Patents

Literature

79results about How to "Surface light" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

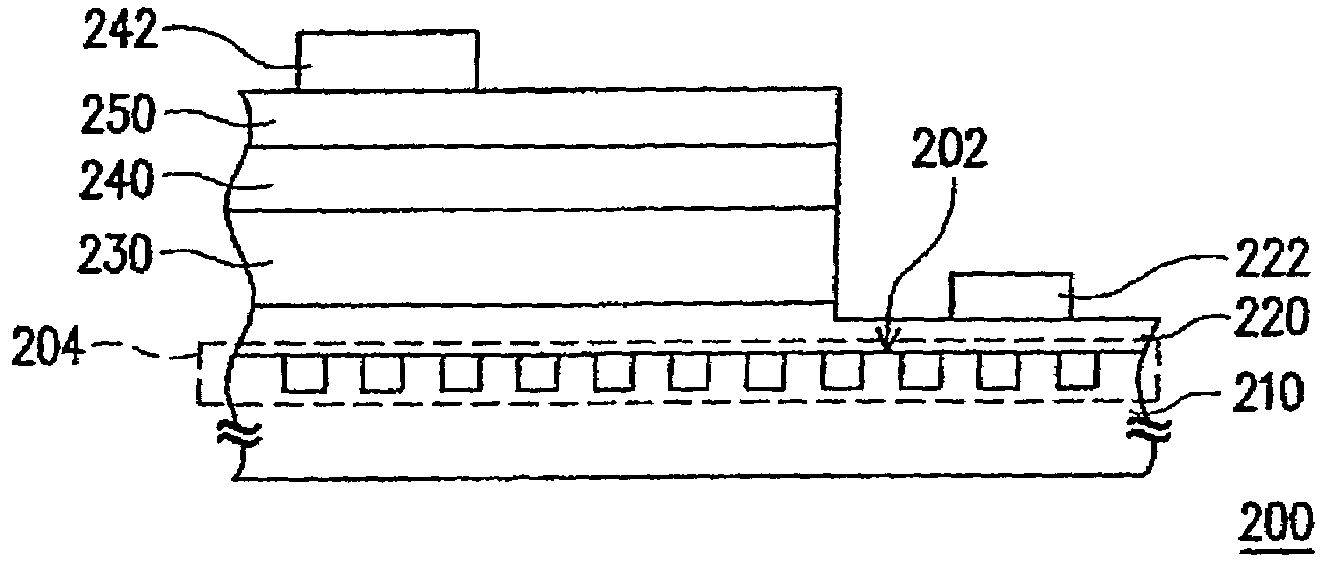

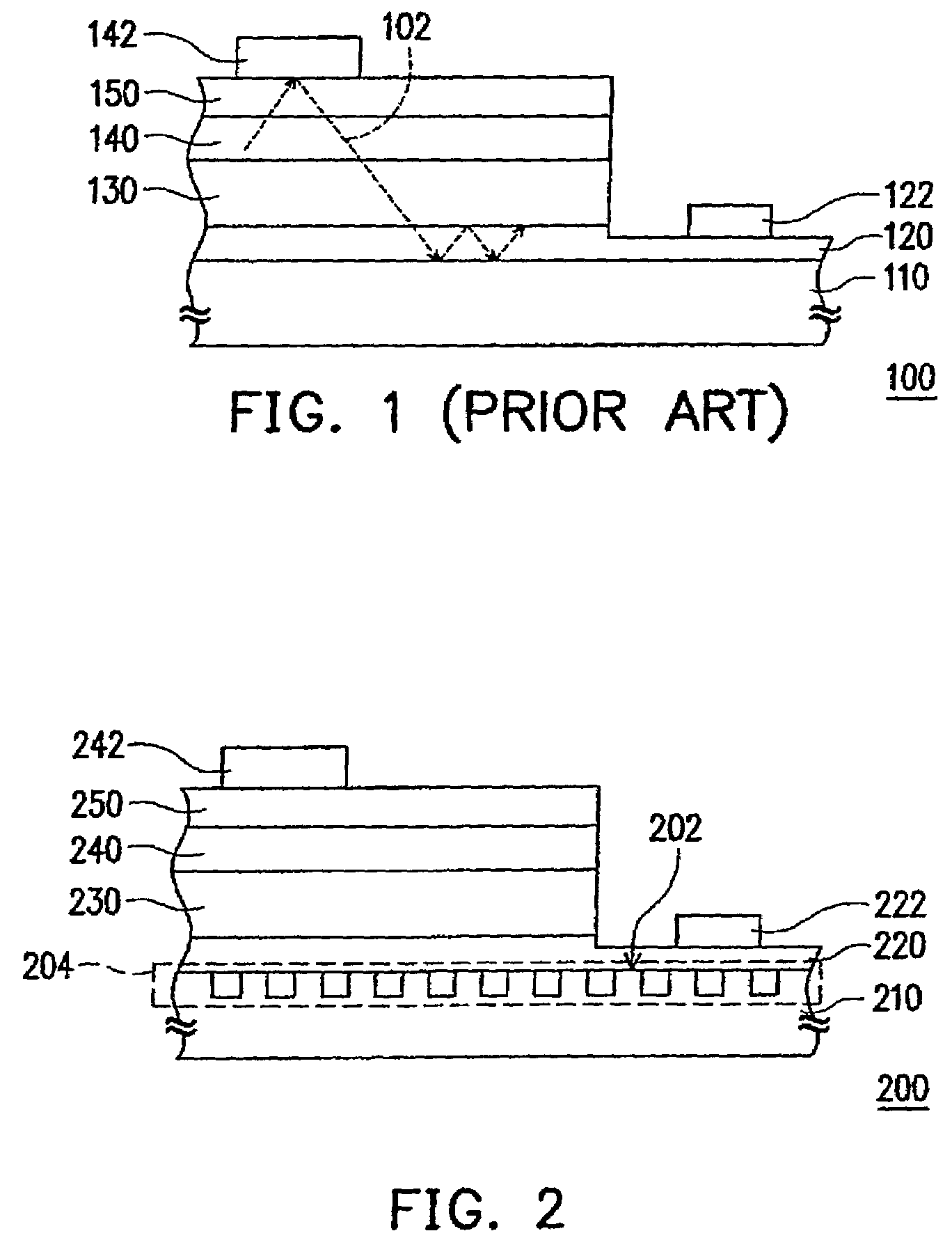

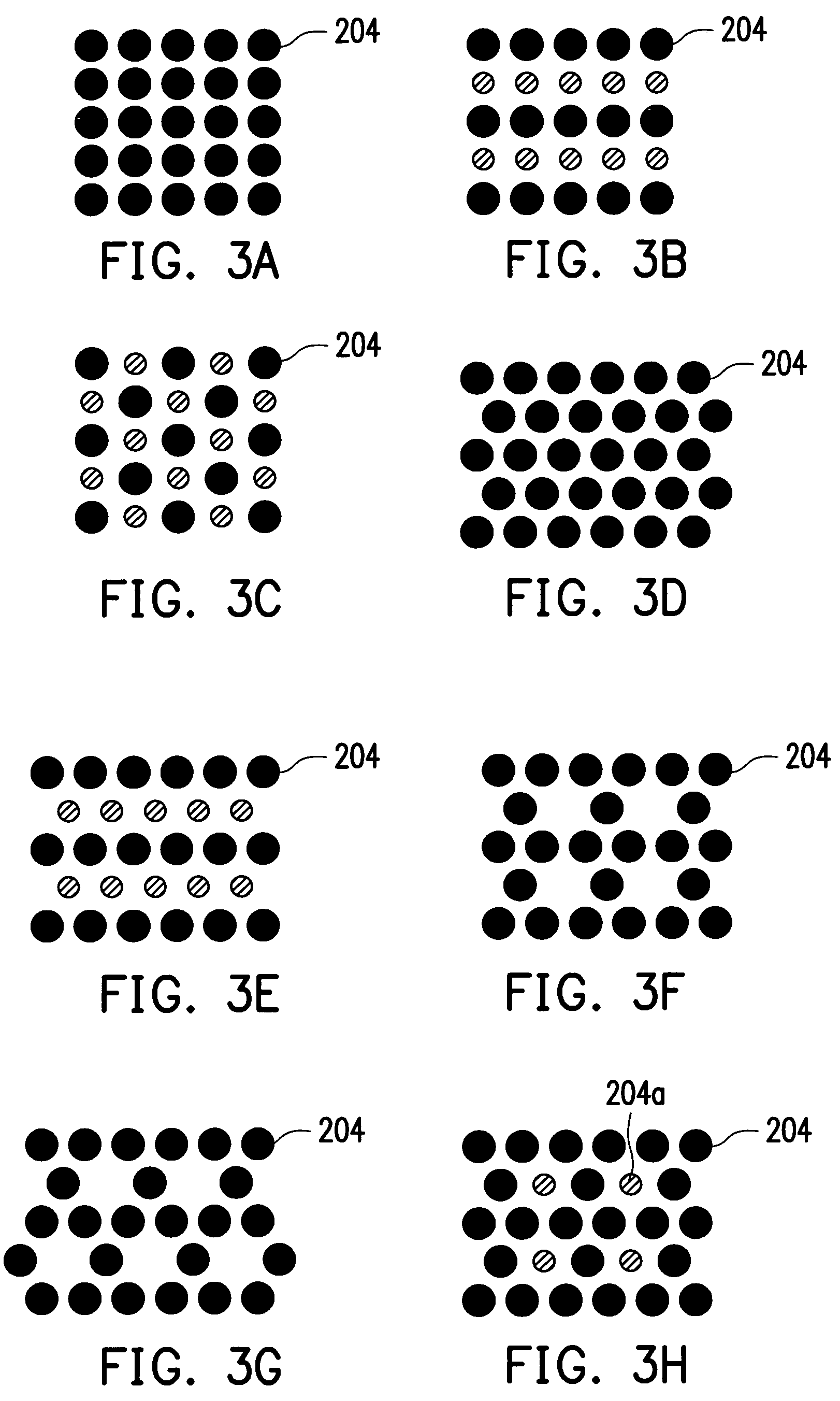

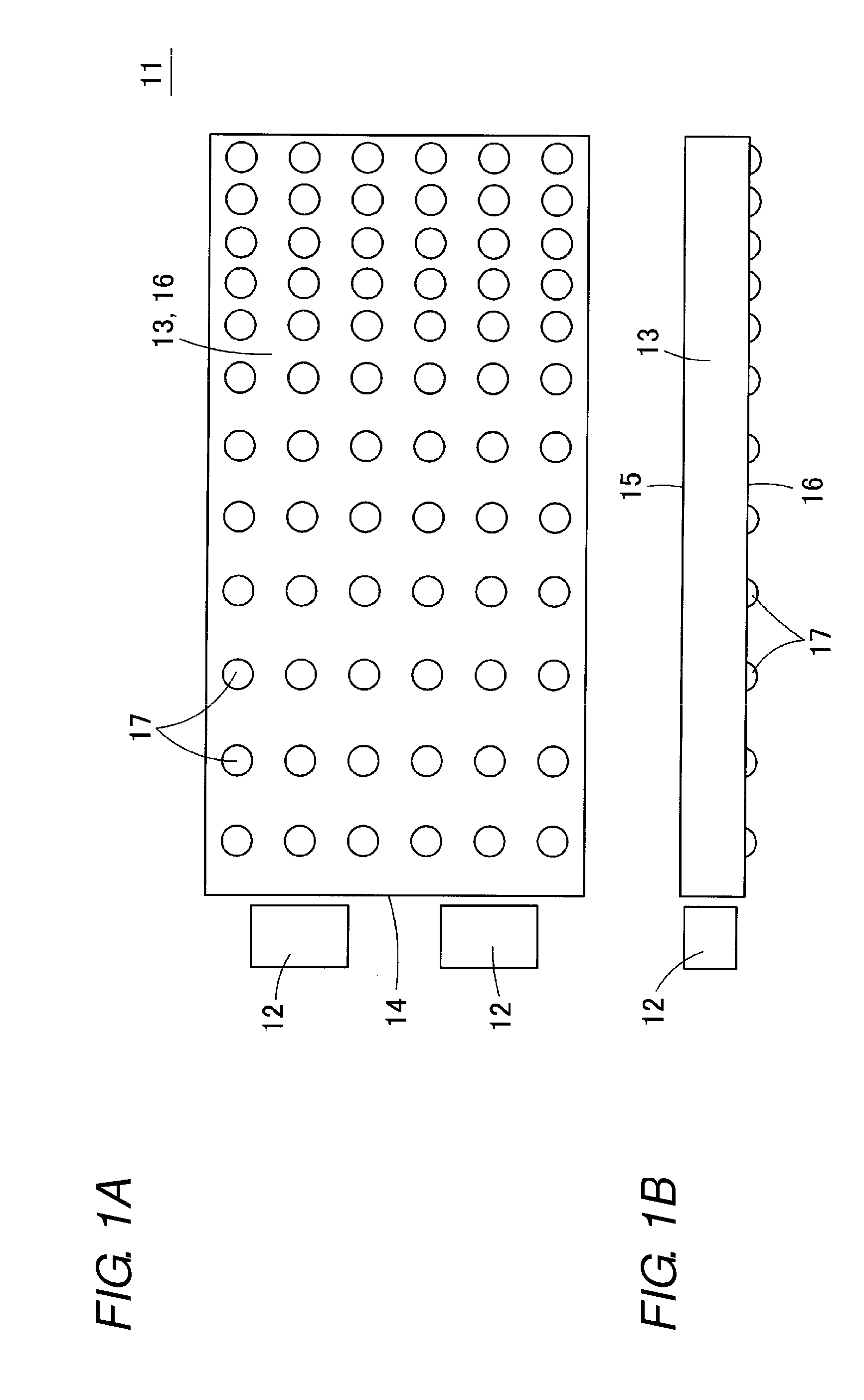

Light emitting diode structure having photonic crystals

ActiveUS7173289B1Improve epitaxy qualitySurface lightSolid-state devicesSemiconductor devicesPhotonic crystalPhotonics

A light emitting diode (LED) structure includes a substrate with a surface and cylindrical photonic crystals, a first type doping semiconductor layer, a first electrode, a light emitting layer, a second type doping semiconductor layer and a second electrode. The first type doping semiconductor layer is formed on the substrate to cover the photonic crystals. The light emitting layer, the second type doping semiconductor layer and the second electrode are sequentially formed on a portion of the first type doping semiconductor layer. The first electrode is formed on the other portion of the first type doping semiconductor layer without being covered by the light emitting layer. Because the substrate with photonic crystals can improve the epitaxial quality of the first type doping semiconductor layer and increase the energy of the light forwardly emitting out of the LED, the light emitting efficiency of the LED is effectively enhanced.

