Photonic crystal fiber polarizer

A technology of photonic crystal fiber and polarizer, which is applied in polarized fiber, clad fiber, optical waveguide and light guide, etc. It can solve the problems of low communication band coverage and difficult performance adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

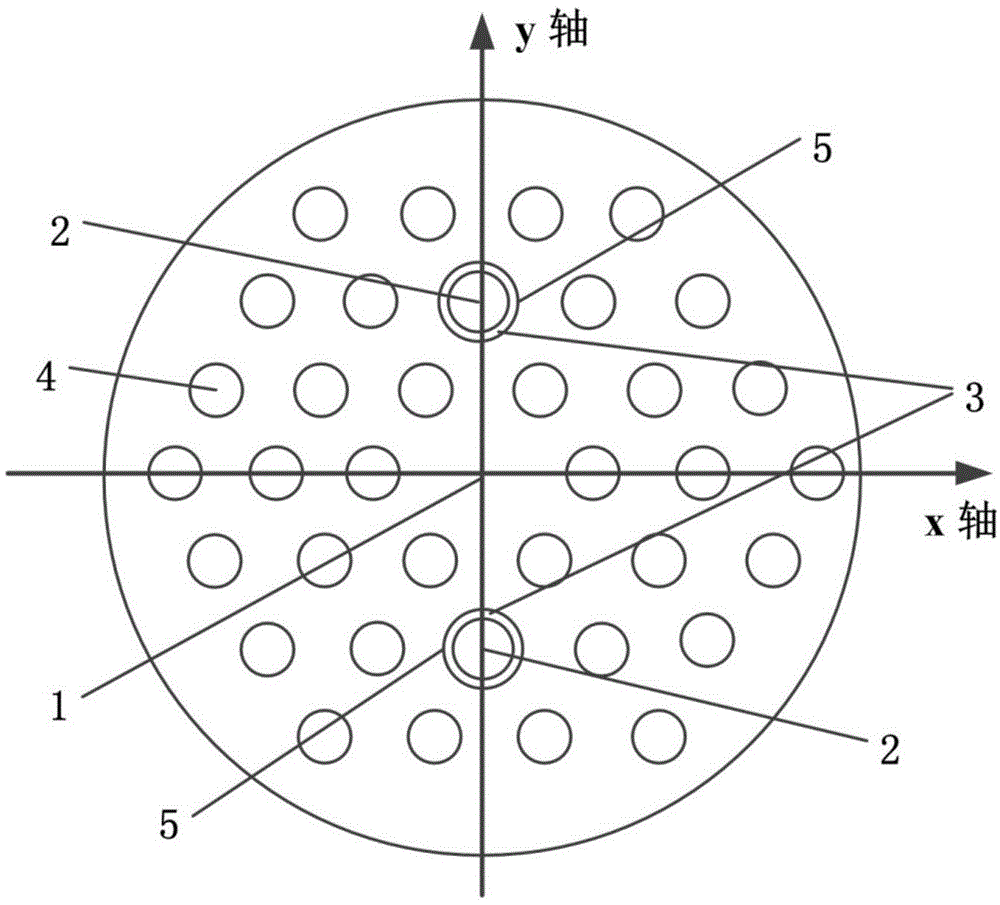

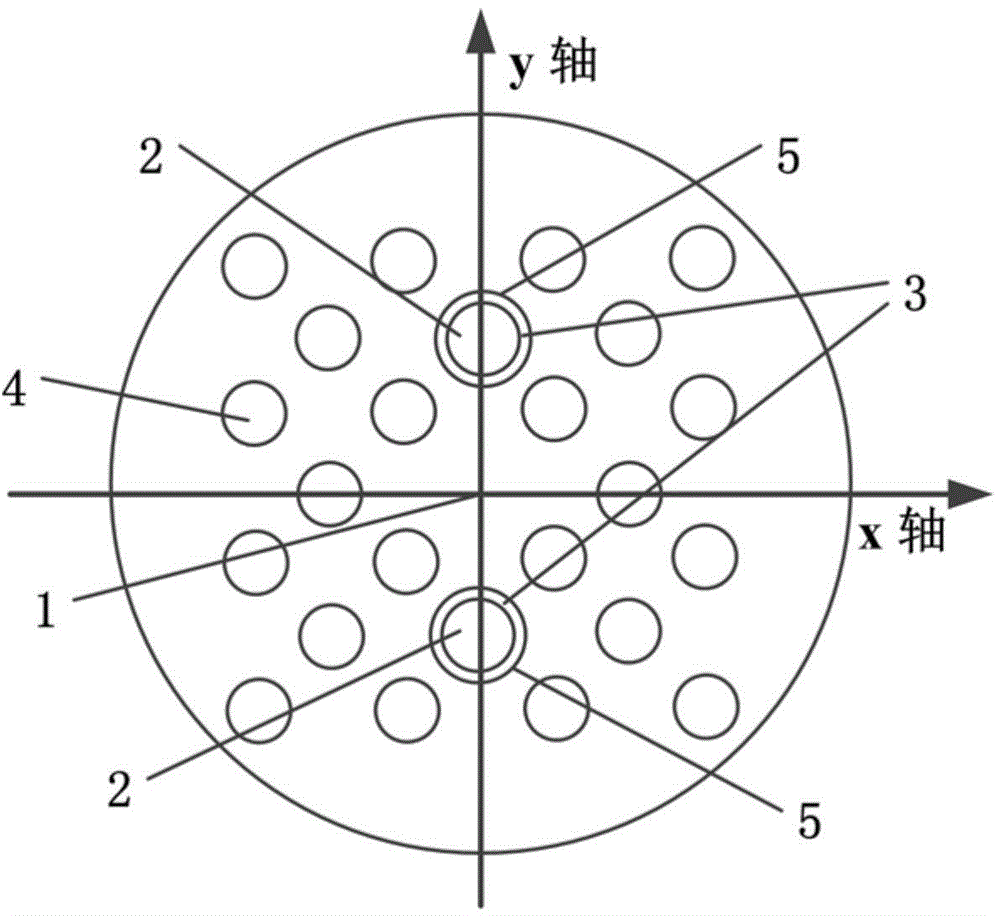

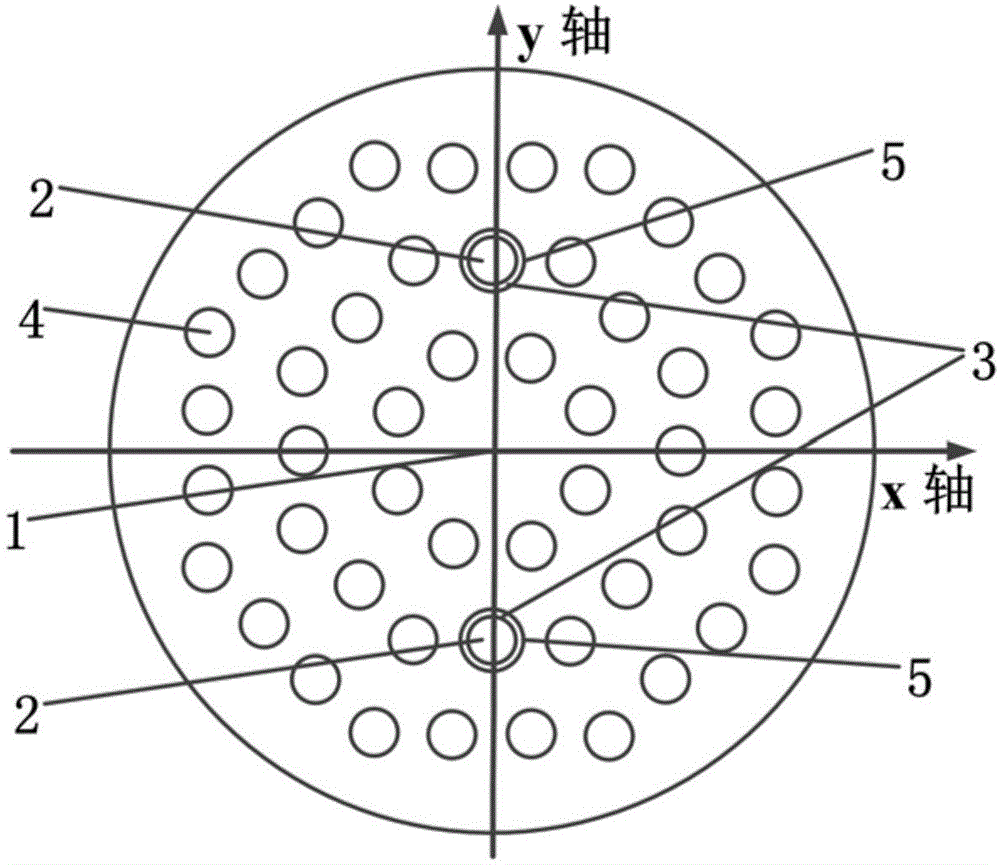

[0020] The photonic crystal fiber is made by the stacking method, the background material is quartz, and an air hole is missing in the center to form a core for conducting the fundamental mode. The hole depth direction of the first air hole is the axial direction of the optical fiber, and the first air hole is distributed in a regular polygon around the fiber core, such as figure 1 As shown, the core 1 of the photonic crystal fiber of the present invention is surrounded by three hexagonal first air holes. That is, the air holes in each circle are arranged in a hexagonal arrangement. Such as figure 2 As shown, the core 1 of the photonic crystal fiber of the present invention is surrounded by three circles of regular quadrilateral first air holes. That is, the air holes in each circle are arranged in four corners. Such as image 3 As shown, the core 1 of the photonic crystal fiber of the present invention is surrounded by three circles of regular octagonal first air holes. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com