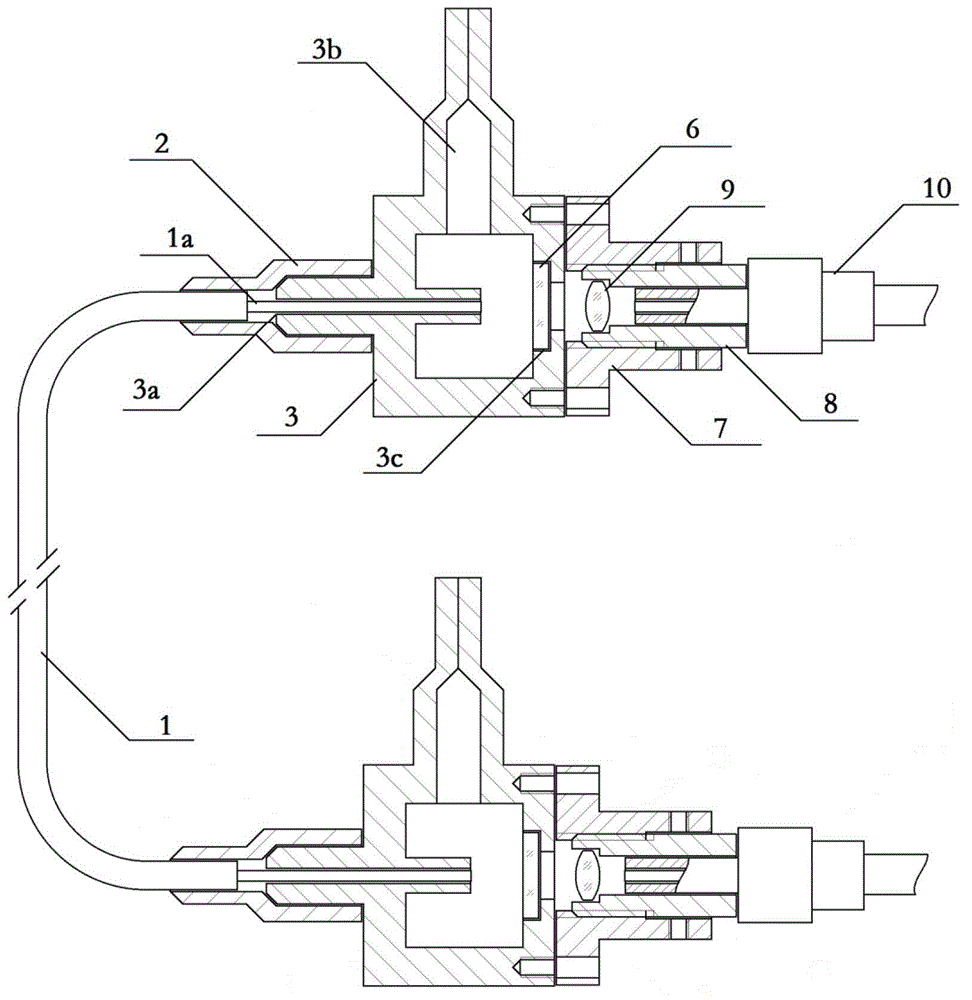

The invention relates to a photonic crystal fiber coupling method and a coupling device thereof. The method comprises the following steps of: determining the equivalent mold field radius of a photonic crystal fiber to be connected according to the specific parameters; selecting a corresponding extender lens and a focusing lens element according to the specific parameters of the photonic crystal fiber to be connected, and calculating the lens coupling optical path to determine a group of distance values for instructing the actual adjusting process; and adjusting the actual coupling optical path according to the distance parameters calculated in step 2 to obtain the minimal loss state, and carrying out a packaging connection. The device comprises a first and a second pins for fixing corresponding one ends of the photonic crystal fiber and a corresponding coupling optical fiber; the extender lens and the focusing lens arranged between the first and the second pins; and an engagement portion for respectively sheathing the first pin and the extender lens as well as the focusing lens and the second pin at the outer periphery of the engagement portion to package the elements; and an outer sleeve for entirely packaging and fixing the elements. The invention has the advantages of simple connection process, high optical fiber coupling efficiency and high connection strength and can eliminate loss resulting from mismatch of mold fields.

Owner:GUANGXUN SCI & TECH WUHAN

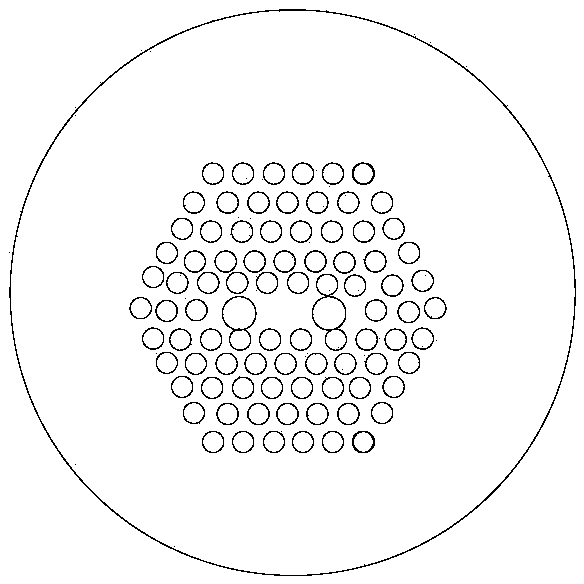

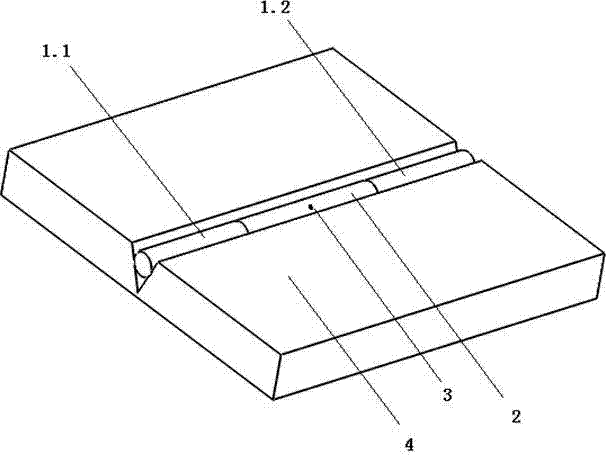

Photonic crystal fiber grinding and polishing technology method

ActiveCN103792619AAchieve regulationImprove machining accuracyCoupling light guidesPhotonic crystalTotal internal reflection

The invention discloses a photonic crystal fiber grinding and polishing technology method. The method comprises the steps that preparation before photonic crystal tail fiber grinding and polishing is conducted; clamping of a photonic crystal tail fiber is conducted; rough grinding is conducted on the end face of the photonic crystal optical fiber; fine grinding is conducted on the end face of the photonic crystal optical fiber; accurate grinding is conducted on the end face of the photonic crystal optical fiber; polishing is conducted on the end face of the photonic crystal optical fiber; examination is conducted on the end face of the optical fiber. According to the grinding and polishing technology method, the wet corrosion photo-etching technology or the cutting technology is adopted, a V-shaped groove is formed in an optical fiber fixing block, the CMP technology where a certain angle is formed between a polishing plane of the end face of the photonic crystal optical fiber and the cross section of the optical fiber is introduced on the basis of common photonic crystal end face grinding and polishing, the photonic crystal optical fiber prepared through the technology method can guarantee that loss of tail fibers is small and the method can be used for grinding and polishing for the angle between the end face of a whole-inner-reflection type photonic crystal optical fiber and the end face of a photonic band gap type photonic crystal optical fiber.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

Hollow photonic crystal optical fiber gas absorption cell device and manufacturing method thereof

InactiveCN102866468ASmall volume of absorption cellReduce volumeMaterial analysis by optical meansCoupling light guidesAbsorption cellPhotonic crystal

The invention relates to a hollow photonic crystal optical fiber gas absorption cell device and a manufacturing method thereof. The device comprises a hollow photonic crystal optical fiber, a protective sleeve, a hermetic cabin, a vacuum gauge, a vacuum valve, window glass, a coupling mirror and a regulating component. According to the device disclosed by the invention, the characteristics that the hollow photonic crystal optical fiber is flexible and bendable and gas can be filled into a fiber core are utilized, quantitative injection of gas can be realized by using the hermetic cabin, the vacuum gauge and the vacuum valve, a light beam can enter the hollow photonic crystal optical fiber by being coupled by the coupling mirror and the window glass, and sealing is performed by an optical fiber metalization and feed-through welding process. The device disclosed by the invention has the characteristics of compact and small structure, high reliability, controllable gas pressure, repeated use and high coincidence degree of the section of the light beam and the gas section. The device disclosed by the invention can be used for gas spectroscopic analysis experiments and the gas absorption cell taking the frequency of a frequency stabilized laser as reference.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