Owner:FORMOSA EPITAXY INCORPORATION +1

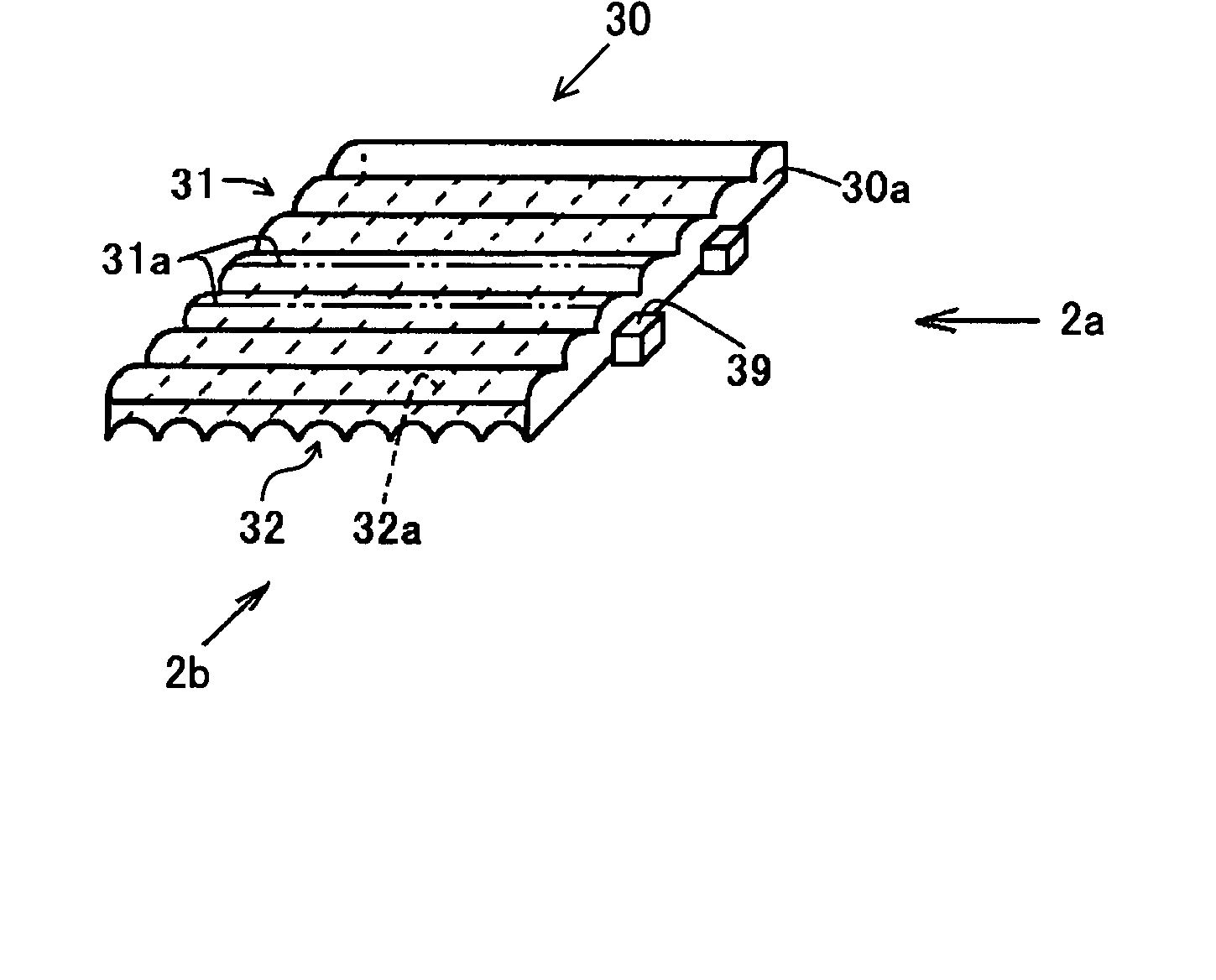

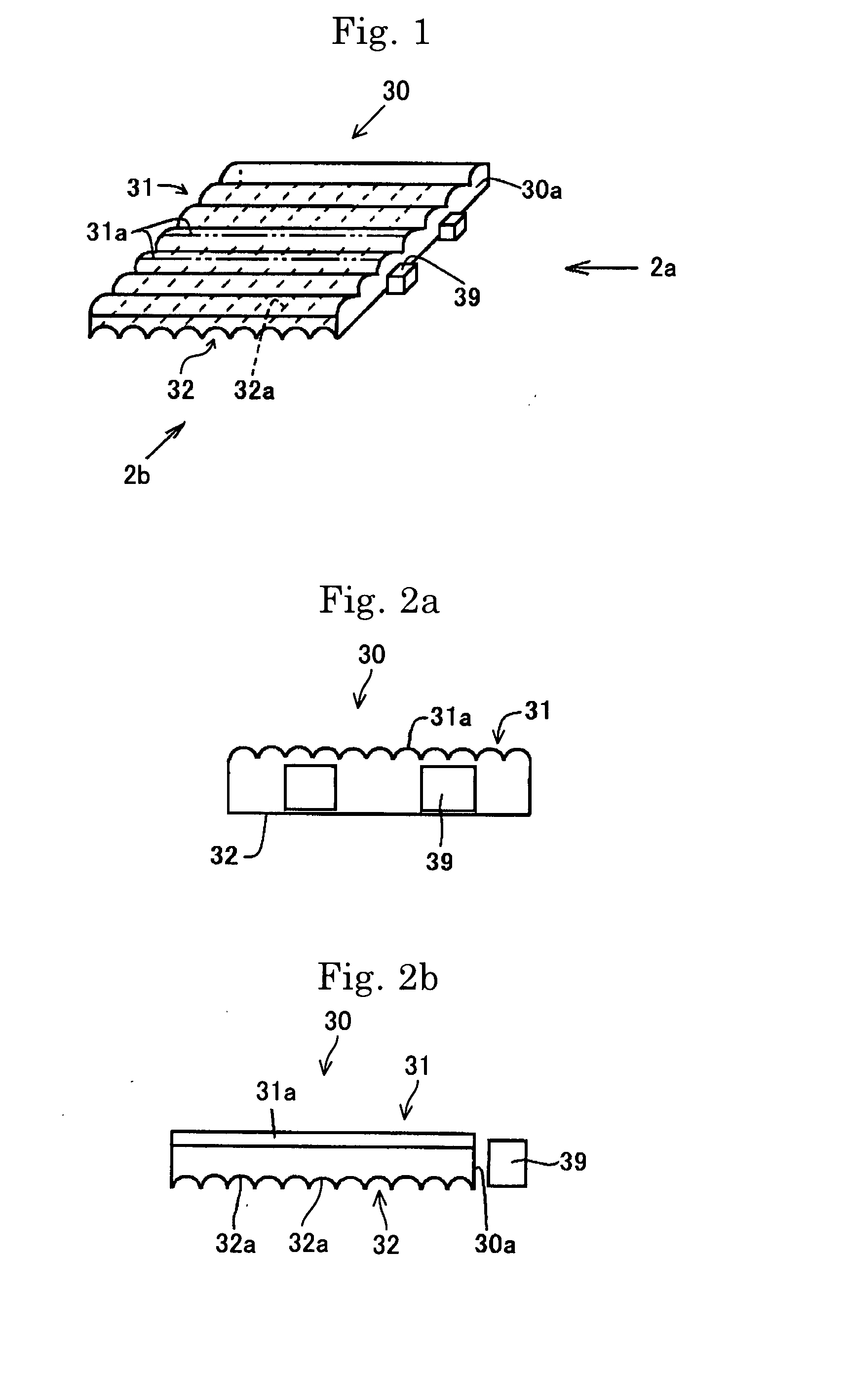

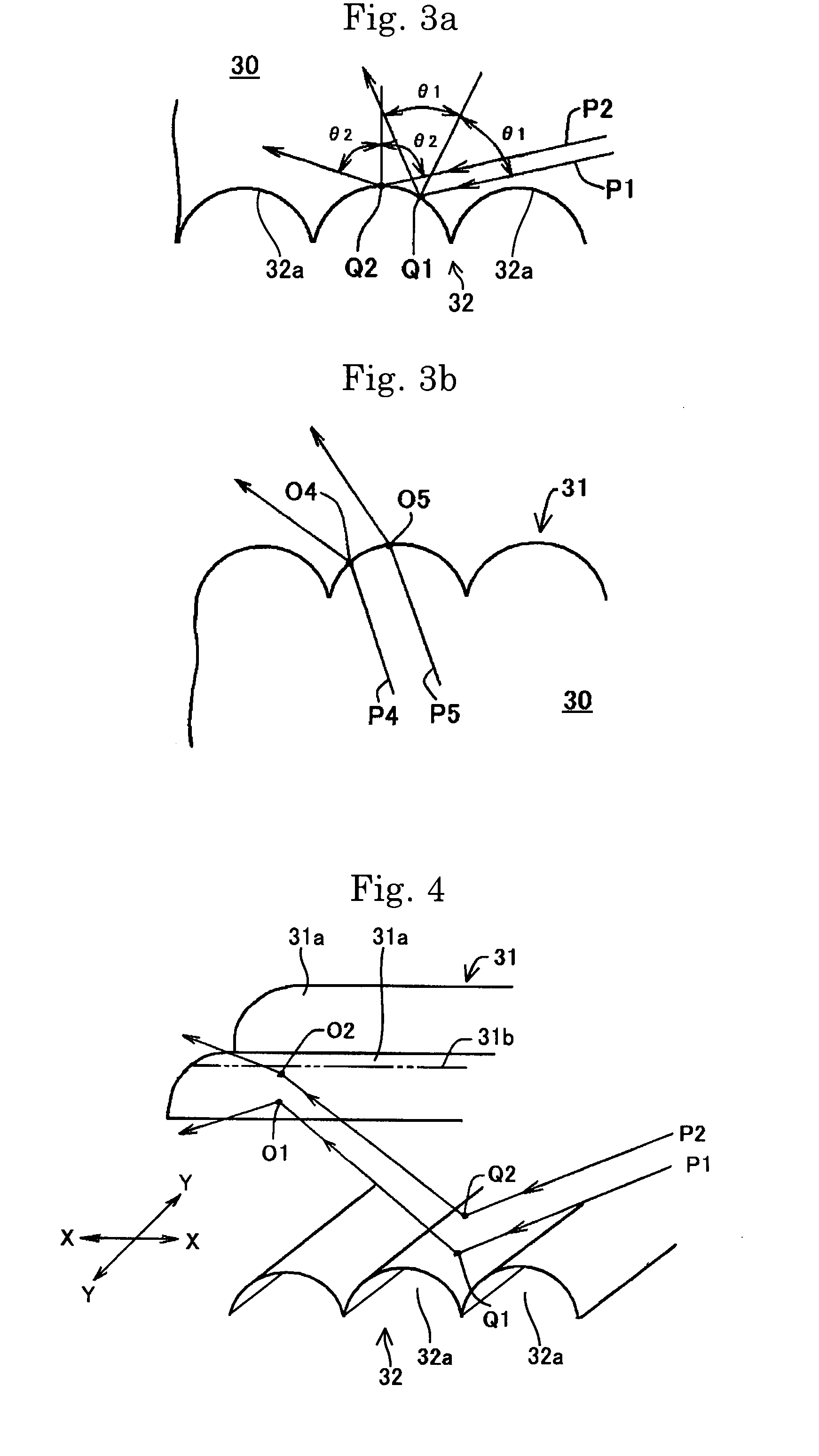

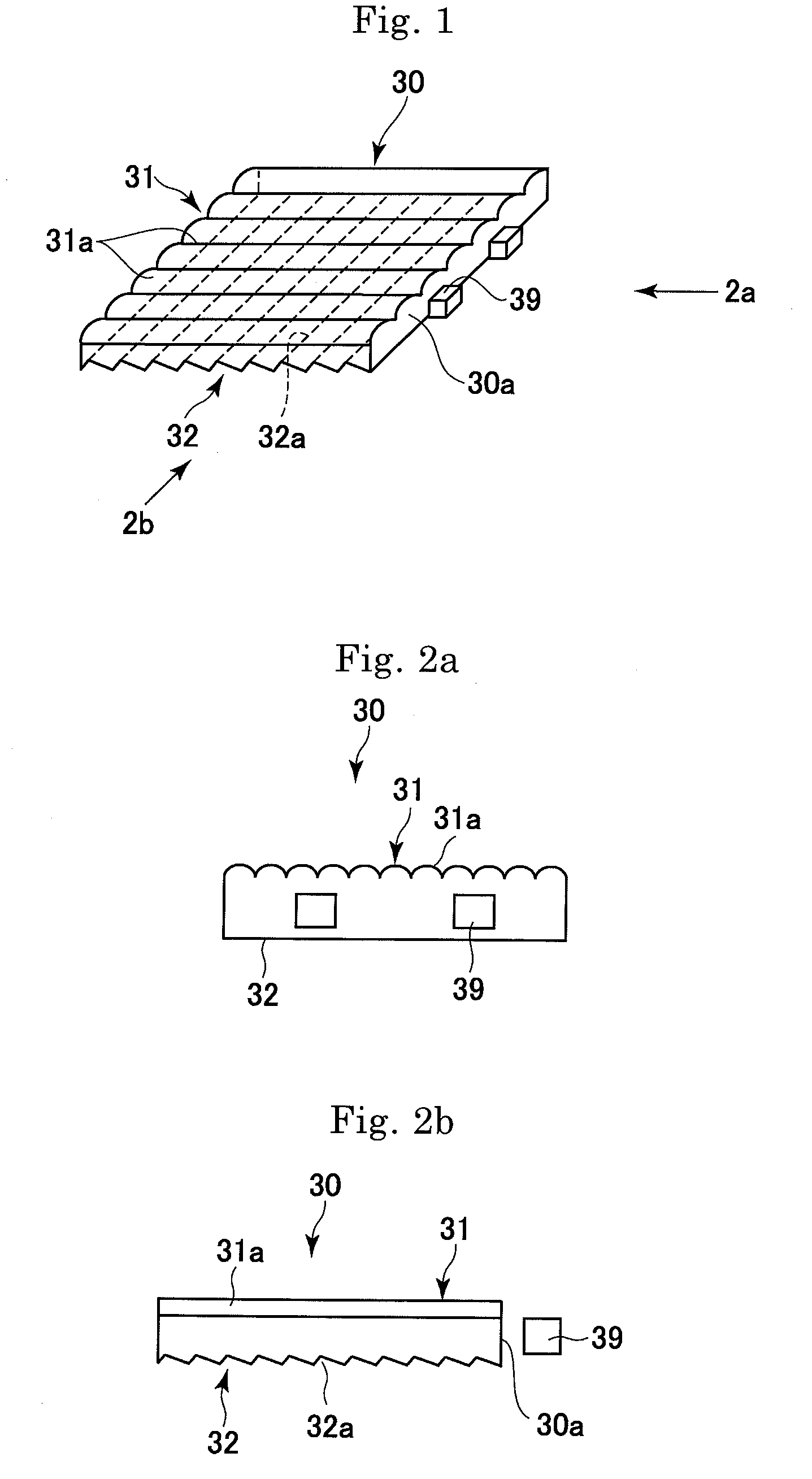

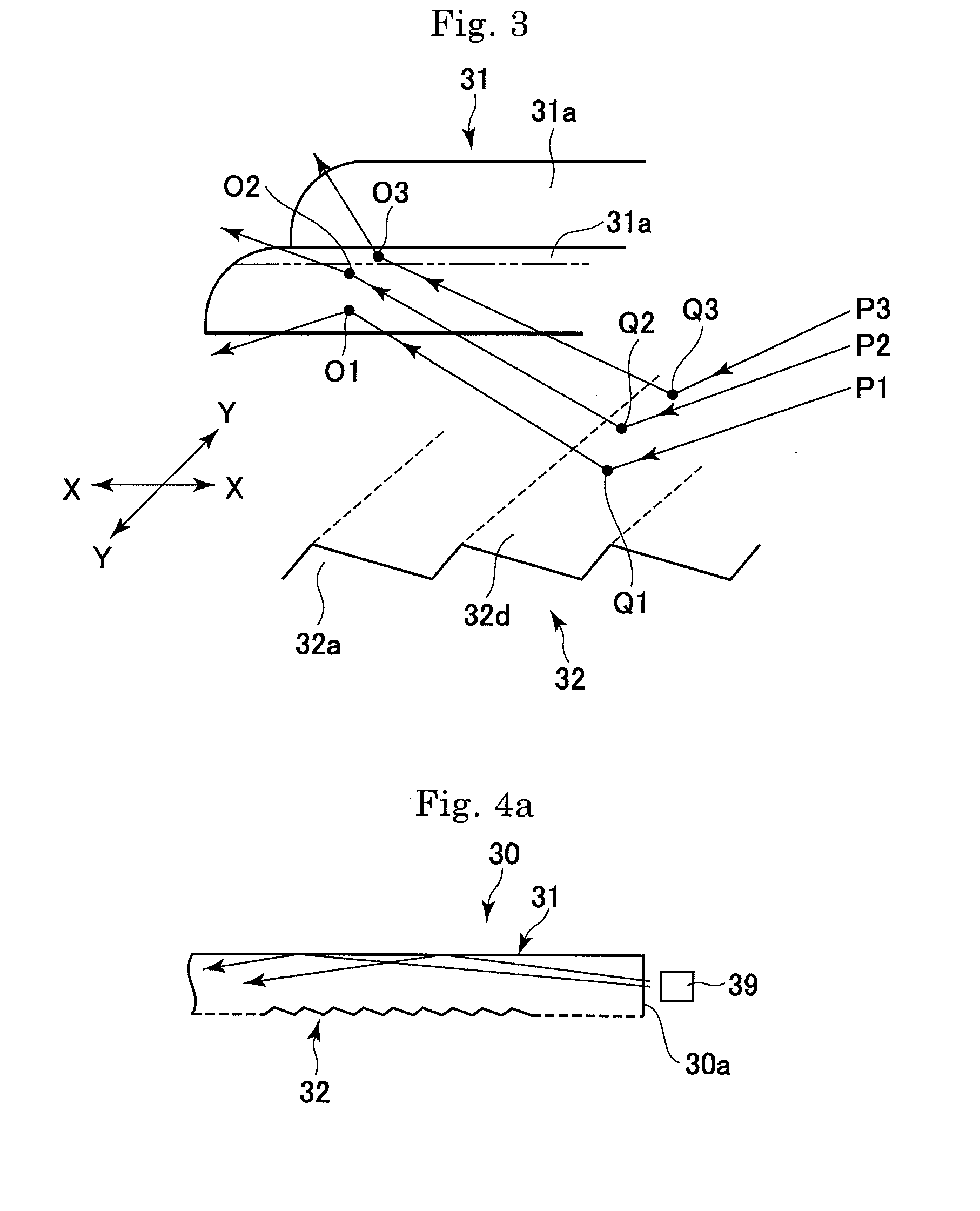

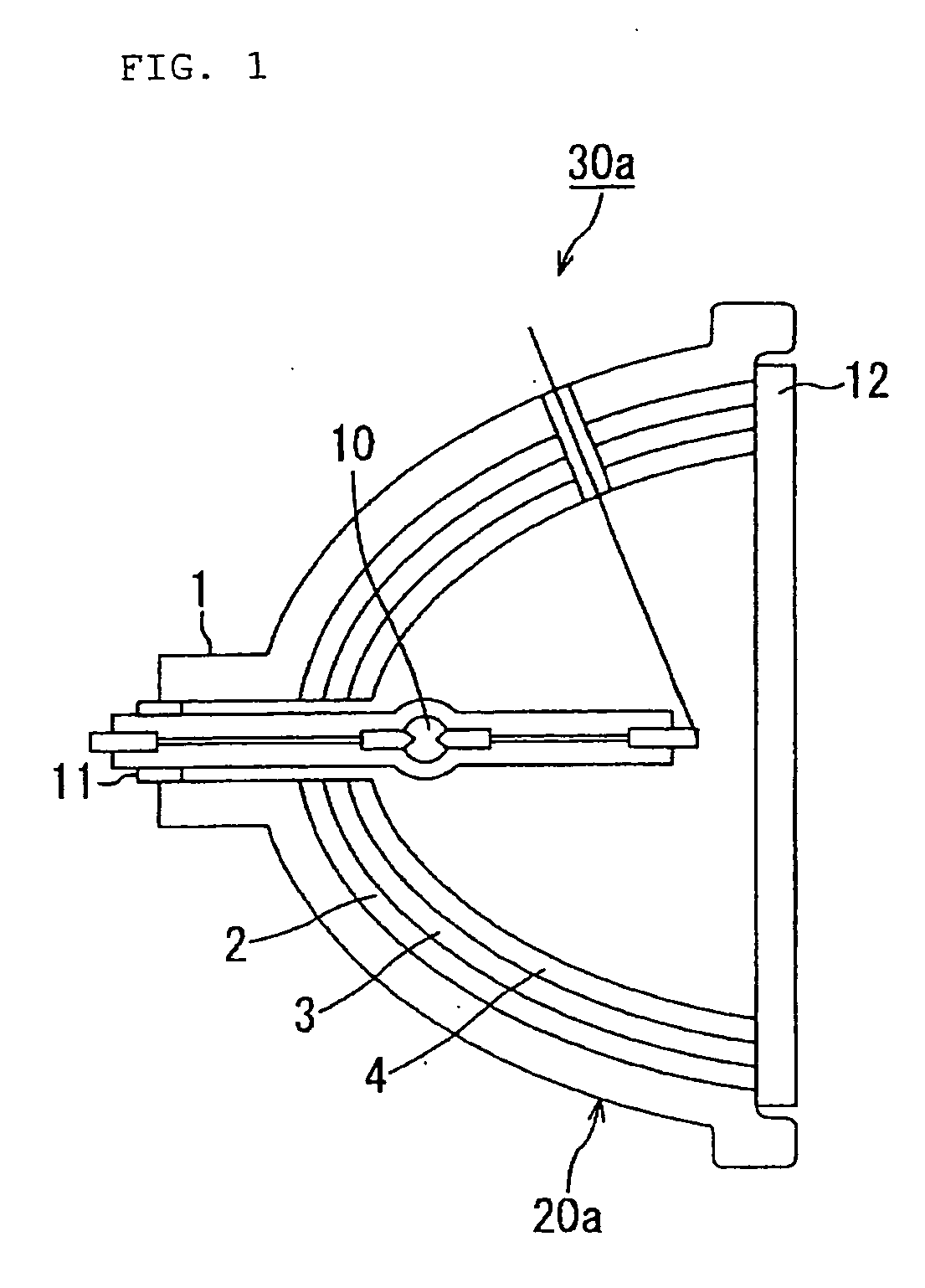

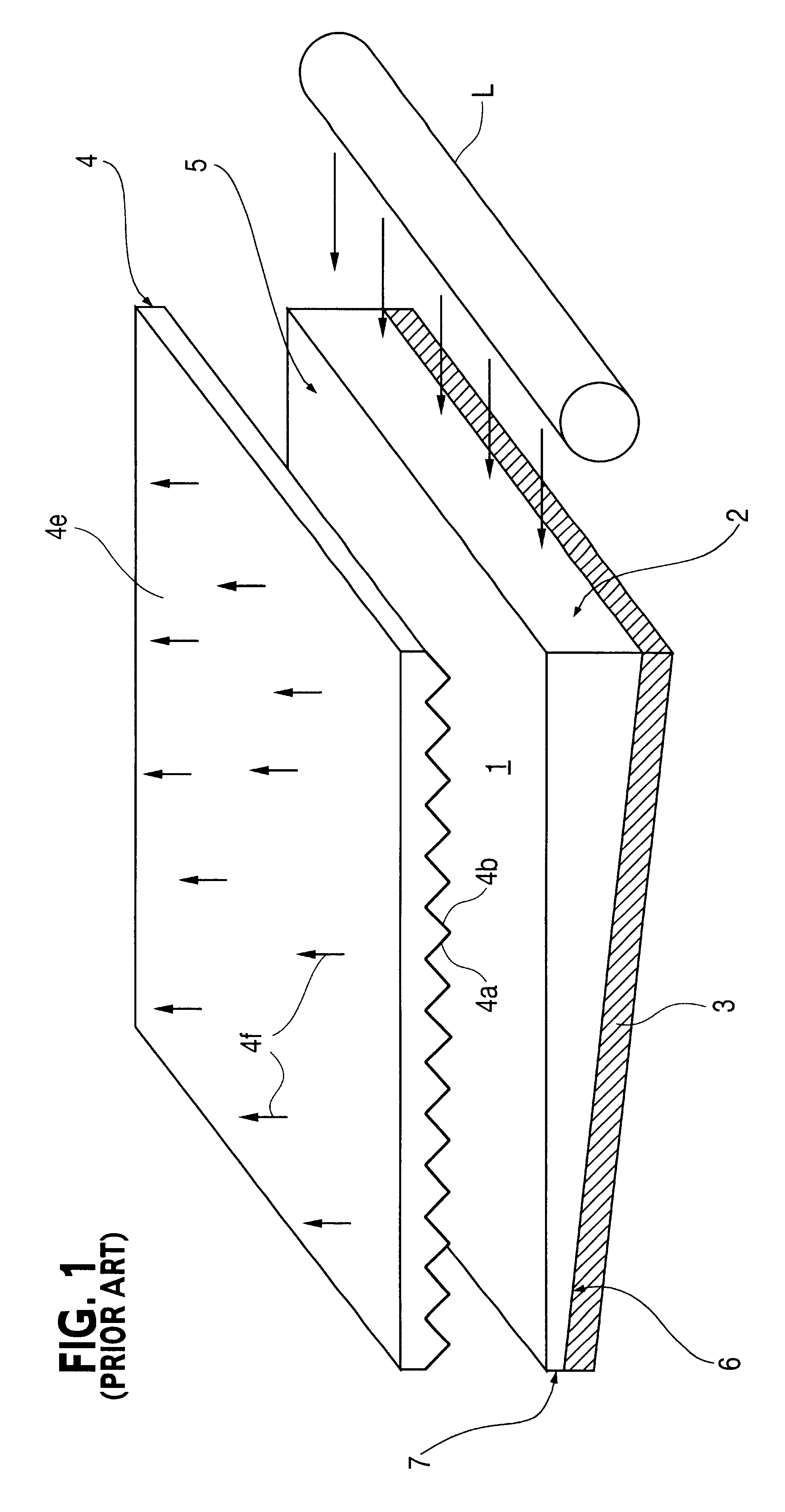

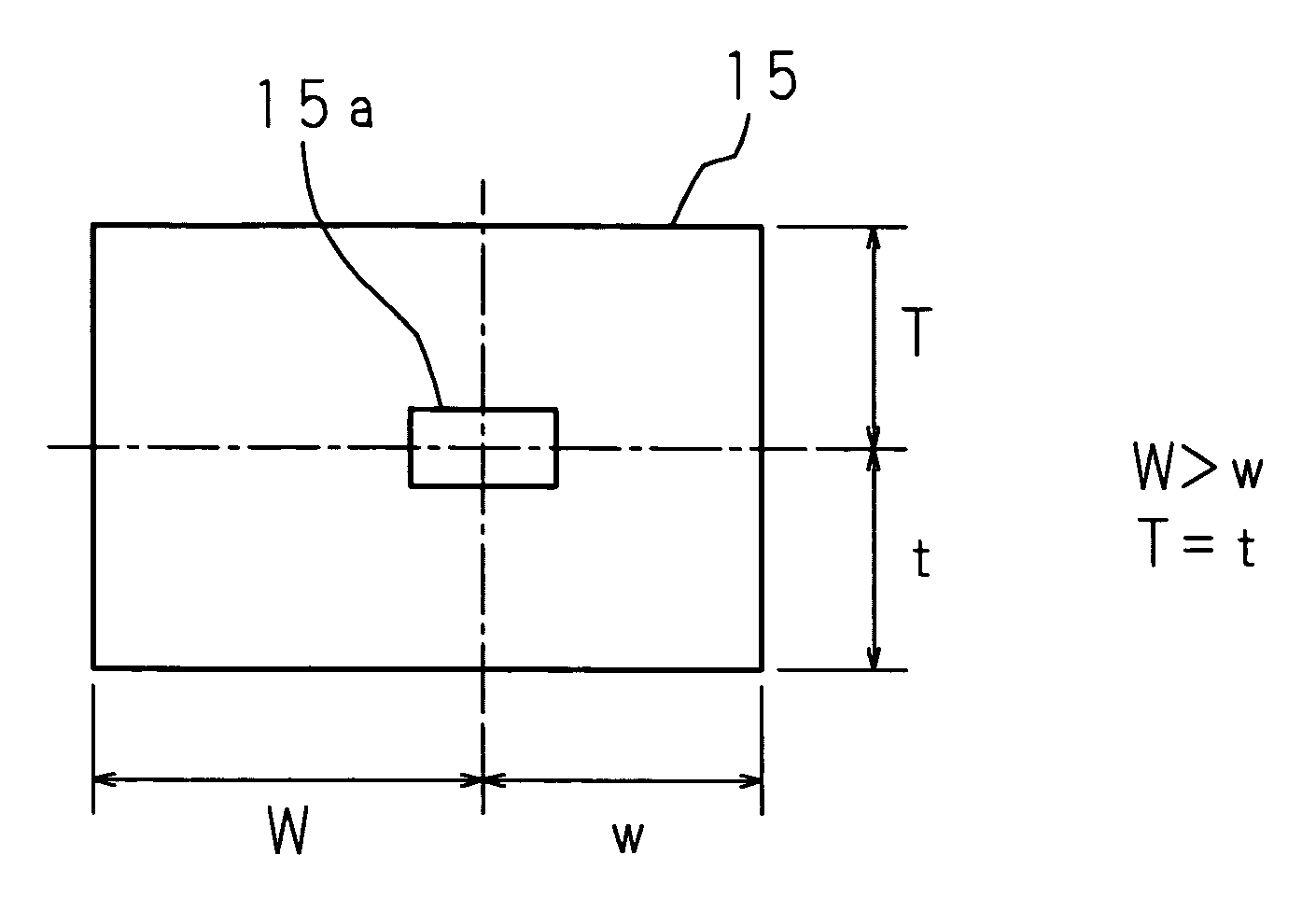

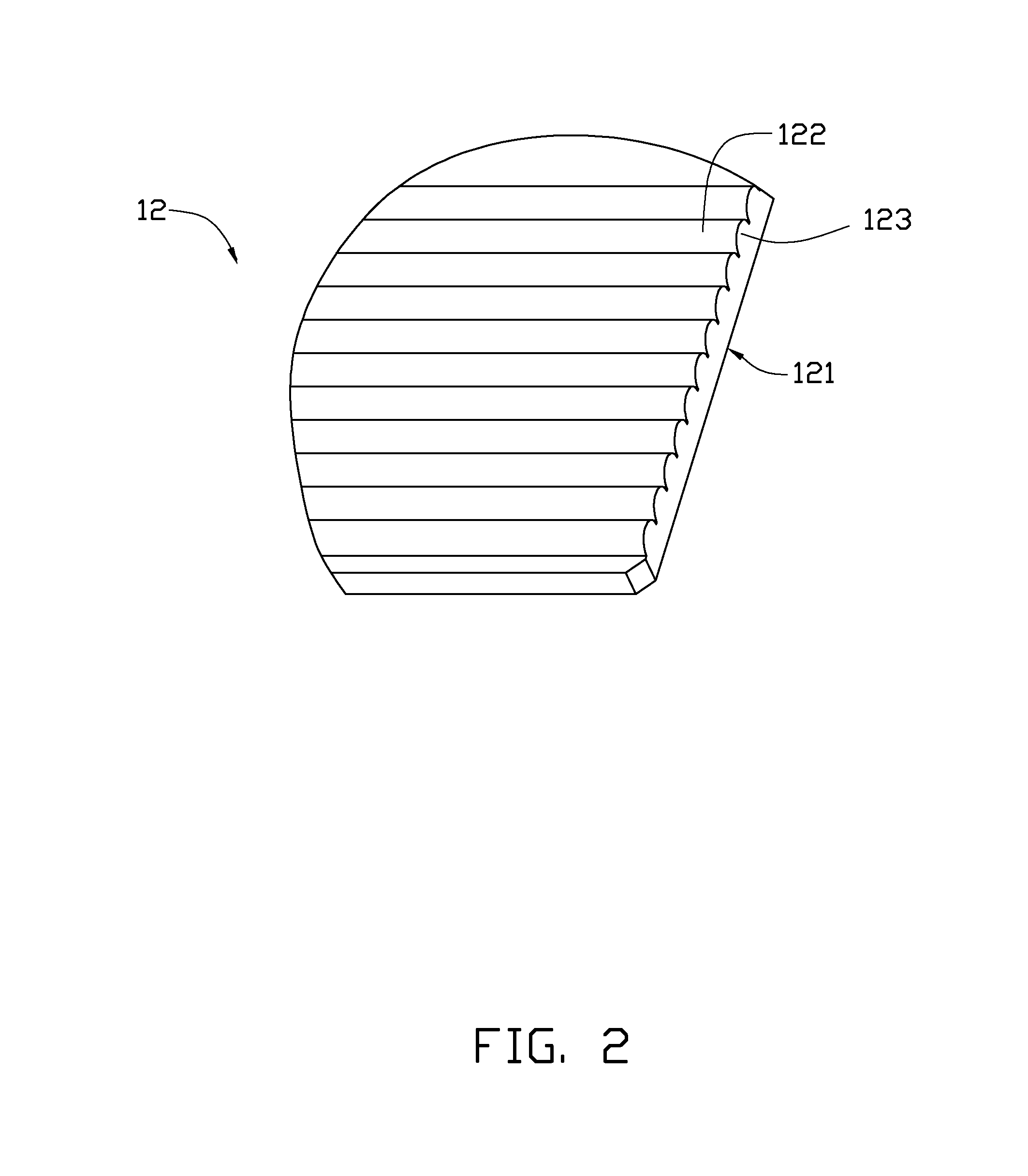

Light guide plate, method of manufacturing light guide plate and backlight with the light guide plate

ActiveUS20080068862A1Surface lightEffectively exitMechanical apparatusOptical articlesEdge surfaceEngineering

An edge-light type light guide plate 30 is provided and has a first surface 31 and a second surface 32 that are opposed to each other, and a peripheral edge surface extending between the peripheral edges of the first and second surfaces. A part of the peripheral edge surface is defined as a light entrance plane 30a. The first surface 31 has a series of parallel elongated convex surfaces 31a that have an arcuate cross-section and extend in a direction substantially perpendicularly intersecting the light entrance plane 30a. The second surface 32 has a series of parallel elongated concave surfaces 32a that have an arcuate cross-section and extend in a direction substantially perpendicularly intersecting the elongated convex surfaces 31a on the first surface.

