Hollow photonic crystal optical fiber gas absorption cell device and manufacturing method thereof

A hollow photonic crystal and gas absorption cell technology, which is used in measurement devices, coupling of optical waveguides, and material analysis by optical means, can solve problems such as unchangeable air pressure or gas type, poor air tightness, etc., and achieve air tightness. And the effect of firm structure, good procedure, compact and compact structure, firm and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with examples and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

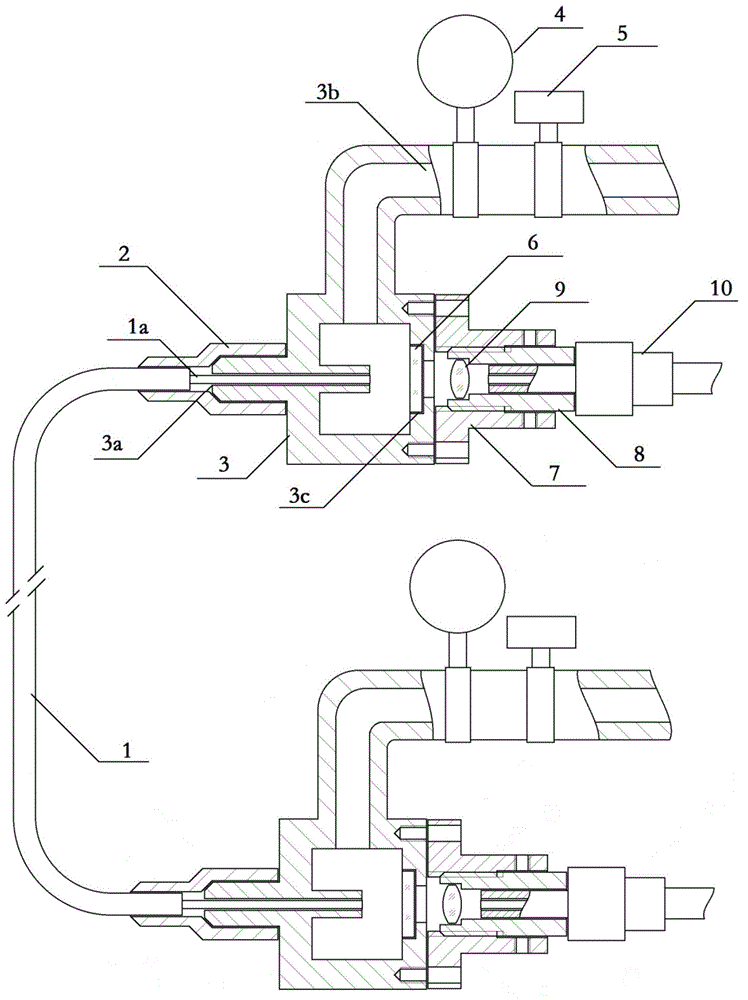

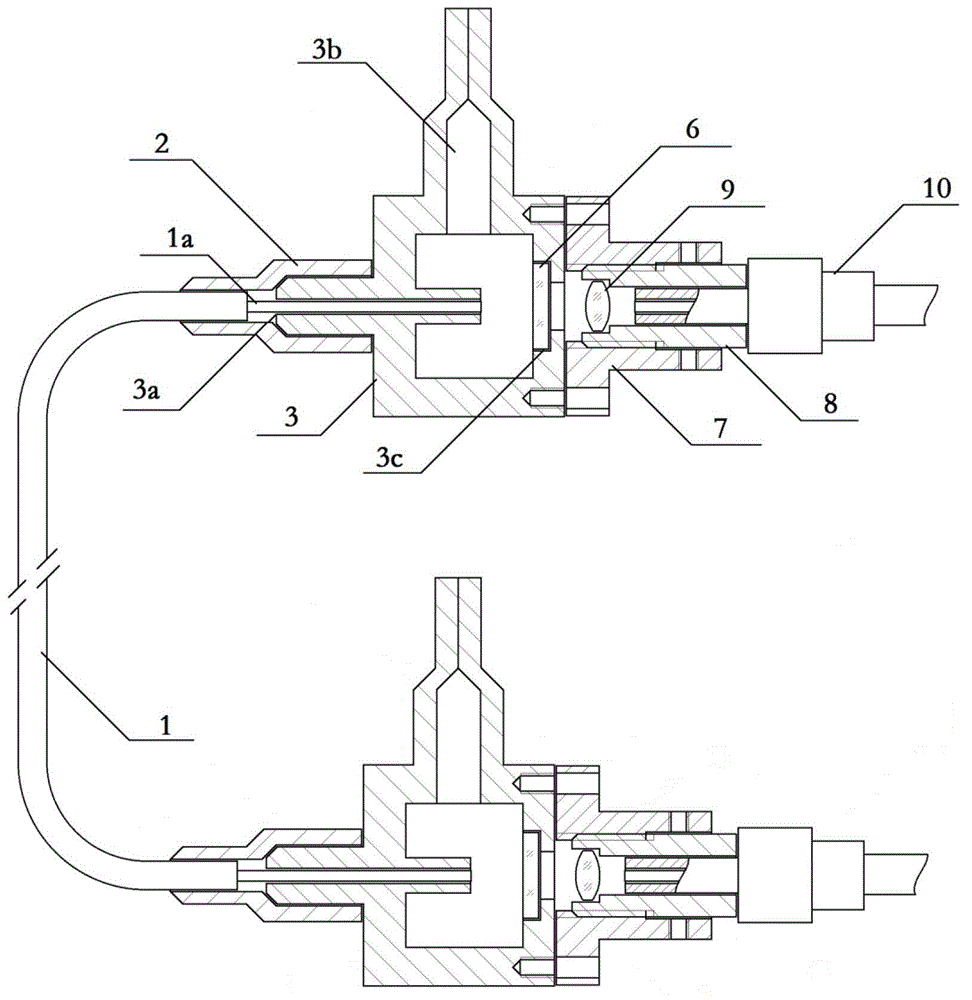

[0029] see first figure 1 , figure 1It is a schematic diagram of the structure of the hollow photonic crystal fiber gas absorption cell device of the present invention. It can be seen from the figure that the hollow photonic crystal fiber gas absorption cell device of the present invention is composed of a hollow photonic crystal fiber 1 and airtight joints at both ends thereof, and the airtight joints have the same structure:

[0030] The airtight joint includes a protective cover 2, an airtight chamber 3, a vacuum gauge 4, a vacuum valve 5, a window glass 6, an external adjustment assembly 7, an internal adjustment assembly 8, and a coupling mirror 9. The connection relationship of the above components is as follows: Described airtight chamber 3 has optical fiber interface 3a,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com