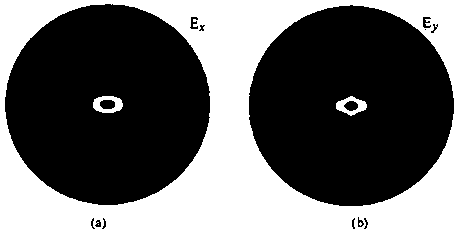

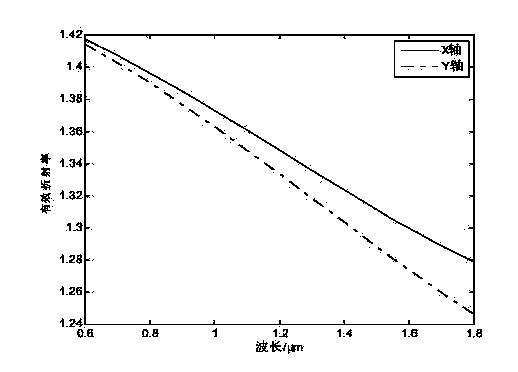

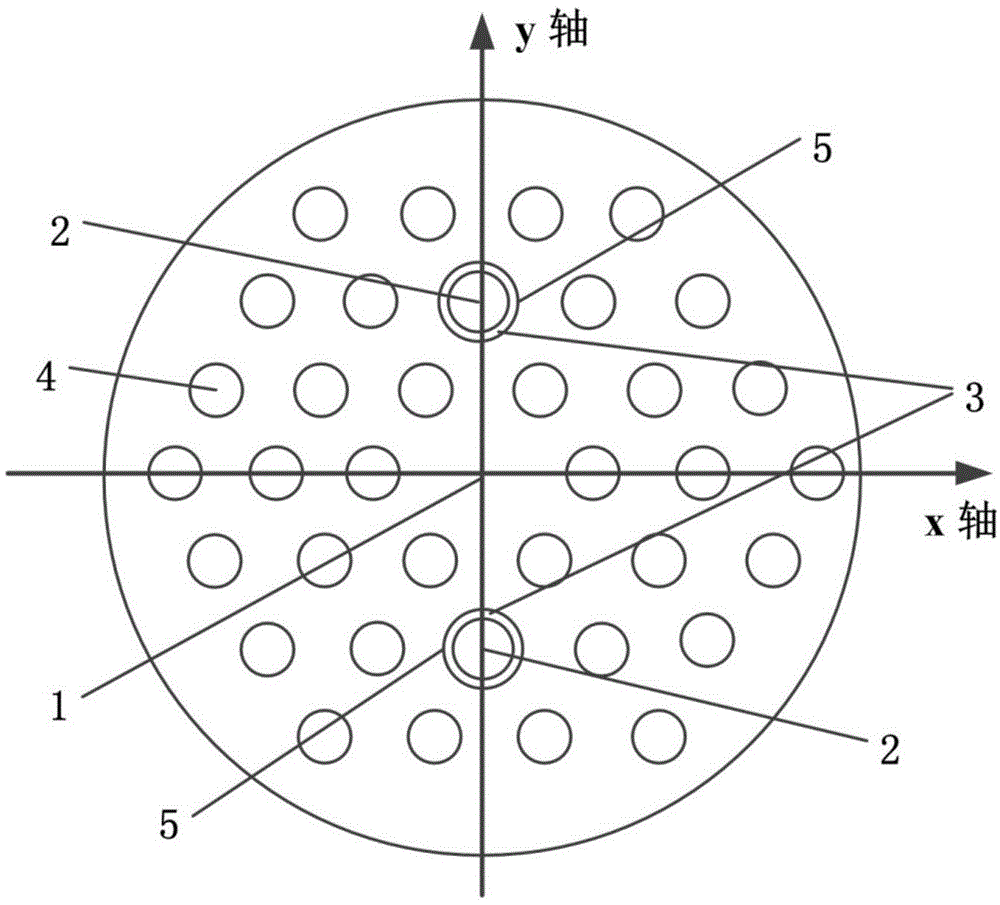

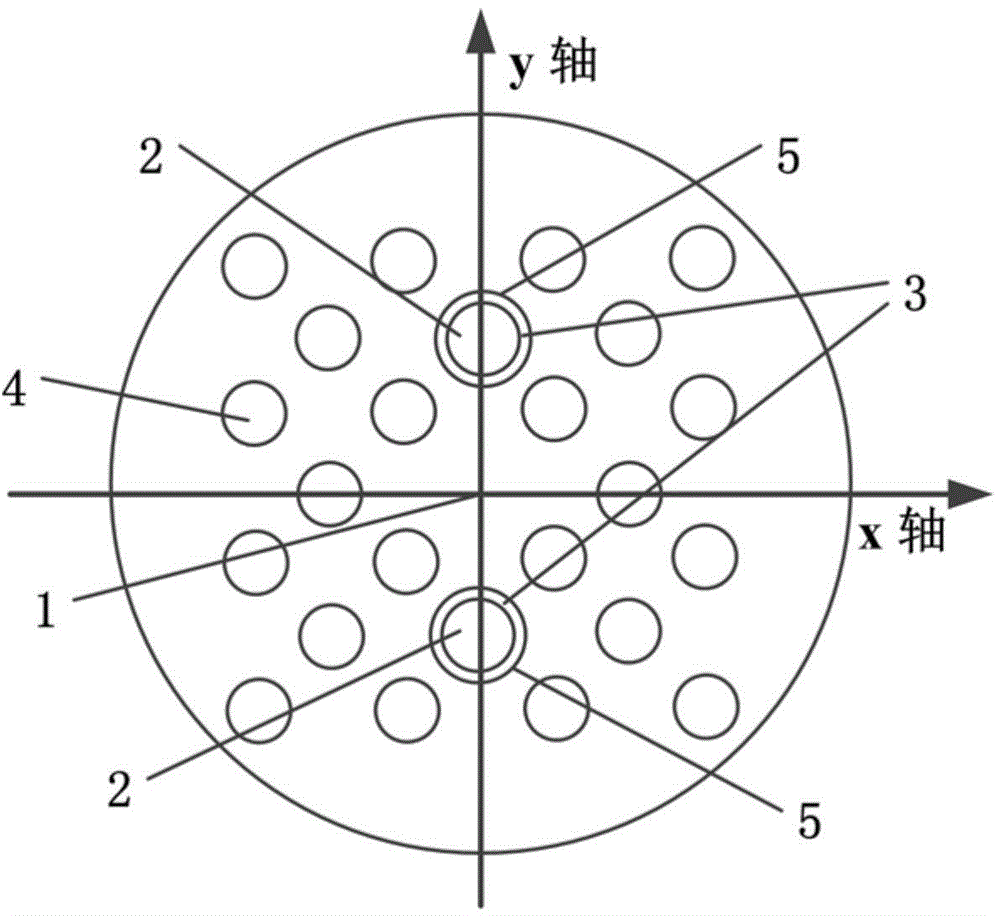

Photonic crystal fiber with high birefringence characteristic

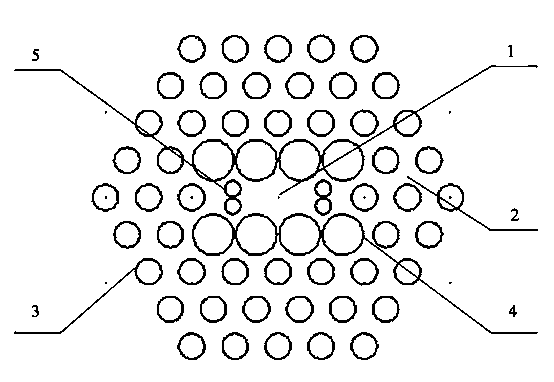

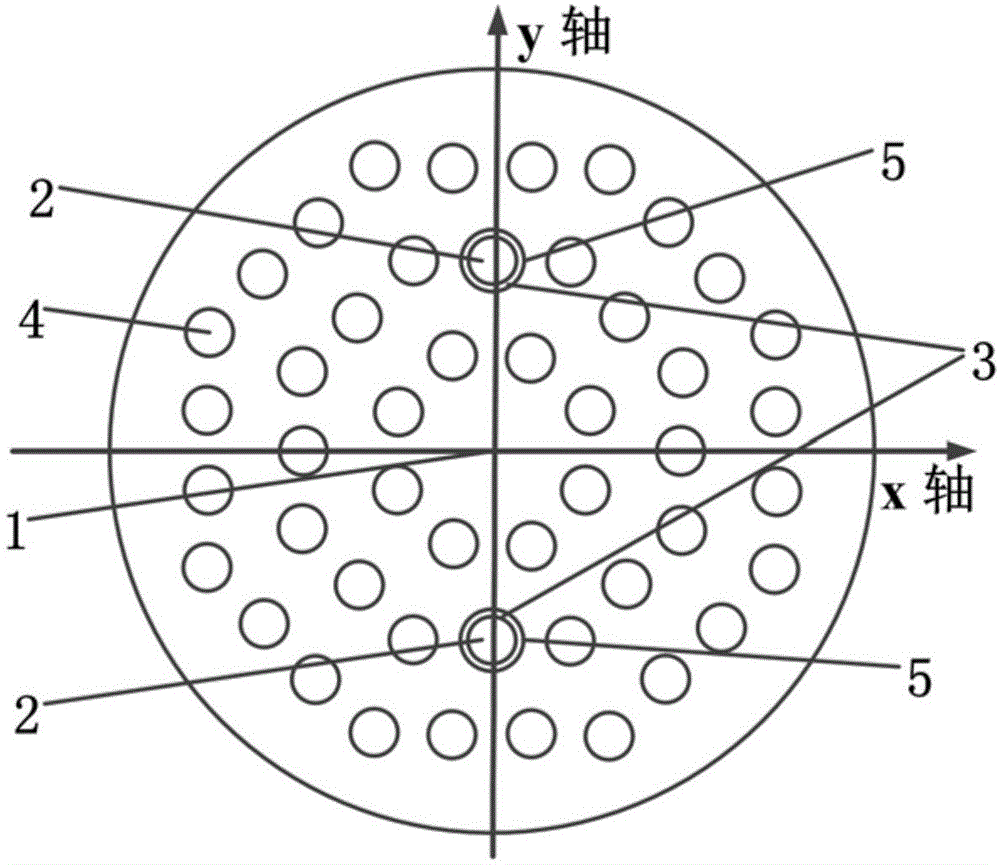

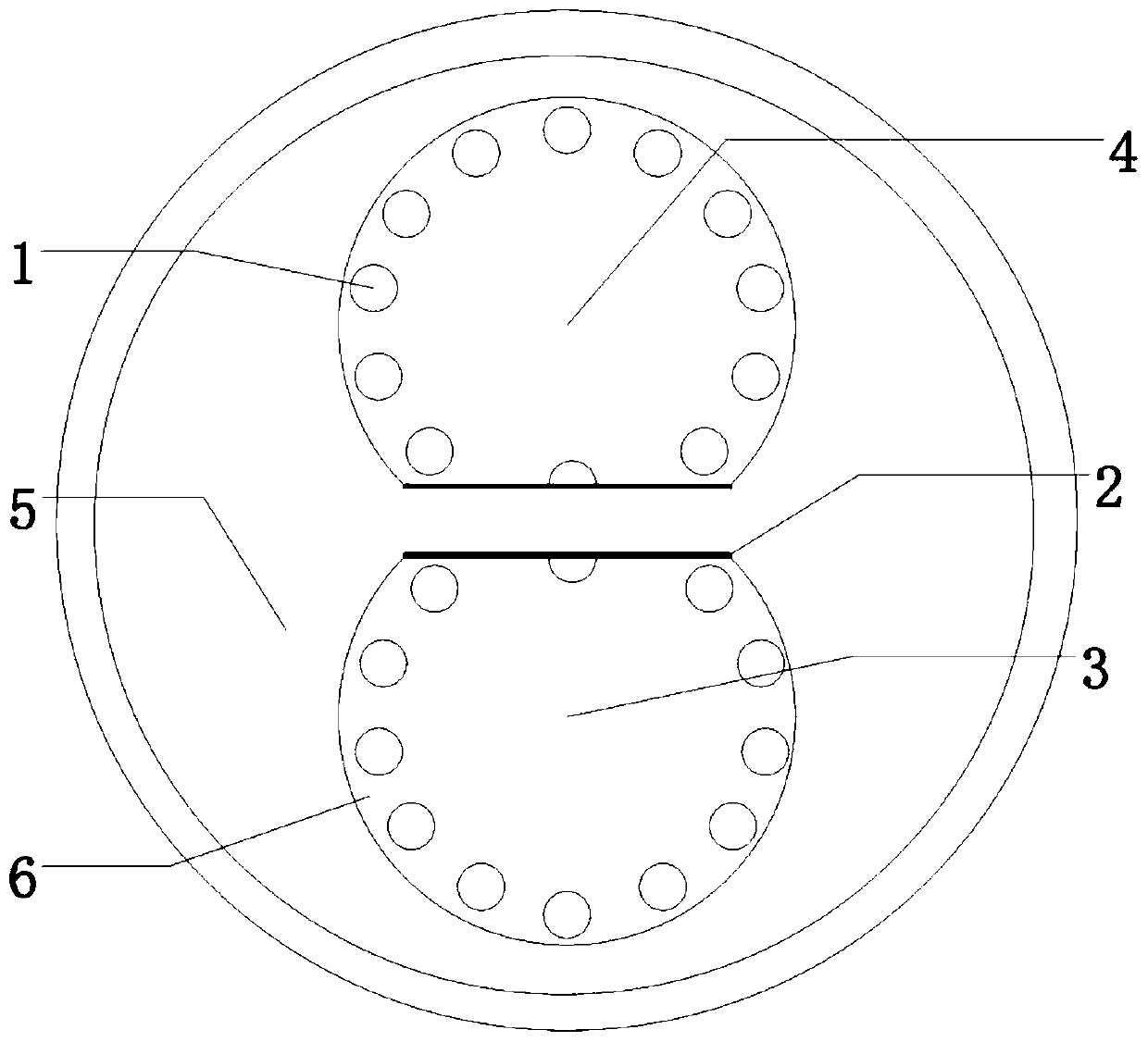

InactiveCN103454720AHas double rotational symmetryHigh birefringenceOptical light guidesPolarization-maintaining optical fiberBirefraction

A photonic crystal fiber with the high birefringence characteristic comprises a fiber core and a piece of cladding, wherein the fiber core is placed in the center of the photonic crystal fiber and is not provided with air vent holes. The cladding is composed of an inner cladding body and an outer cladding body. The inner cladding body which wraps the fiber core is provided with eight circular large air vent holes and four circular small air vent holes, wherein the eight circular large air vent holes are symmetrically distributed, and the four circular small air vent holes are arrayed in a rectangular mode and symmetrically distributed. The outer cladding body which wraps the inner cladding body comprises circular air vent holes, wherein the circular air vent holes of the outer cladding body are distributed according to grid nodes, namely, every three adjacent circular air vent holes are arrayed on the cross section of the photonic crystal fiber to form a regular triangle structure. The photonic crystal fiber has the advantages that the photonic crystal fiber is novel in structure, the photonic crystal fiber has double-rotation symmetry due to the fact that the structural arrangement of the photonic crystal fiber is changed, the photonic crystal fiber is very high in birefringence and high in nonlinear coefficient, the photonic crystal fiber can be used for manufacturing a polarization maintaining optical fiber which is nonlinear or has the polarization characteristic and for manufacturing other related optical fiber devices, due to the fact that the birefringence of the photonic crystal fiber is achieved when the physical dimension of the air vent holes is changed, the photonic crystal fiber is hardly influenced by the temperature and the pressure, and the photonic crystal fiber is good in stability and more suitable for application.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Photonic crystal fiber polarizer

InactiveCN104536084AAdjust polarization characteristicsPerformance online adjustable functionOptical fibre with polarisationOptical waveguide light guidePhotonic crystalMiniaturization