Owner:CITIZEN ELECTRONICS CO LTD

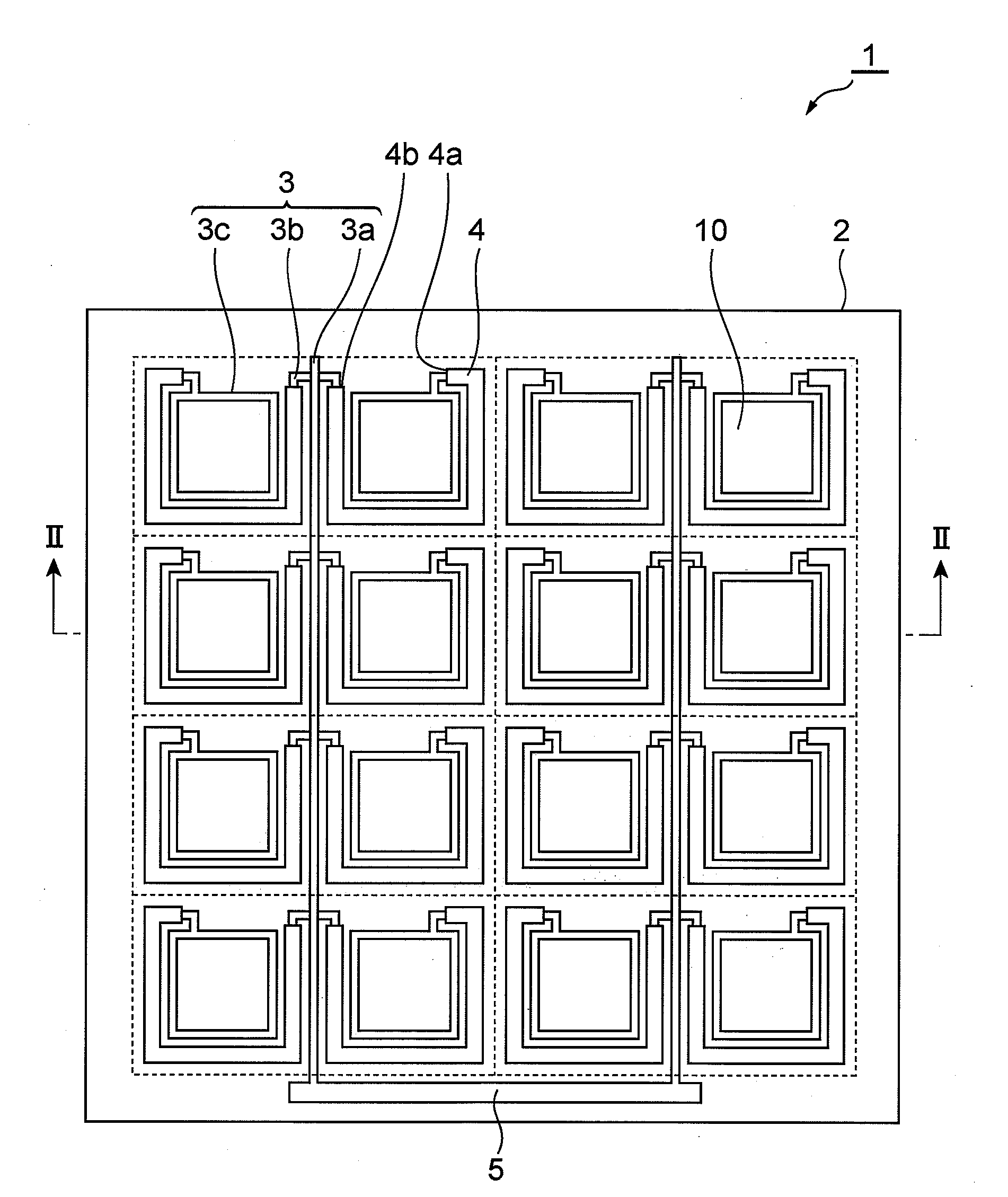

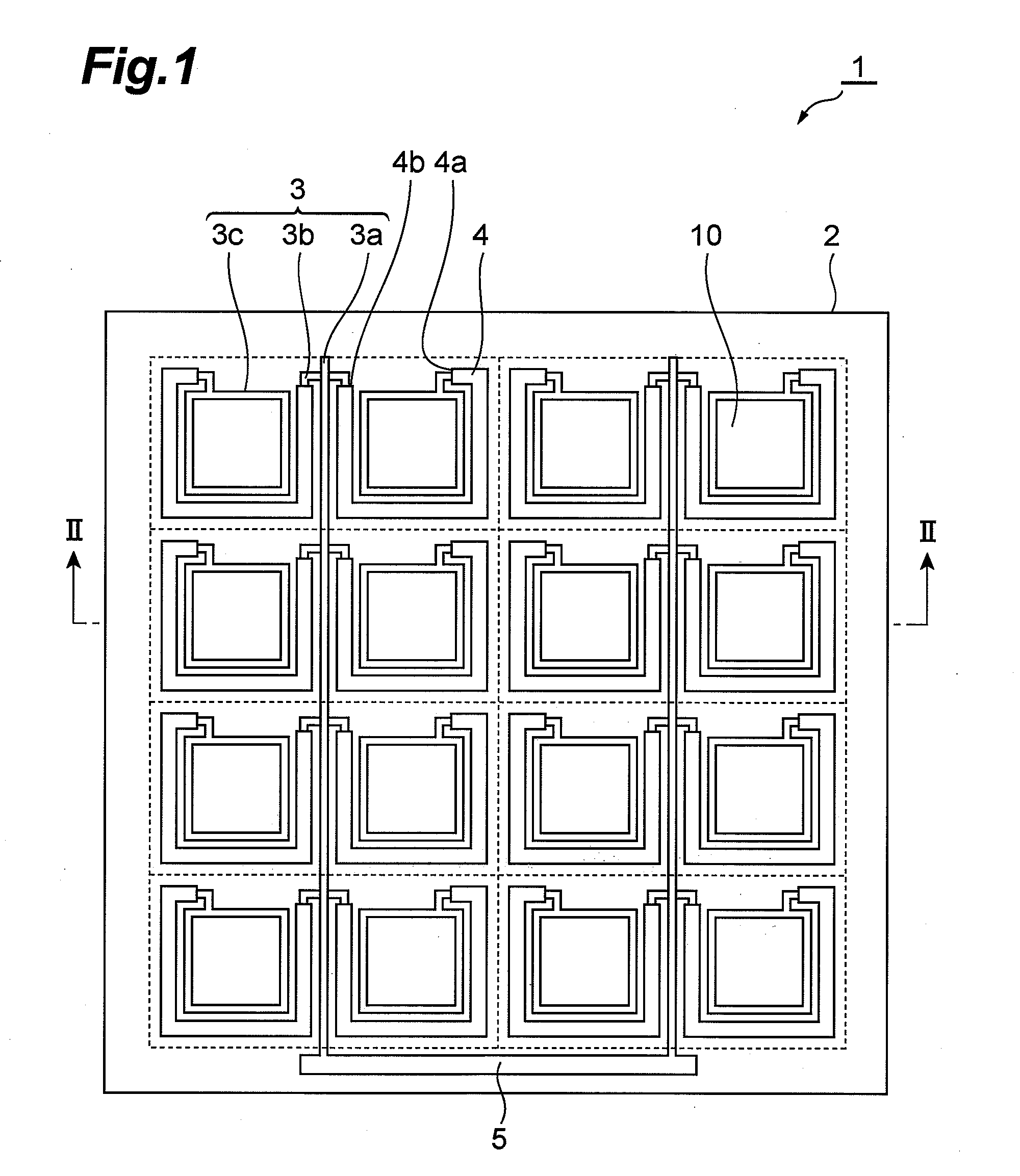

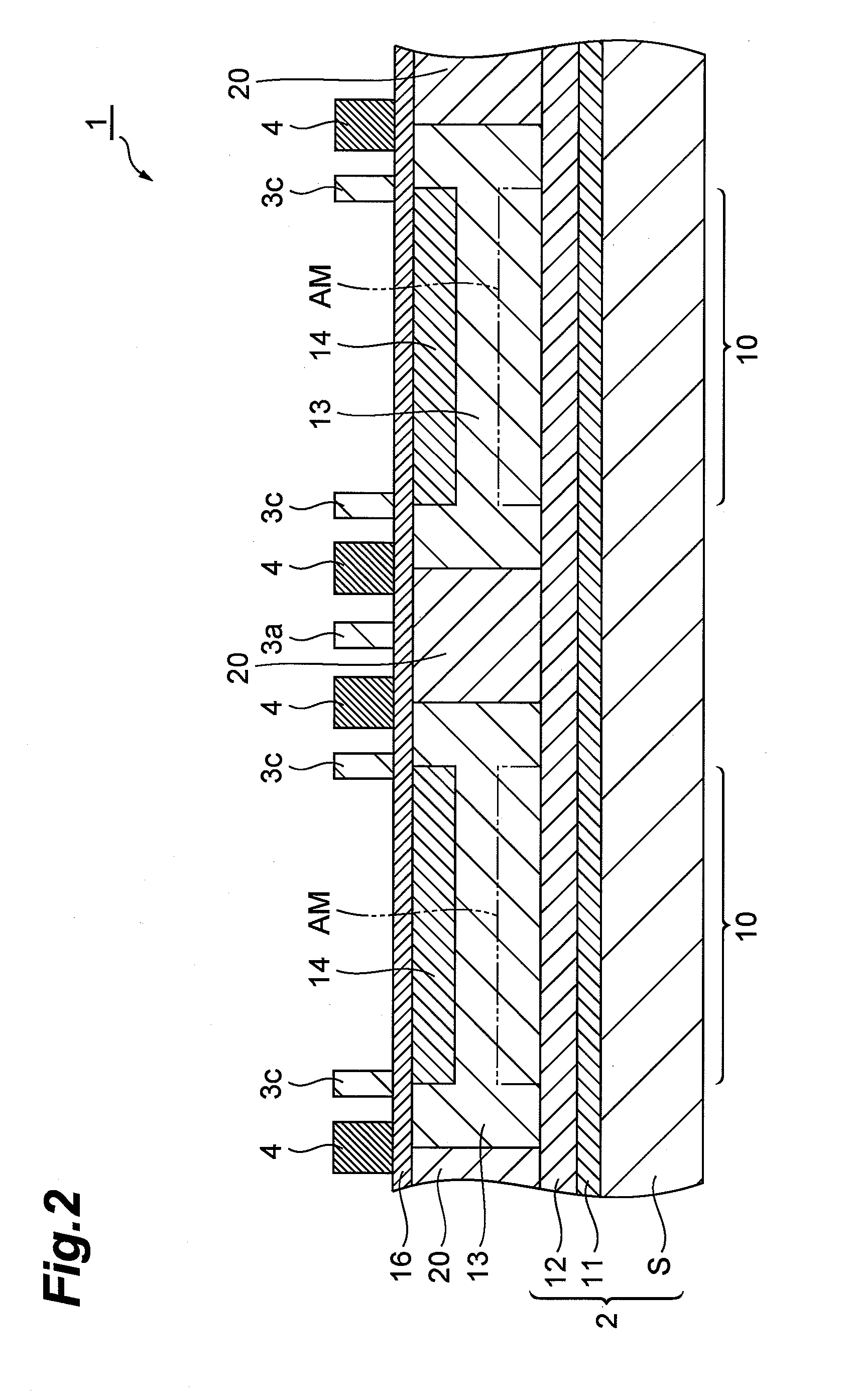

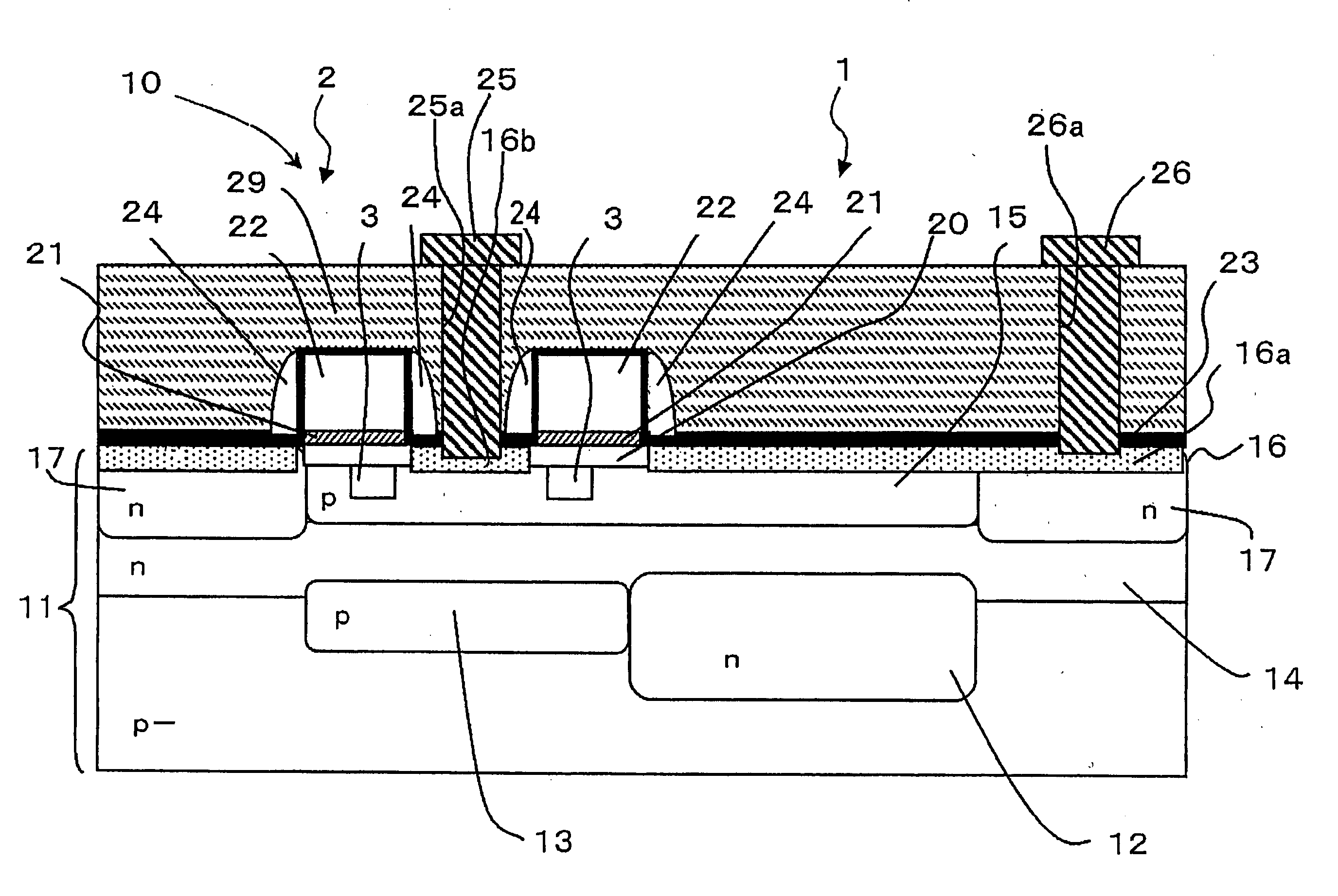

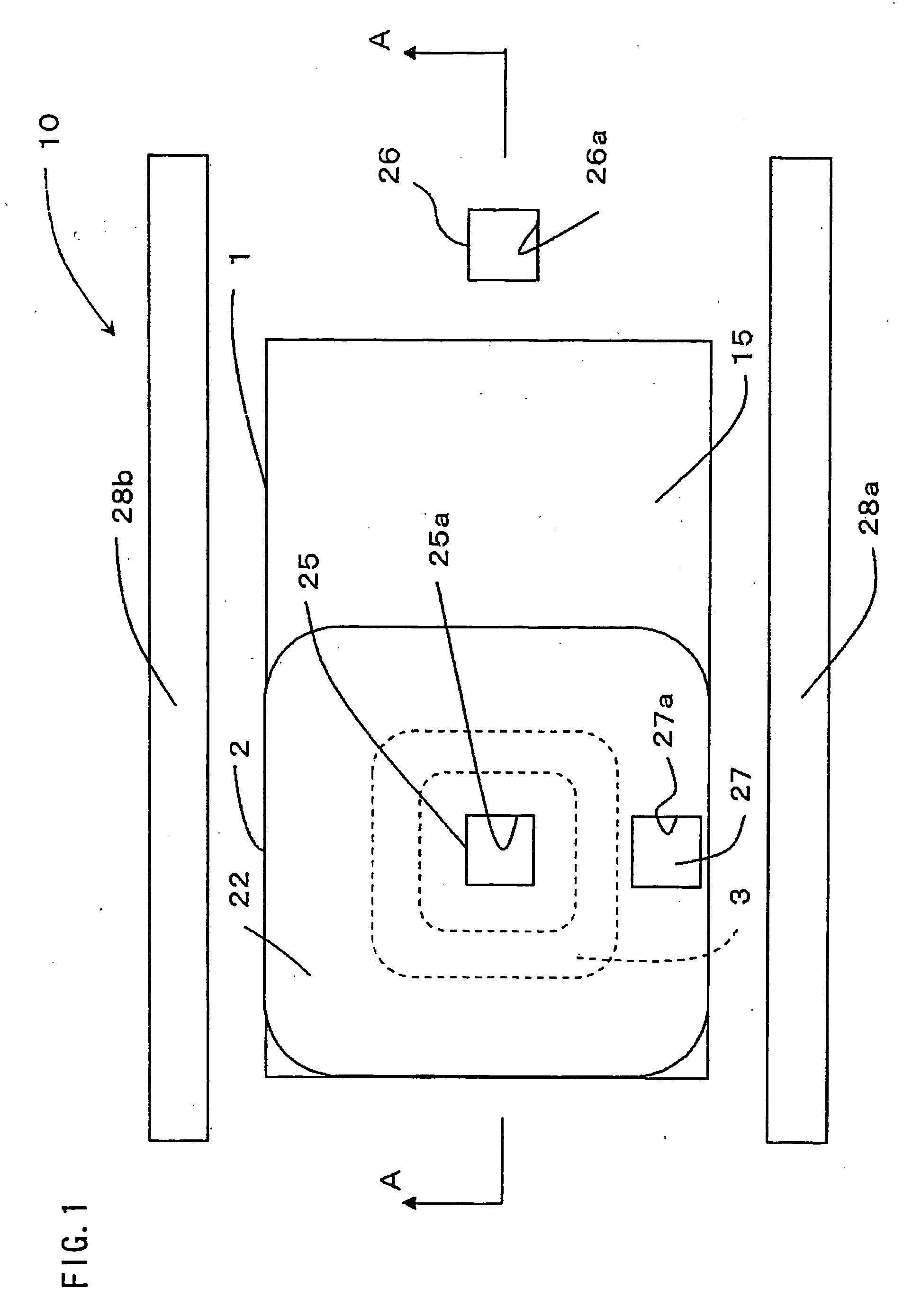

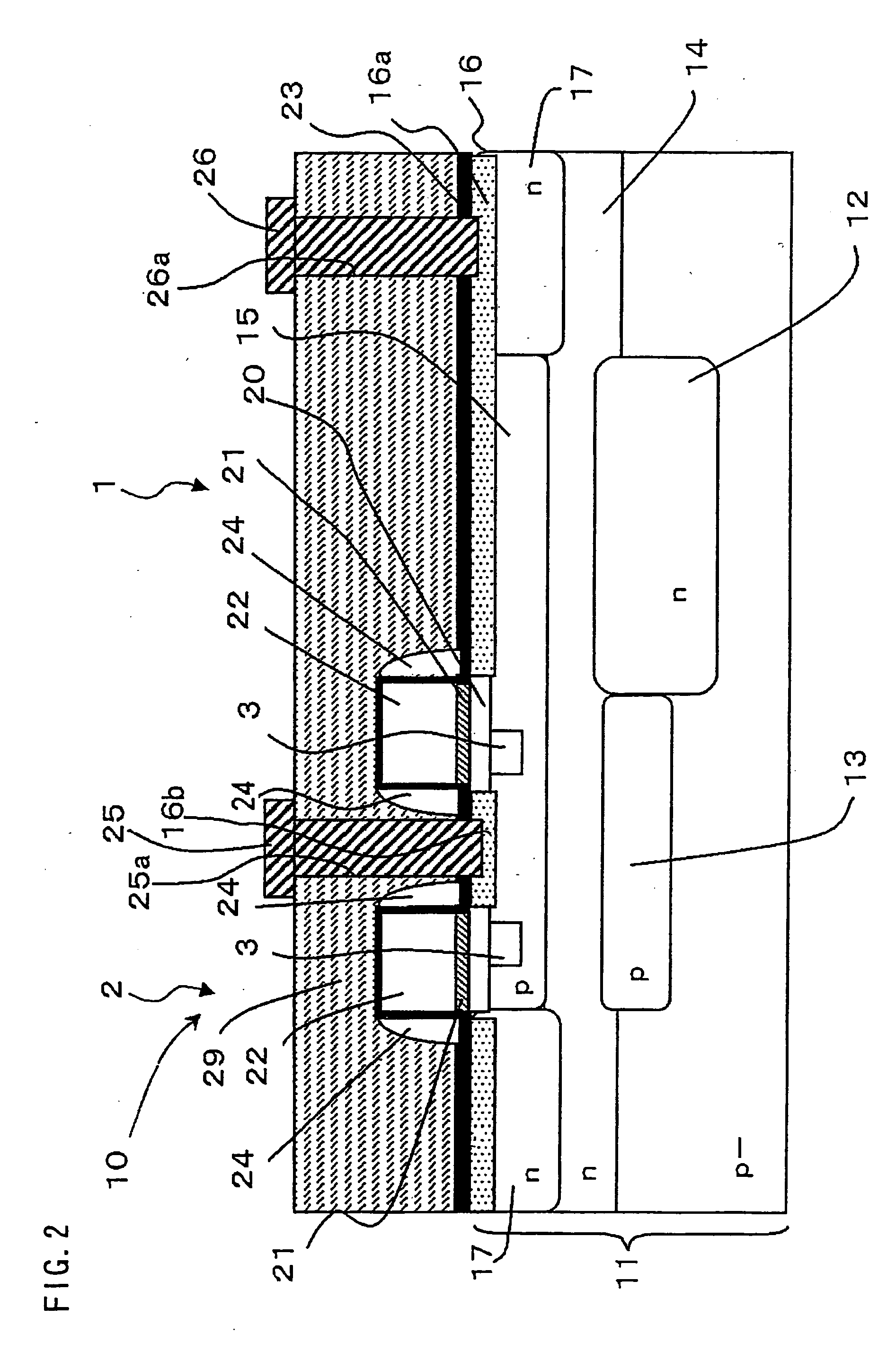

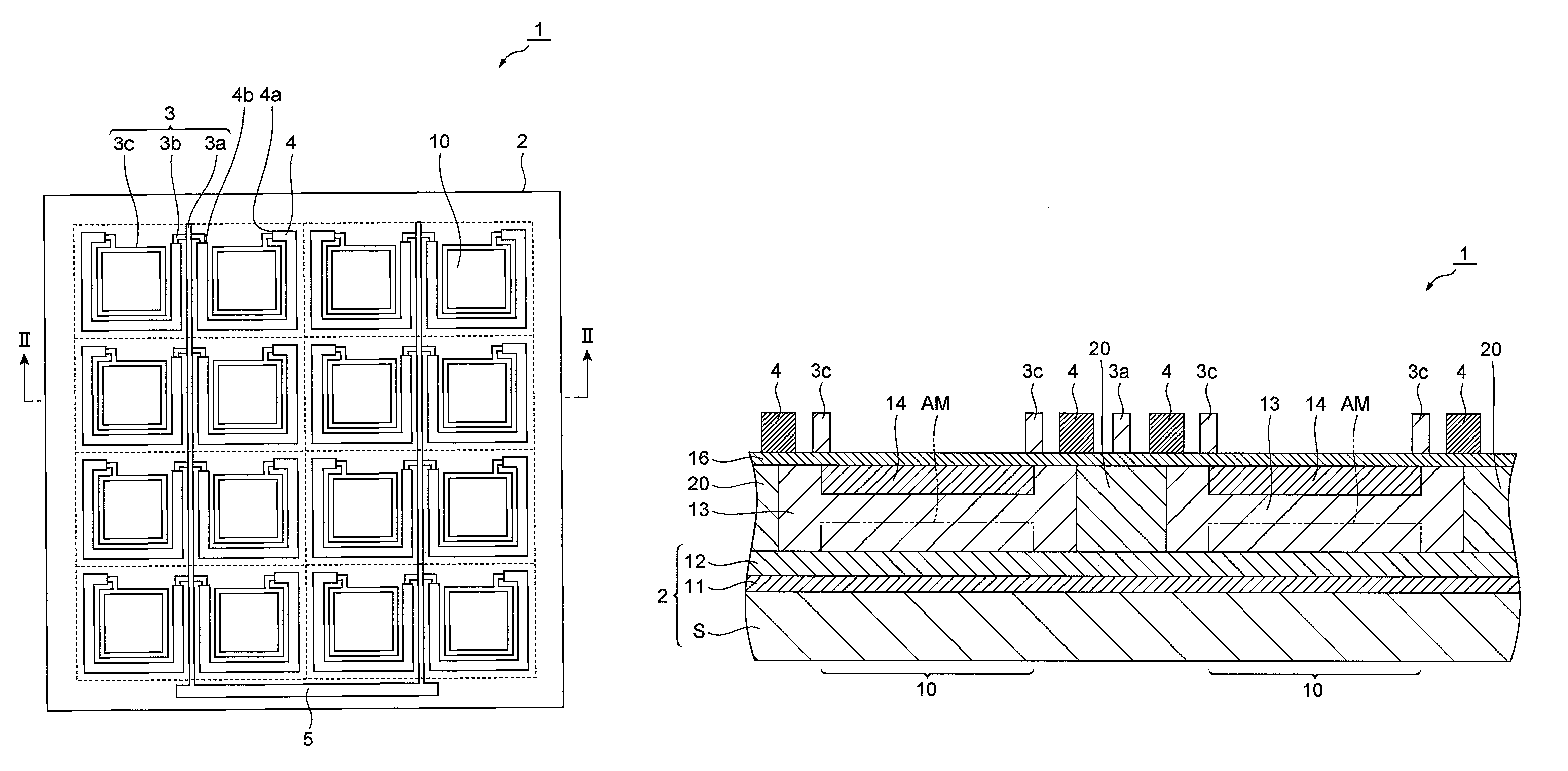

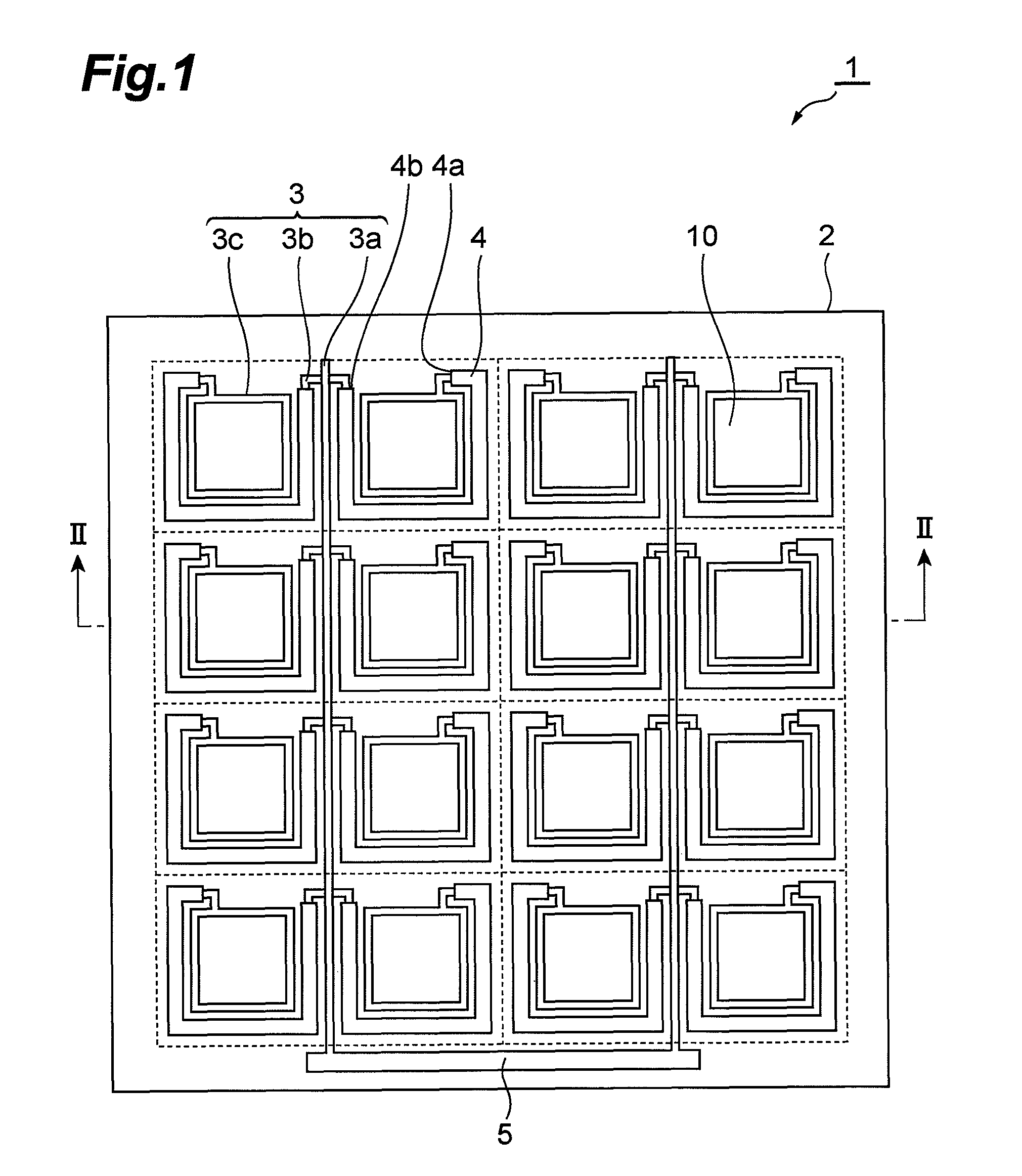

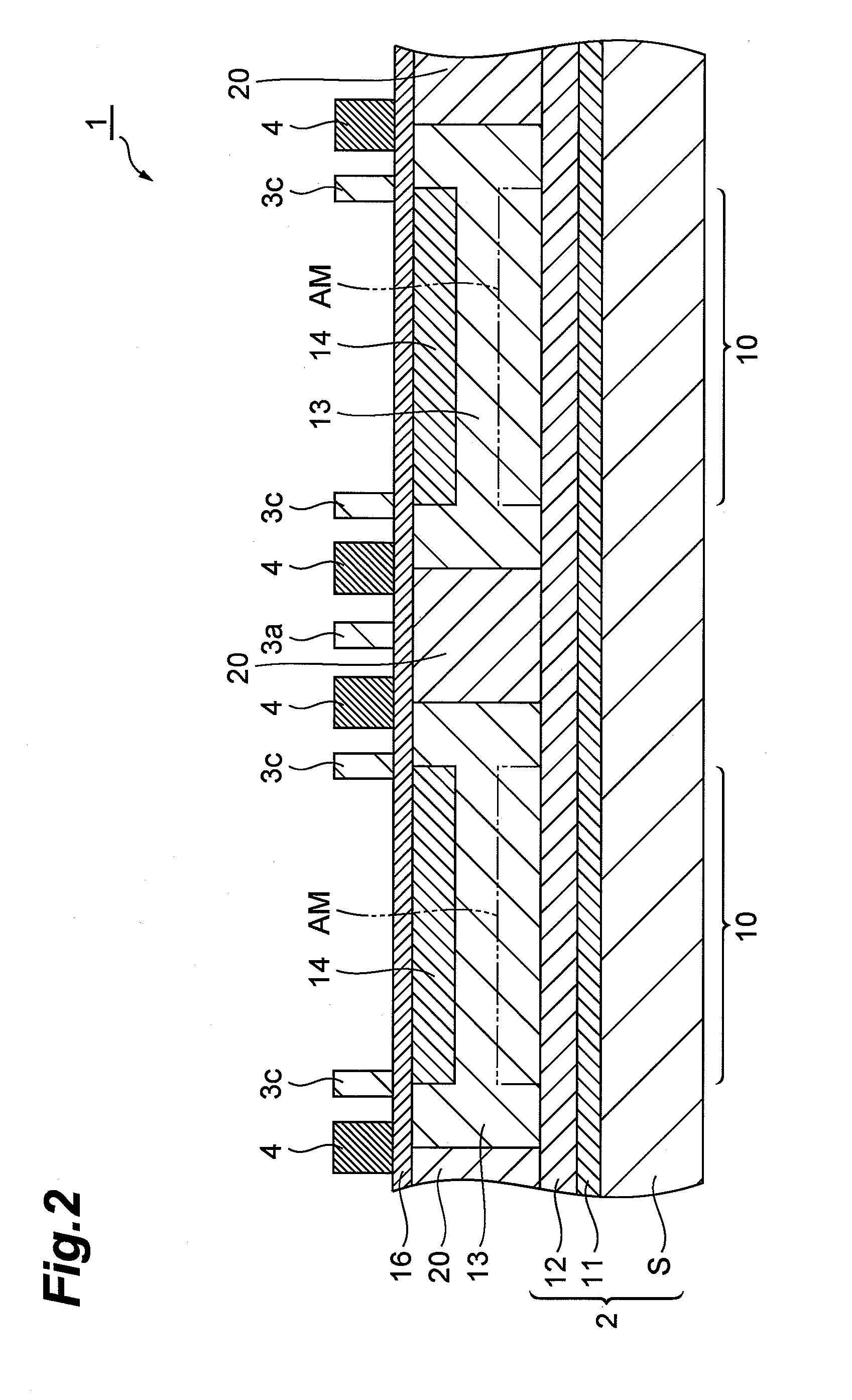

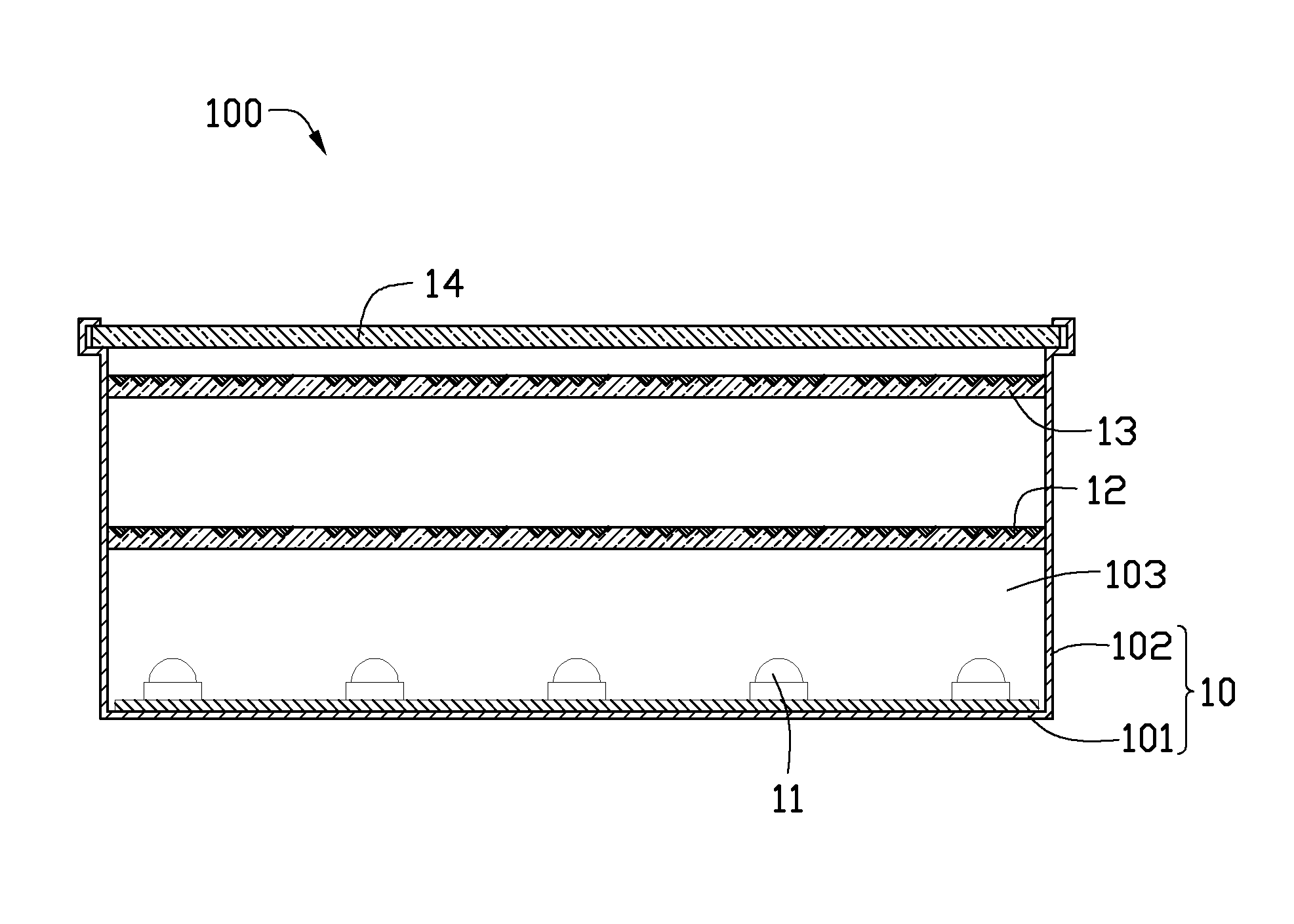

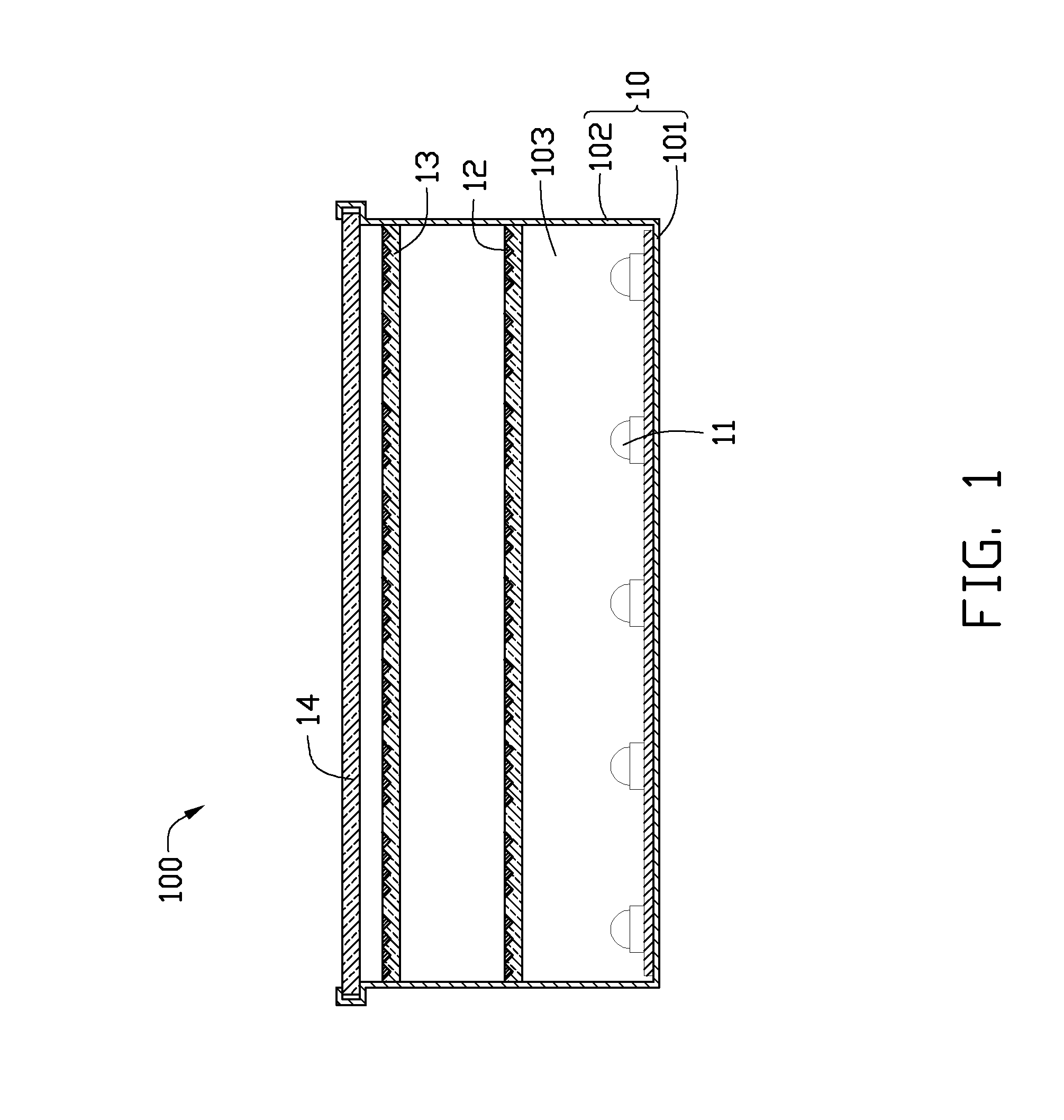

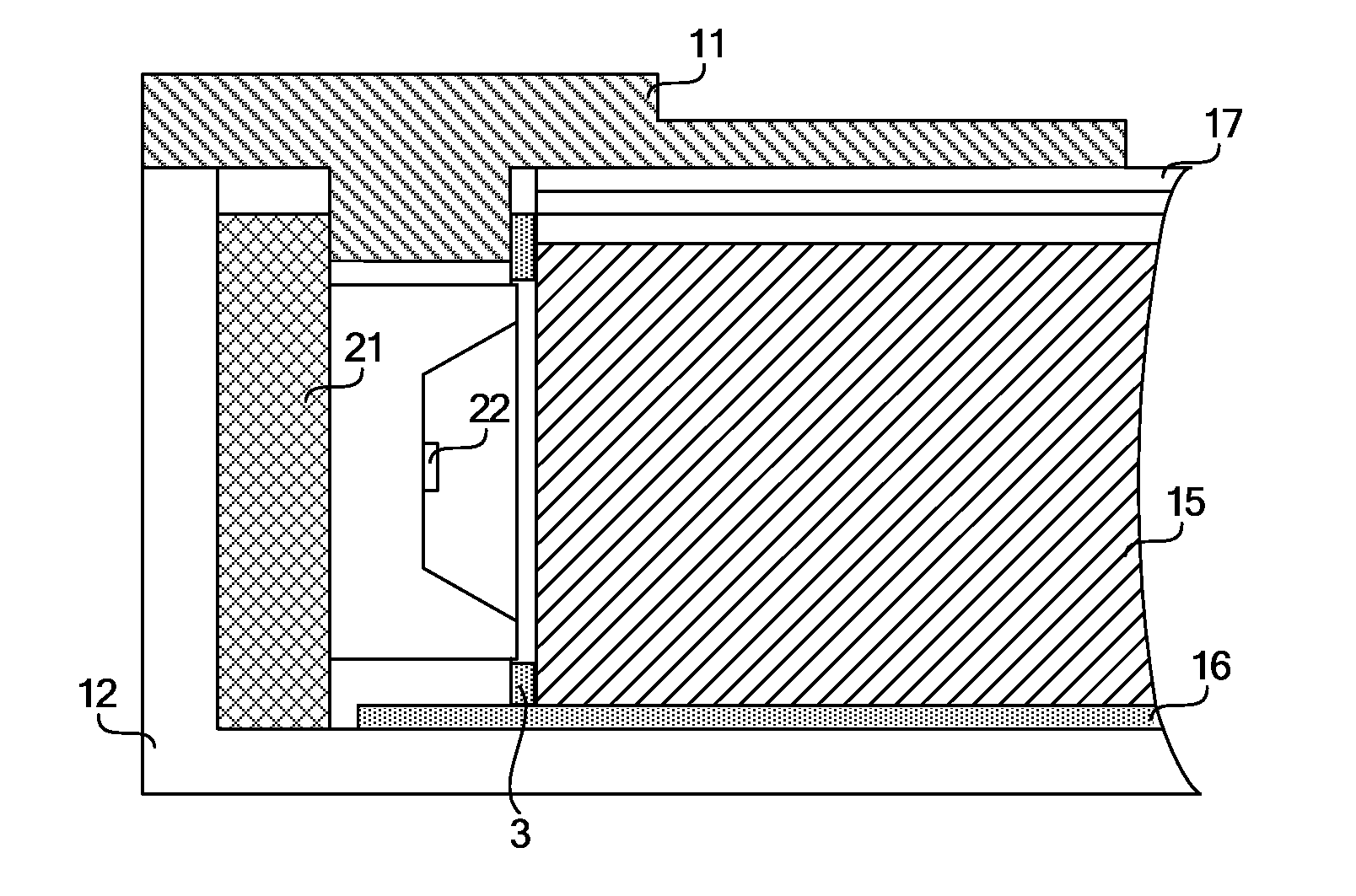

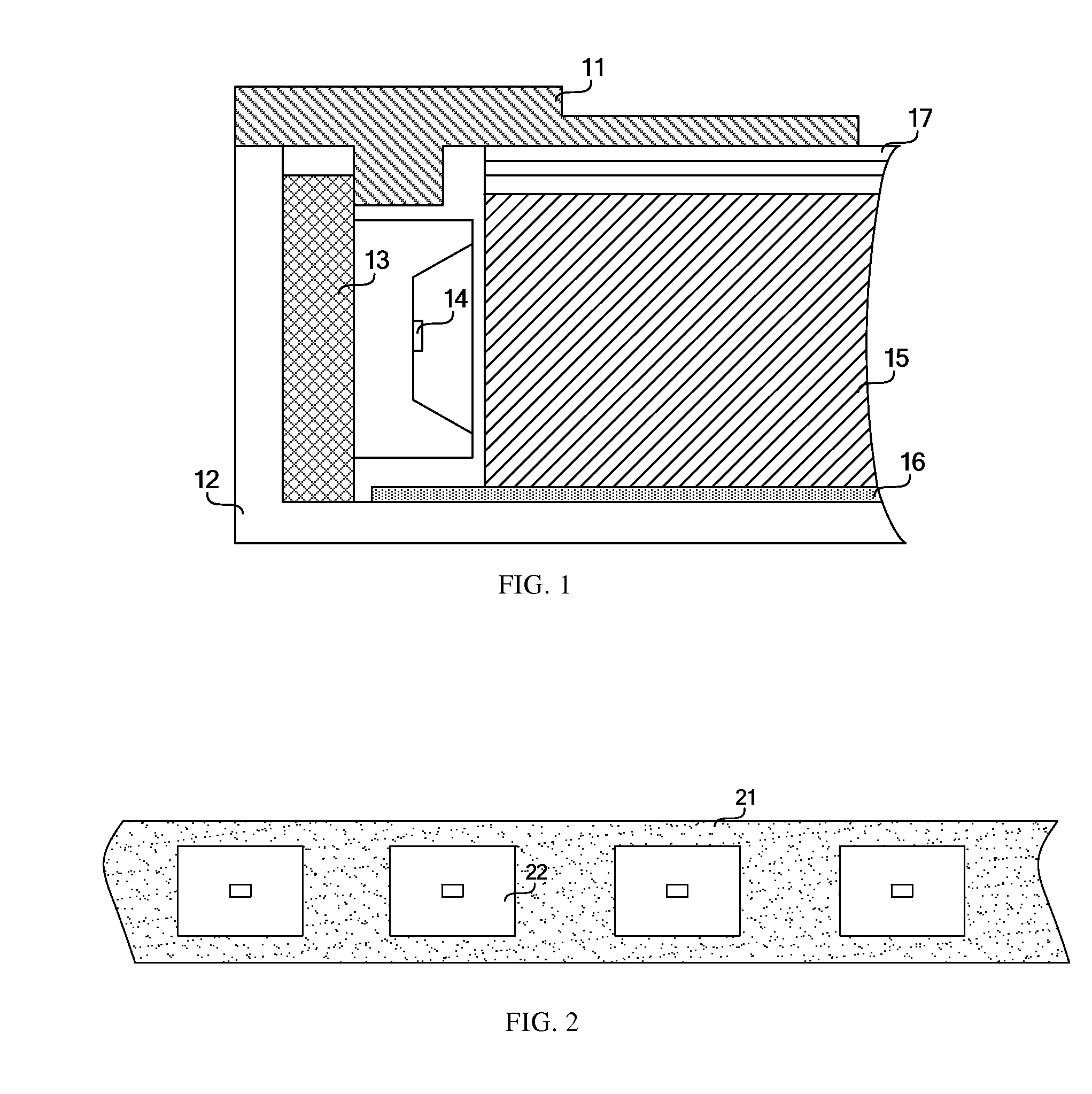

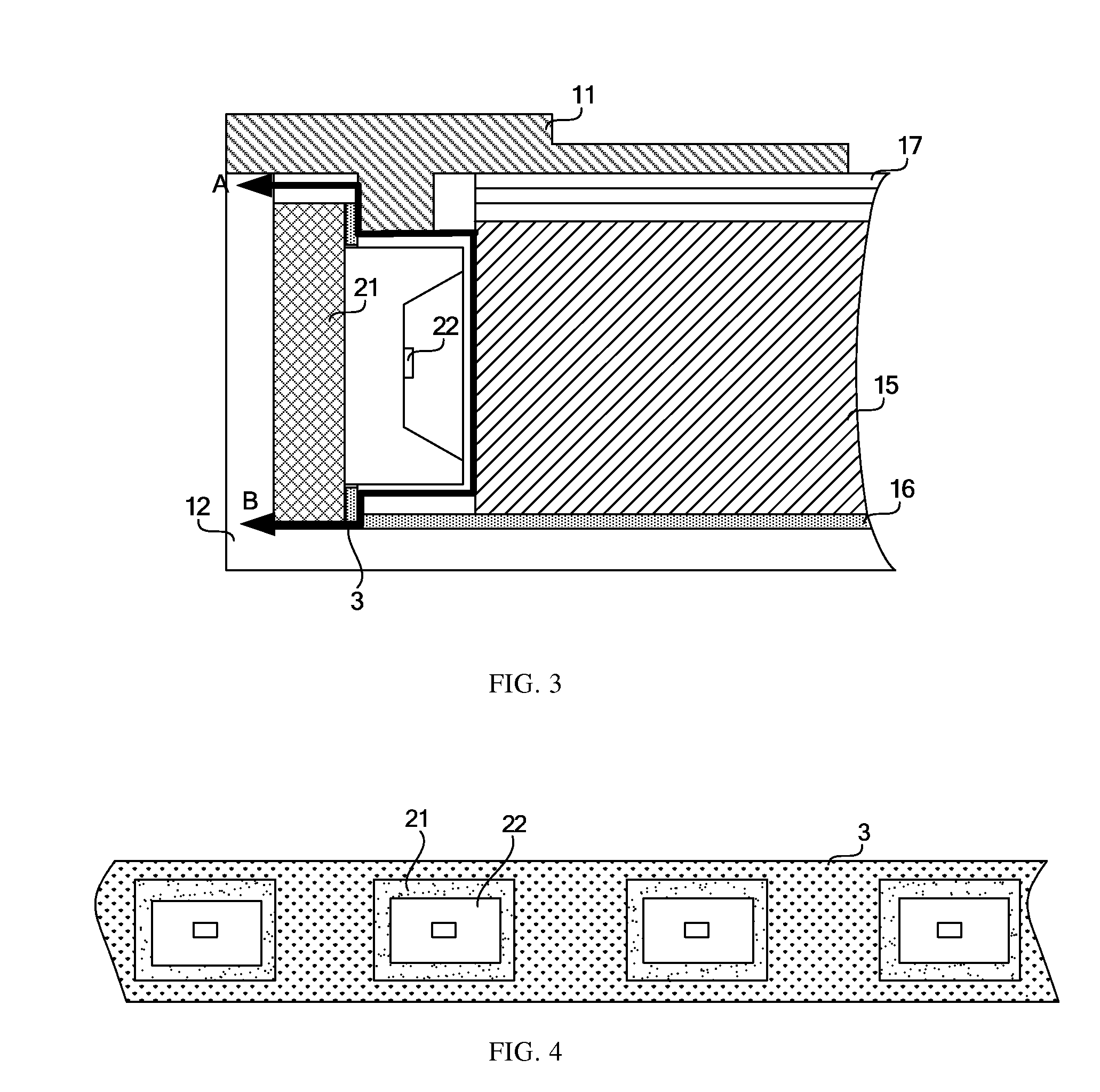

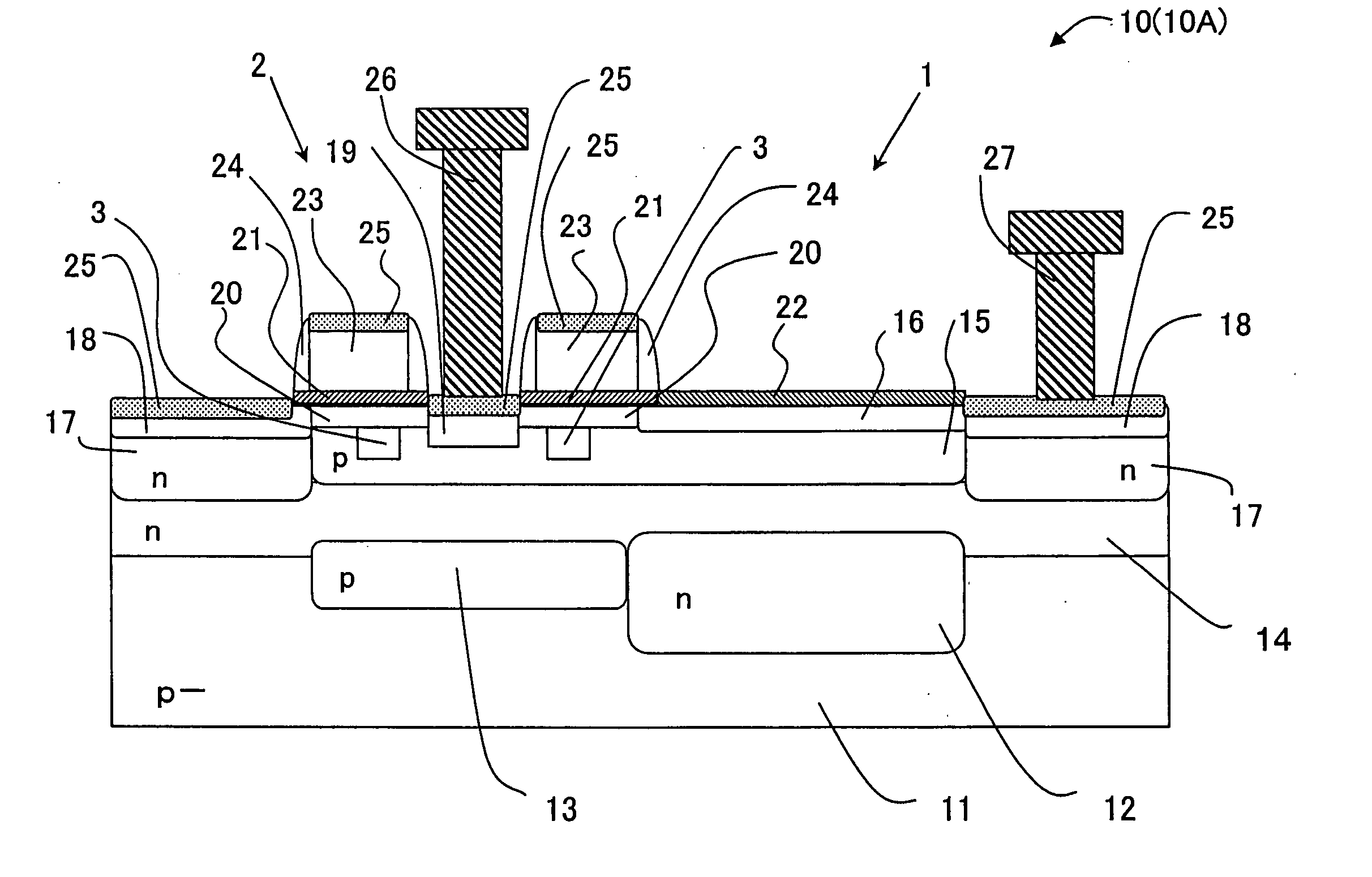

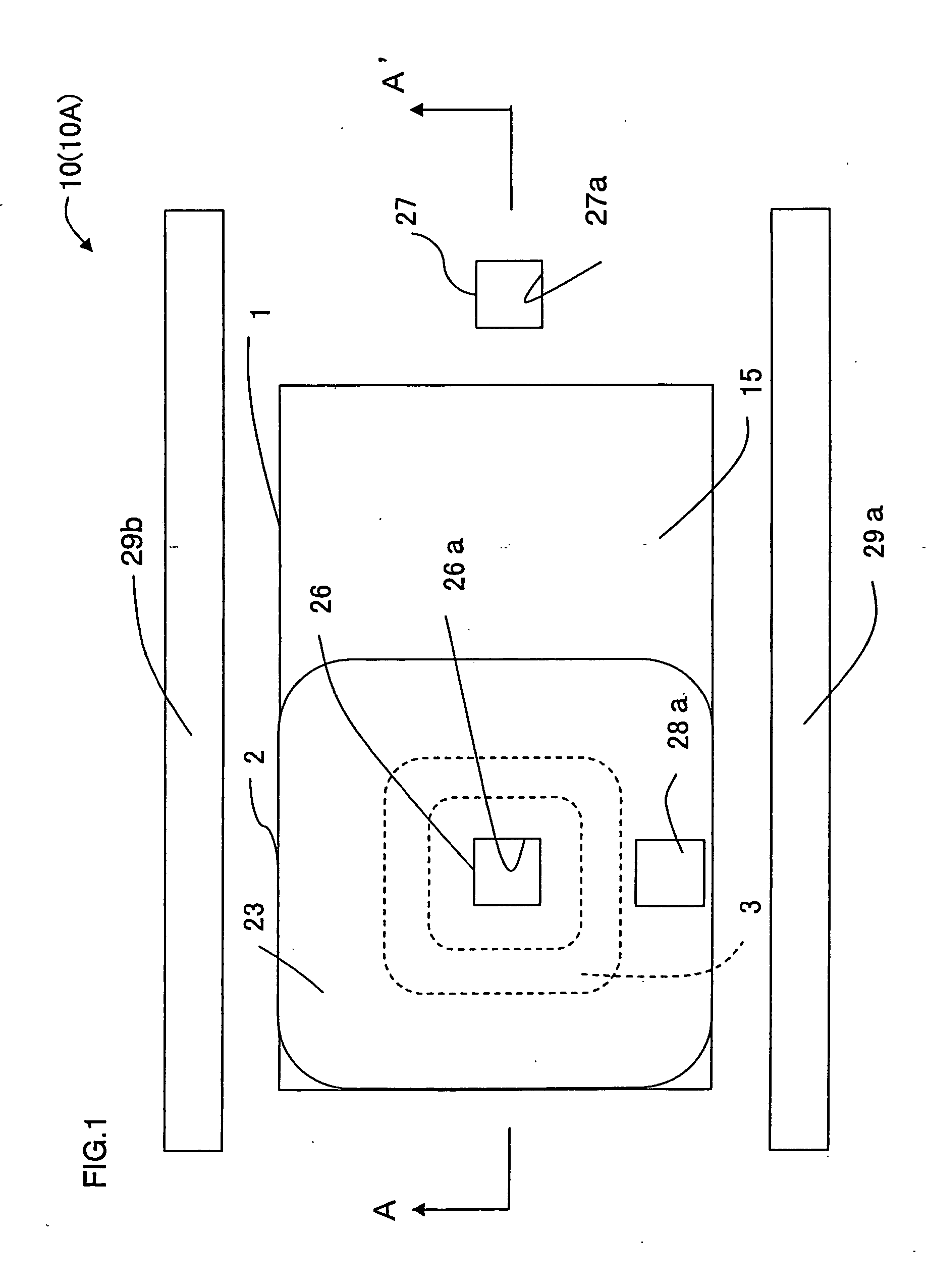

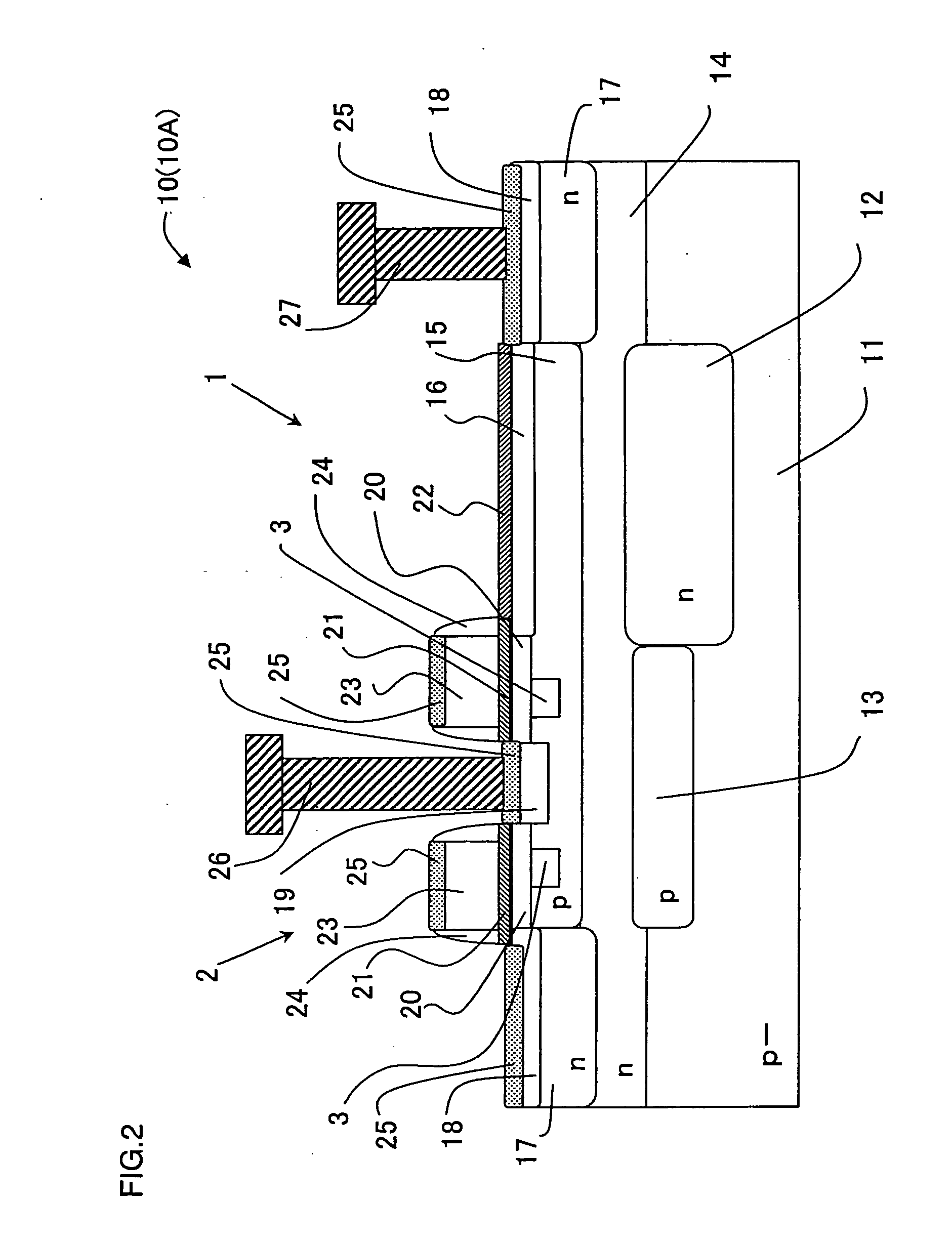

Photodiode array

ActiveUS20090256223A1High ratioImprove detection efficiencySolid-state devicesRadiation controlled devicesPhotodetectorPhotovoltaic detectors

A photodiode array 1 has a plurality of photodetector channels 10 which are formed on an n-type substrate 2 having an n-type semiconductor layer 12, with a light to be detected being incident to the plurality of photodetector channels 10. The photodiode array 1 comprises: a p−-type semiconductor layer 13 formed on the n-type semiconductor layer 12 of the substrate 2; resistors 4 each of which is provided to each of the photodetector channels 10 and is connected to a signal conductor 3 at one end thereof; and an n-type separating part 20 formed between the plurality of photodetector channels 10. The p−-type semiconductor layer 13 forms a pn junction at the interface between the substrate 2, and comprises a plurality of multiplication regions AM for avalanche multiplication of carriers produced by the incidence of the light to be detected so that each of the multiplication regions corresponds to each of the photodetector channels. The separating part 20 is formed so that each of the multiplication regions AM of the p−-type semiconductor layer 13 corresponds to each of the photodetector channels 10.

Owner:HAMAMATSU PHOTONICS KK

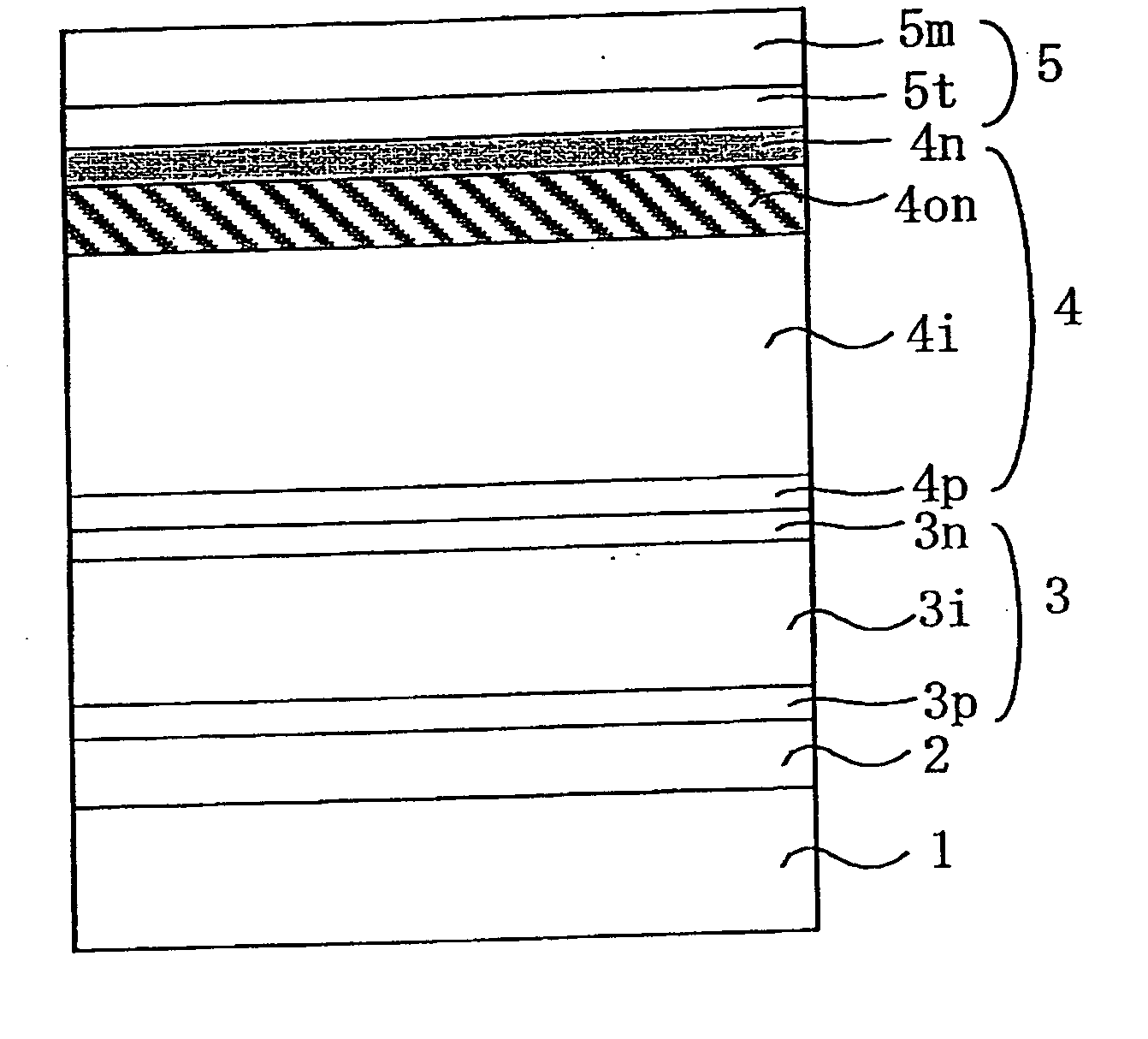

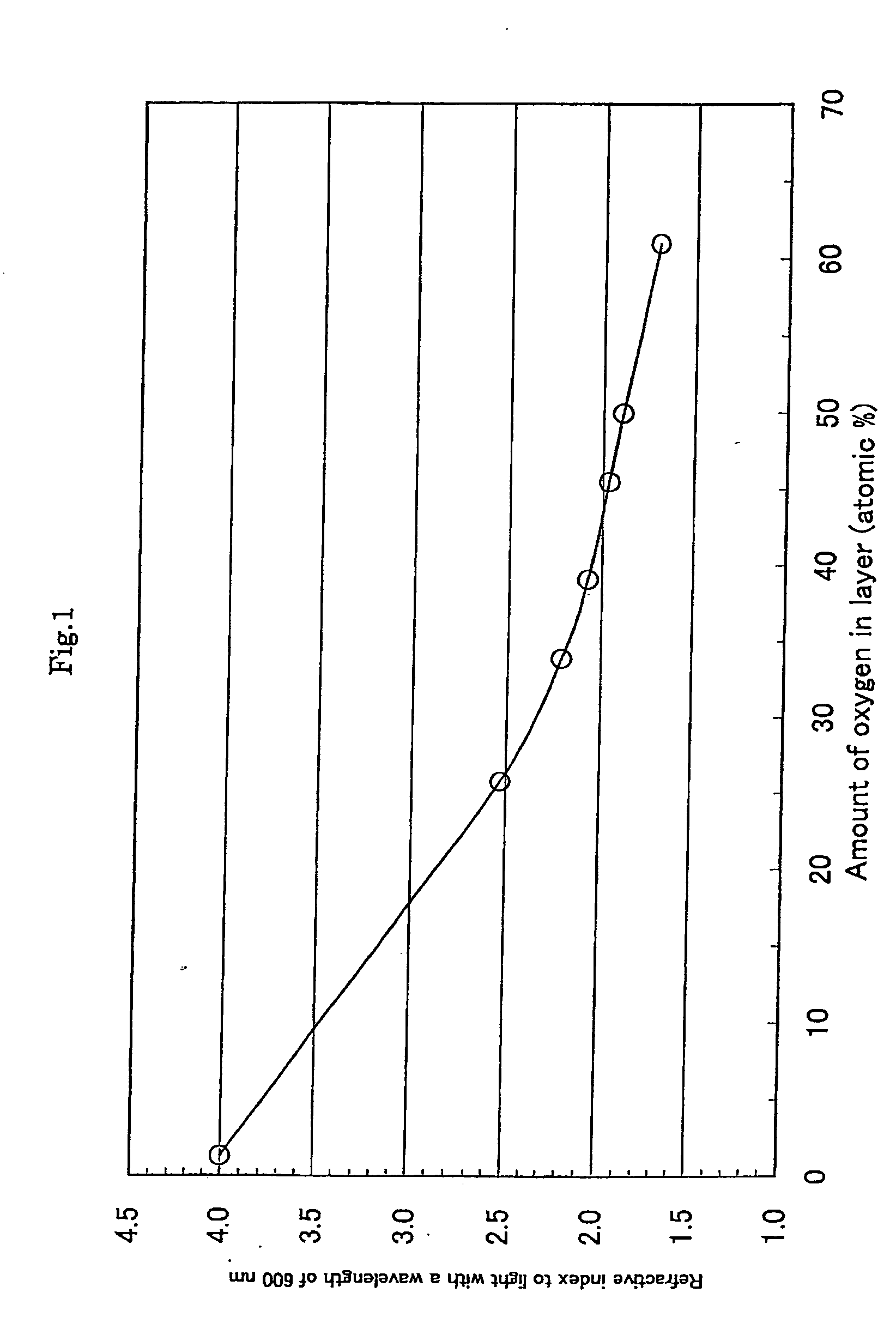

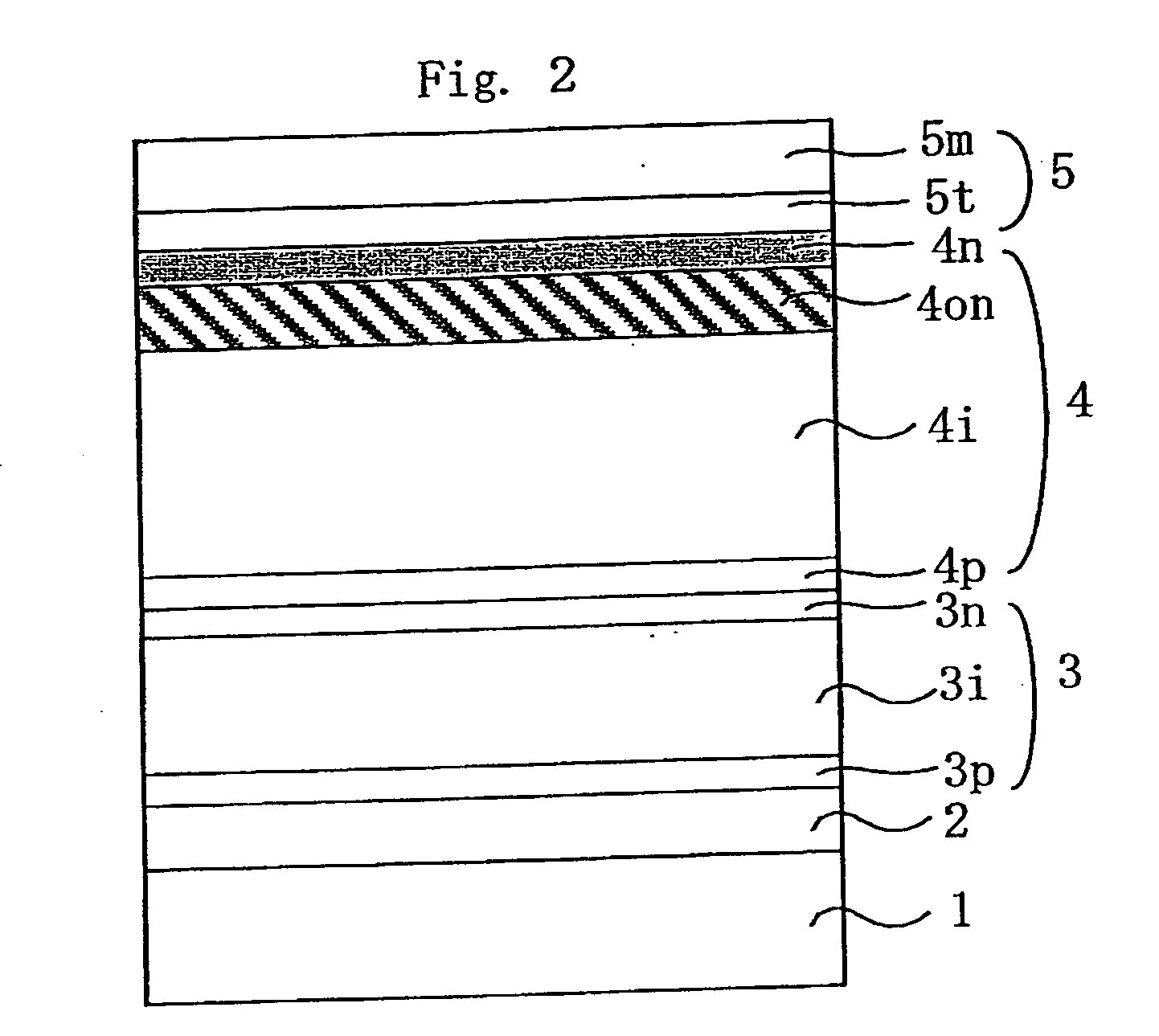

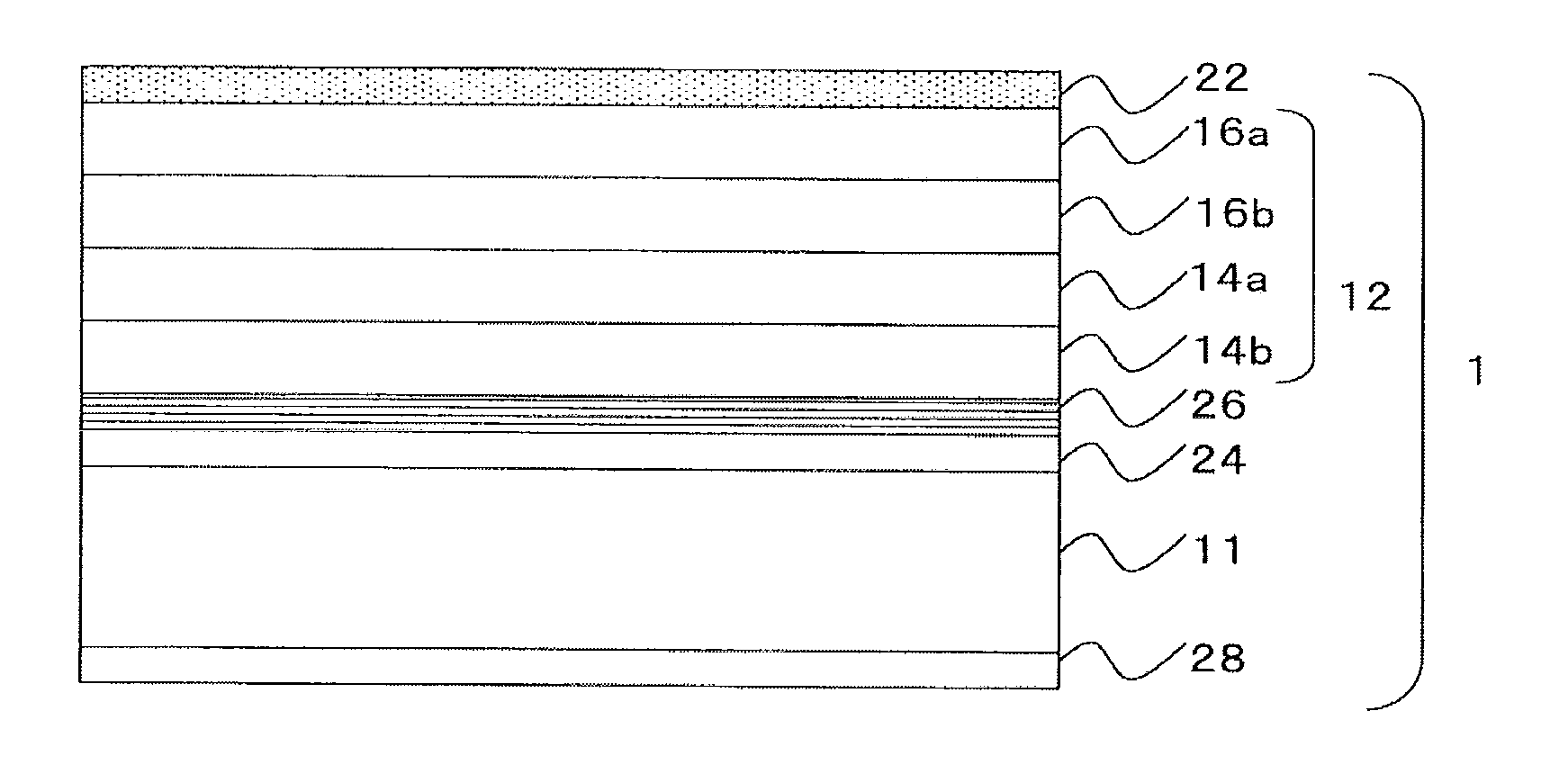

Silicon based thin film solar cell

InactiveUS20060174935A1Low costSufficient light trapping effectPhotovoltaic energy generationSemiconductor devicesElectrical resistance and conductanceTrapping

According to the present invention, sufficient light trapping effect can be exhibited and series resistance can be kept small, by sequentially forming a silicon based low refractive index layer and a thin silicon based interface layer on a backside of a photoelectric conversion layer observed from a light incident side, and as a result a silicon based thin film solar cell may be provided efficiently and at low cost.

Owner:KANEKA CORP

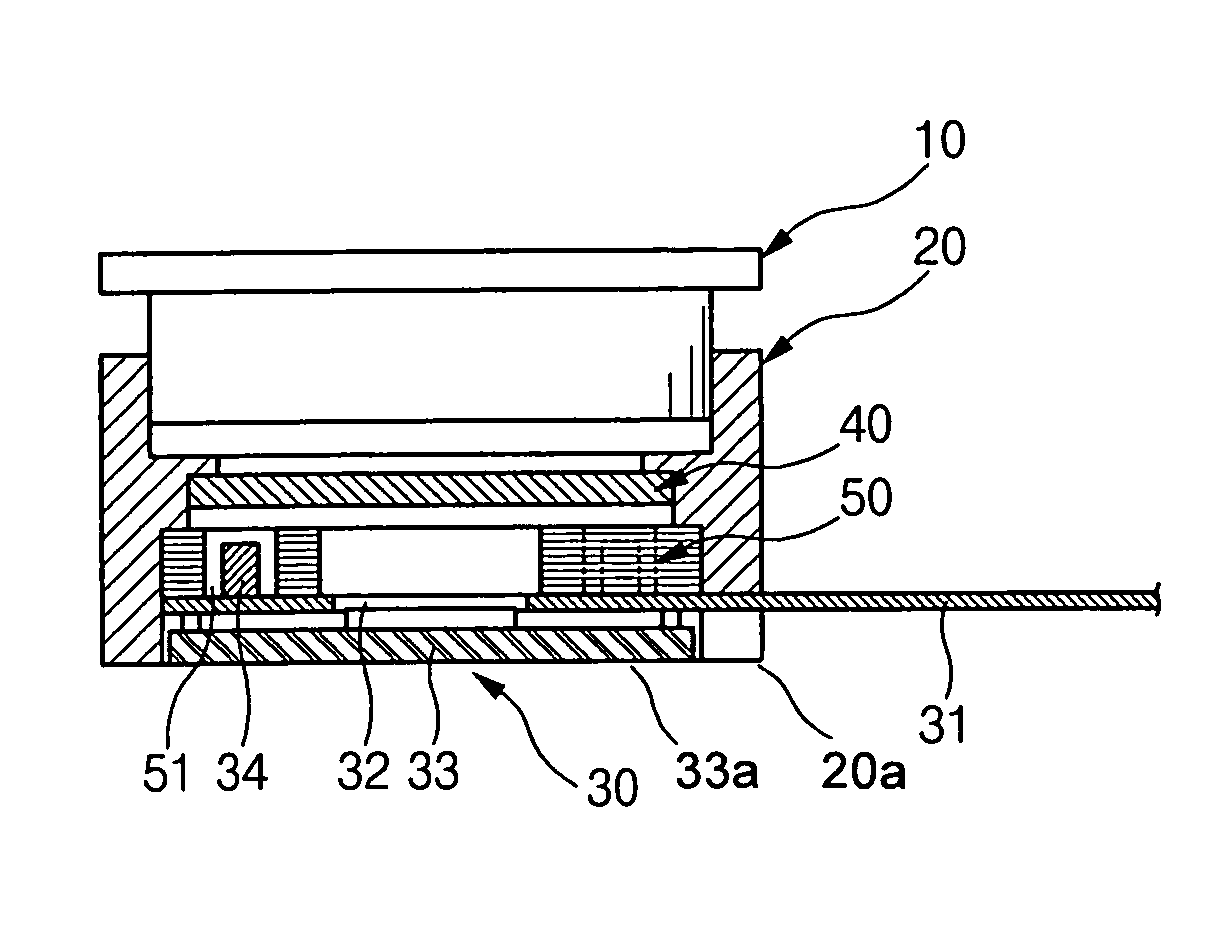

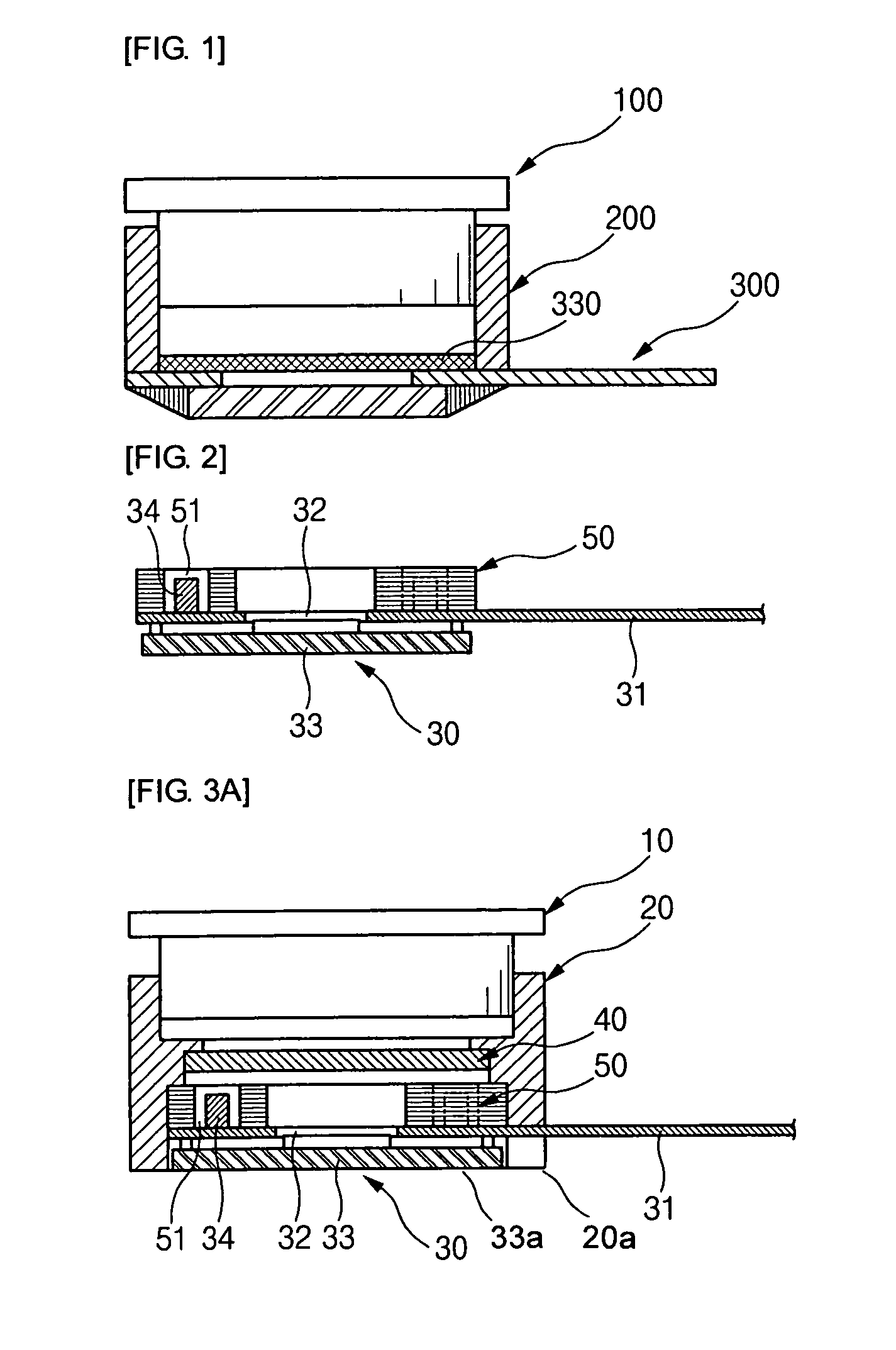

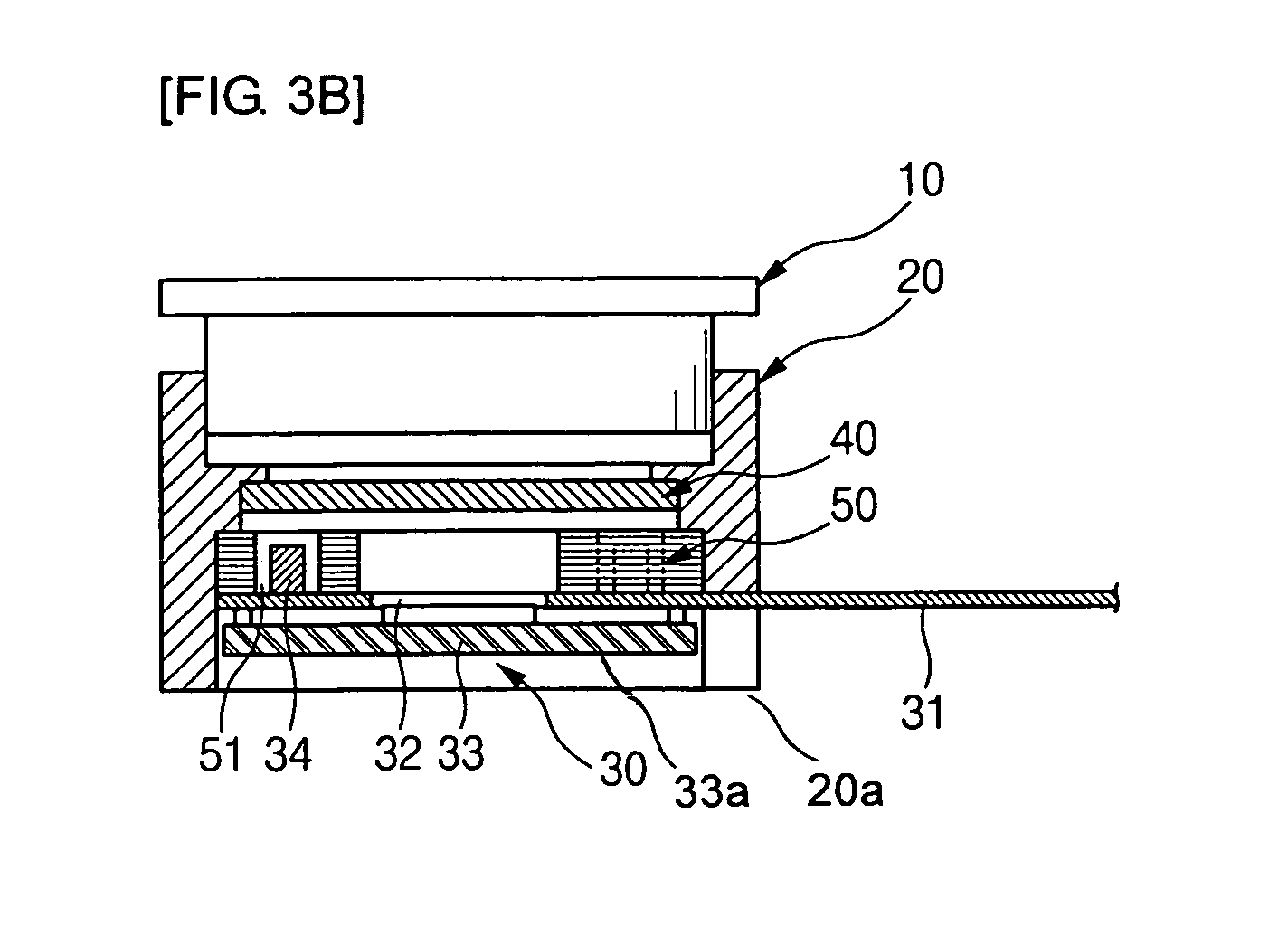

Camera module package

ActiveUS7664390B2Reliability defectOut circumference of becomes largeTelevision system detailsColor television detailsCouplingComputer module

A camera module package comprises a housing having a lens section mounted therein; a circuit board having a window through which light transmitted through the lens section of the housing passes; an image sensor that is flip-chip bonded to a lower surface of the circuit board; and an impact absorbing member attached to an upper surface of the circuit board, of which the side surface serves as a coupling guide which is coupled to an inner periphery of the housing.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

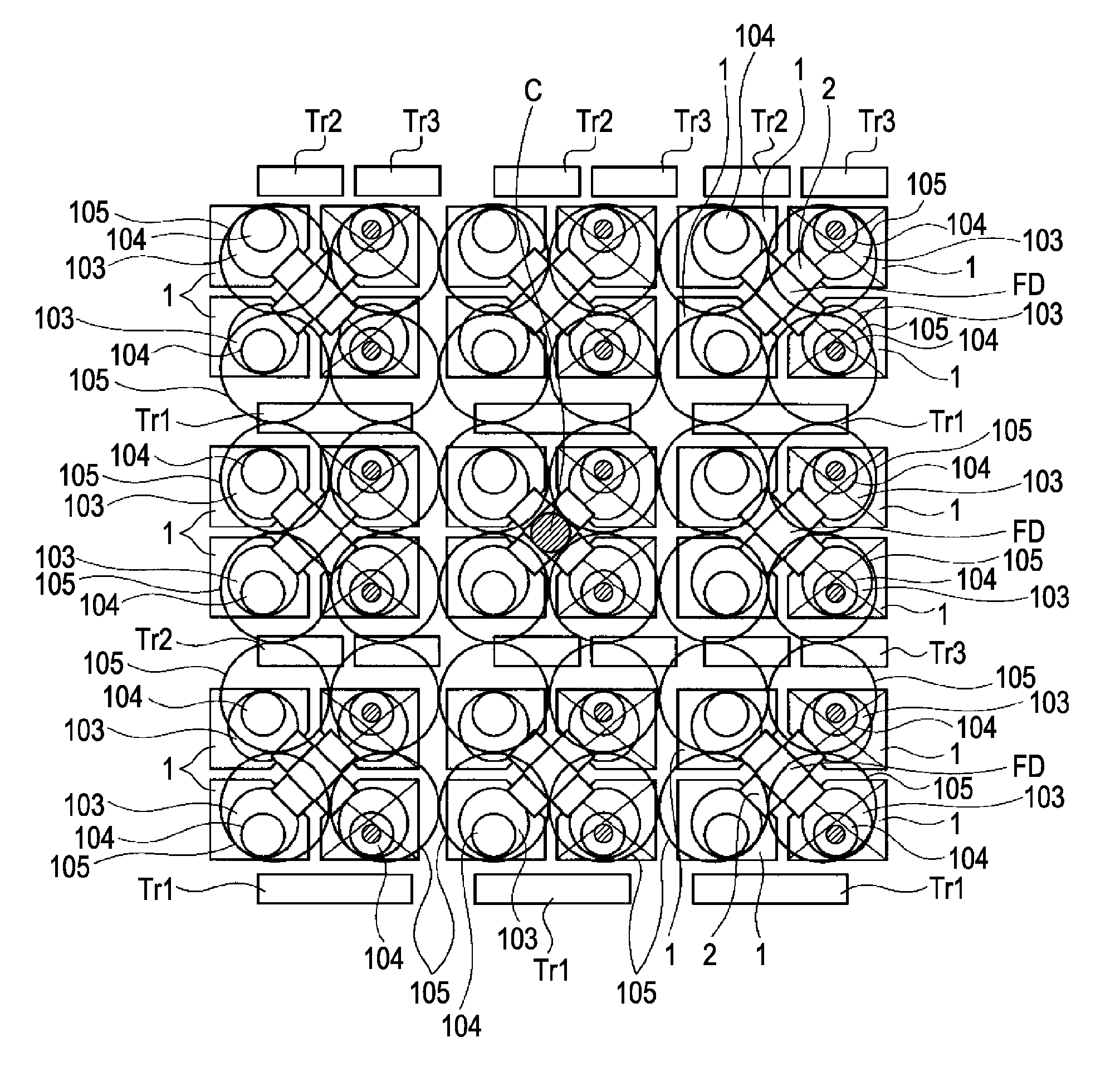

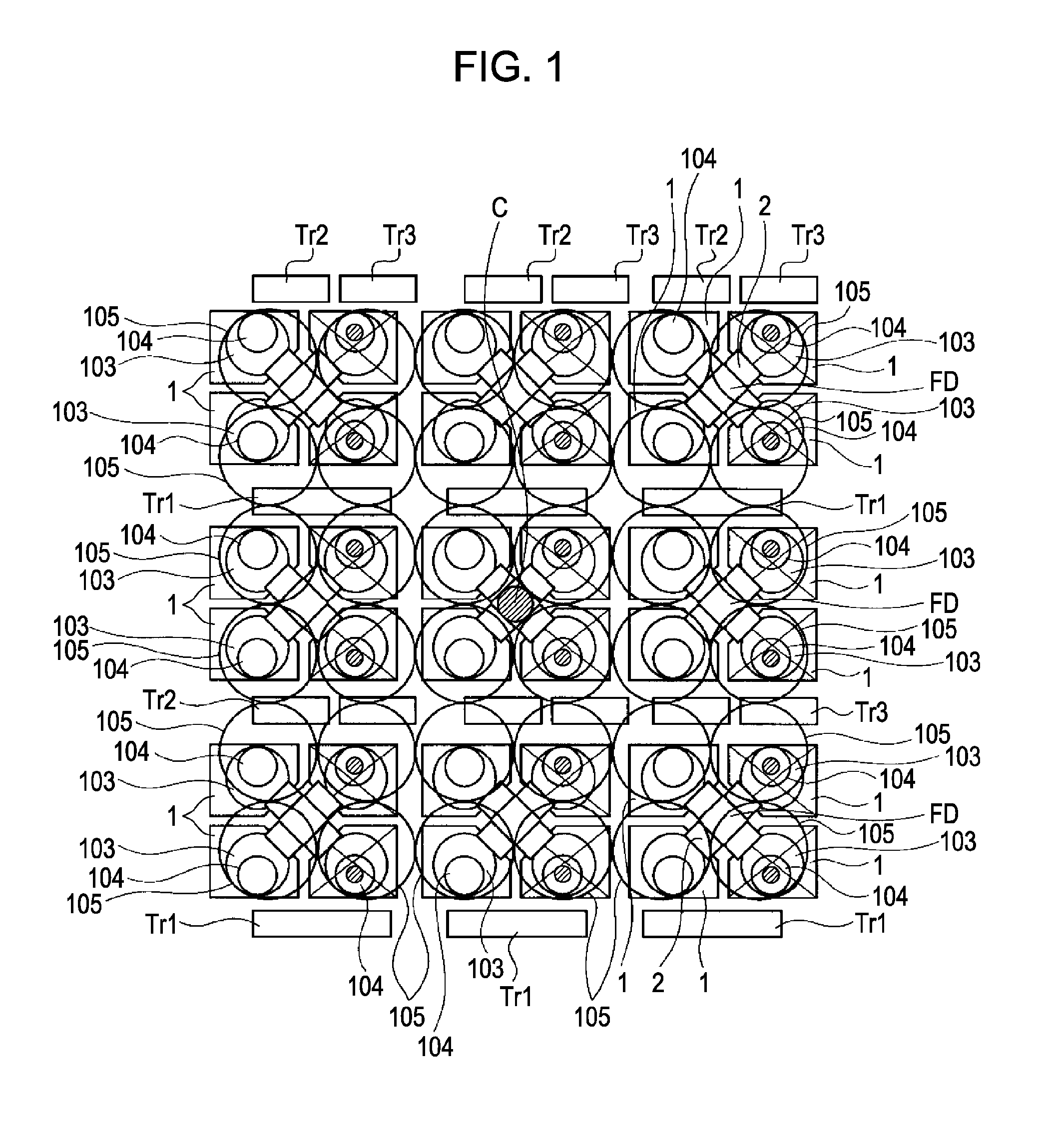

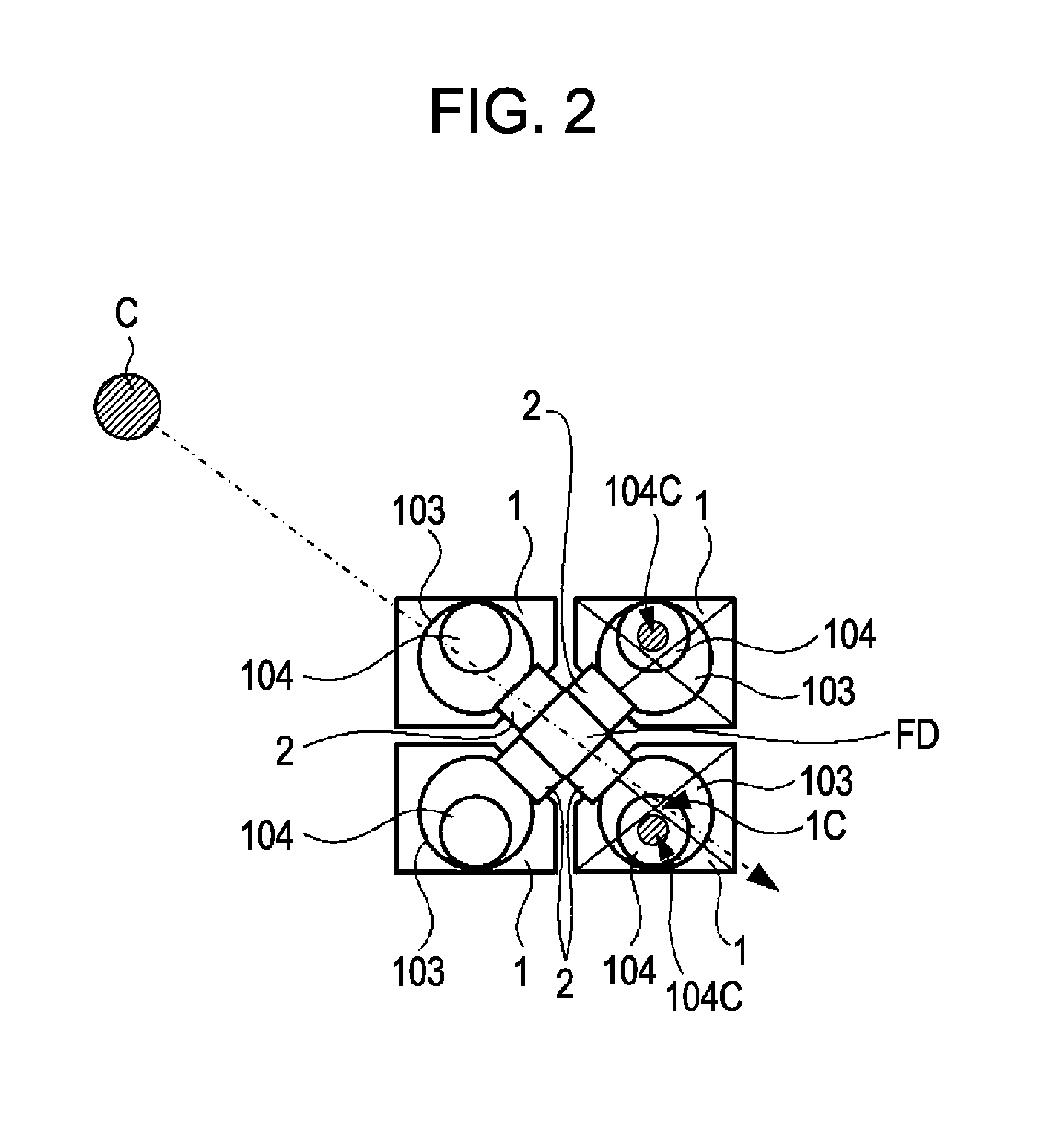

Solid-state imaging device and imaging apparatus

ActiveUS20100245648A1Avoid it happening againSimple structureTelevision system detailsTelevision system scanning detailsFloating diffusionWaveguide

An imaging device includes a basic cell having two or more the pixels that share floating diffusion. The imaging device also includes a transistor shared by the two or more pixels in the basic cell and arranged on the outside of the two or more pixels. The imaging device further includes a light receiving unit connected to the floating diffusion shared by the pixels in the basic cell through a transfer gate. In the imaging device, on-chip lenses are arranged substantially at regular intervals. Also, an optical waveguide is formed so that the position thereof in the surface of the solid-state imaging device is located at a position shifted from the center of the light receiving unit to the transistor and in the inside of the light receiving unit and the inside of the on-chip lens.