The invention discloses a photonic crystal fiber polarizer. The photonic crystal fiber polarizer is a section of photonic crystal fiber comprising a fiber core and cladding. A medium of the cladding is provided with a plurality of first air holes and two second air holes. The hole depth direction of the first air holes is the axial direction of the fiber, and the first air holes are distributed around the fiber core in a regular polygon mode; the two second air holes are located in the diameter part of circular fiber cross sections on the two sides of the fiber core, and there is no first air hole existing between the two second air holes for interference and obstruction; the two second air holes are each internally plated with a metal thin film with the thickness ranging from 20 microns to 90 microns so that coupled metallic waveguide can be formed between the two second air holes. The polarizer breaks through the limitation that the coverage rate of a second communication waveband of an existing fiber polarizer is low, and meanwhile a solution for achieving miniaturization and integration of a communication and sensing system is provided through the temperature adjusting polarization bandwidth character.

Owner:HUAZHONG UNIV OF SCI & TECH

Method and device for manufacturing light trap with hollow photonic crystal fiber

InactiveCN103575930AImprove energy utilizationImprove alignment accuracyAcceleration measurement using interia forcesTrappingOptoelectronics

The invention discloses a method and device for manufacturing a light trap with a hollow photon crystal fiber. The two ends of the hollow photonic crystal fiber are connected with the emission ends of two single mode fibers in a butt fusion mode. Afterwards, fundamental mode gauss beams emitted from the two single mode fibers are used for binding globular particles in a hollow fiber core in the hollow photonic crystal fiber, and therefore the globular particles are stressed and balanced in the light trap. The gauss beams are transmitted towards each other. The light power of the different single mode fibers is changed and the light trapping force exerted on the globular particles is changed. The acceleration and the motion displacement of the globular particles are controlled. The device comprises a substrate of a fiber light trap system, the two single mode fibers, the hollow photonic crystal fiber, a coupler, a light intensity modulator, a laser device, a photoelectricity image detector, a computer and like. According to the method and device for manufacturing the light trap with the hollow photonic crystal fiber, the energy utilization rate of the laser beams and the registration precision of the laser beams are improved and the influences on the motion state of the globular particles by Brownian movement in liquid are avoided.