Owner:SONY SEMICON SOLUTIONS CORP

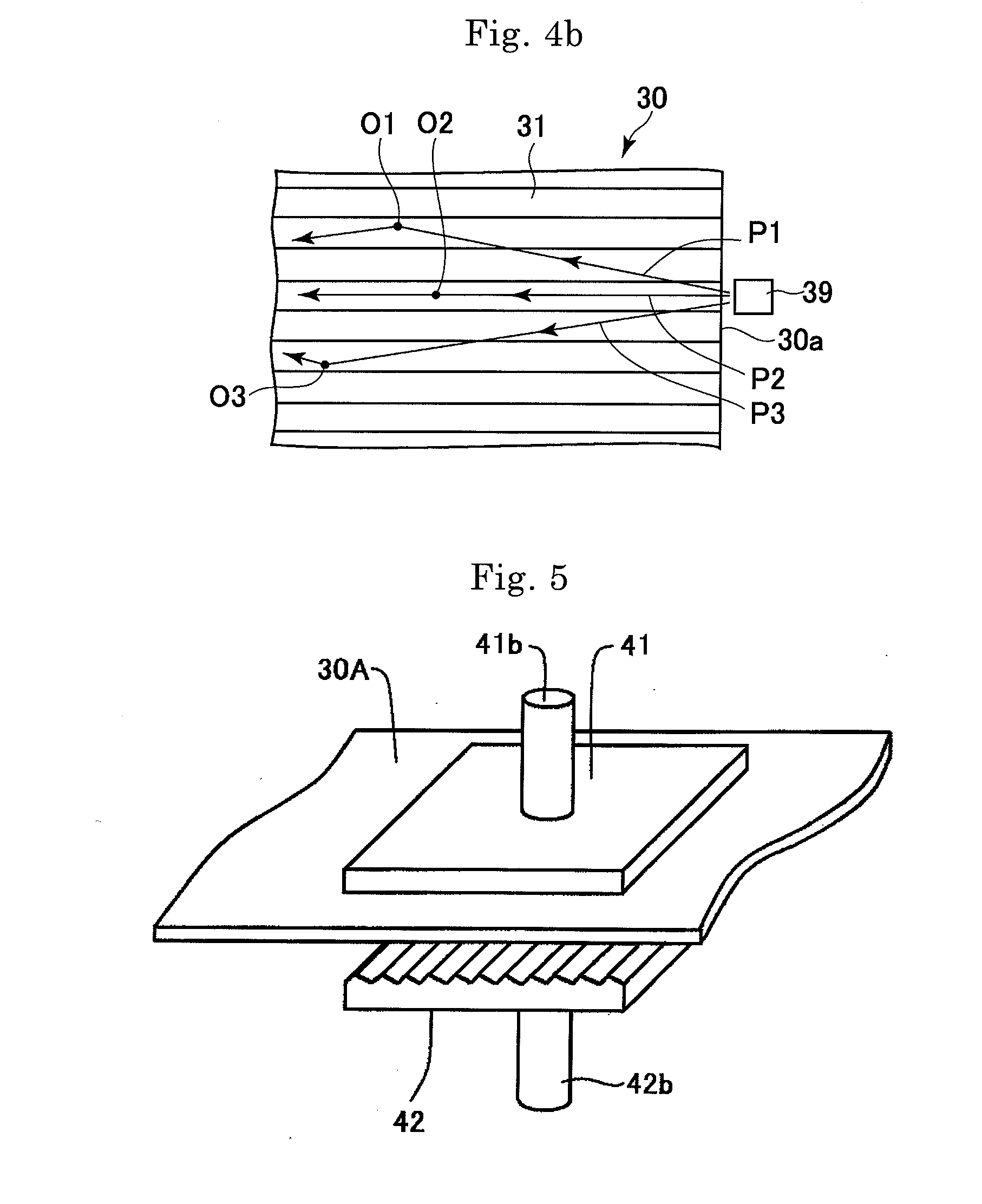

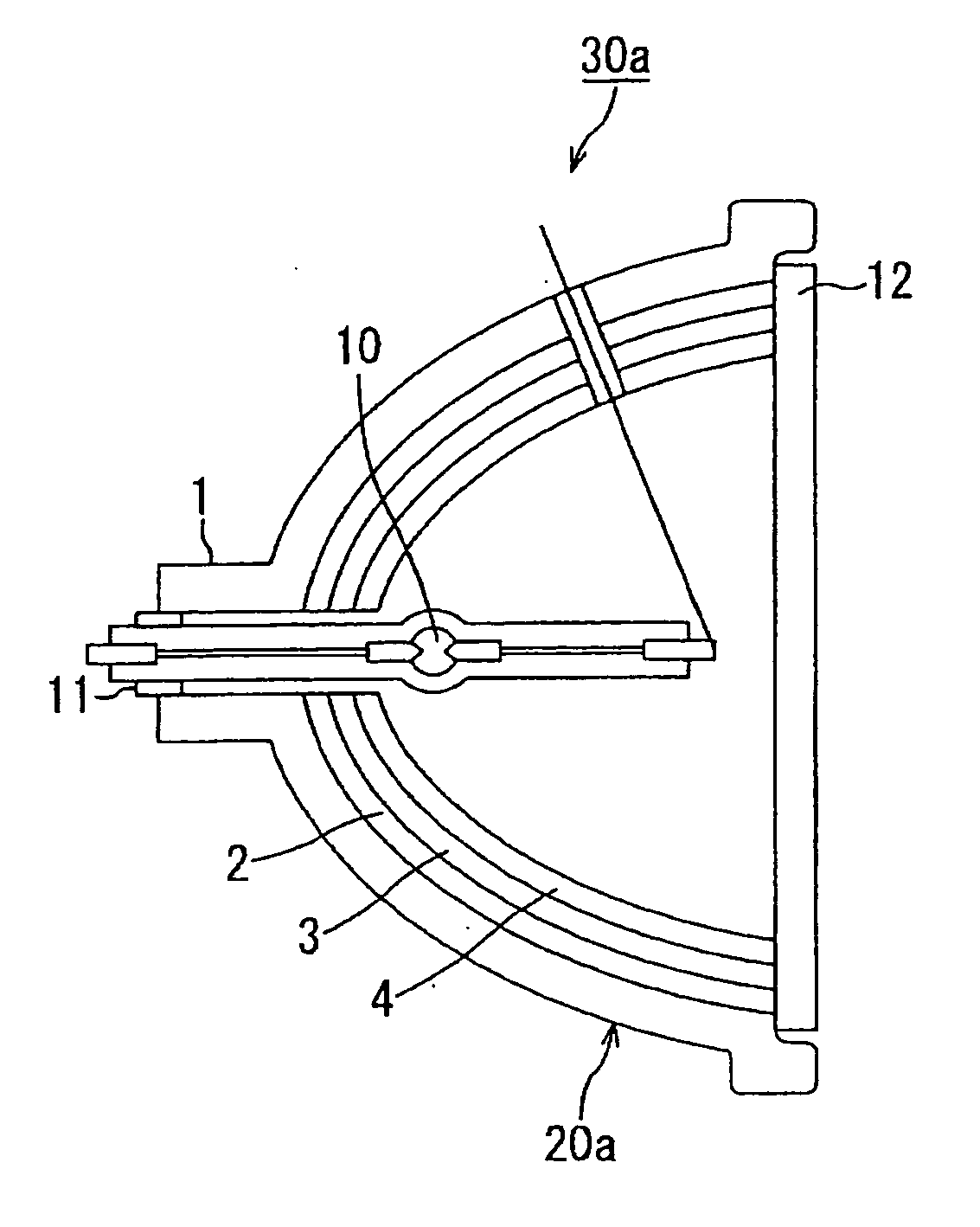

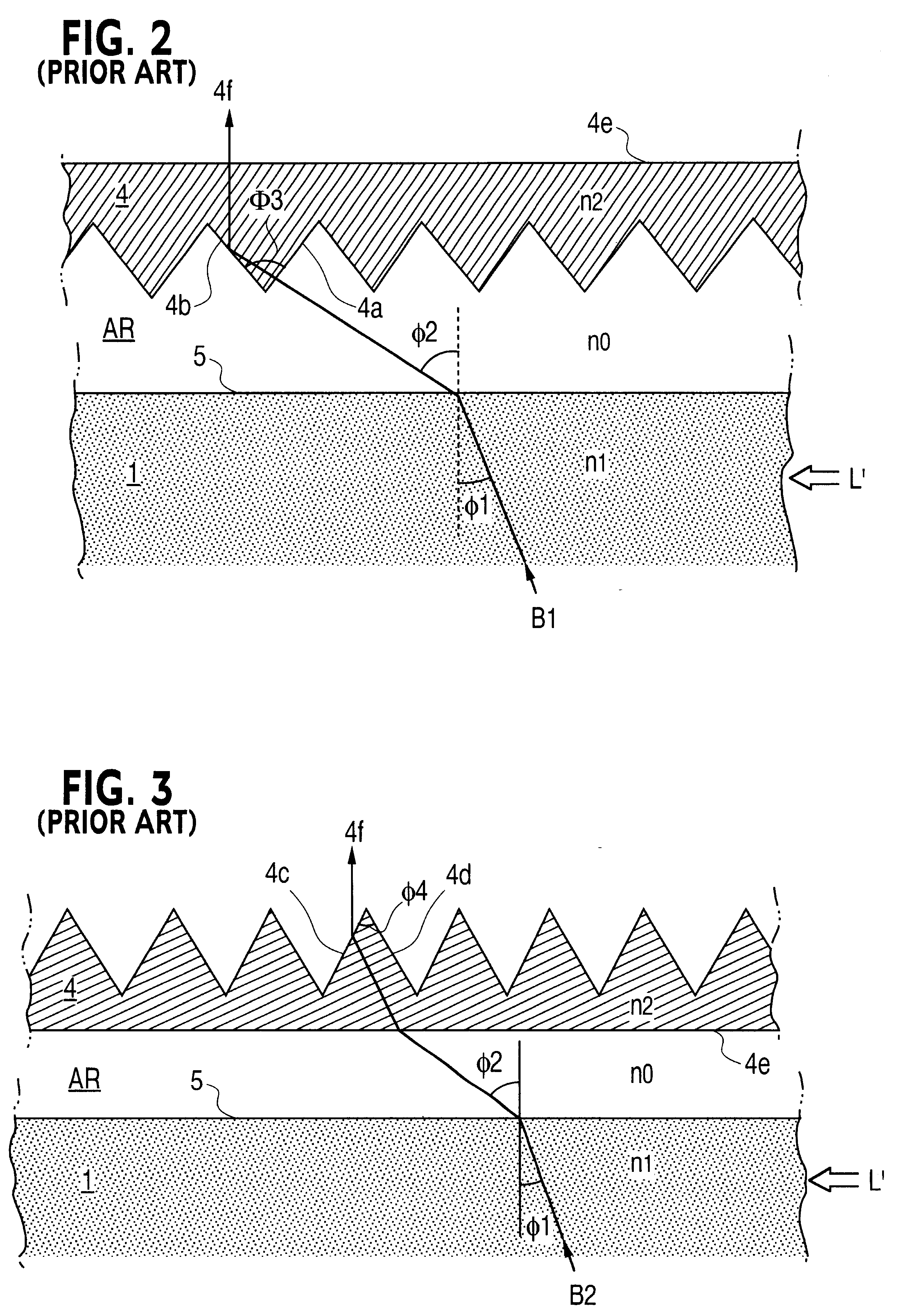

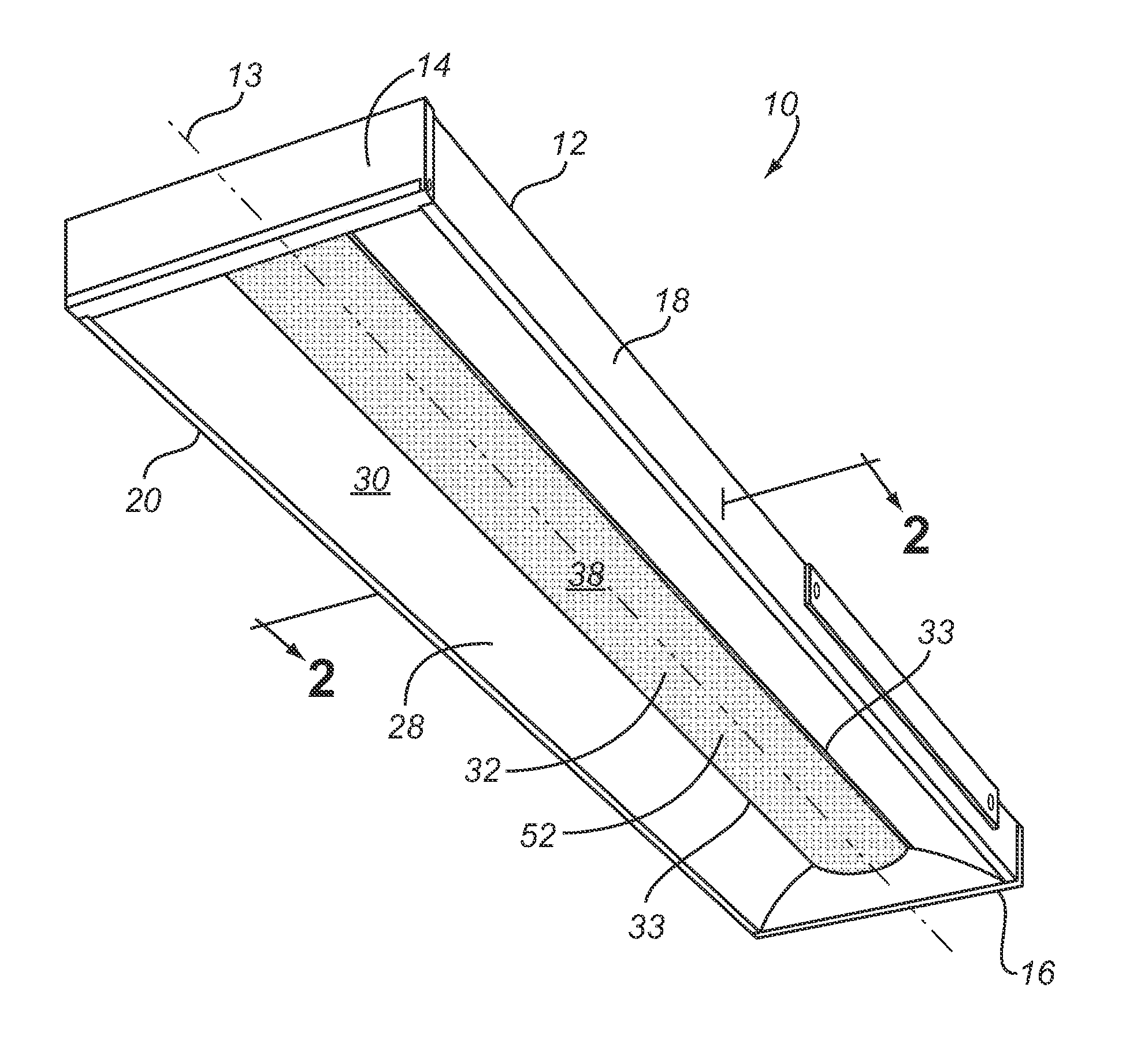

LIGHT GUIDE PLATE, METHOD OF MANUFACTURING LIGHT GUIDE PLATE AND BACKLIGHT UNIT with the LIGHT GUIDE PLATE

InactiveUS20080130317A1Efficiently mass-producedMinimize luminance unevennessMechanical apparatusOptical articlesEdge surfaceEngineering

An edge-light type light guide plate (30) is provided that has a first surface (31) and a second surface (32) that are opposed to each other, and a peripheral edge surface extending between the peripheral edges of the first and second surfaces. A part of the peripheral edge surface is defined as a light entrance plane (30a). The first surface (31) has a series of parallel elongated raised surfaces (31a) of arcuate cross-section that extend in a direction substantially normal to the light entrance plane (30a). The second surface (32) has a series of parallel elongated recessed surfaces (32a) of triangular cross-section that extend in a direction substantially normal to the elongated raised surfaces (31a) on the first surface.

Owner:CITIZEN ELECTRONICS CO LTD

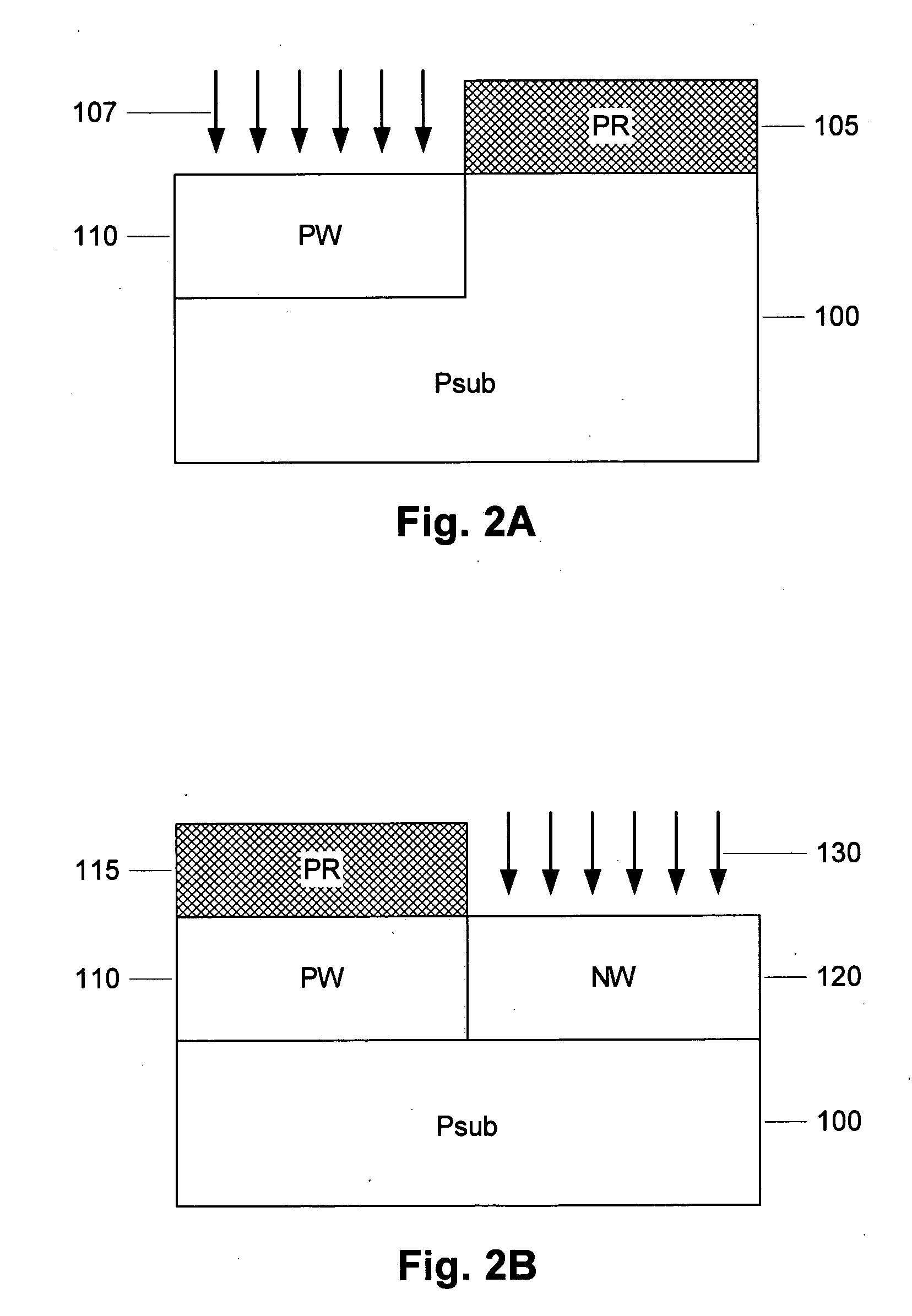

Solid-state image sensor and method for fabricating the same

InactiveUS20060086955A1Total current dropHigh sensitivityTelevision system detailsSolid-state devicesLight irradiationDepth direction

A solid-state image sensor in which a plurality of unit pixel portions, each including a light receiving area which generates electric charges by light irradiation and a transistor which outputs an electric signal in accordance with the light receiving area, are arranged in a two-dimensional array, in which: each of the unit pixel portions includes a first conductive type well region provided on a second conductive type semiconductor layer in a first conductive type substrate, a part of the first conductive type well region and a second conductive type semiconductor layer region laminated on a part of the first conductive type well region form the light receiving area; electric charge storage area for storing electric charges generated in the light receiving area is provided in the first conductive type well region to read out an electric signal in accordance with an amount of electric charges stored in the electric charge storage area from the transistor; and the second conductive type semiconductor layer region has a maximum impurity concentration portion in the depth direction of the first conductive type substrate is at a surface of the first conductive type substrate.

Owner:SHARP KK

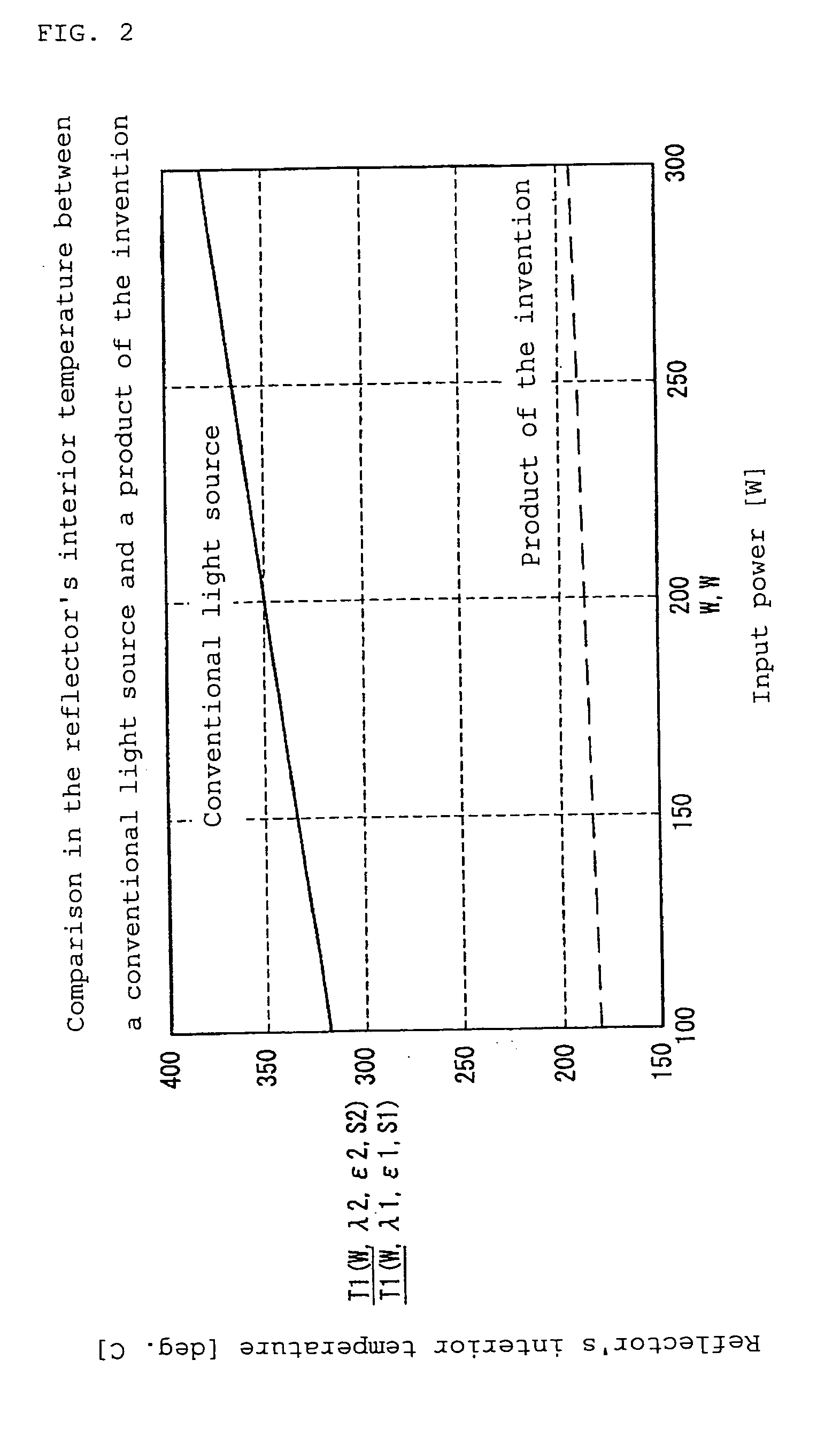

Reflector, light source device and projection display apparatus

InactiveUS20070041197A1Efficiently convertSuppress deformationMirrorsPoint-like light sourceAnodic oxidationThermal conductivity

A concave mirror substance 1 constituting a reflector is composed of a base material having a high thermal conductivity such as aluminum etc. An infrared-to-heat converting layer 2 is film-formed by anodizing the substrate formed of aluminum etc., so as to absorb light in a wavelength range which passes through a visible light reflecting layer 4 and convert it into heat. A gloss-forming buffer layer 3 is film-formed by calcining Si resin or polyimide resin over the inner side (the light source-side surface) of infrared-to-heat converting layer 2 at high temperatures, so as to buffer the two layers in a manner that does not allow infrared-to-heat converting layer 2 and visible light reflecting layer 4 to be in direct contact with each other, and so as to reduce the influence of projections and indentations present on infrared-to-heat converting layer 2 and smoothen the light source-side surface of visible light reflecting layer 4. In this way, it is possible to suppress performance degradation by efficient discharge of heat by converting light into heat and by alleviating thermal stress and strain due to the difference in expansion coefficient between components, and it is also possible to achieve reduction in cost, miniaturization and weight reduction.

Owner:SHARP KK

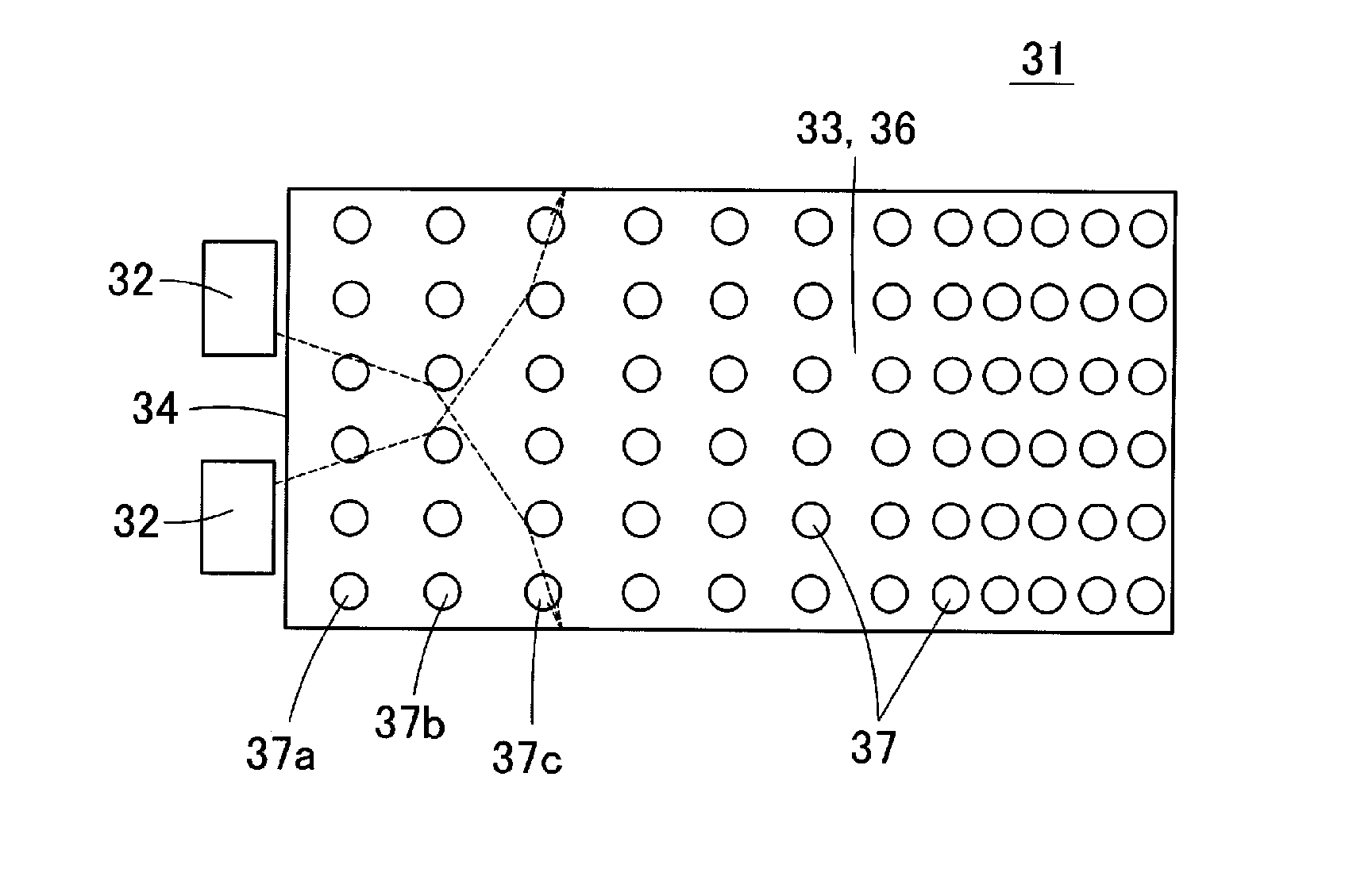

Photodiode array

ActiveUS8008741B2Improve detection efficiencyRaise the ratioSolid-state devicesRadiation controlled devicesPhotovoltaic detectorsPhotodetector

A photodiode array 1 has a plurality of photodetector channels 10 which are formed on an n-type substrate 2 having an n-type semiconductor layer 12, with a light to be detected being incident to the plurality of photodetector channels 10. The photodiode array 1 comprises: a p−-type semiconductor layer 13 formed on the n-type semiconductor layer 12 of the substrate 2; resistors 4 each of which is provided to each of the photodetector channels 10 and is connected to a signal conductor 3 at one end thereof; and an n-type separating part 20 formed between the plurality of photodetector channels 10. The p−-type semiconductor layer 13 forms a pn junction at the interface between the substrate 2, and comprises a plurality of multiplication regions AM for avalanche multiplication of carriers produced by the incidence of the light to be detected so that each of the multiplication regions corresponds to each of the photodetector channels. The separating part 20 is formed so that each of the multiplication regions AM of the p−-type semiconductor layer 13 corresponds to each of the photodetector channels 10.

Owner:HAMAMATSU PHOTONICS KK

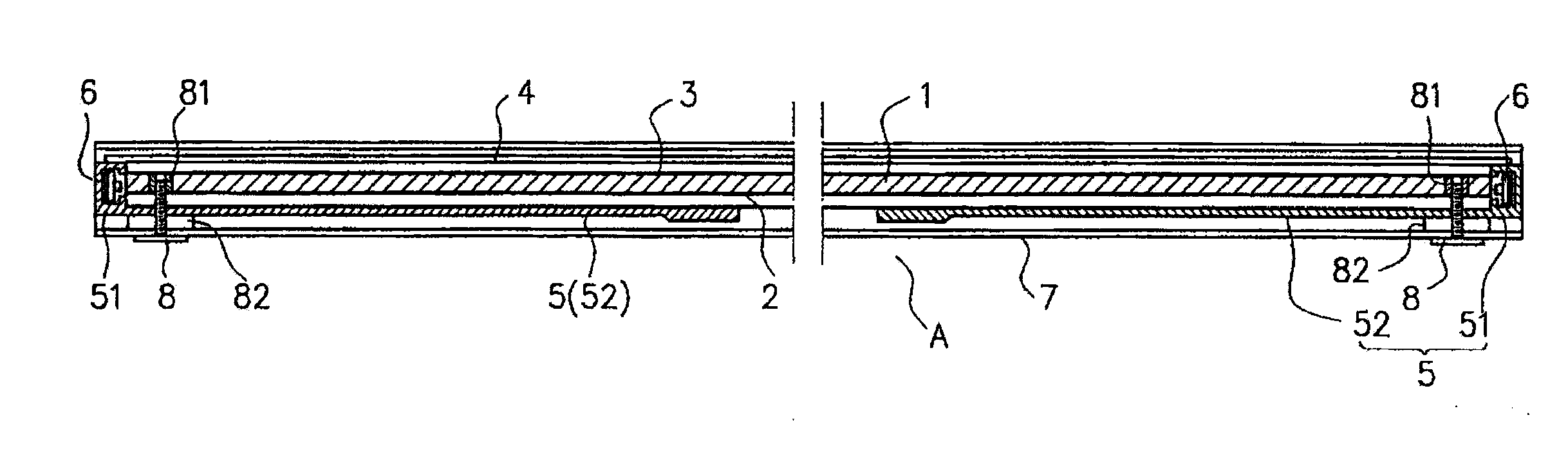

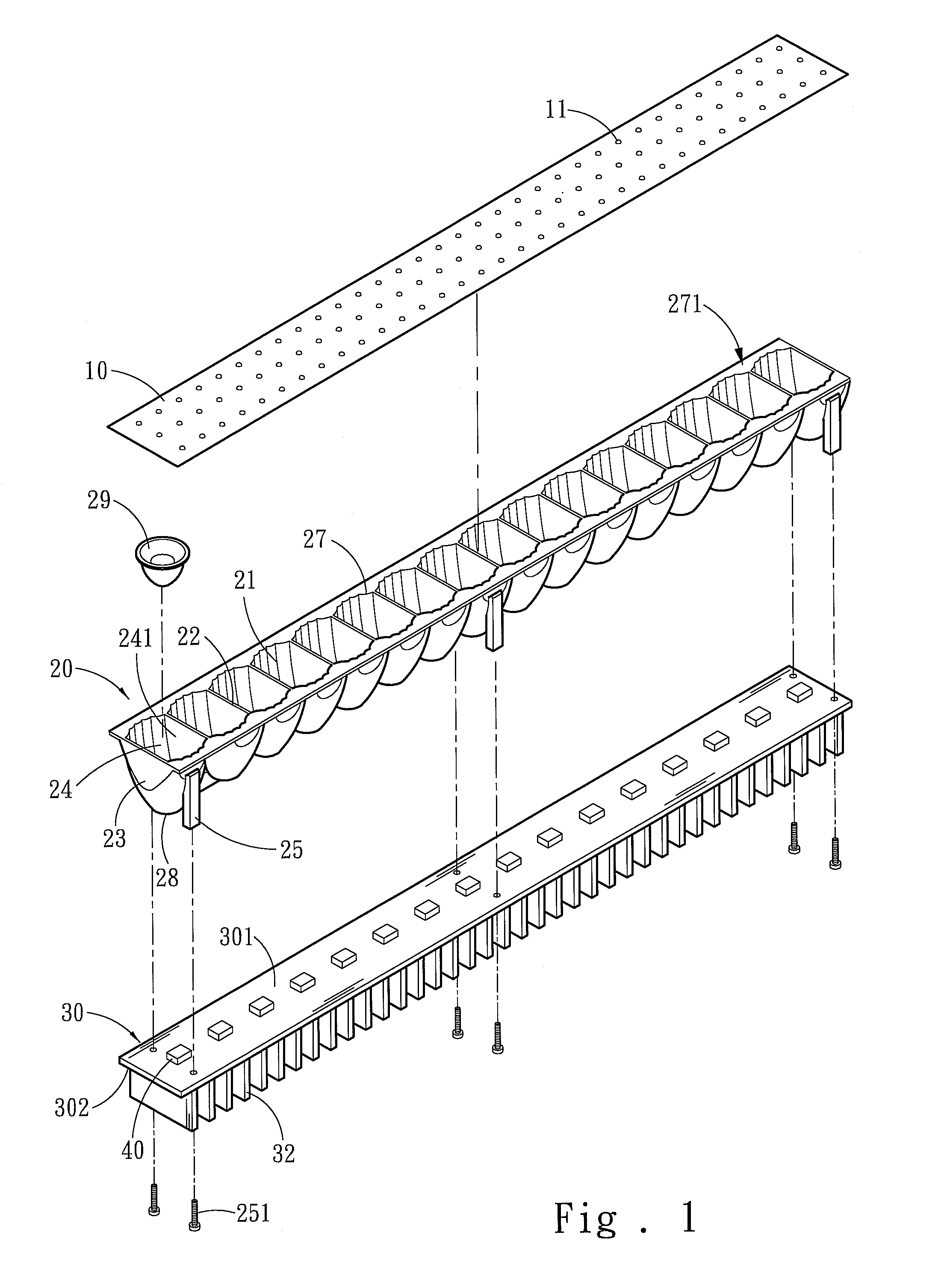

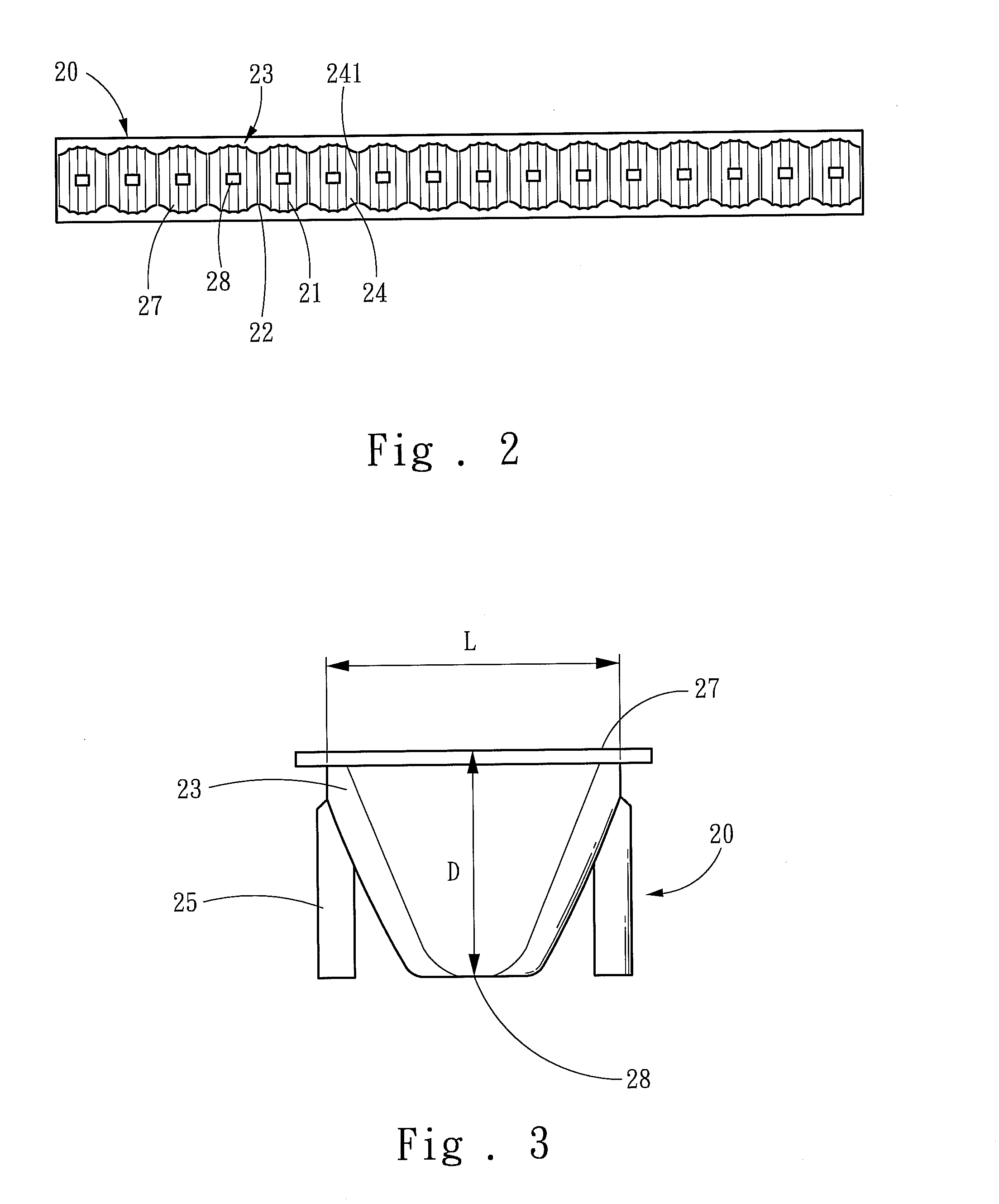

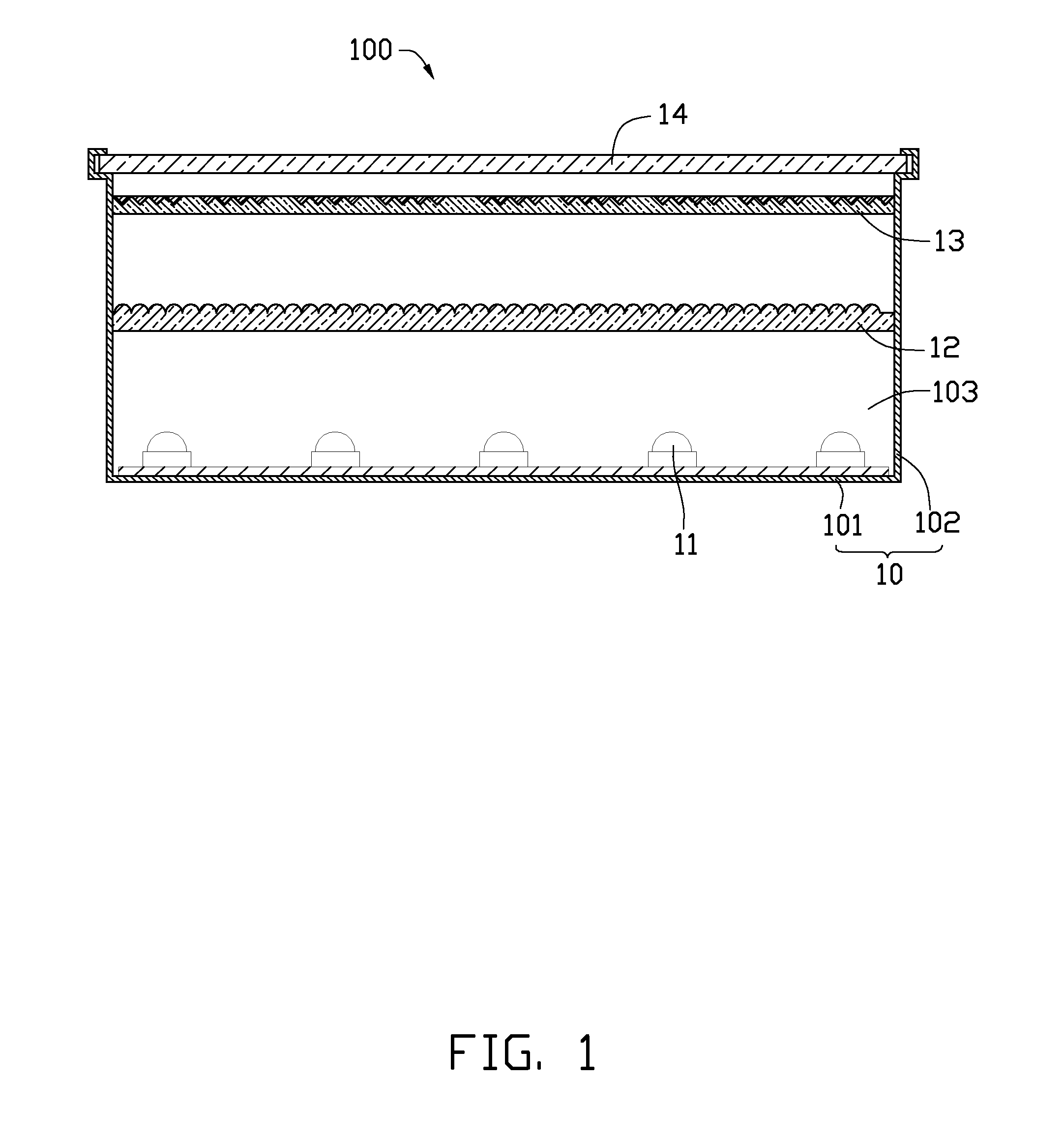

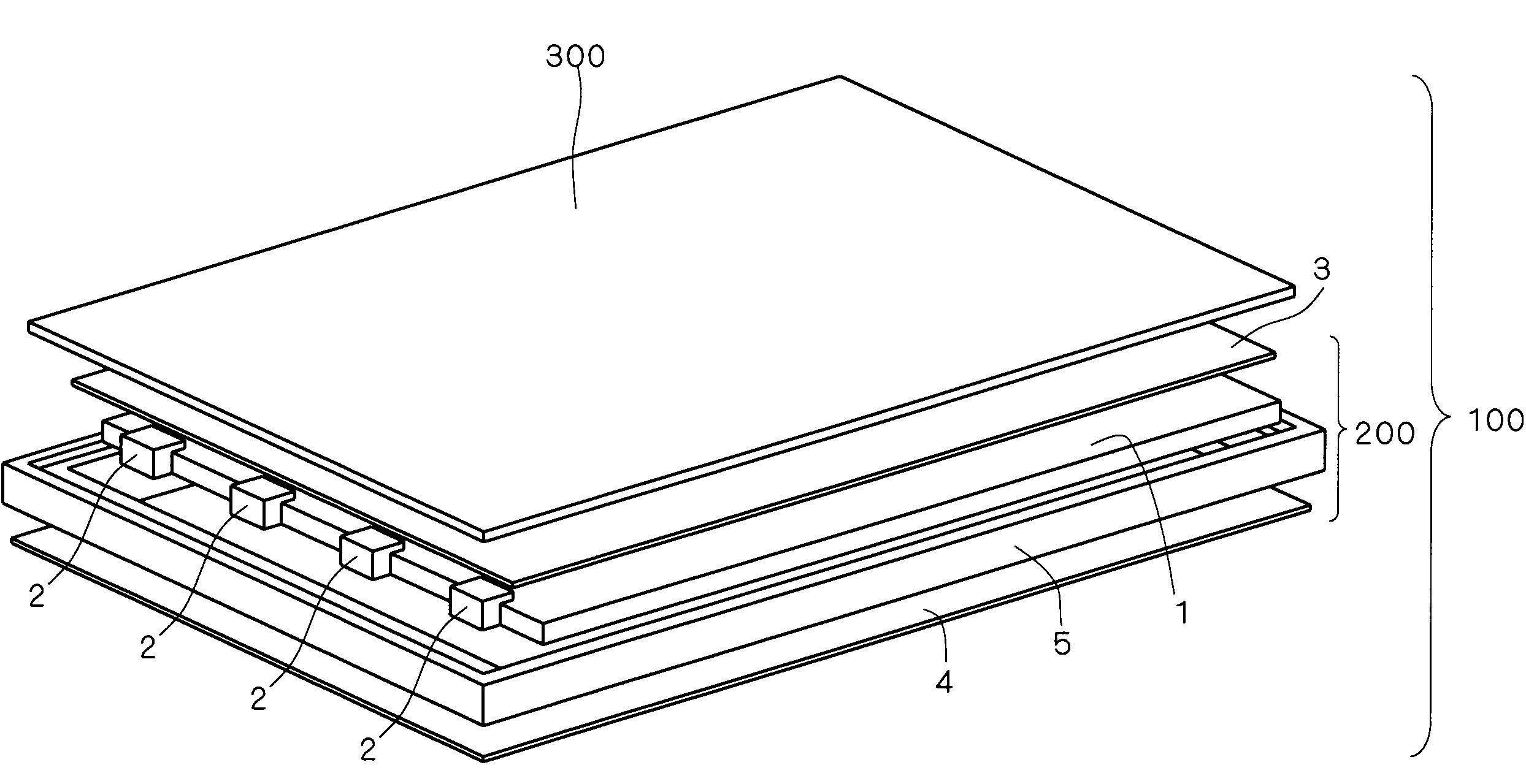

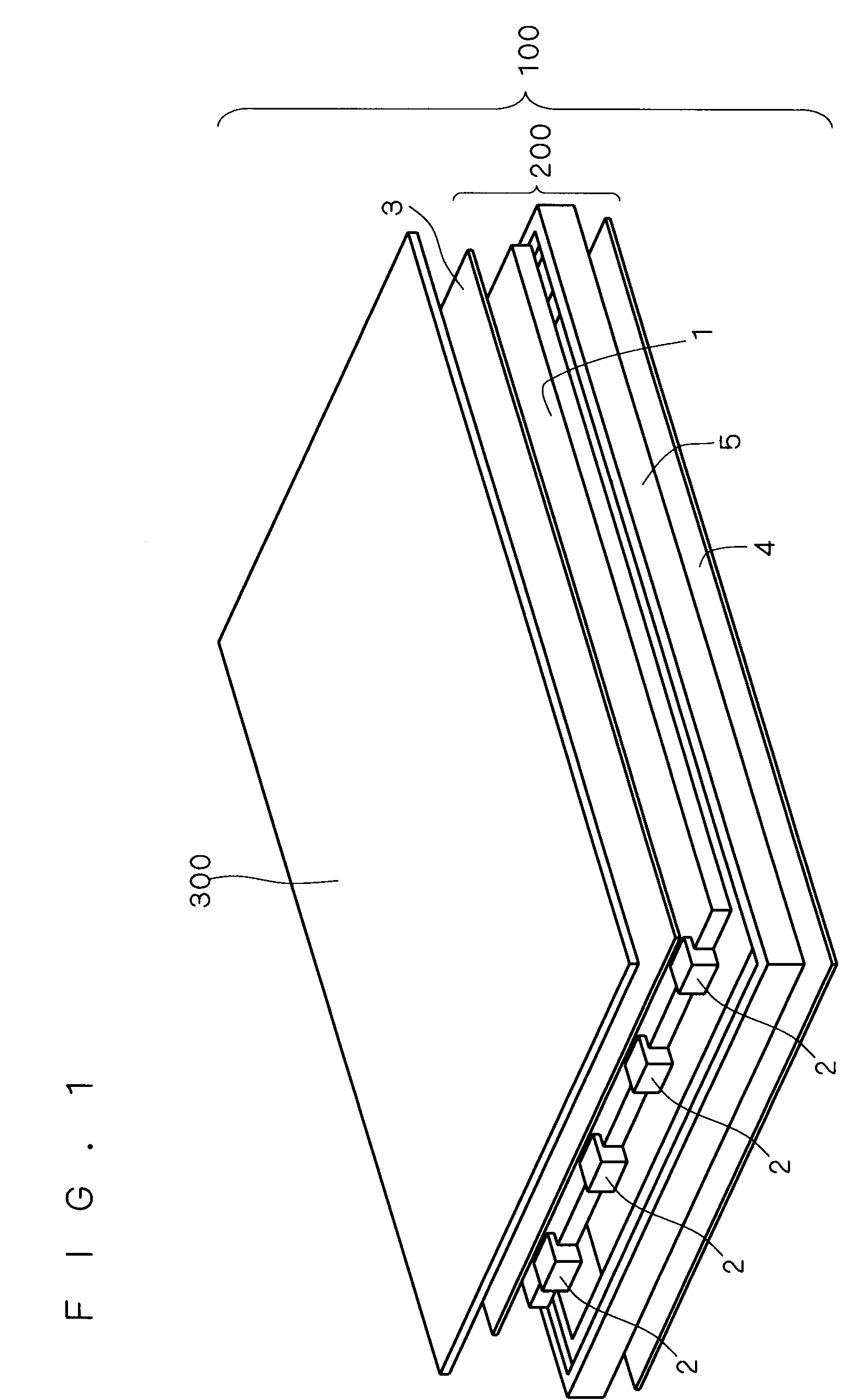

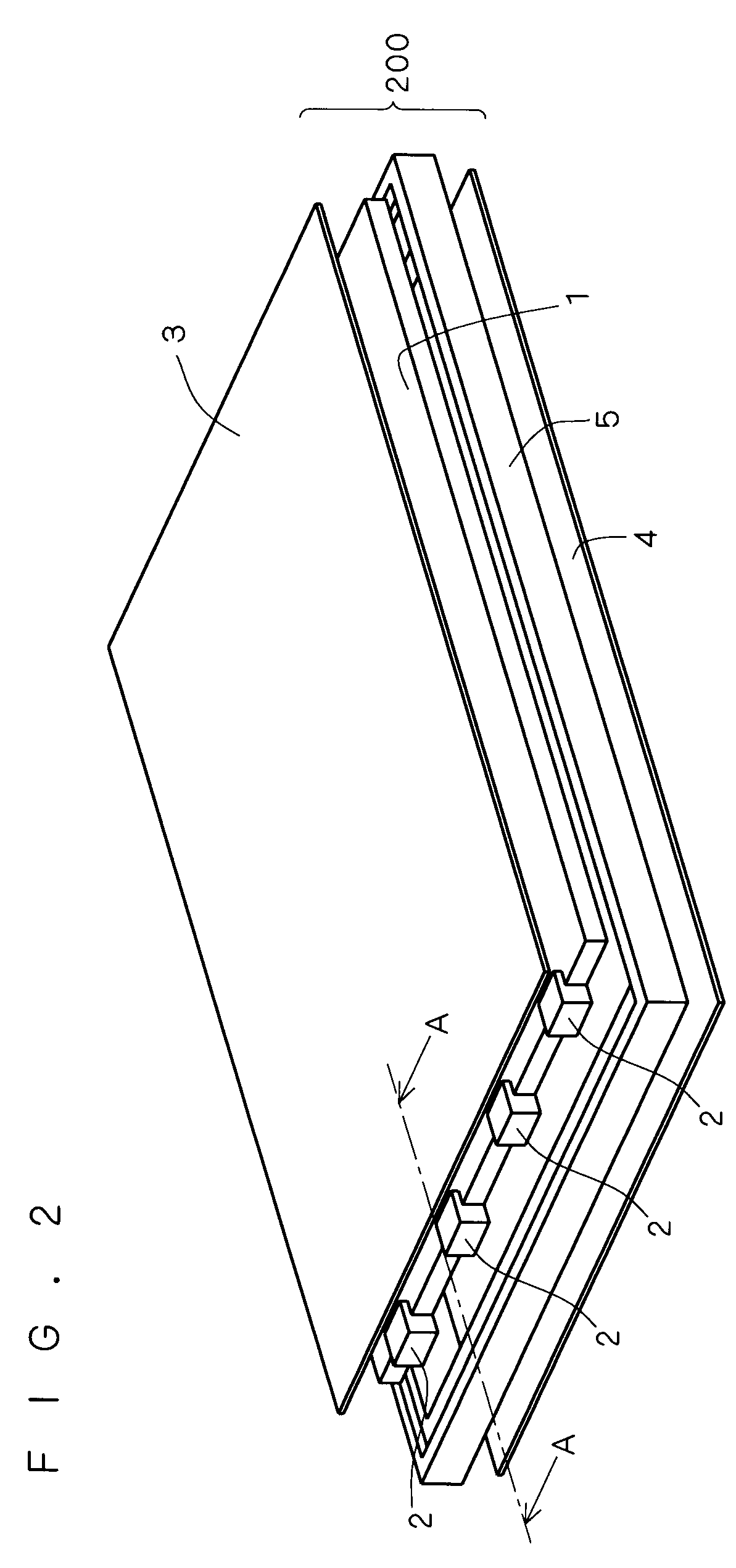

Surface Light Source Assembly

InactiveUS20120092890A1Easy constructionAvoid lightPlanar light sourcesMechanical apparatusLight guideEngineering

A surface light source assembly is disclosed. The surface light source assembly includes a light guide plate, a reflective sheet, a light diffuser sheet and a transparent cover arranged in front of the light diffuser sheet, an insert-nut embedded in the light guide plate, and a supporting frame having a vertical plate and a screw movable hole arranged on the vertical plate. In the insert-nut, a screw is screwed from an end holding frame overlapped on both ends of the supporting frame and arranged in both ends of the light guide plate via the screw movable hole. The screw can be moved in the screw movable hole depending on a heat expansion and contraction of the light guide plate.

Owner:MEITAKU IND

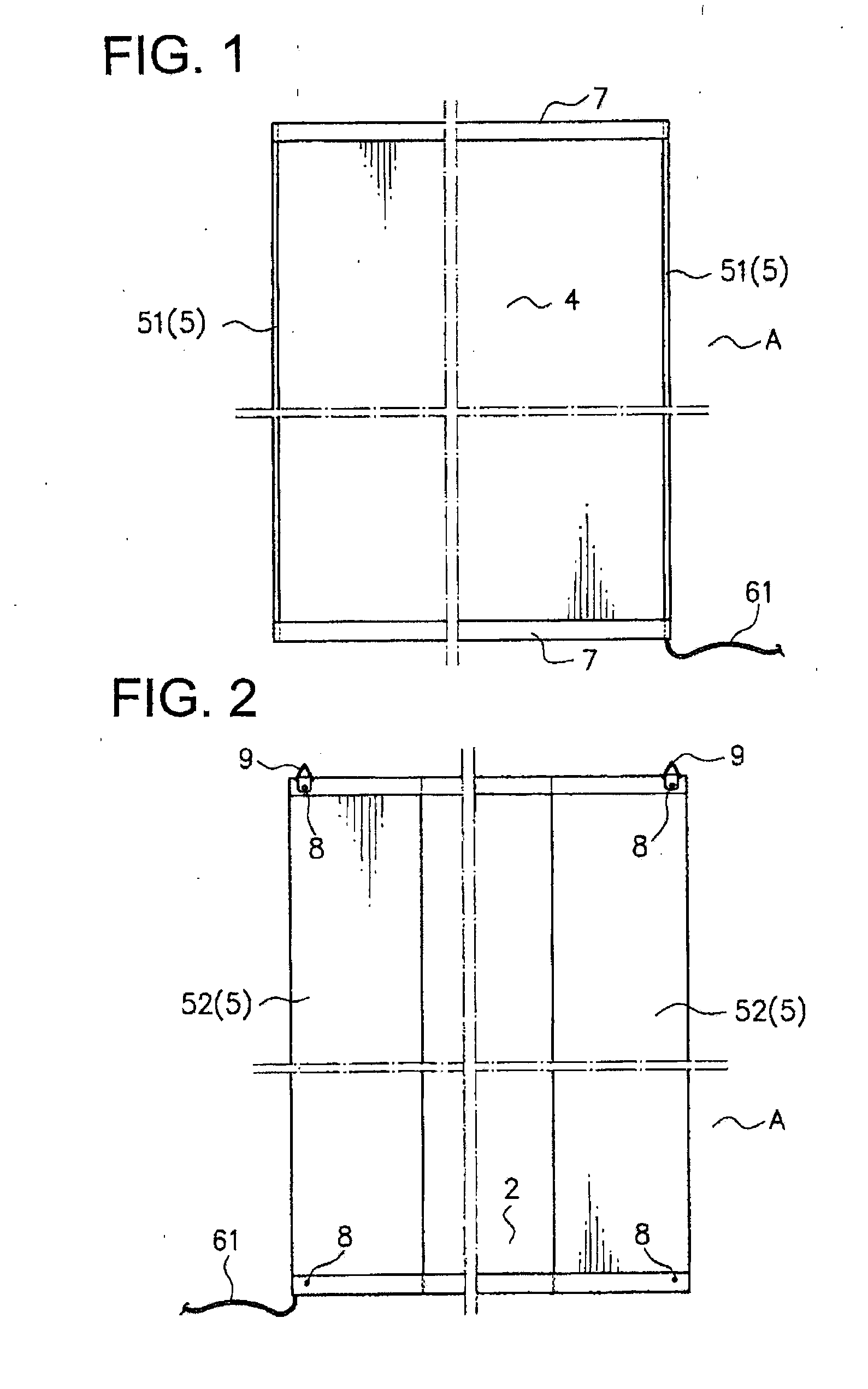

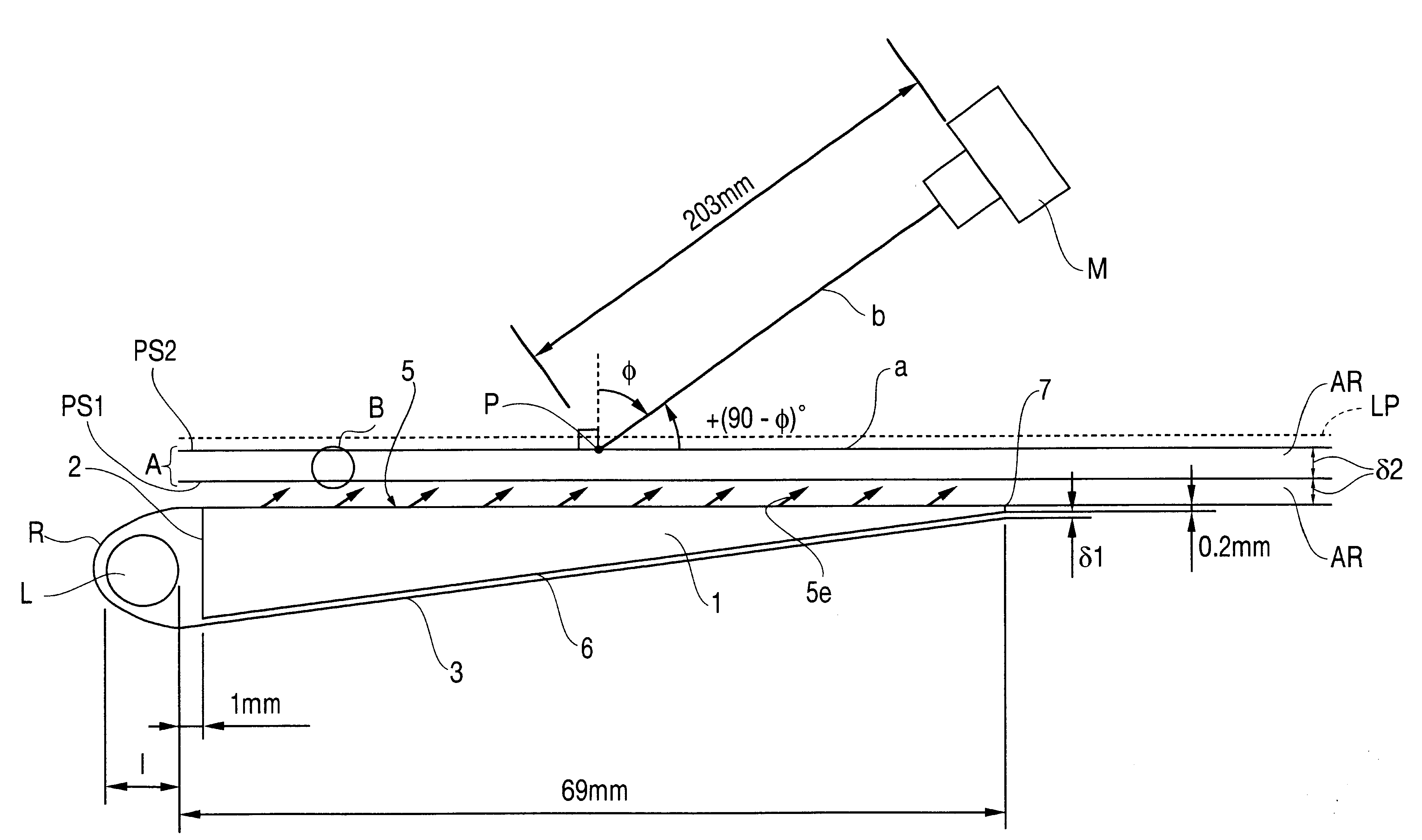

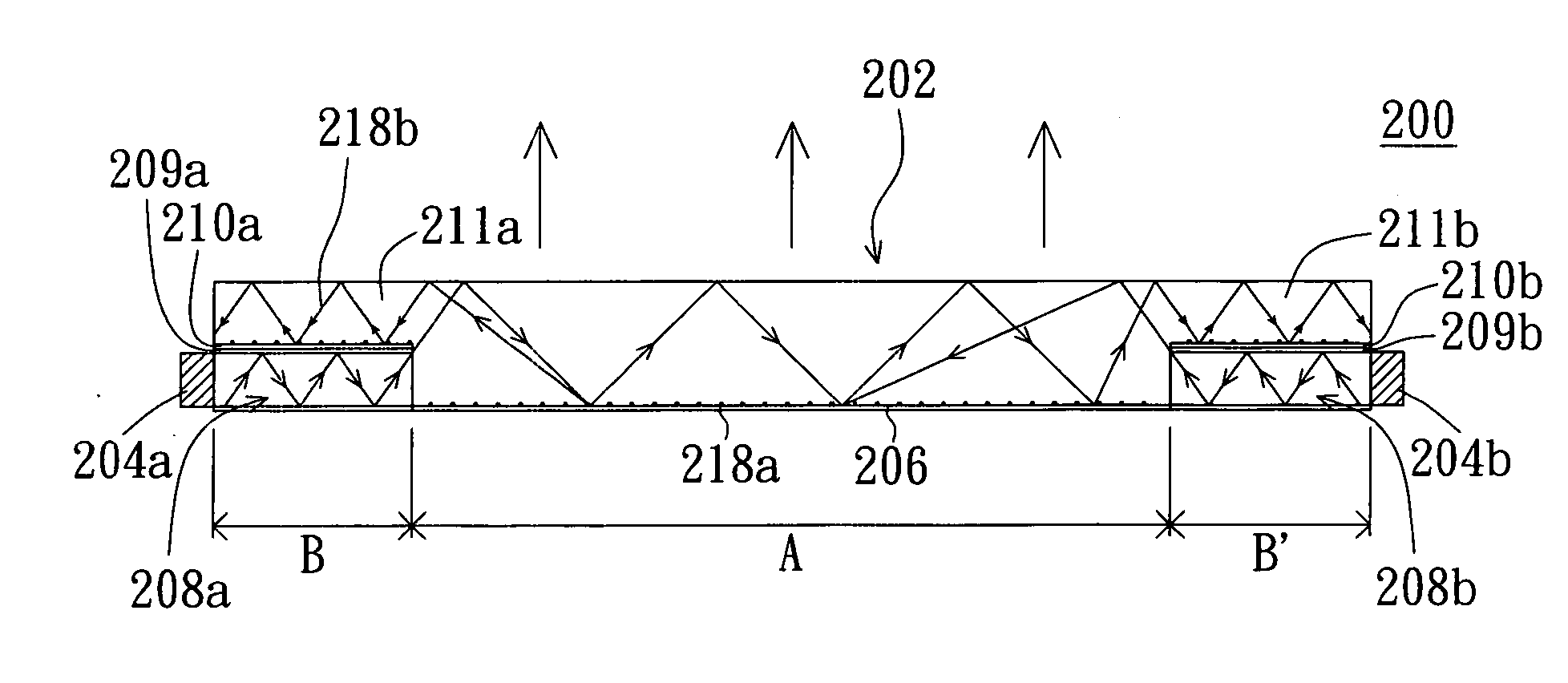

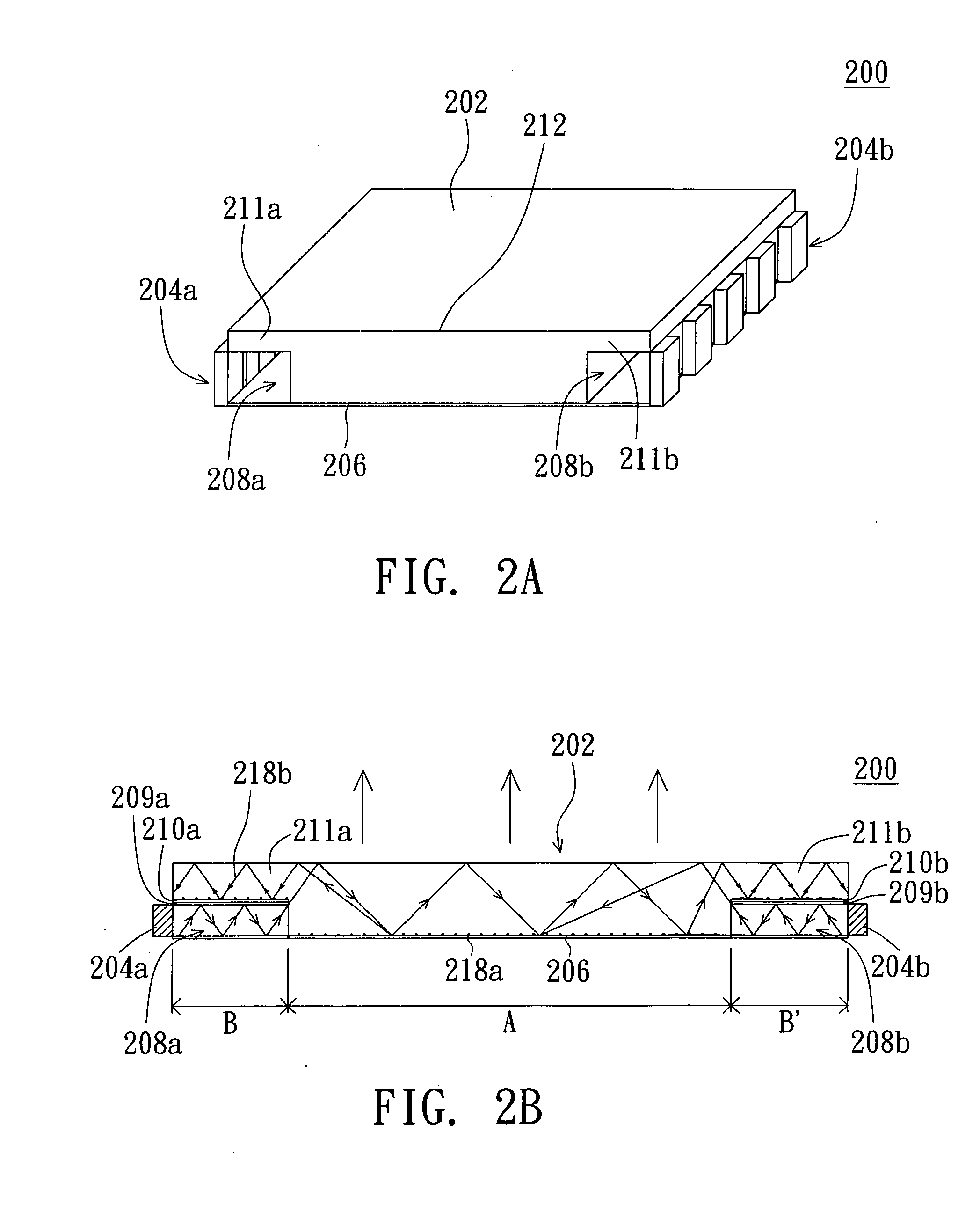

Surface light source device and liquid crystal display

InactiveUS6309080B1Increase brightnessImprove display qualityPlanar light sourcesMachines/enginesLight fluxPrism

A surface light source device has a narrowed visual field and increased brightness. The surface light source device can be applied to a liquid crystal display. The back side of a fluorescent lamp is covered with silver foil. Light emitted from the lamp enters a wedge-shaped light guide plate through its incident surface. The light guide plate is designed so that directional light exits from the guide plate. When the light is guided toward a thin-walled end surface through the light guide plate, the light is scattered, reflected, and undergoes other action. Collimated light flux gradually exits from the exiting surface. The light flux passes through two prism sheets successively. As a result, the direction of propagation of the light is restricted in two dimensions. The light flux of increased brightness is directed to the liquid crystal panel. V-shaped channels formed in the prism faces of the two prism sheets PS1, PS2 are arrayed in two mutually perpendicular directions while facing outward. The prismatic vertical angles of the two sheets PS1, PS2 have various desirable combinations of values. For example, where the first sheet PS1 is disposed vertical to the lamp, the vertical angles of the two sheets PS1, PS2 are preferably 90° and 70°, respectively.

Owner:ENPLAS CORP +1

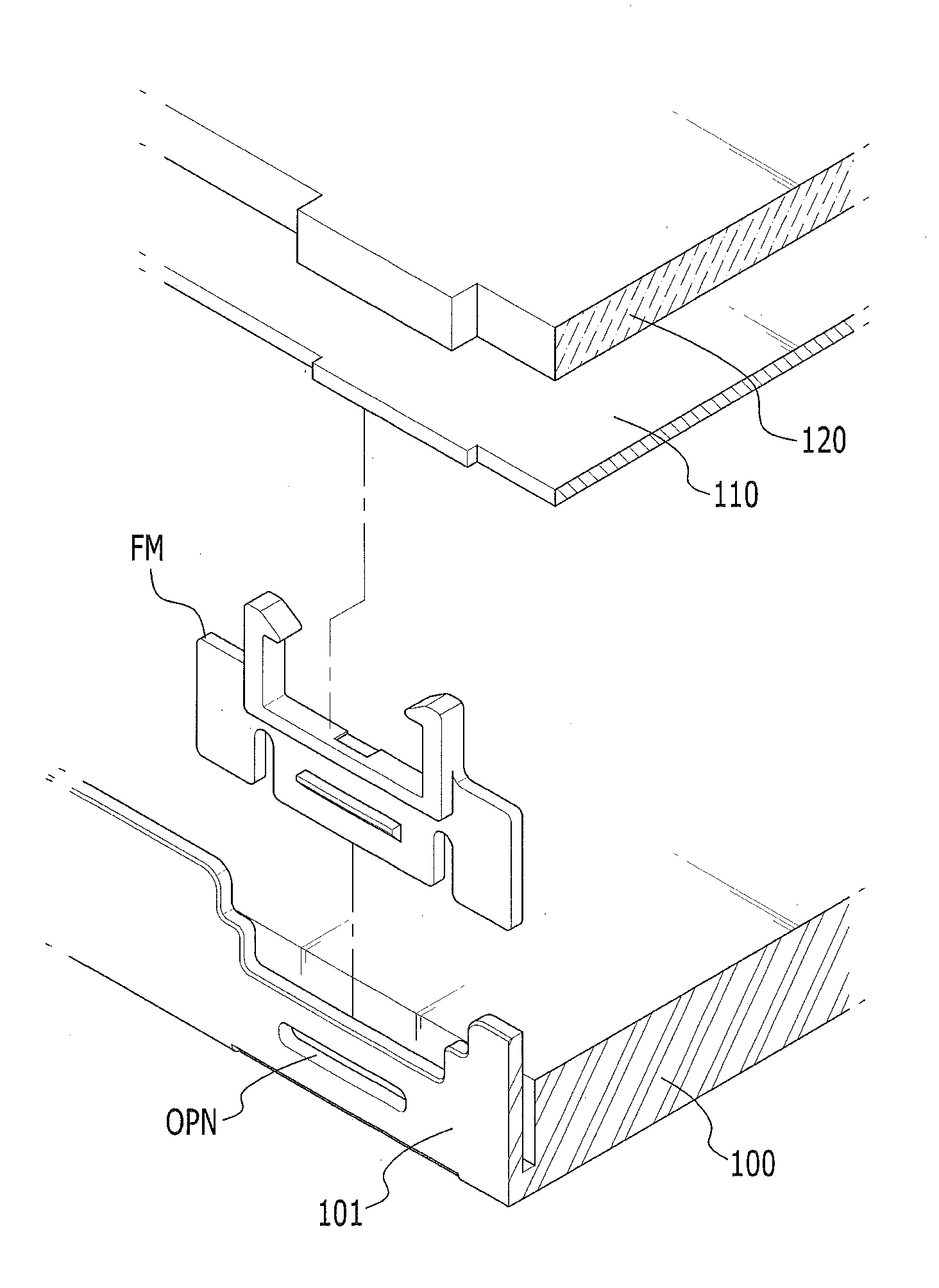

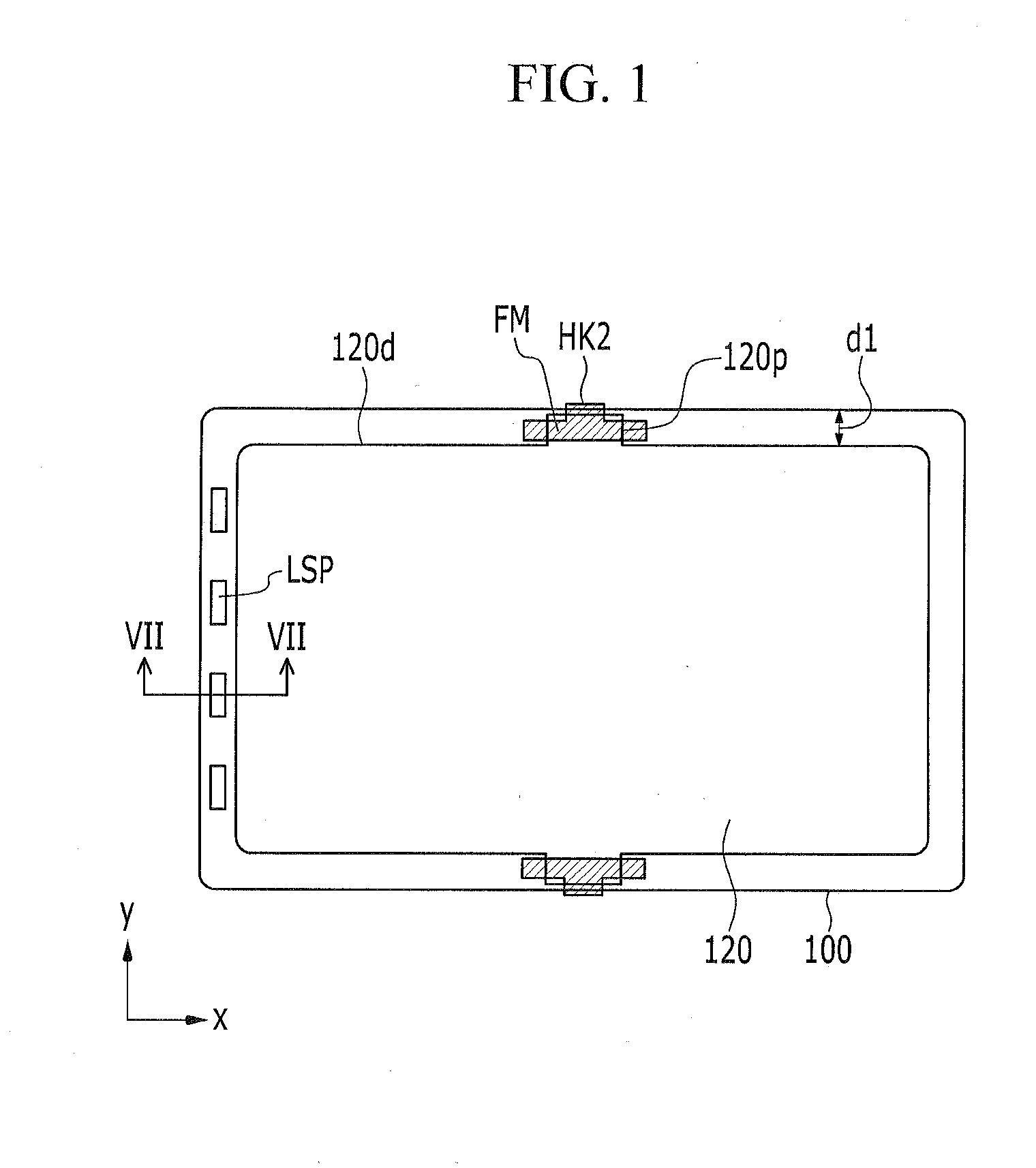

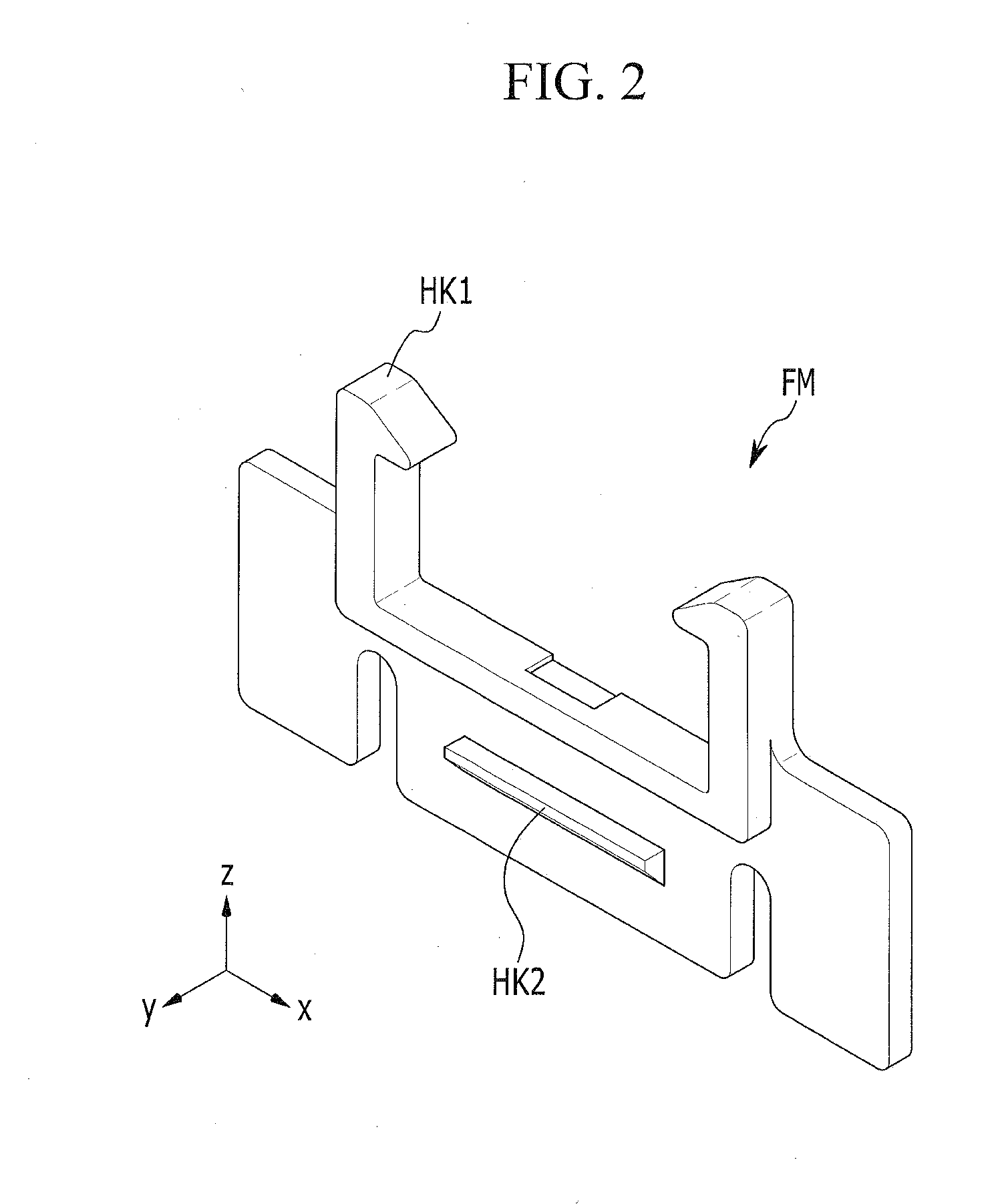

Backlight device and display device including the same

ActiveUS20140043848A1Surface lightMechanical apparatusLight guides for lighting systemsLight guideDisplay device

A backlight device according to an exemplary embodiment of the present invention includes, wherein a light guide plate including a convex portion and a recess portion, a lower cover including a lateral surface cover part positioned adjacent to the convex portion, the lower cover surrounding the light guide plate, and a fixing member positioned between the light guide plate and the lateral surface cover part of the lower cover, in which the lateral cover part includes an opening, and the fixing member includes a first hook surrounding the convex portion and a second hook protruding through the opening of the lateral surface cover part.