Owner:ZHEJIANG UNIV

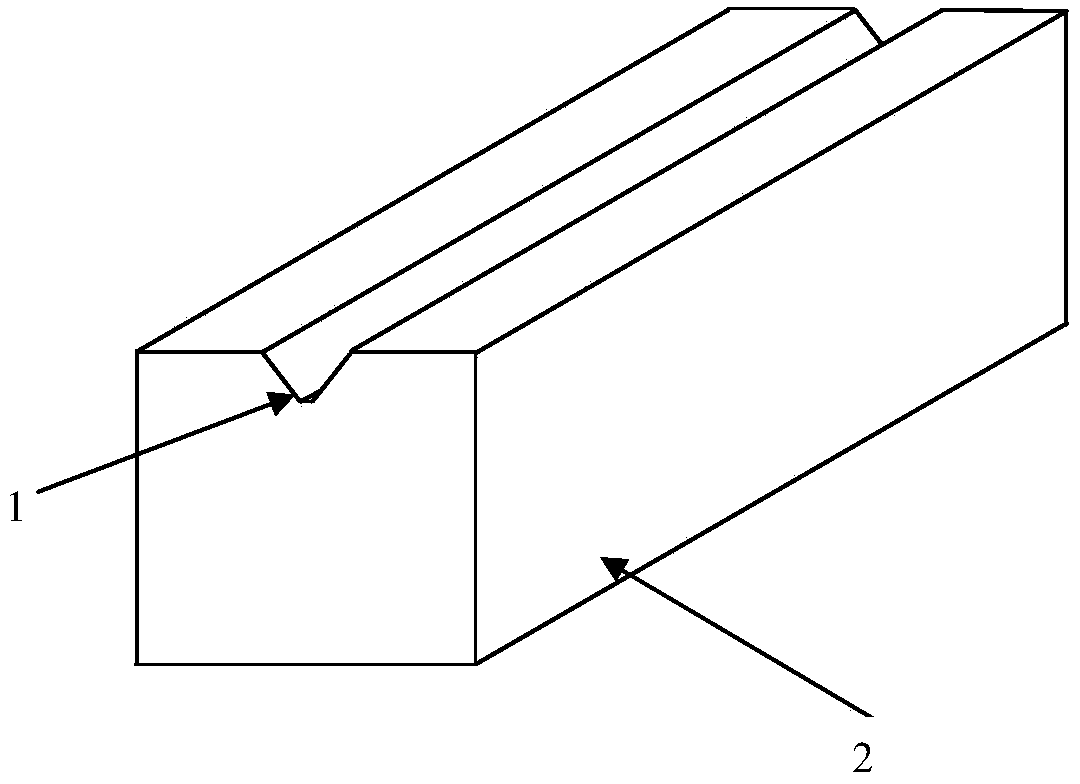

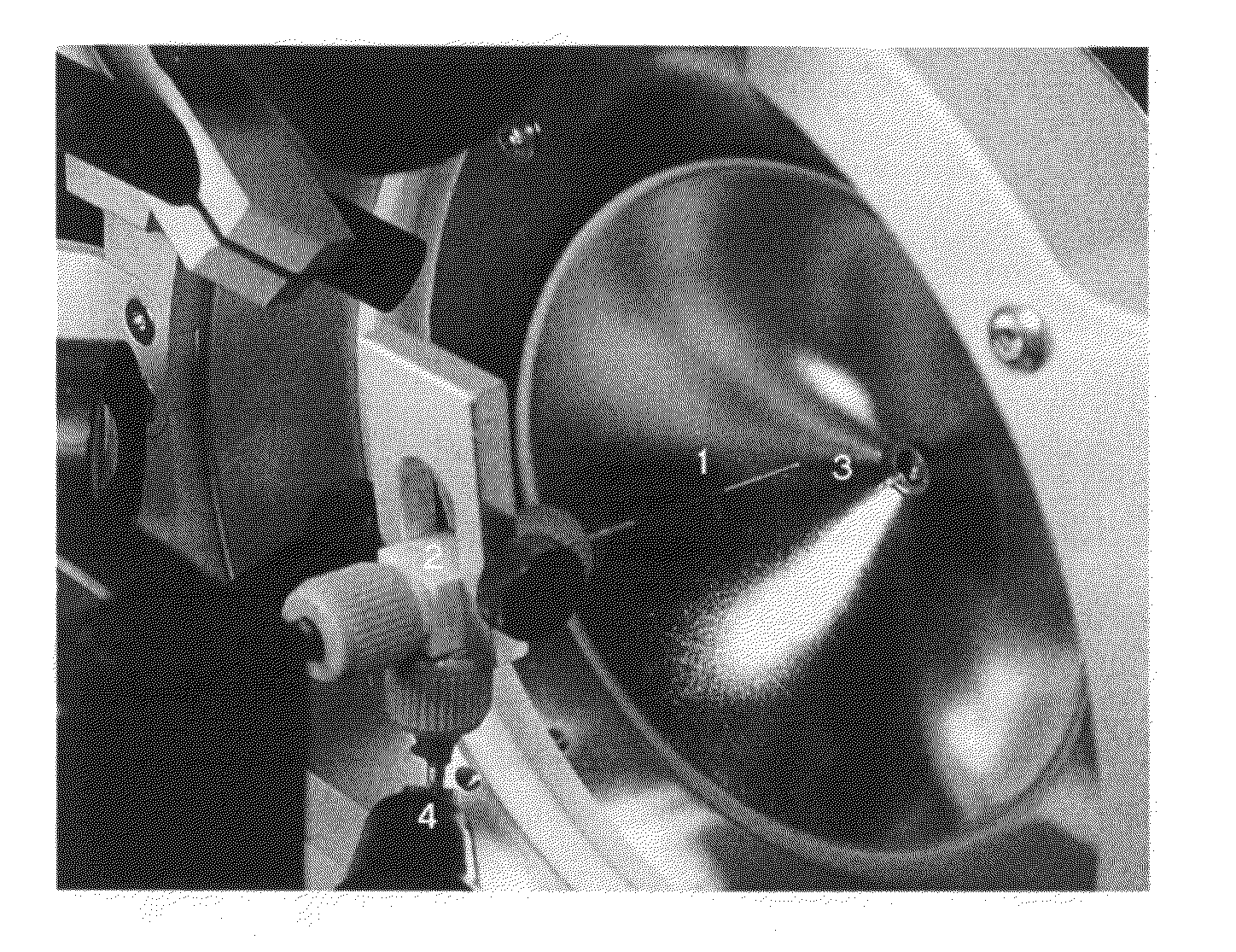

Photon crystal optical fiber fusion splicing three-dimensional alignment apparatus and method

InactiveCN101251624AStrong anti-vibration interference abilitySimple structureCoupling light guidesProgramme control in sequence/logic controllersMicro imagingEngineering

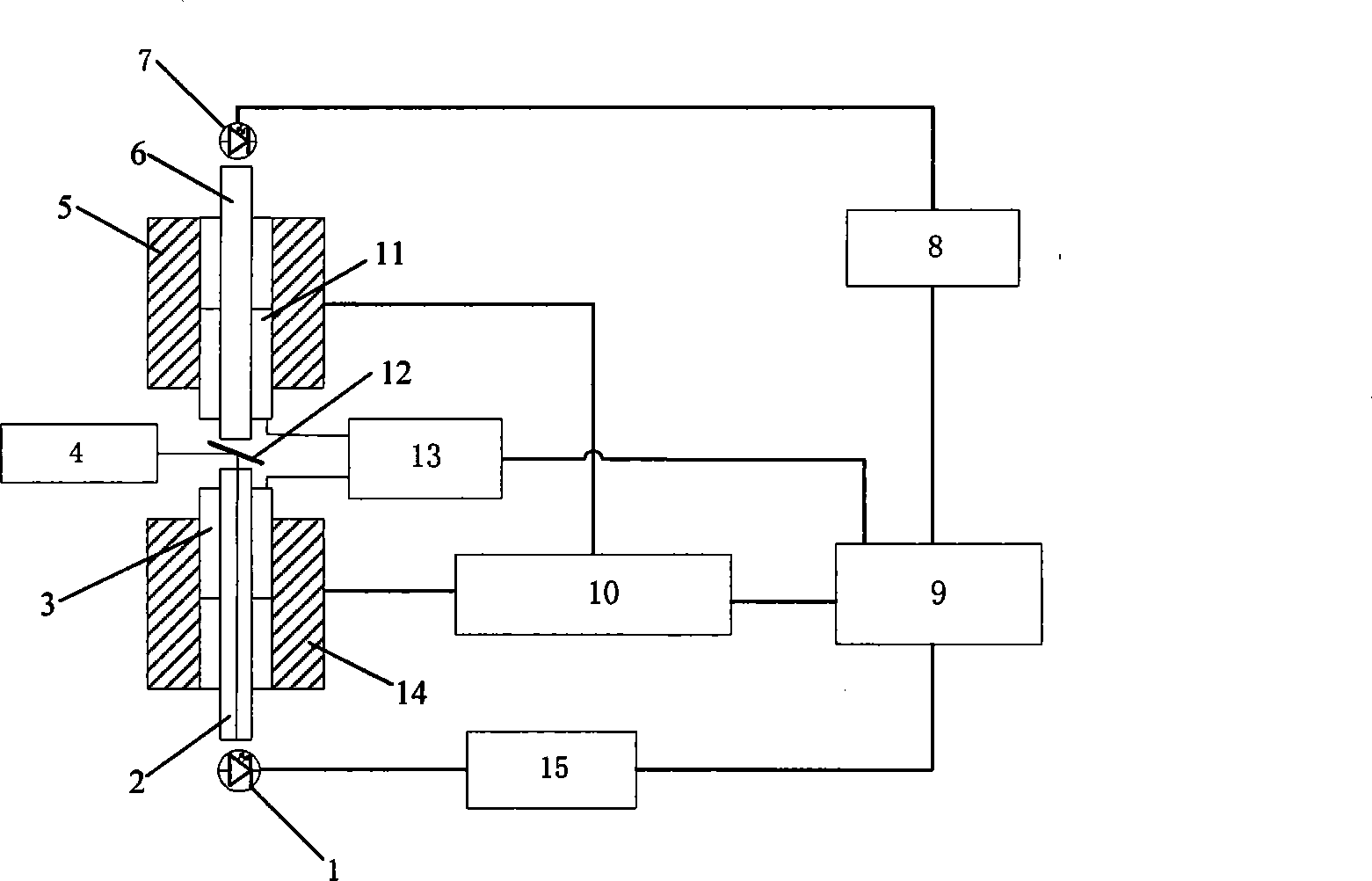

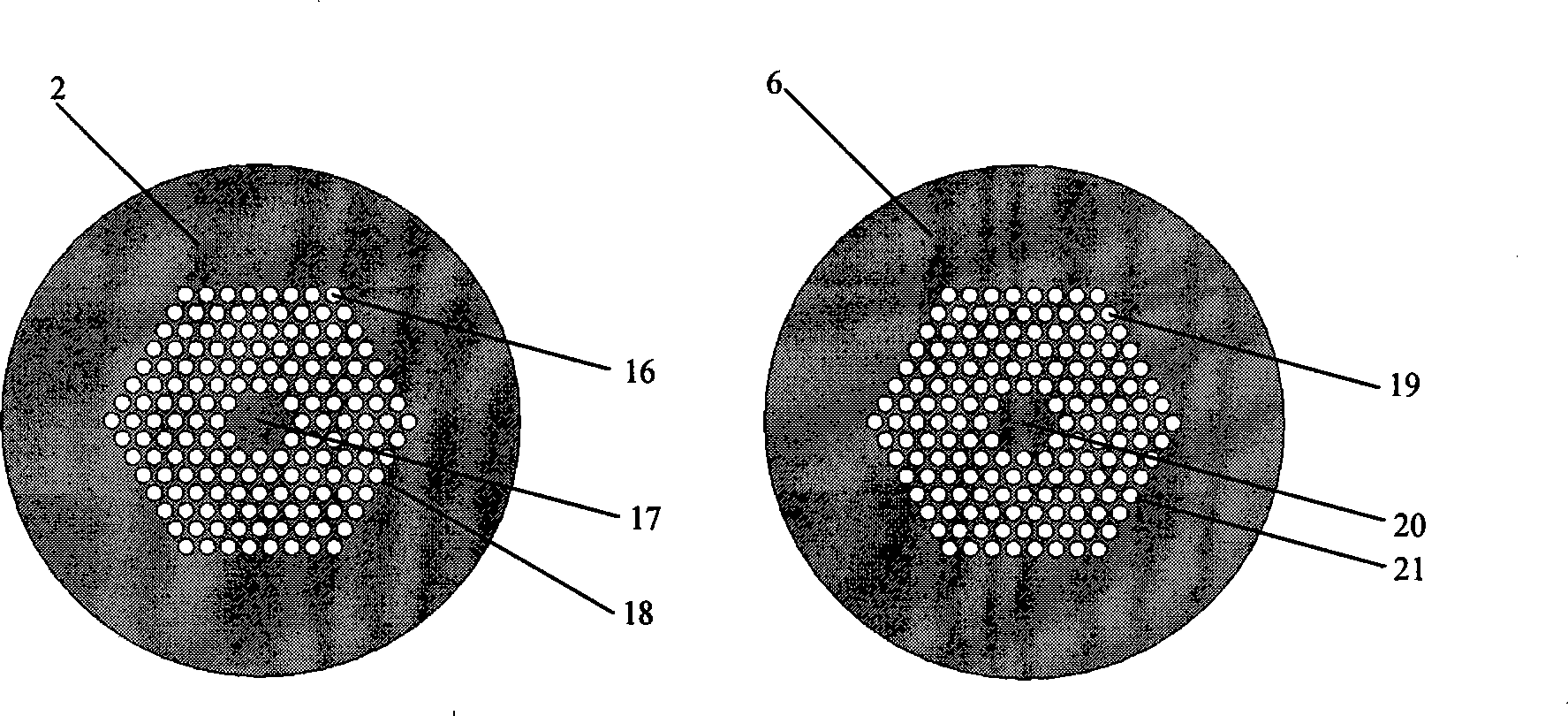

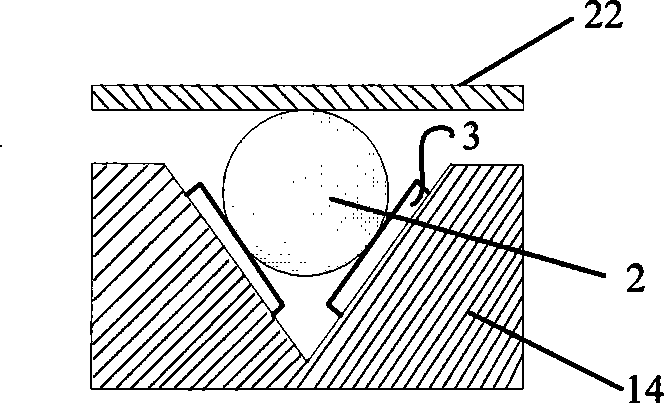

The invention discloses a three-dimensional alignment device for welding a photonic crystal fiber and a method thereof, wherein, mechanical transmission mechanisms of an upper three-dimensional motion V-shaped groove device (5) and a lower three-dimensional motion V-shaped groove device (14) of the device are connected with an alignment controller of a three-dimensional alignment controller and a clamp control unit (10), and a lower stress sensor (3) and an upper stress sensor (11) are connected with a stress sensor modulating unit (13); a double-sided holophote (12) of a micro-imaging unit (4) images a head face of the photonic crystal fiber and captures a geometric structure of the photonic crystal fiber which is positioned and identified by using a Hough transformation; and light emission and light receiving are achieved by coupling type light intensity determination units (1, 7, 8 and 15). The method comprises the following steps that: 1) the micro-imaging unit (4) acquires information of structure, and performs an identification and position for the geometric structure of the photonic crystal fiber by using the Hough transformation; 2) a clamping force is automatically adjusted by the upper three-dimensional motion V-shaped groove device (5) and the lower three-dimensional motion V-shaped groove device (14); 3) an initial alignment is performed for the photonic crystal fiber; and then a fine alignment is performed for the photonic crystal fiber. The three-dimensional alignment device for welding a photonic crystal fiber has the advantages of simple structure, strong capability of anti-interference of vibration and high sensitivity, and is suitable for the three-dimensional alignment between the photonic crystal fibers with different specifications and between the photonic crystal fiber and a conventional optical fiber.

Owner:YANSHAN UNIV

Novel pohotonic crystal fiber

InactiveCN103913801AHigh nonlinear coefficientSolve the real problemCladded optical fibreOptical waveguide light guideFiberRefractive index

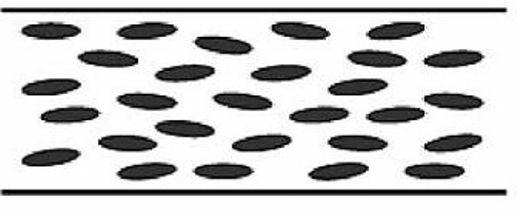

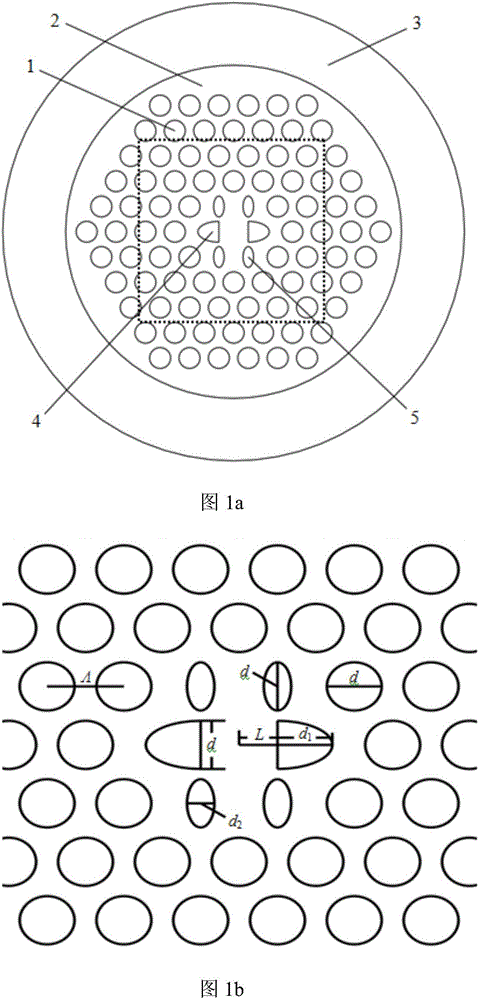

The invention discloses a novel pohotonic crystal fiber. Air holes arranged in the shape of a regular triangle are formed in a body of the novel pohotonic crystal fiber, pure quartz glass serves as a background material, and the novel pohotonic crystal fiber is wrapped with a perfect matching layer the same as the background material in refractive index. The novel pohotonic crystal fiber is characterized in that the air holes in the innermost ring are replaced by oval and semioval air holes, two air holes in bilateral symmetry are replaced by the semioval air holes separated by a short axis, the other four air holes are replaced by the oval air holes, the geometric center of the oval air holes is the center of a circle of original air holes, and besides, a long axis of the oval air holes is perpendicular to a long axis of the semioval air holes. The novel pohotonic crystal fiber having high nonlinearity, high birefringence and zero dispersion will play an important role in the aspects of optical soliton communication, optical fiber devices, optical fiber sensing, high-speed optical networks, super-continuum spectrum transmission and the like.