Owner:SAMSUNG DISPLAY CO LTD

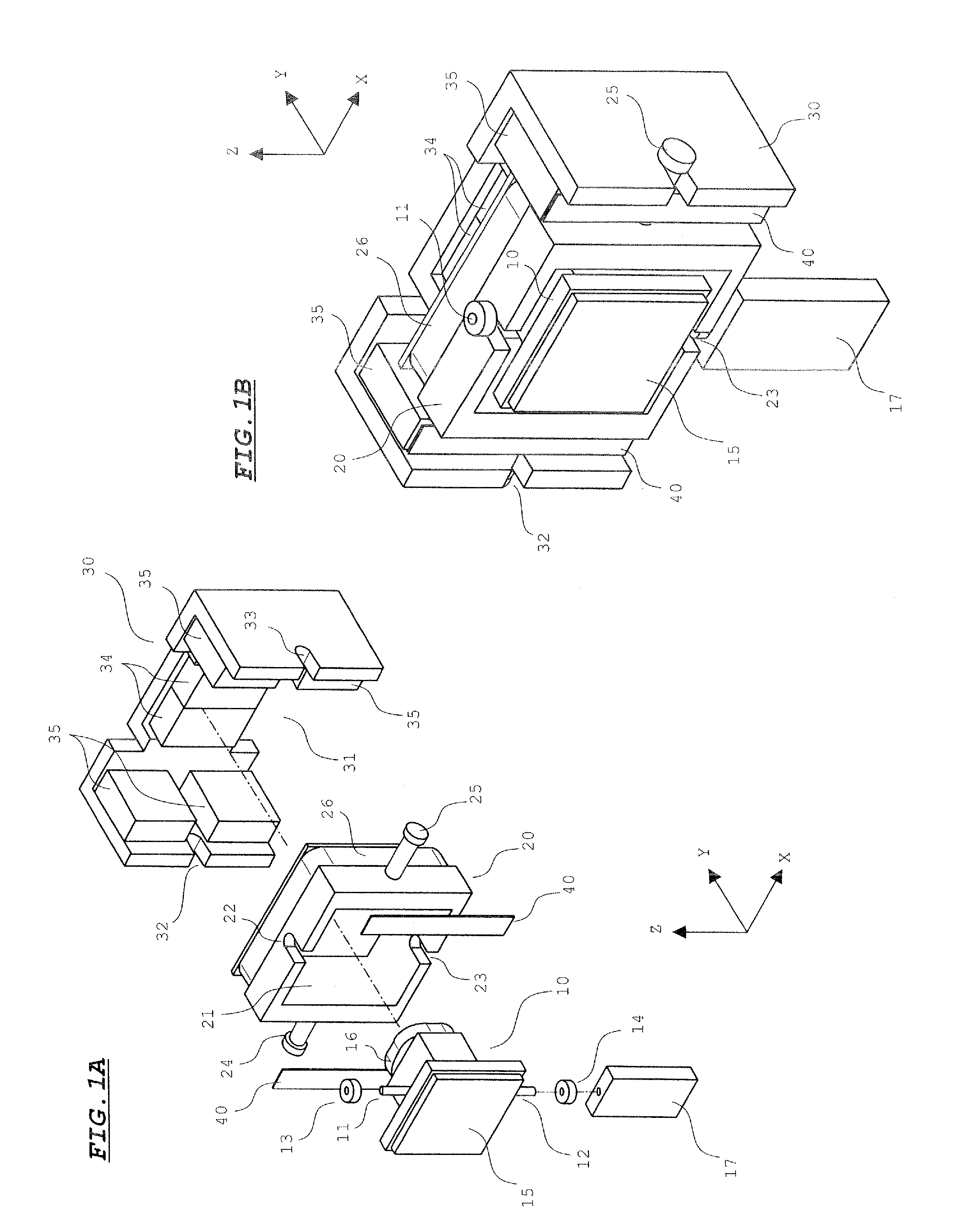

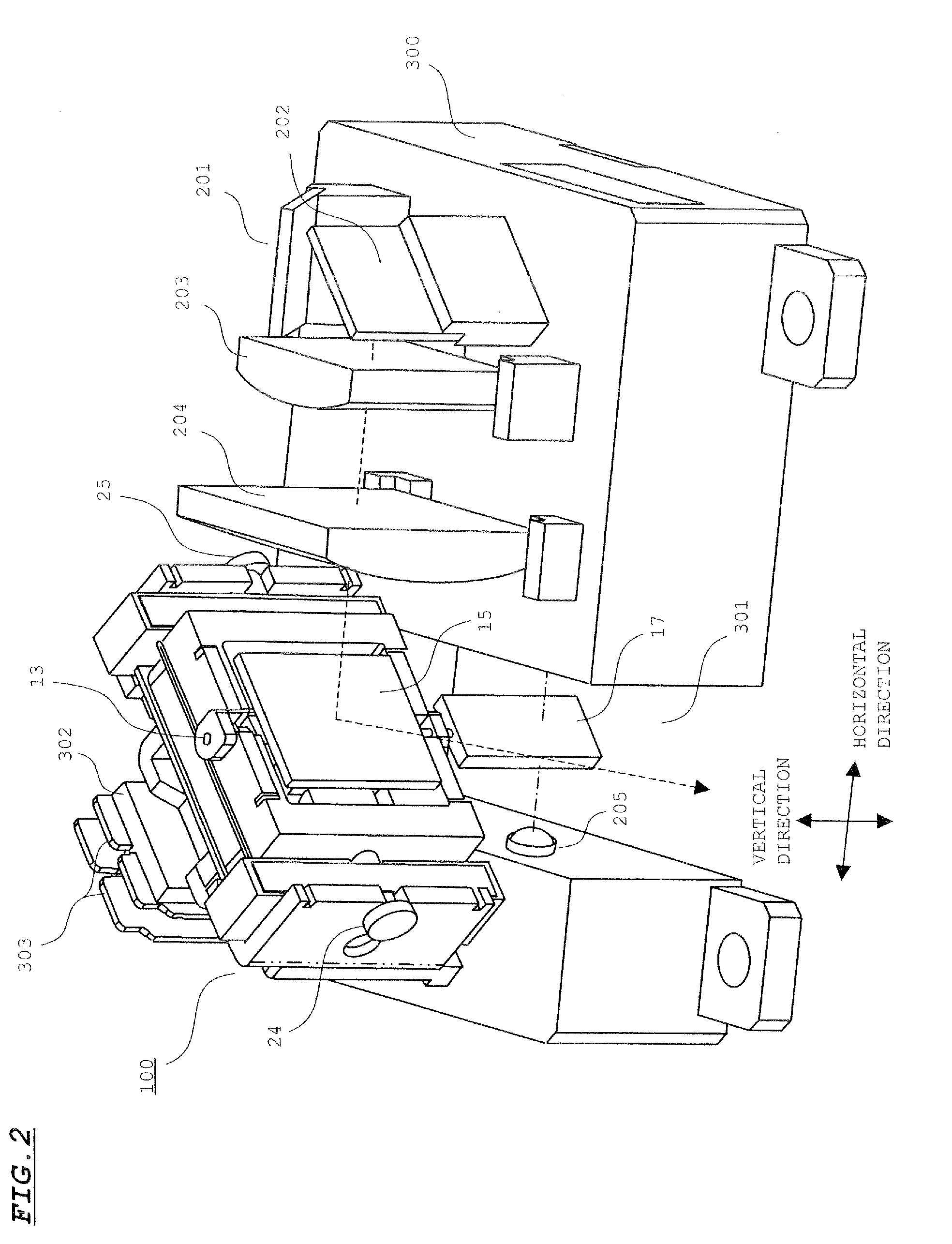

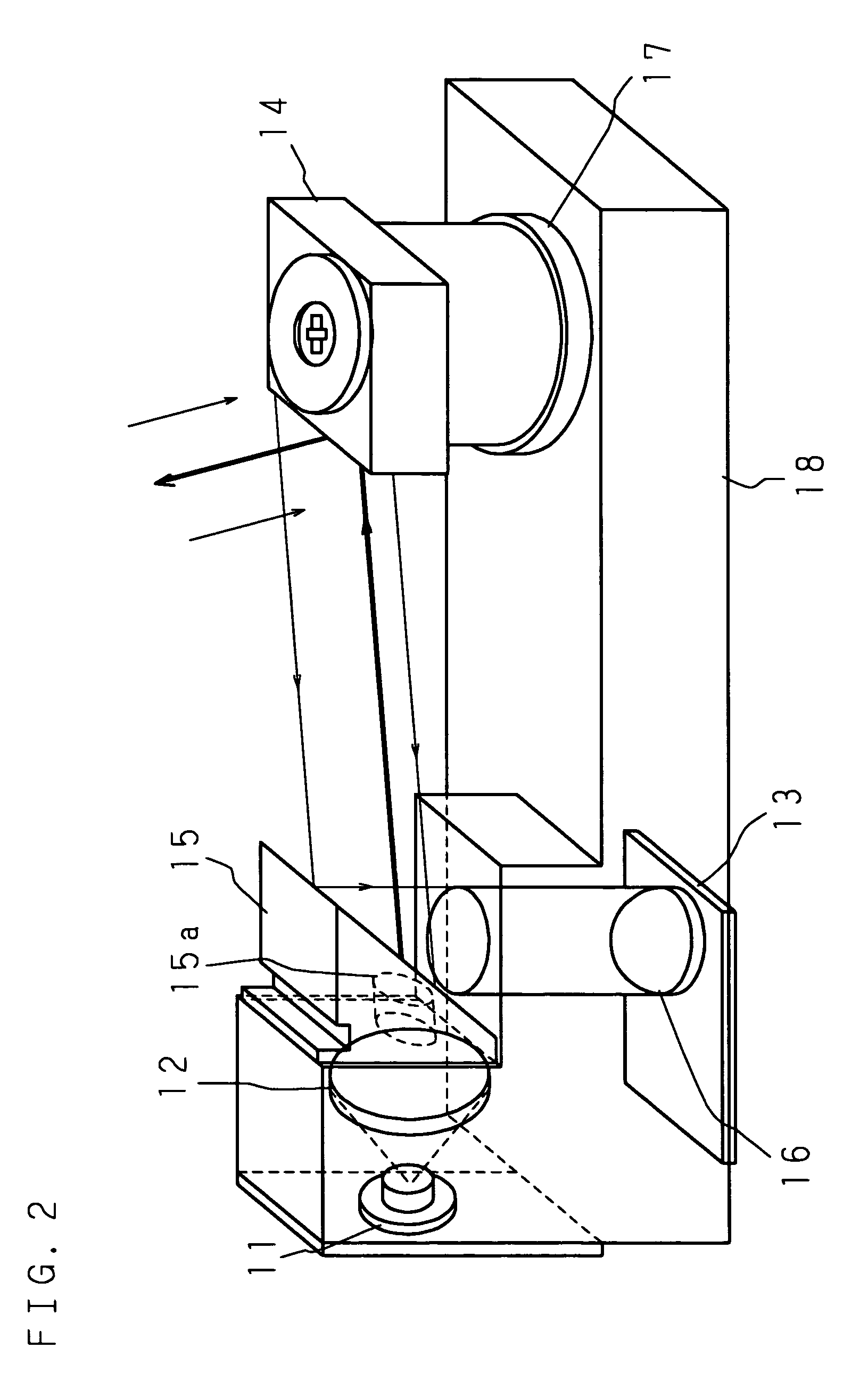

Beam irradiation apparatus

InactiveUS20100073750A1Reduce weightImprove responsivenessInstruments for comonautical navigationMaterial analysis by optical meansParallel plateLight beam

A light refracting element formed in parallel plate shape is attached to a support shaft of a mirror holder, a semiconductor laser and a PSD are disposed at positions between which the light refracting element is sandwiched. The light refracting element is rotated by rotation of the mirror holder, and whereby a laser beam irradiation position is changed on a light acceptance surface of PSD. The laser beam irradiation position on a light acceptance surface corresponds to the mirror rotation position, so that the mirror rotation position and a laser beam scanning position in a target area can be detected based on an output from the PSD.

Owner:SANYO ELECTRIC CO LTD +1

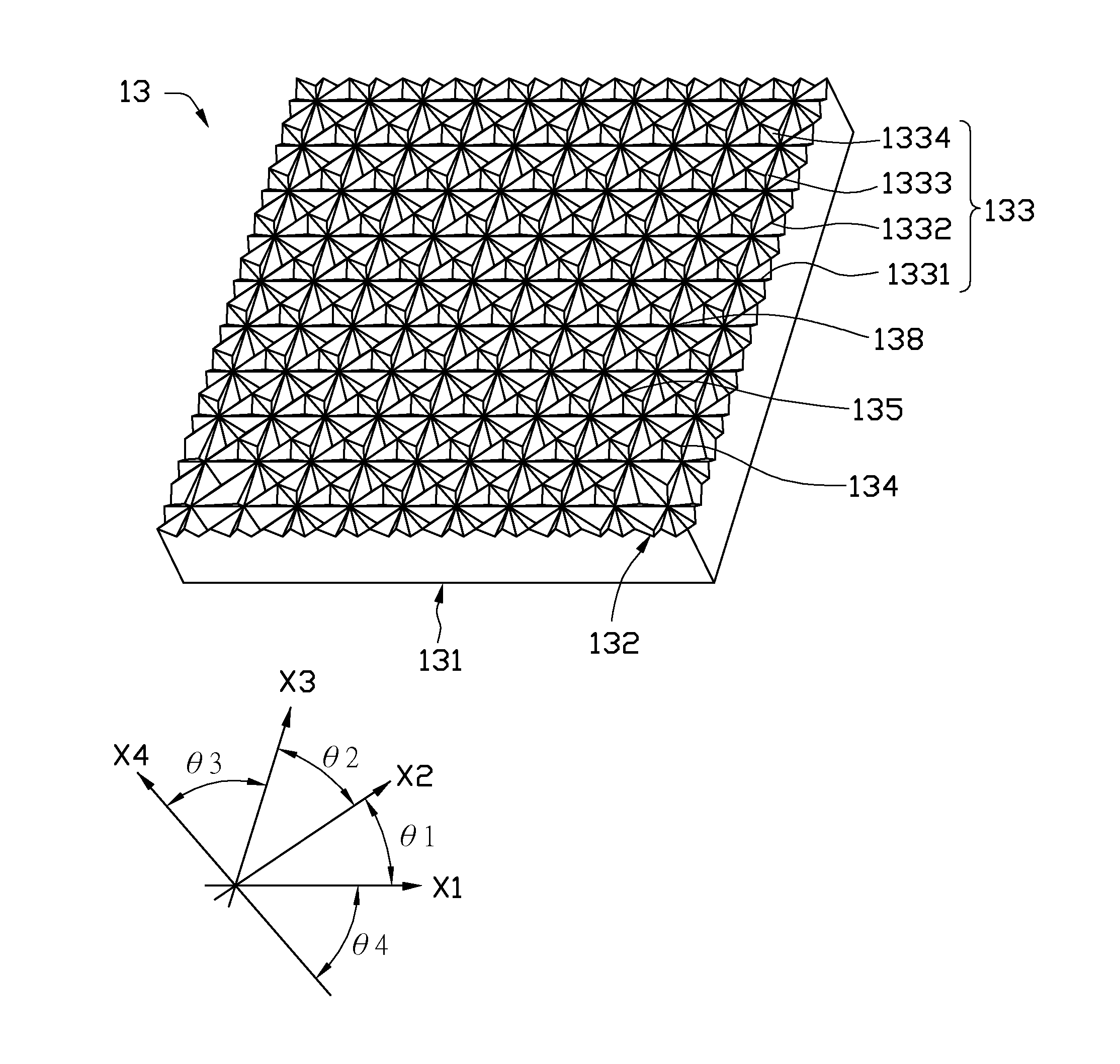

Surface light source device

InactiveUS20120020078A1Improve directionalityIncrease the light areaNon-electric lightingPlanar light sourcesDiffusionLight beam

A surface light source device includes a number of light sources, a first prism sheet and a second prism sheet. The light sources are distributed on a bottom plate of a housing. The first prism sheet and the second prism sheet are arranged above the light sources in that order. The light sources and the first prism sheets are spaced by a first predefined distance, and the first prism sheets and the second prism sheets are spaced by a second predefined distance. The light emitting surface of the first prism sheet includes a number of first diffusion structures, and the light emitting surface of the second prism sheet includes a number of second diffusion structures. Light beams emitted by the light sources are substantially diffused after passing through the first prism sheet and the second prism sheet and become surface light beams.

Owner:HON HAI PRECISION IND CO LTD

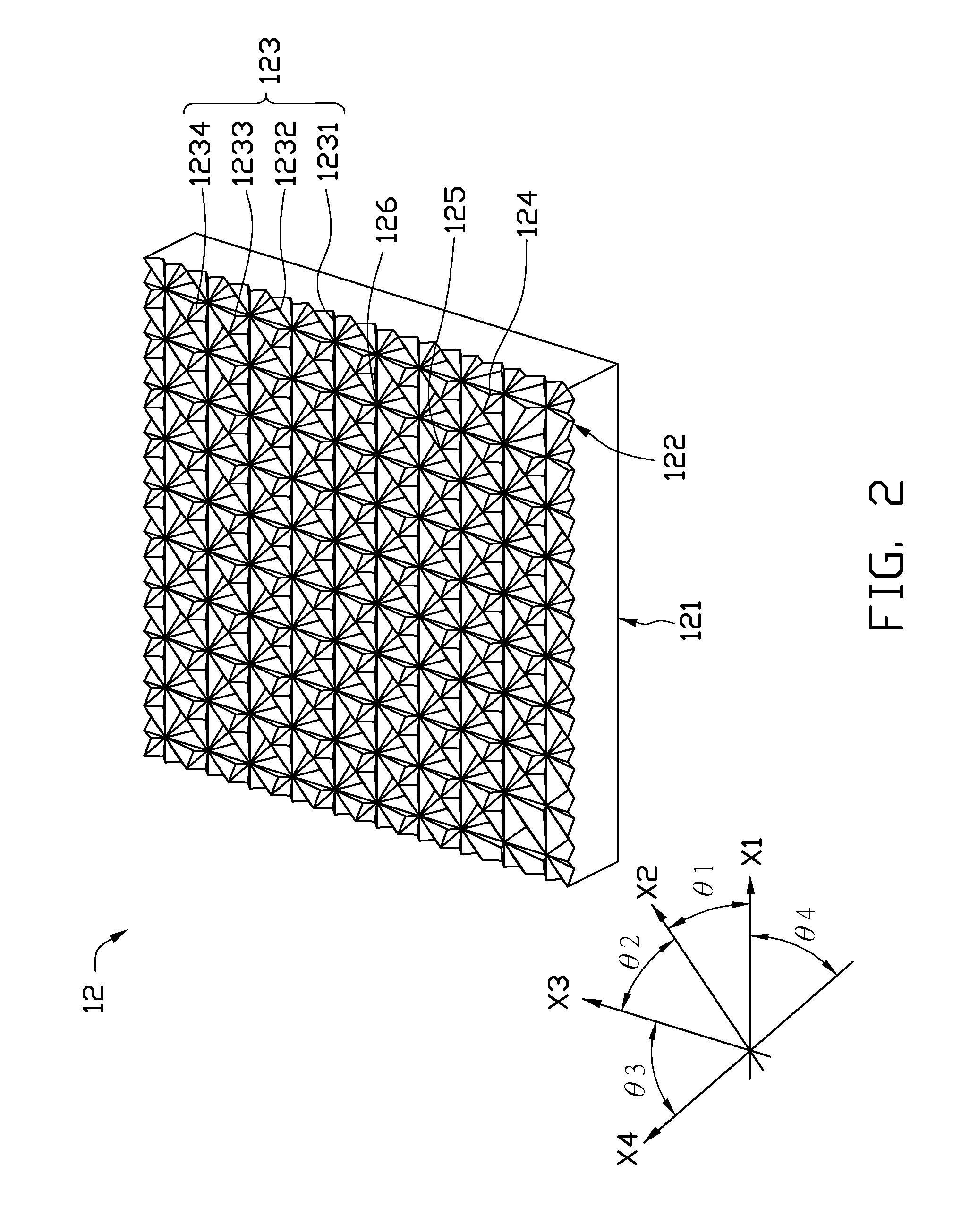

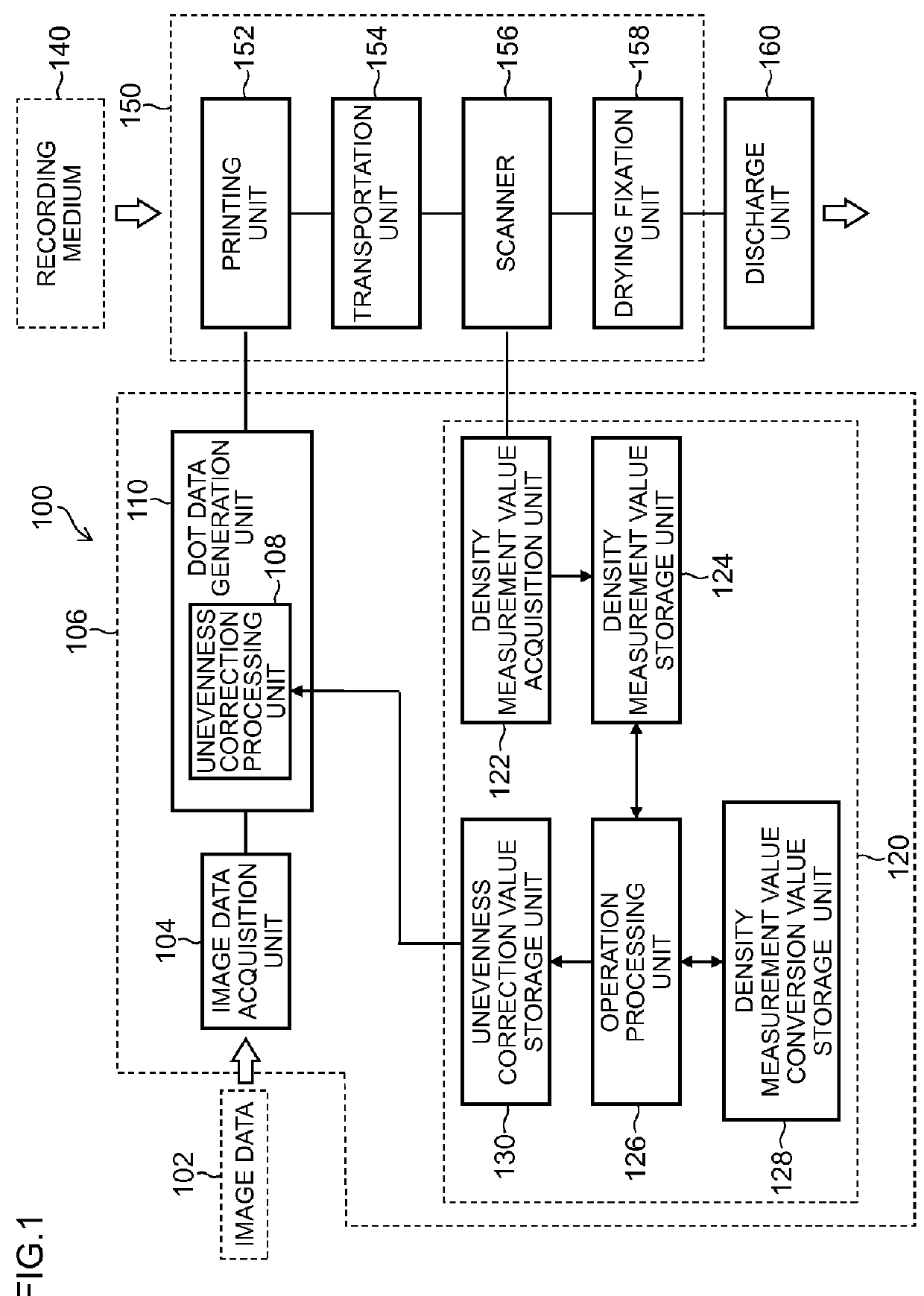

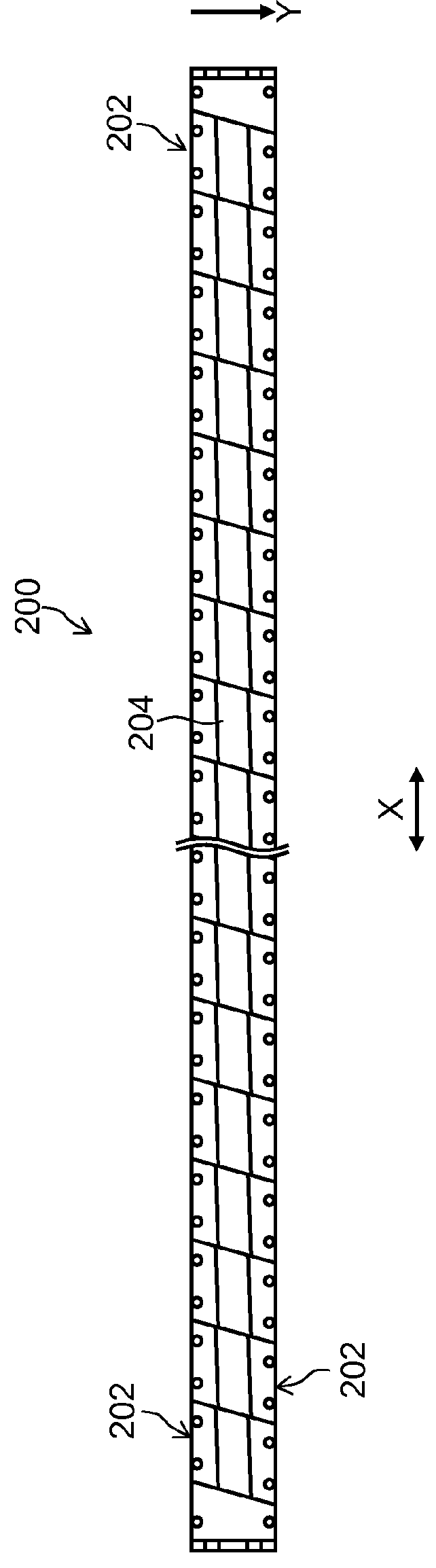

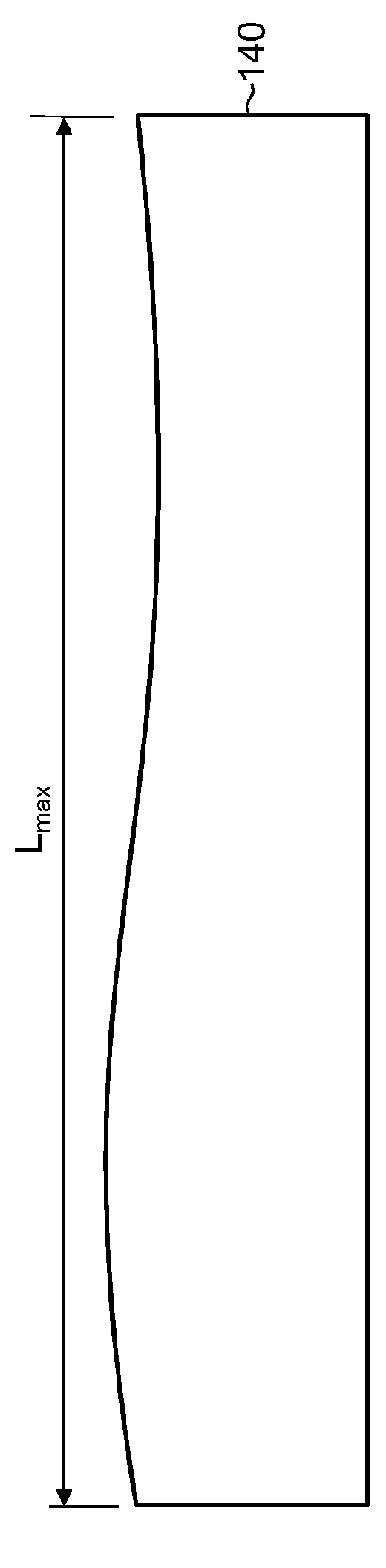

Image processing method and inkjet recording apparatus

ActiveUS20160052300A1Possible to performSurface lightOther printing apparatusPictoral communicationValue setImaging processing

An image processing method includes: forming an image for density unevenness measurement on a recording medium in a single-pass method, using an inkjet head in which nozzles are disposed in a main scanning direction; acquiring a density measurement value of each set gradation value from an image for density unevenness measurement before drying; converting the acquired density measurement value into a conversion density measurement value corresponding to a post-dry density measurement value, using a density measurement value conversion value set for each region in the main scanning direction; and deriving a new unevenness correction value using this conversion density measurement value.

Owner:FUJIFILM CORP

Infrared light reflector

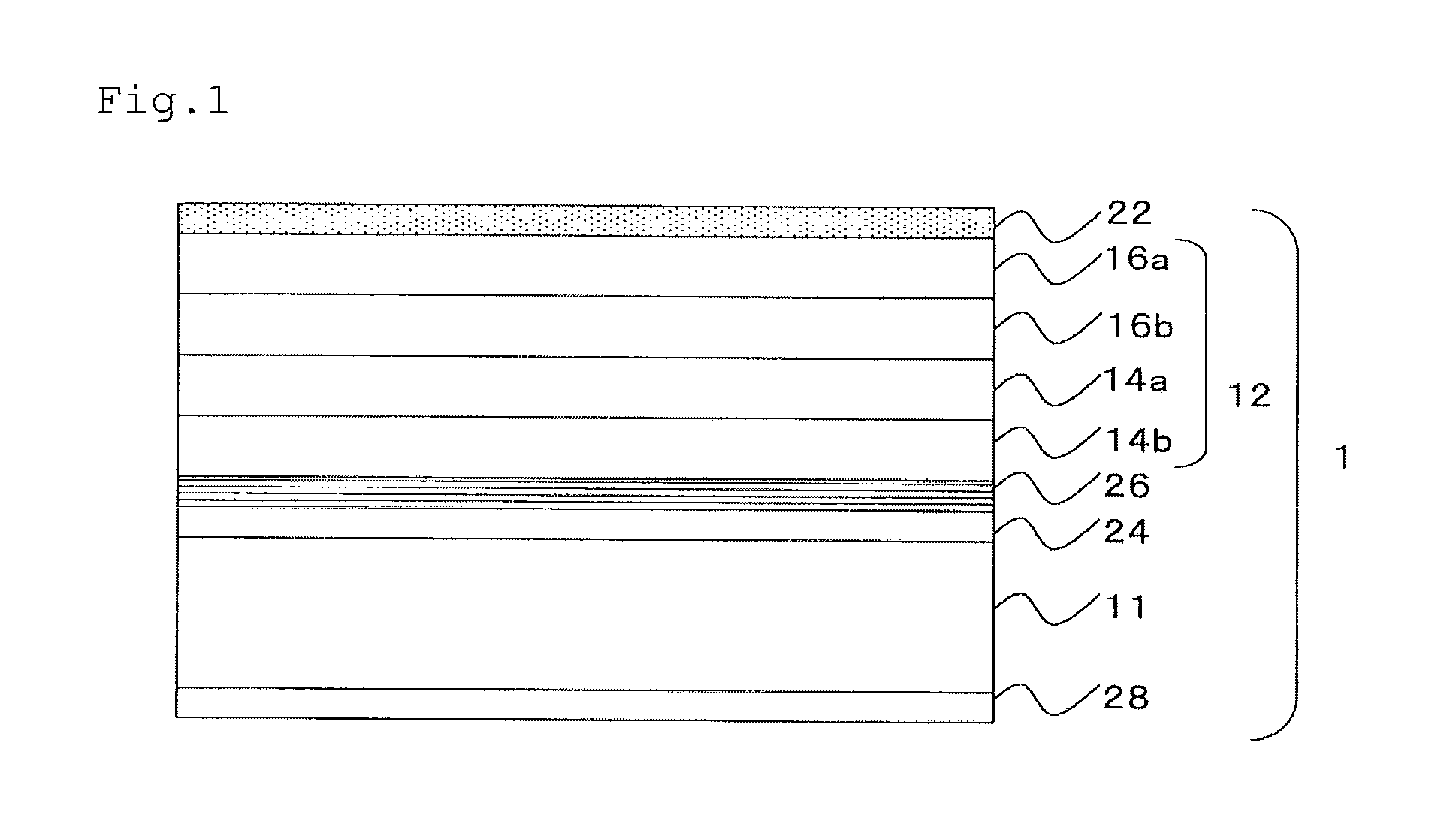

ActiveUS20120050847A1High film strengthImprove surface conditionLiquid crystal compositionsMirrorsReflective layerFluorine containing

An infrared light reflector having an infrared light reflective layer formed by polymerizing an infrared light reflective layer composition that contains a polyfunctional polymerizable compound, a cholesteric liquid crystal compound and a fluorine-containing alignment controlling agent in an amount of at least 60 ppm relative to the liquid crystal compound, wherein when a functional layer composition is applied onto at least one surface of the infrared light reflective layer, the number of the coating liquid cissing defects having a diameter of at least 5 μm is at most 10 / m2.

Owner:FUJIFILM CORP

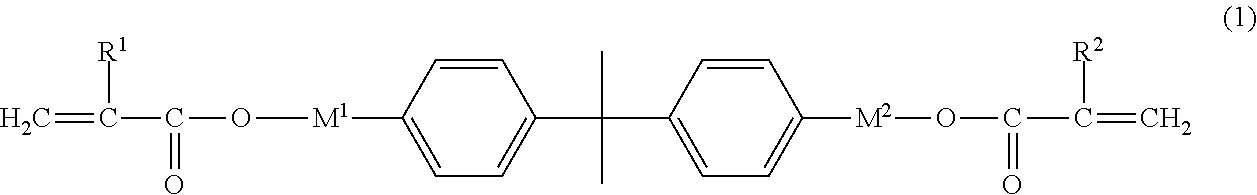

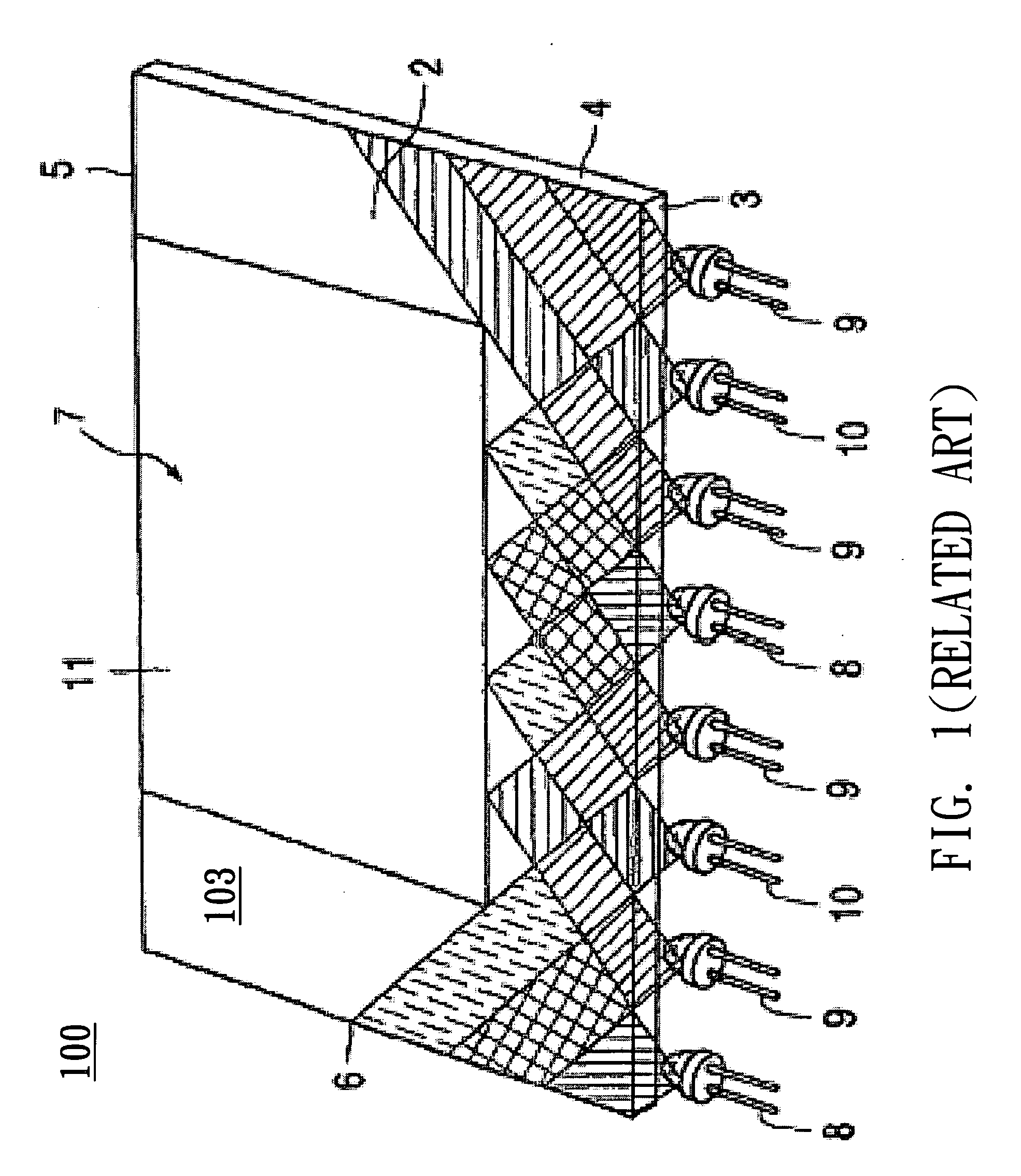

LED lamp set for enhancing illumination and eliminating ghost images

InactiveUS20130194812A1Convenient lightingEliminate ghostingPoint-like light sourceElongate light sourcesElectricityEngineering

An LED lamp set for enhancing illumination and eliminating ghost images includes a lamp shade, a diffusion membrane and a circuit board. The lamp shade has a plurality of light cups each having a housing chamber to hold at least one LED. The housing chamber has an aperture at the bottom run through by the LED to form electric connection with the circuit board and an opening remote from the aperture to define a light output surface. The diffusion membrane covers the light output surface and is made of a transparent material and includes a plurality of transparent bumps on the surface. The circuit board is located below the lamp shade. Through the concave shape of the light cups and repetitive reflection of the bumps, light can be condensed to avoid scattering and loss. Moreover, as the light is greatly and uniformly condensed, ghost images can be eliminated.