Owner:HEFEI UNIV OF TECH

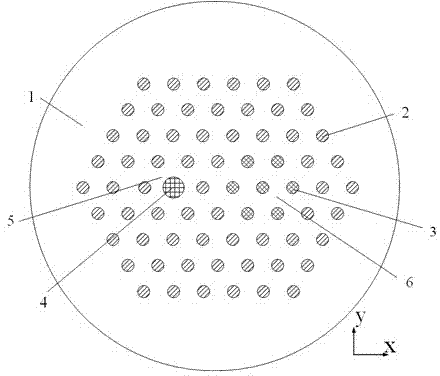

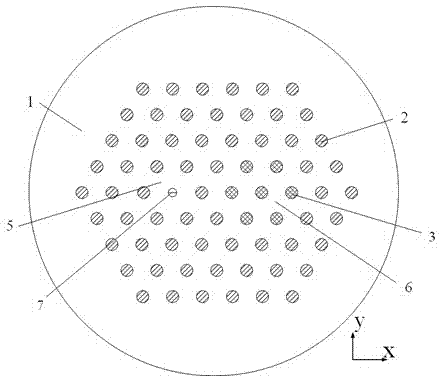

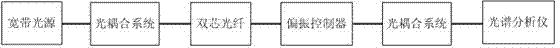

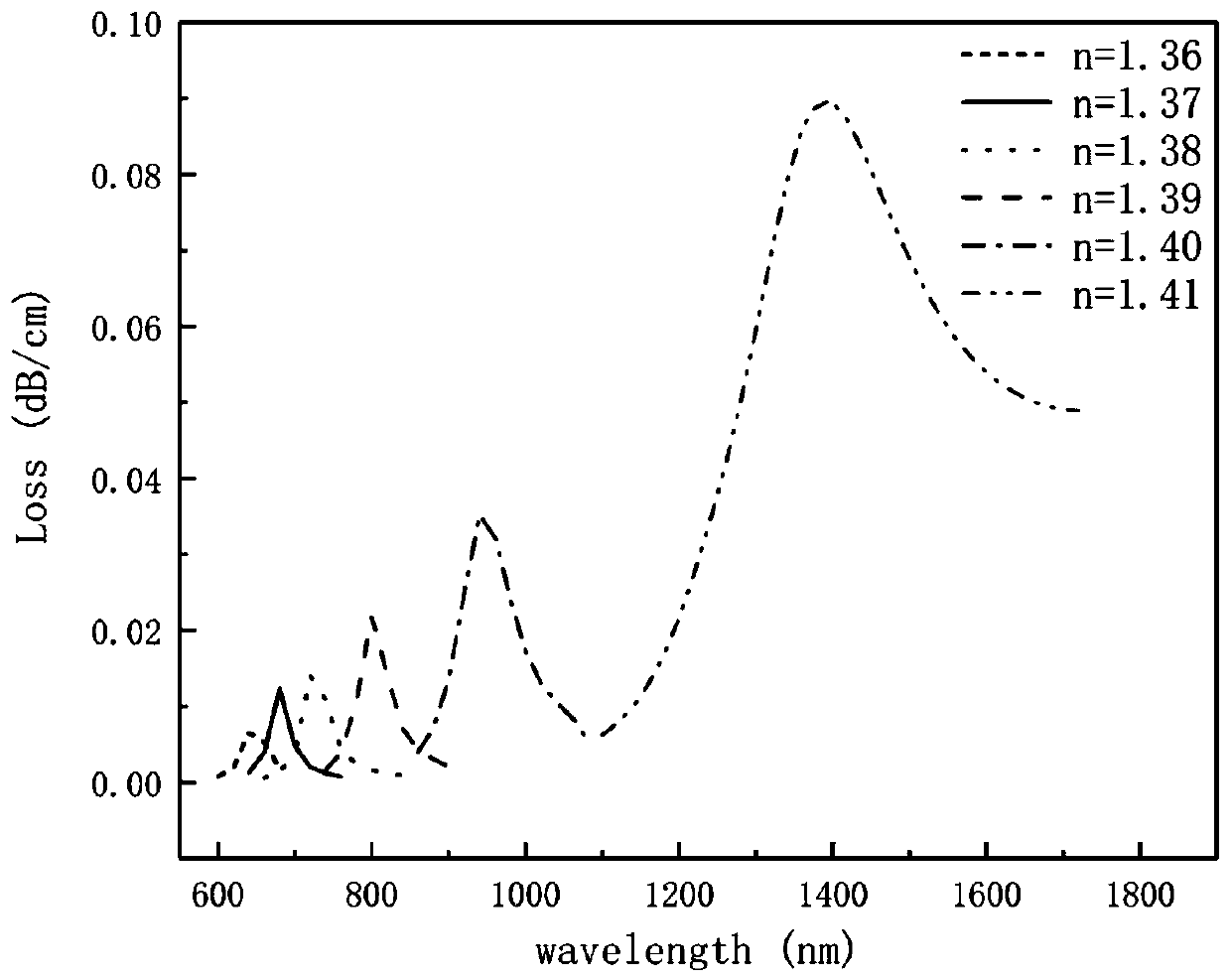

Two-core photonic crystal optical fibre refractive index sensor and sensing system

InactiveCN102495022AHigh sensitivityLow detection limitCladded optical fibrePhase-affecting property measurementsRefractive indexOptical polarization

The invention discloses a two-core photonic crystal optical fibre refractive index sensor and a sensing system; the sensor comprises a cladding, a fibre core (5) and a micro-structural fibre core (6); a small air hole (7), the diameter of which is less than that of an air hole (2), or a medium rod (4), the refractive index of which is lower than that of a substrate material (1), is arranged in the fibre core (5); the micro-structural fibre core (6) is an area formed from seven filling holes (3) in an encircling manner; and the sensing system is composed of a board band light source, an optically coupled system, a photonic crystal optical fibre, a polarization controller and a spectrum detection system. The sensor and the sensing system are easy to inject a sample to be detected, so that the high-sensitivity refractive index detection is realized.

Owner:JIANGSU UNIV

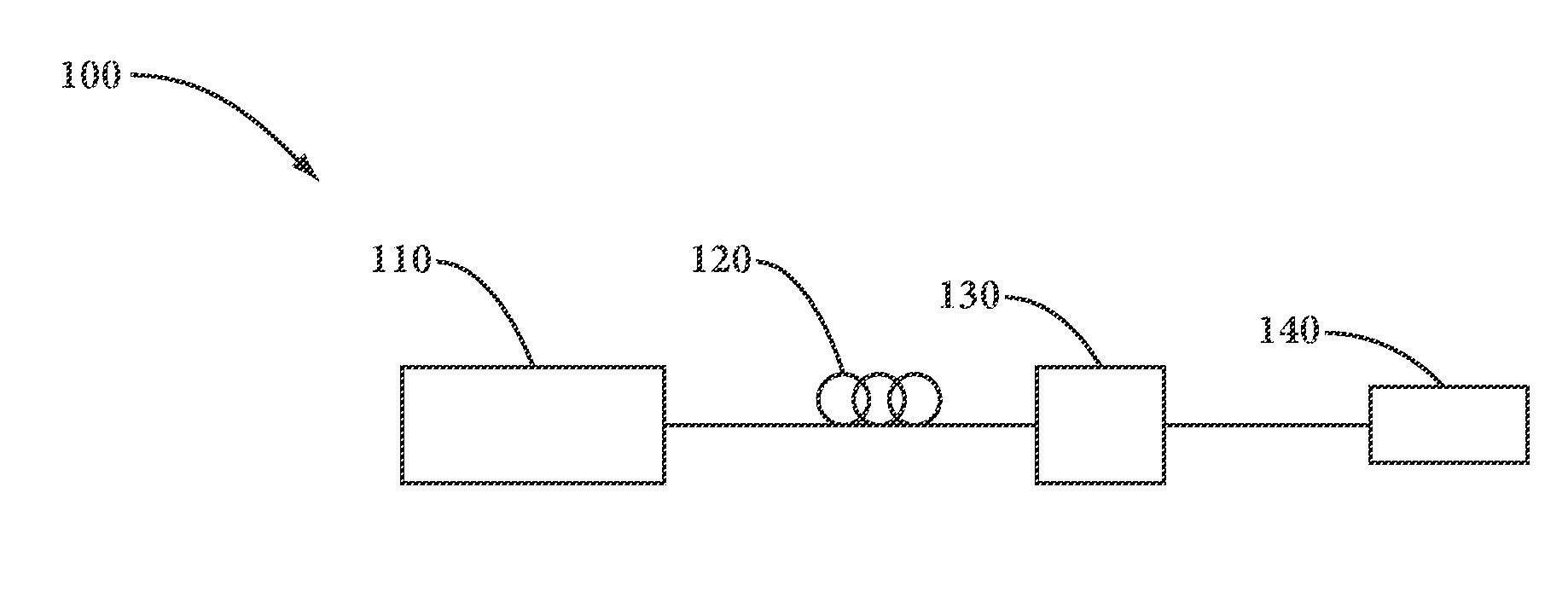

Spectral Broadening for DTS Application

InactiveUS20130209029A1Reduce the impactGood effectThermometers using physical/chemical changesCoupling light guidesRayleigh scatteringPhotonic crystal

An apparatus and method for use in distributed temperature sensing (DTS) systems to reduce coherent Rayleigh scattering in fiber optic cables by using photonic crystal fibers.

Owner:HALLIBURTON ENERGY SERVICES INC

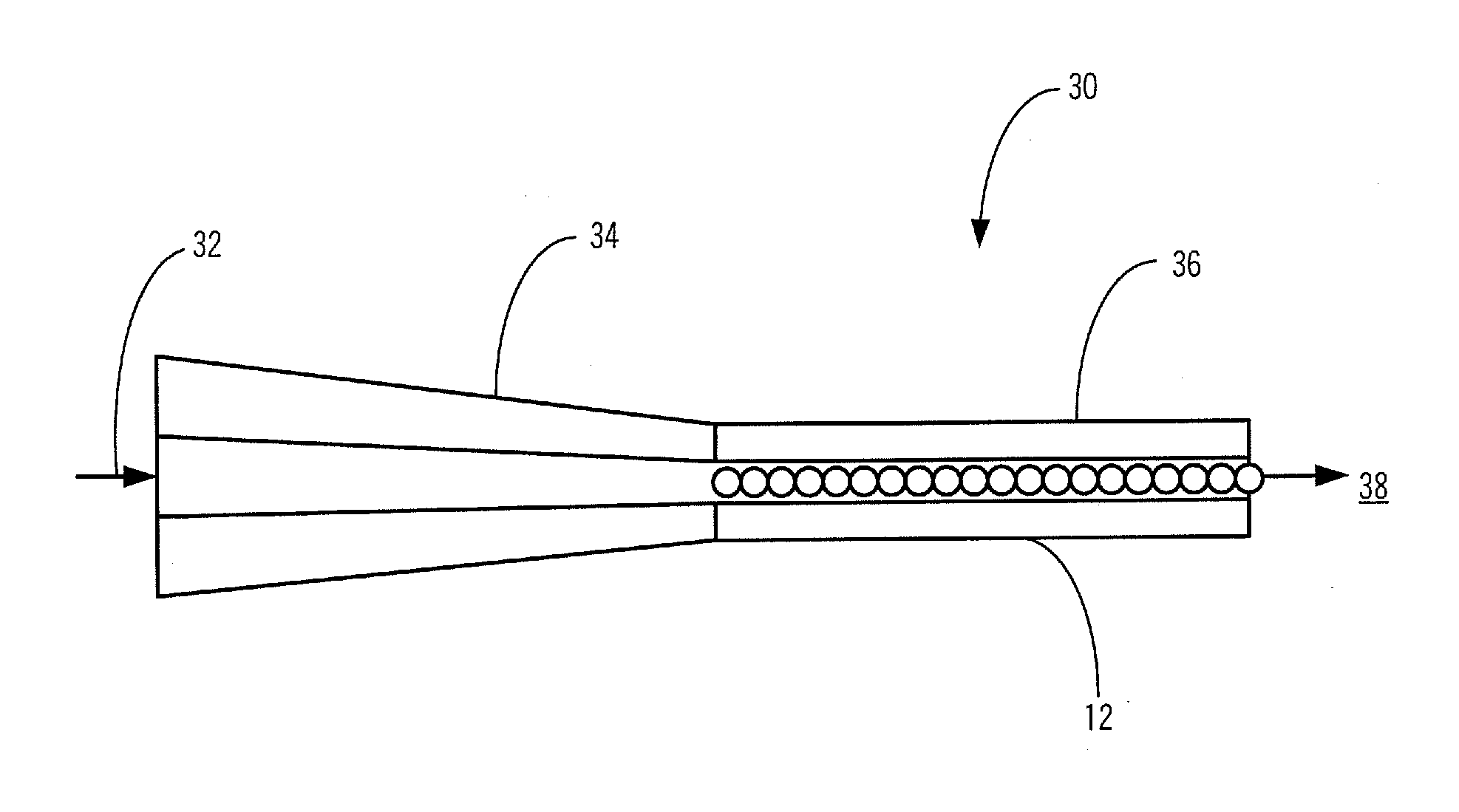

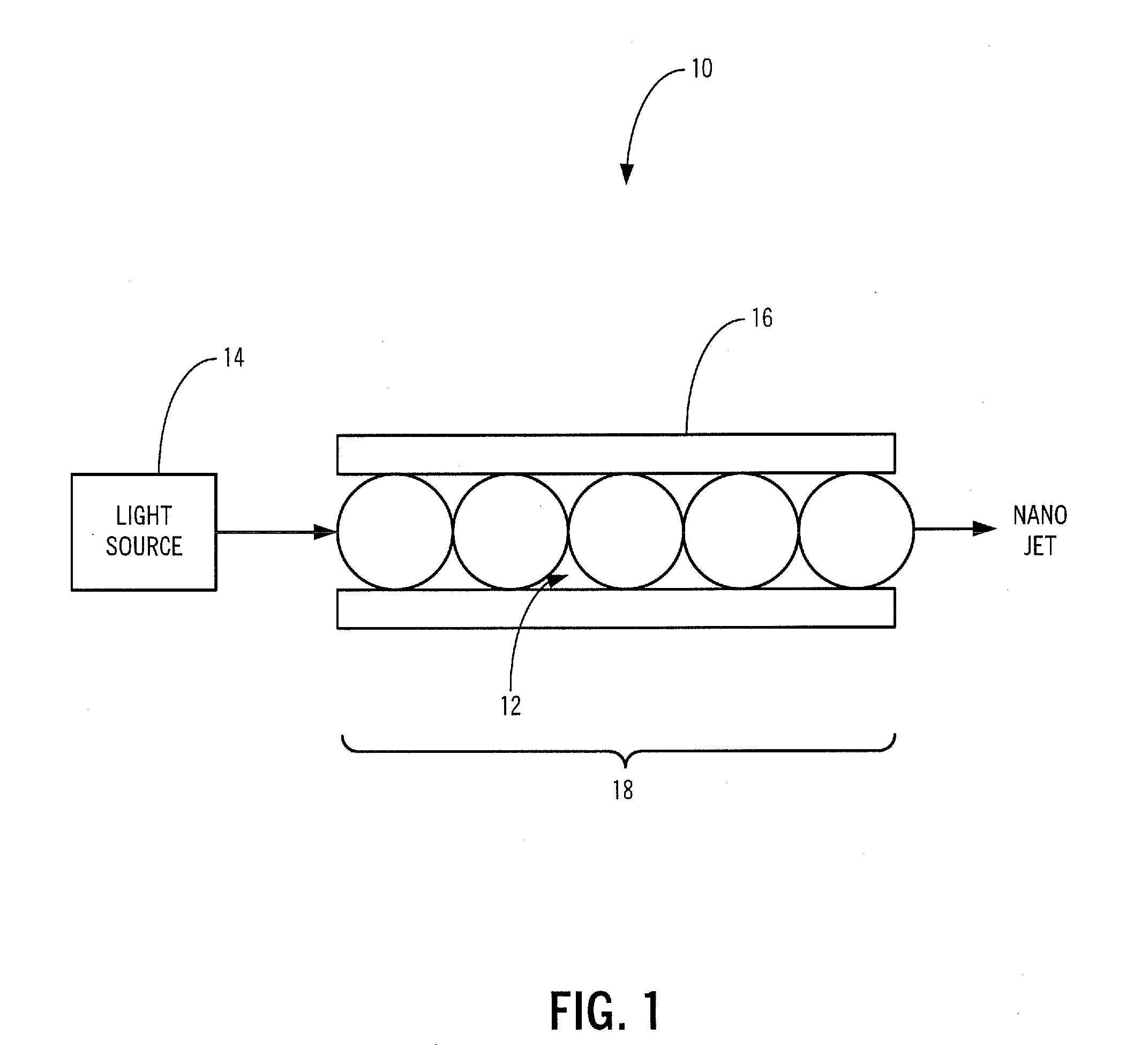

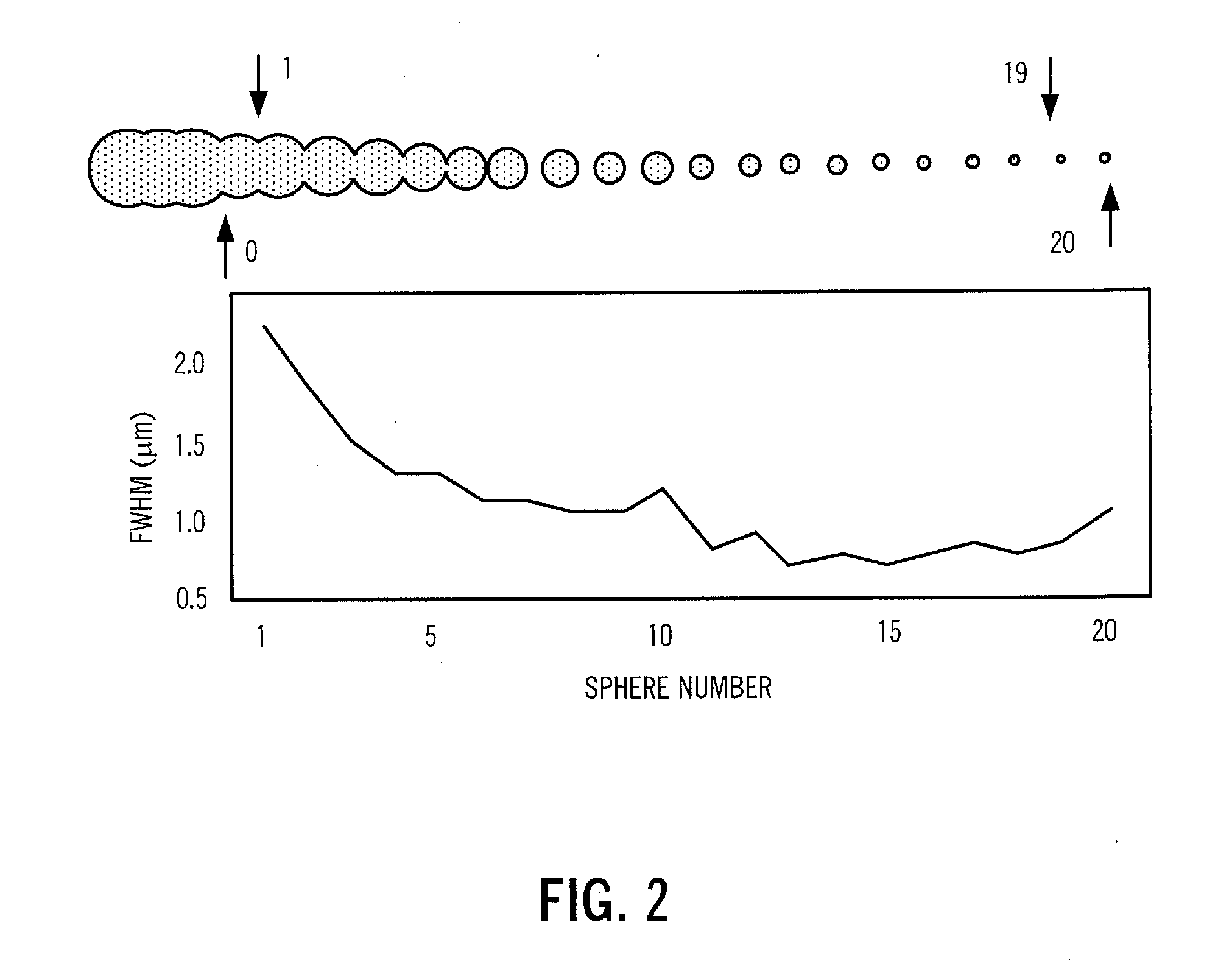

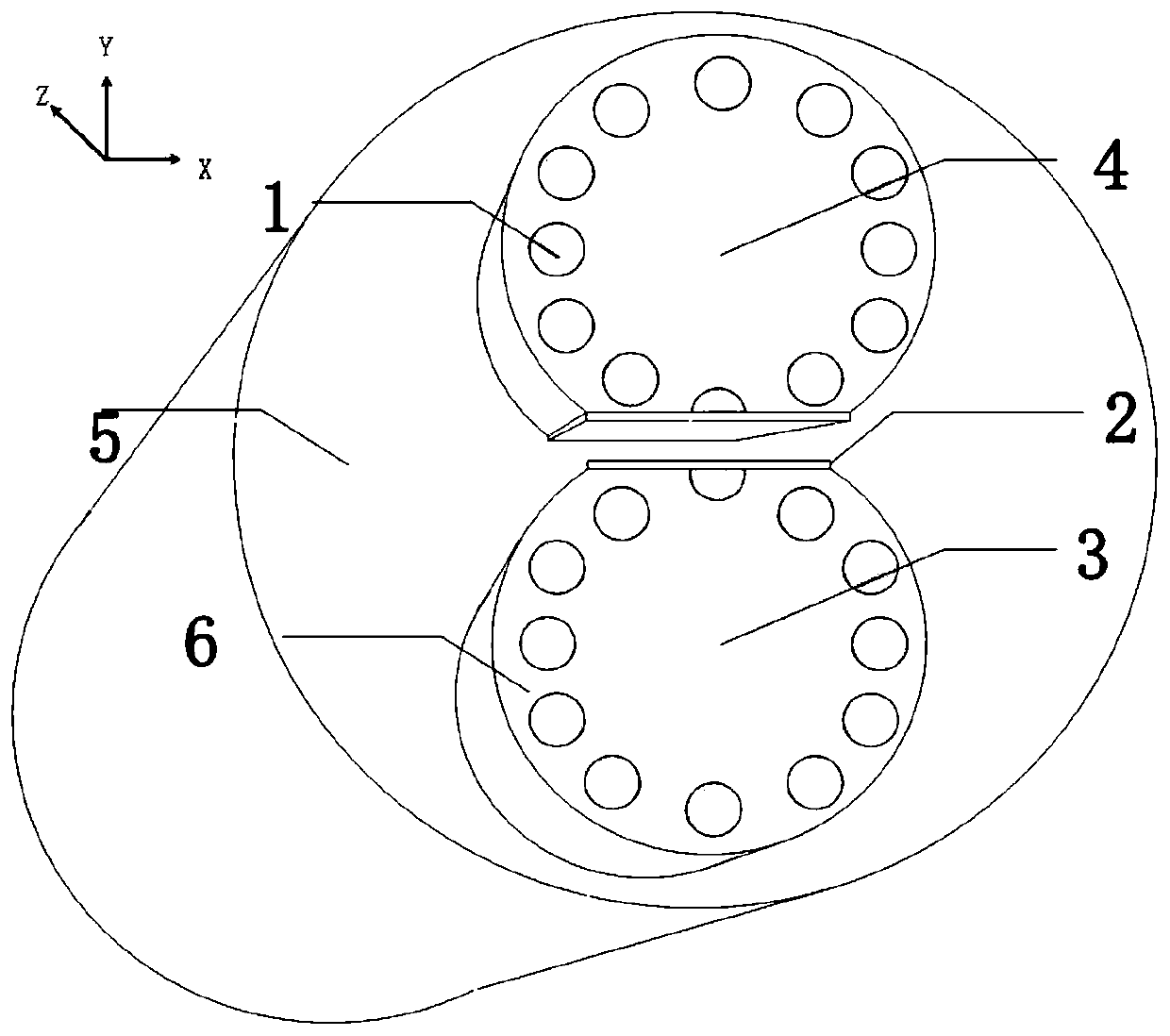

Focusing multimodal optical microprobe devices

ActiveUS20120091369A1Improve spatial resolutionEfficient couplingNanoopticsSurgical instrument detailsHollow coreWavelength scale

The present invention provides an optical microprobe device and method for focusing multimodal radiation with wavelength-scale spatial resolution and delivering the focused radiation to a specimen, including: a radiation source; and one or more of a plurality of optically transparent or semitransparent spheres and a plurality of optically transparent or semitransparent cylinders optically coupled to the radiation source; wherein the one or more of the plurality of optically transparent or semitransparent spheres and the plurality of optically transparent or semitransparent cylinders periodically focus radiation optically transmitted from the radiation source such that radiation ultimately transmitted to the specimen has predetermined characteristics. Preferably, the spheres or cylinders are assembled inside one of a hollow waveguide, a hollow-core photonic crystal fiber, a capillary tube, and integrated in a multimode fiber. Alternatively, the spheres or cylinders are assembled on a substrate. Optionally, the optical microprobe device also includes one or more of a waveguide, an optical fiber, a lens, and an optical structure disposed between the radiation source and the spheres or cylinders. Optionally, the spheres or cylinders are made from optically nonlinear or active materials that permit efficient nonlinear frequency generation and low-threshold lasing using the optical microprobe device.

Owner:JUNIVERSITI OF NORT KAROLINA EHT SHARLOTT

Near-infrared band double-D type photonic crystal fiber SPR sensor

InactiveCN111521582ASmall sizeReduce transmission lossPhase-affecting property measurementsRefractive indexSurface plasmonic resonance

The invention discloses a double-D type structure photonic crystal fiber sensor based on surface plasma resonance. The photonic crystal fiber comprises a photonic crystal fiber, air holes and a nanogold film. Air holes are formed in the inner edge of the silicon dioxide. The two photonic crystal fibers are symmetrically distributed in parallel, the photonic crystal fibers are both side-thrown intoa D shape, the side-thrown surface is coated with a nanogold film, an air hole in the middle of the side-thrown surface is semicircular, and the air hole and the neighborhood of the air hole form a photonic crystal fiber core, namely, an area defined by the air hole forms the photonic crystal fiber core. According to the sensor, the two parallel D-type optical fibers are used for achieving coupling, the sensitivity of the sensor can be effectively improved, and the sensor is a practical refractive index sensor.

Owner:GUILIN UNIV OF ELECTRONIC TECH

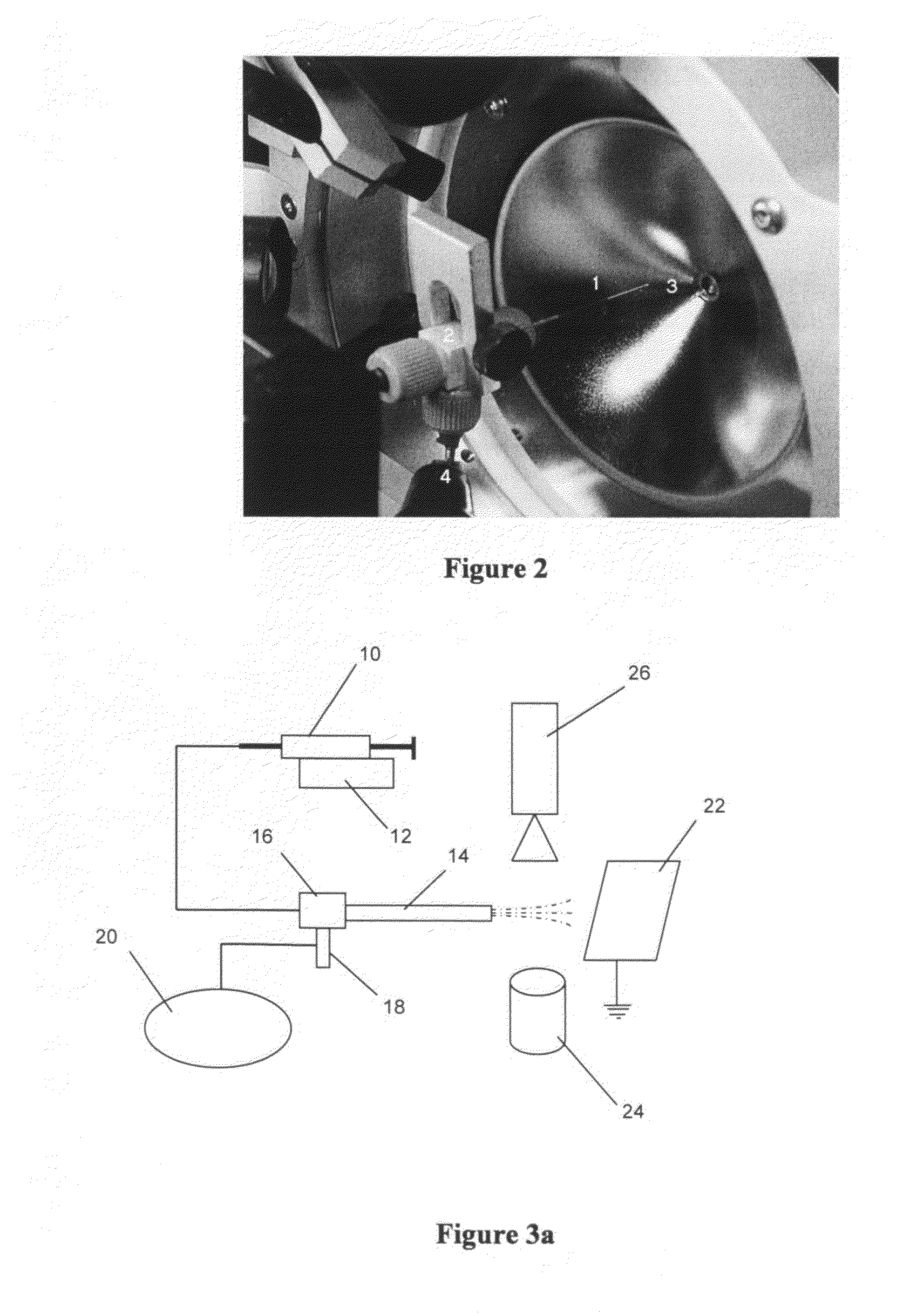

Multi-Channel Electrospray Emitter

Owner:QUEENS UNIV OF KINGSTON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com