Owner:TSENG HUI PENG

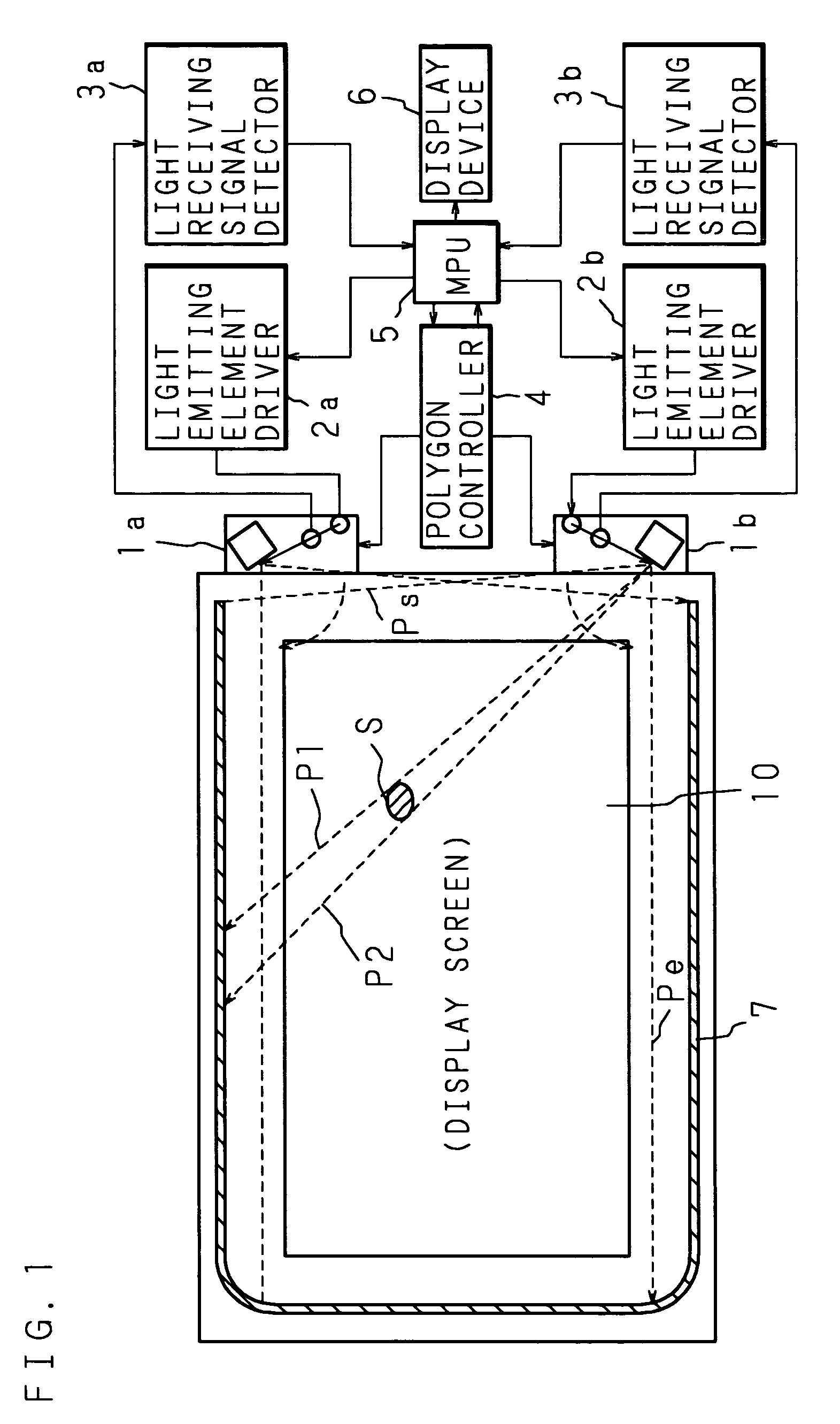

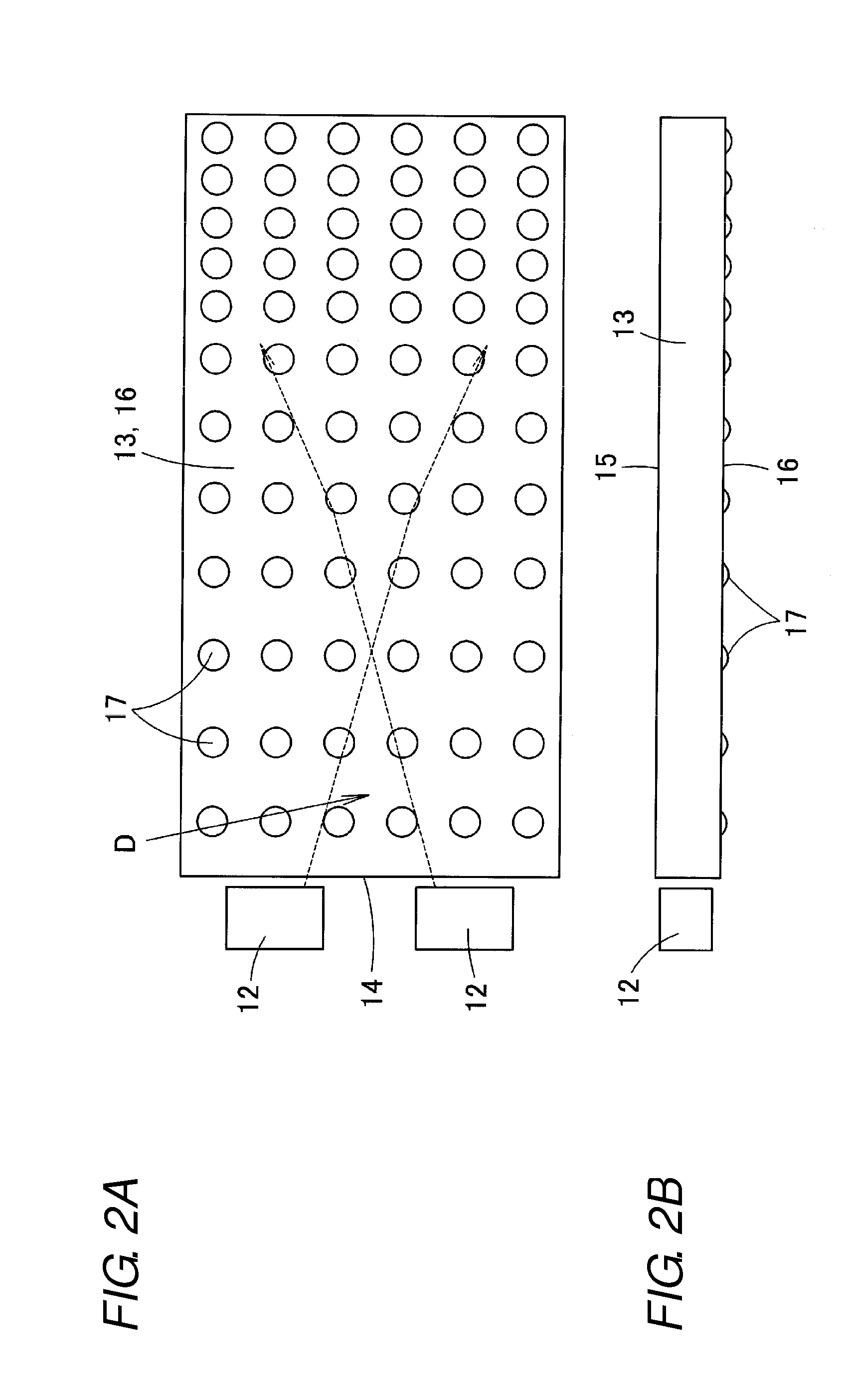

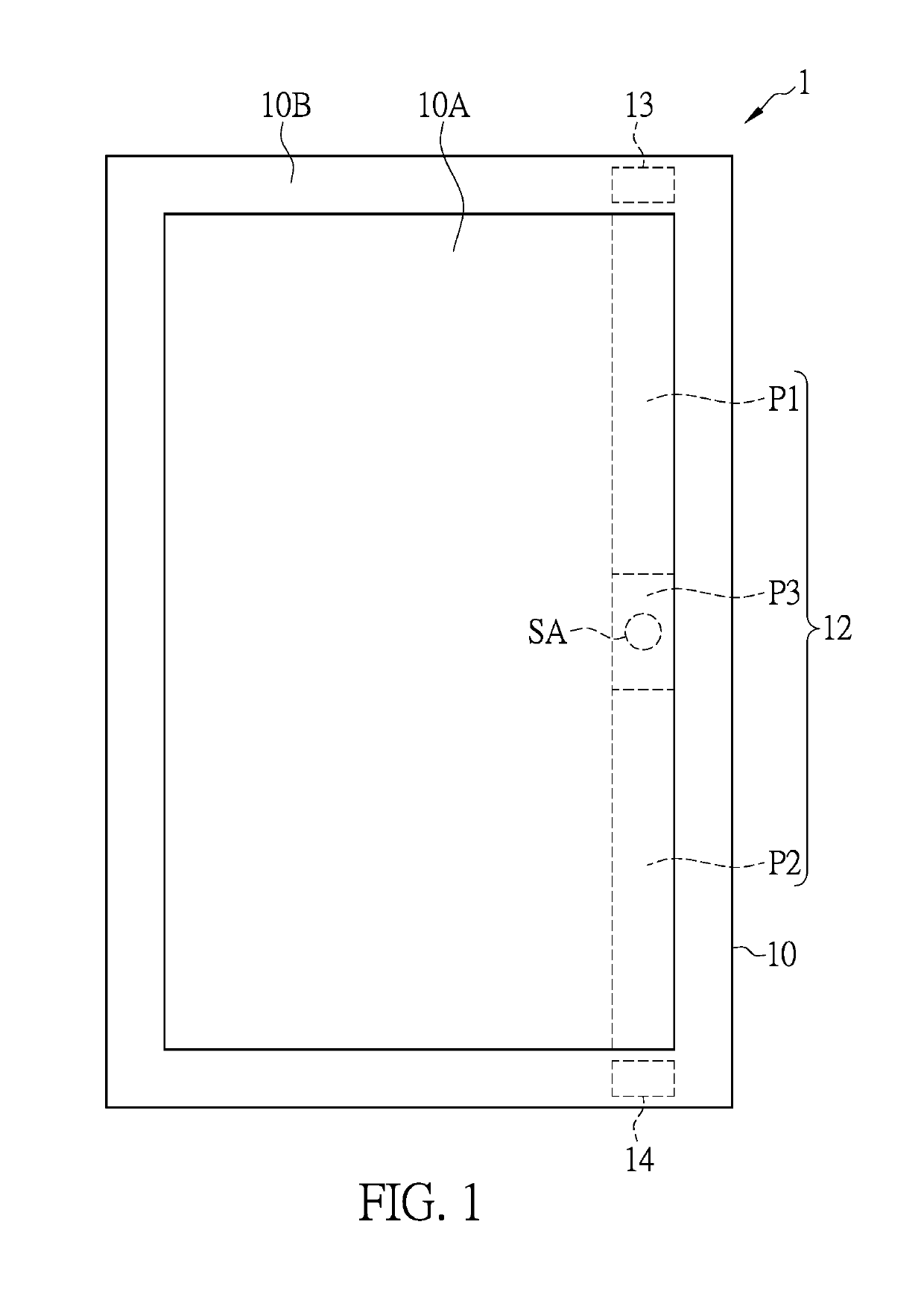

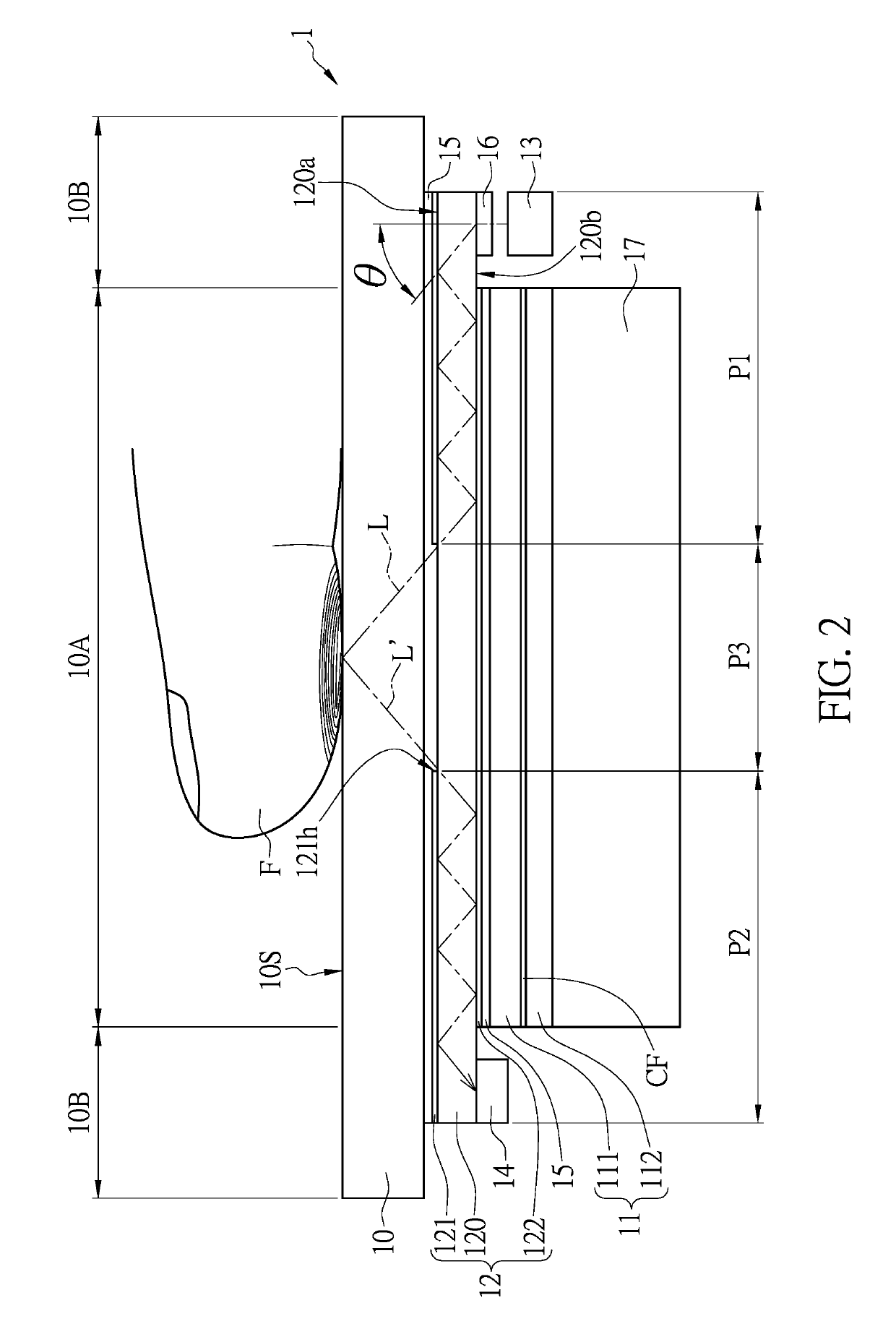

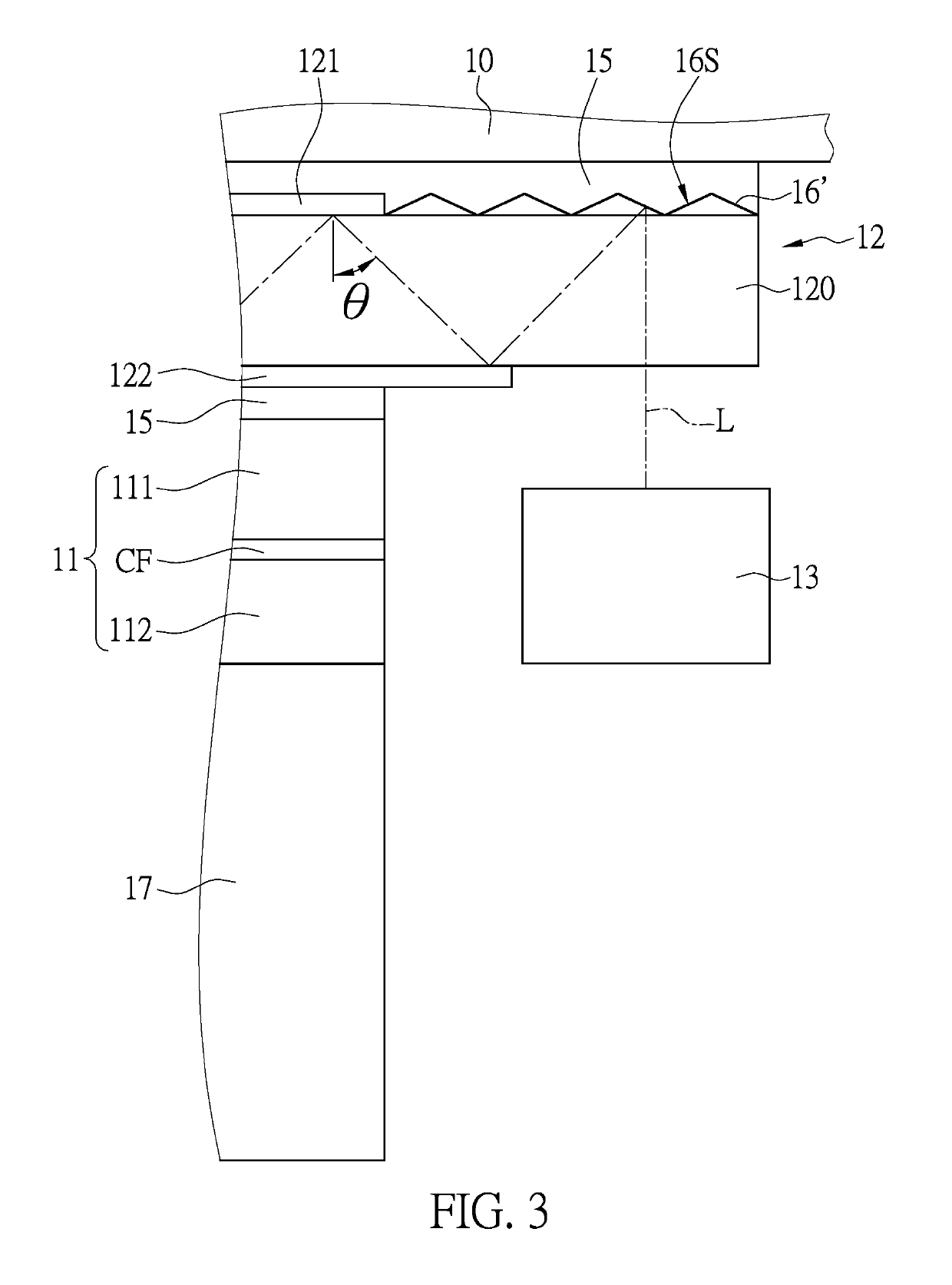

Optical scanning-type touch panel

InactiveUS7522156B2Improve light receiving signal levelIncrease the effective light-receiving areaInput/output processes for data processingAngular scanOptical axis

Owner:FUJITSU LTD

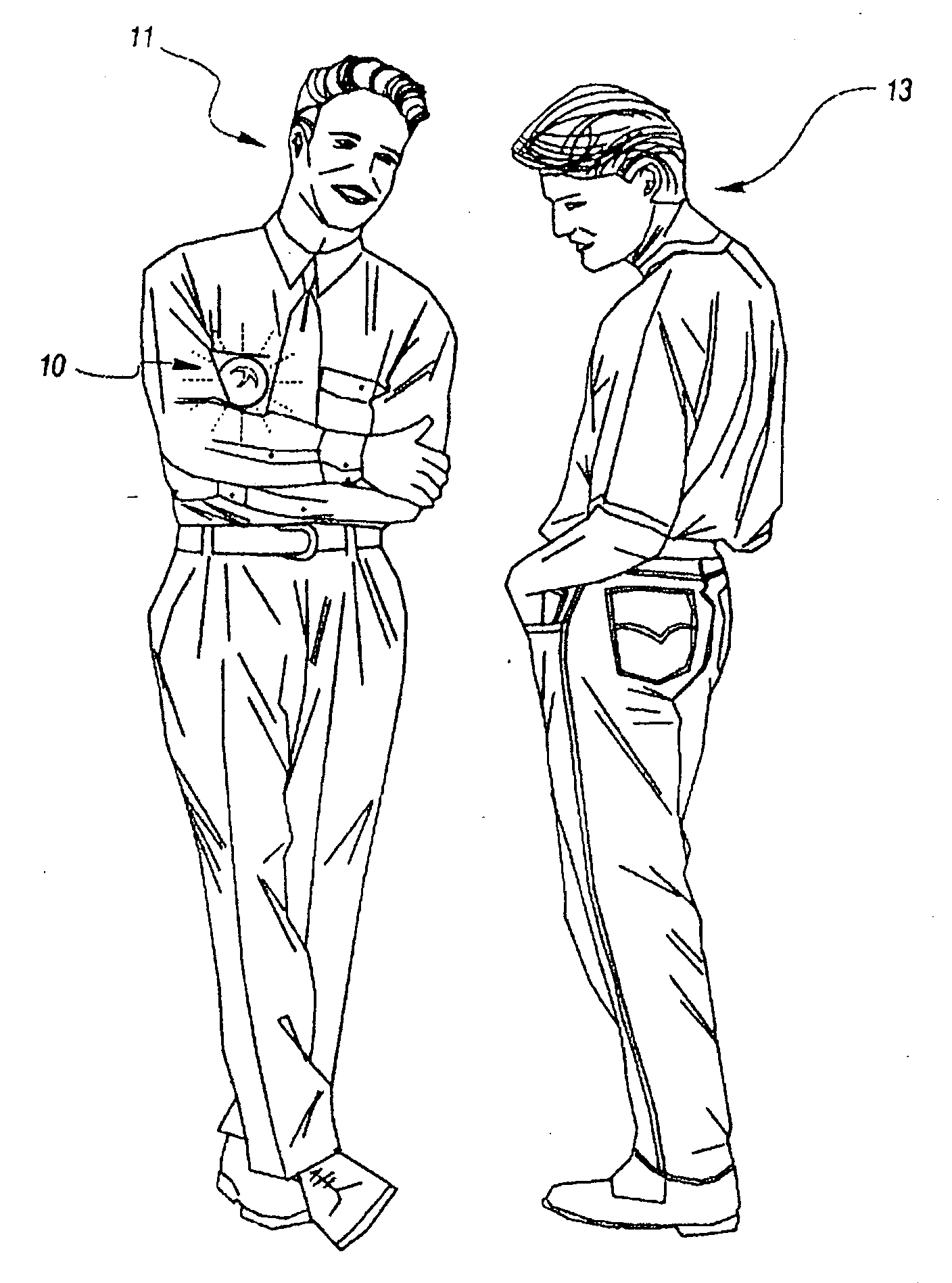

Interactive actuatable wearable display

InactiveUS20090213572A1Extend your lifeAccentuate designElectrical apparatusWith electric batteriesDisplay deviceElectric power

A display apparatus that can be worn by a user, attached to a surface, and / or comprise a stand-alone display containing a light source that emits light and is positioned so as to illuminate a design on the surface of the display apparatus, and / or that incorporates a lighted surface or video-capable technology and that may be connected to a microprocessor and / or light, sound or motion sensor functionalities connected to a microprocessor that can interpret external stimulus and modify the display according to various criteria to attract viewers. The display apparatus also is connected to or in the case of a wearable display contains a power supply that provides power to the light source or lighted display technology and microprocessor and / or sensor functionalities. In some embodiments, the invention may also include a promotional display member that displays advertising or sponsoring information. This promotional display member is configured to attach to display apparatus and surround the design on the front surface of the display apparatus.

Owner:ENVISAGE PRODS

Edge-lighting LED backlight and LCD thereof

ActiveUS20100103344A1Low costReduce in quantityOptical light guidesIlluminated signsLight guideEffect light

The present invention relates to an edge-lighting LED backlight and LCD. The edge-lighting LED backlight comprises an LED light bar and a light guide plate, wherein a reflector is disposed between the LED light bar and the light guide plate, holes are set on the reflector, and light emitted from the LED light bar enters into the light guide plate through the holes. An LCD comprises the above edge-lighting LED backlight. In the above solution, the surface reflectance of the LED light bar is improved, the light loss is decreased and the utilization rate of light is improved by disposing the reflector between the LED light bar and the light guide plate, which decreases the quantity of the LEDs and the cost of the backlight.

Owner:BOE TECH GRP CO LTD

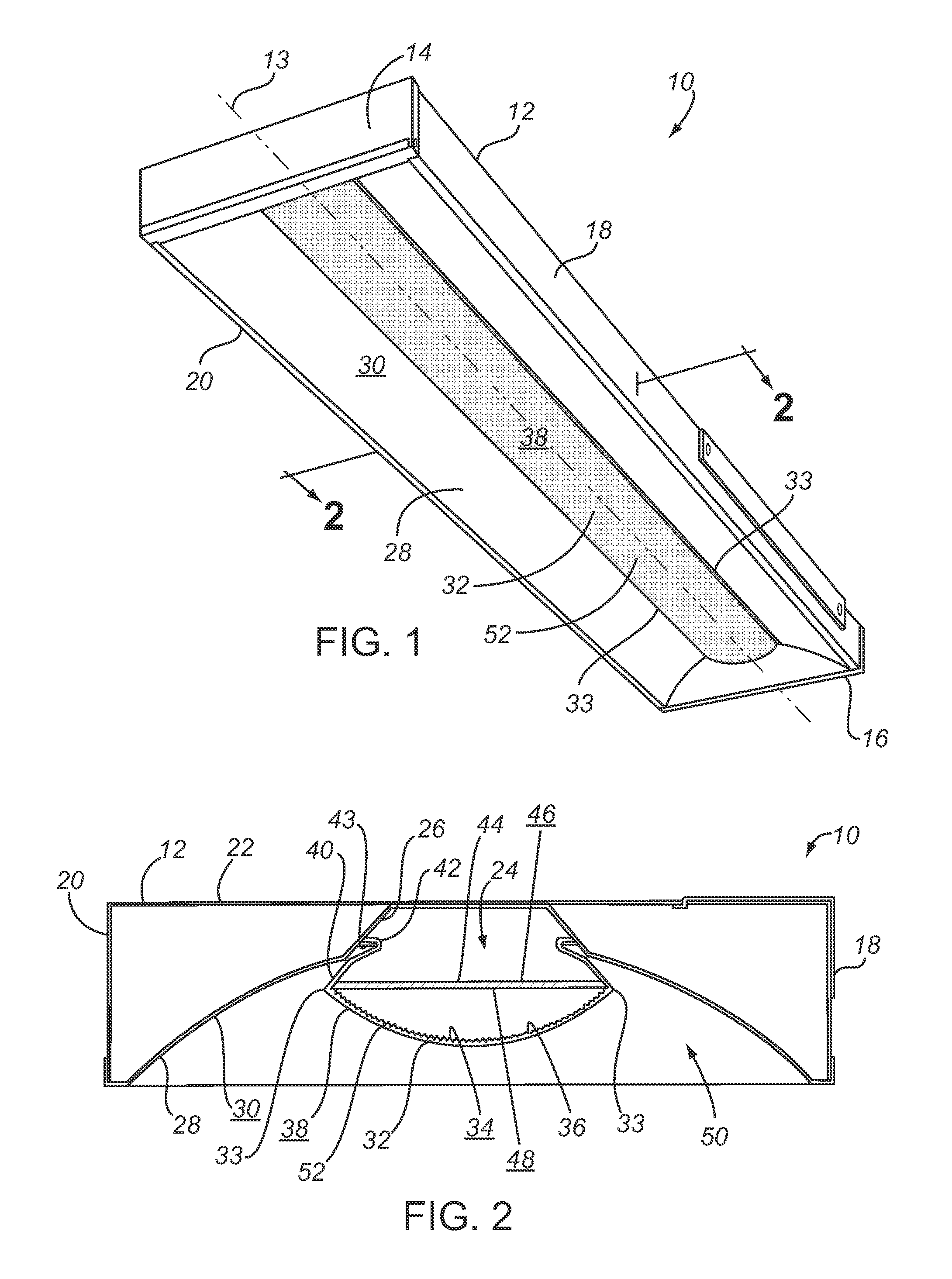

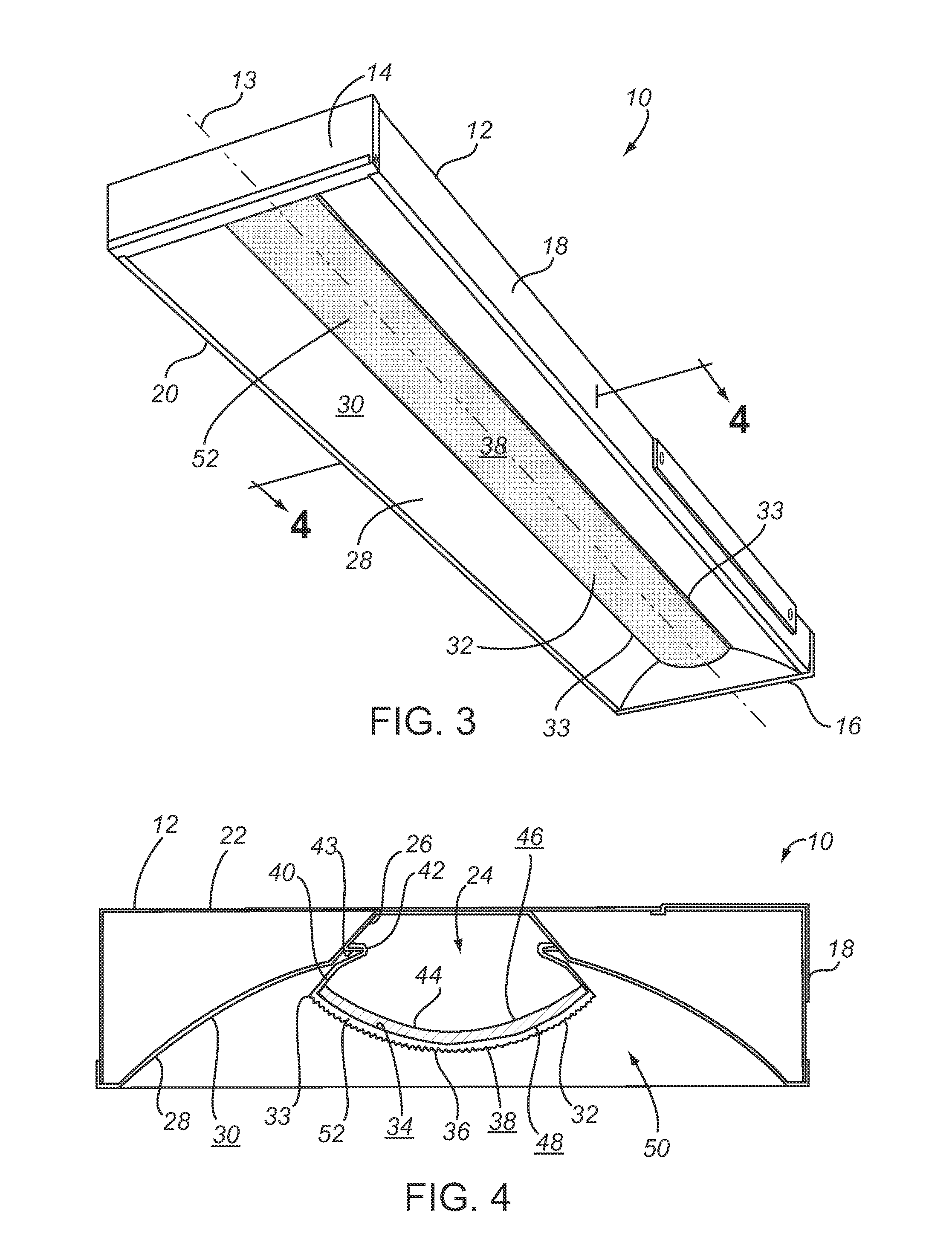

Light Fixtures Comprising Organic Light Emitting Diodes

InactiveUS20110310625A1Maximize light efficiencyOptical efficiency maximizedPlanar light sourcesProtective devices for lightingLight-emitting diodeOLED

Light fixtures comprising an organic light emitting diode (OLED) as the light source, and further comprising a housing, at least one hollow, and an optic. The at least one hollow defines an intended area where light is emitted, and includes a reflective surface to reflect light within the intended area. The optic comprises a refractive portion that is defined by two edges. In one embodiment, the OLED is coupled to the two edges of the optic. In another embodiment, the OLED is coupled to and contacts an inner surface of the refractive portion. In either embodiment, the OLED is either sufficiently close to or contacting the refractive portion such that surface area of emitted light is maximized. Additionally, the OLED is placed sufficiently close to (or within) the intended area that reflected light and optical efficiency are maximized.

Owner:ABL IP HLDG

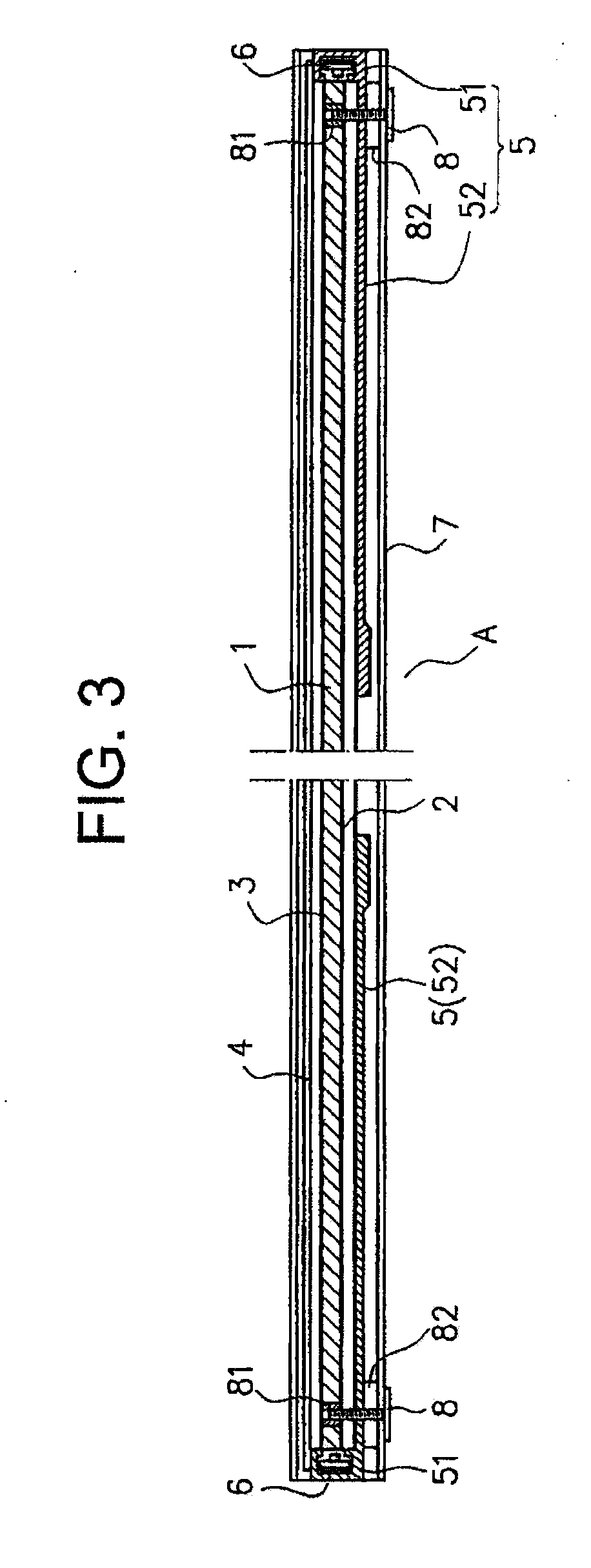

Surface light source device

ActiveUS20130242613A1Reduce variationReduce intensityMechanical apparatusPlanar/plate-like light guidesLight guideSlant angle

A variation in luminance is reduced near a light source without decreasing intensity of a light exit pattern. A light source is disposed and a light exit pattern is formed. The light exit pattern reflects light guided in a light guide plate and outputs the light. In inclined angles of tangents of the light exit patterns in a section passing through a center axis of the light exit pattern, a largest inclined angle of the tangent is defined as a maximum inclined angle of the light exit pattern. At this time, in the light exit pattern provided in the light guide plate, the maximum inclined angle is decreased with increasing distance from a light incident surface in a region near the light incident surface, and the maximum inclined angle is decreased or kept constant with increasing distance from the light incident surface in a region distant from the region near the light incident surface.

Owner:TOHOKU DENSHI CO LTD

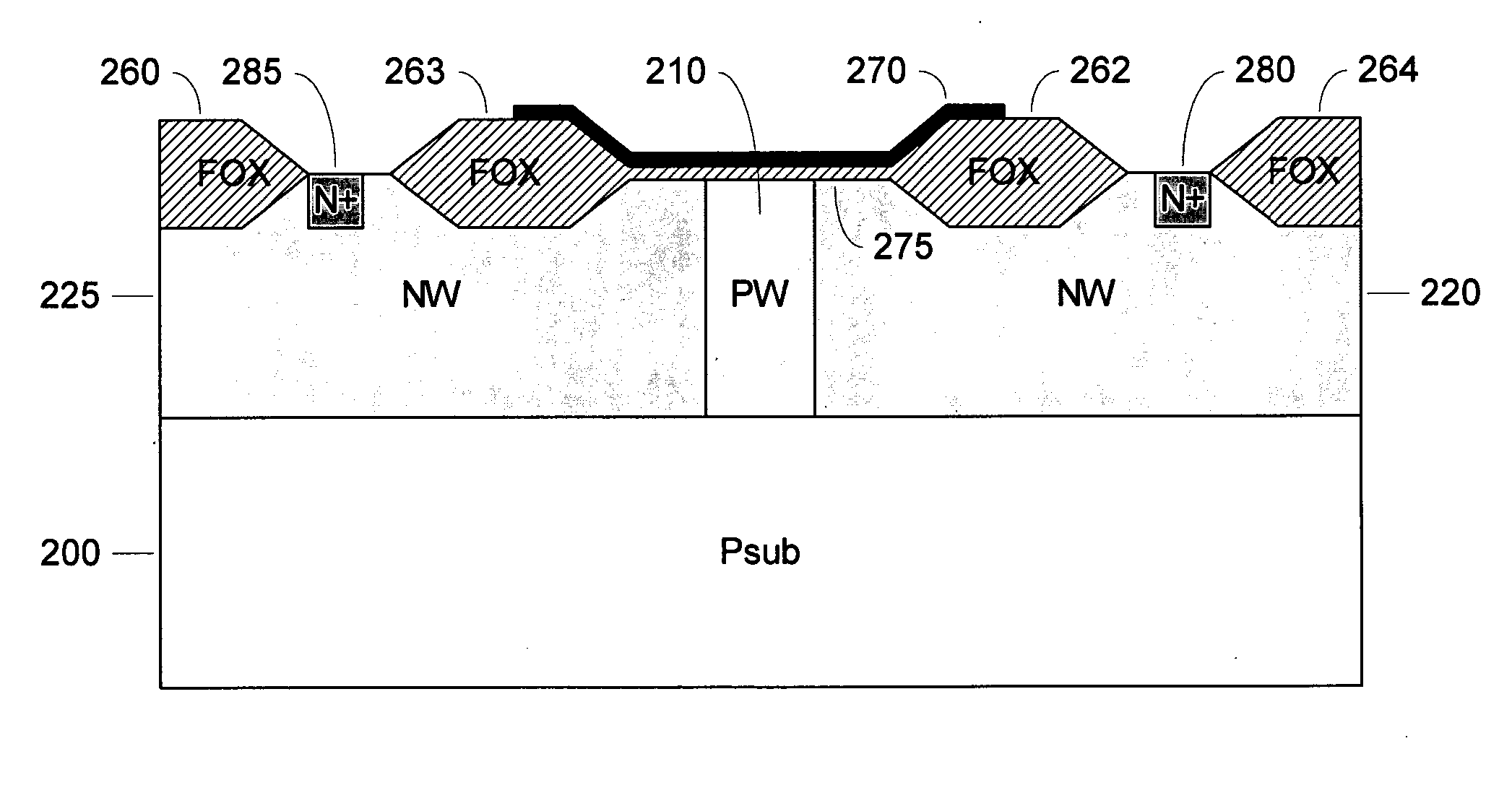

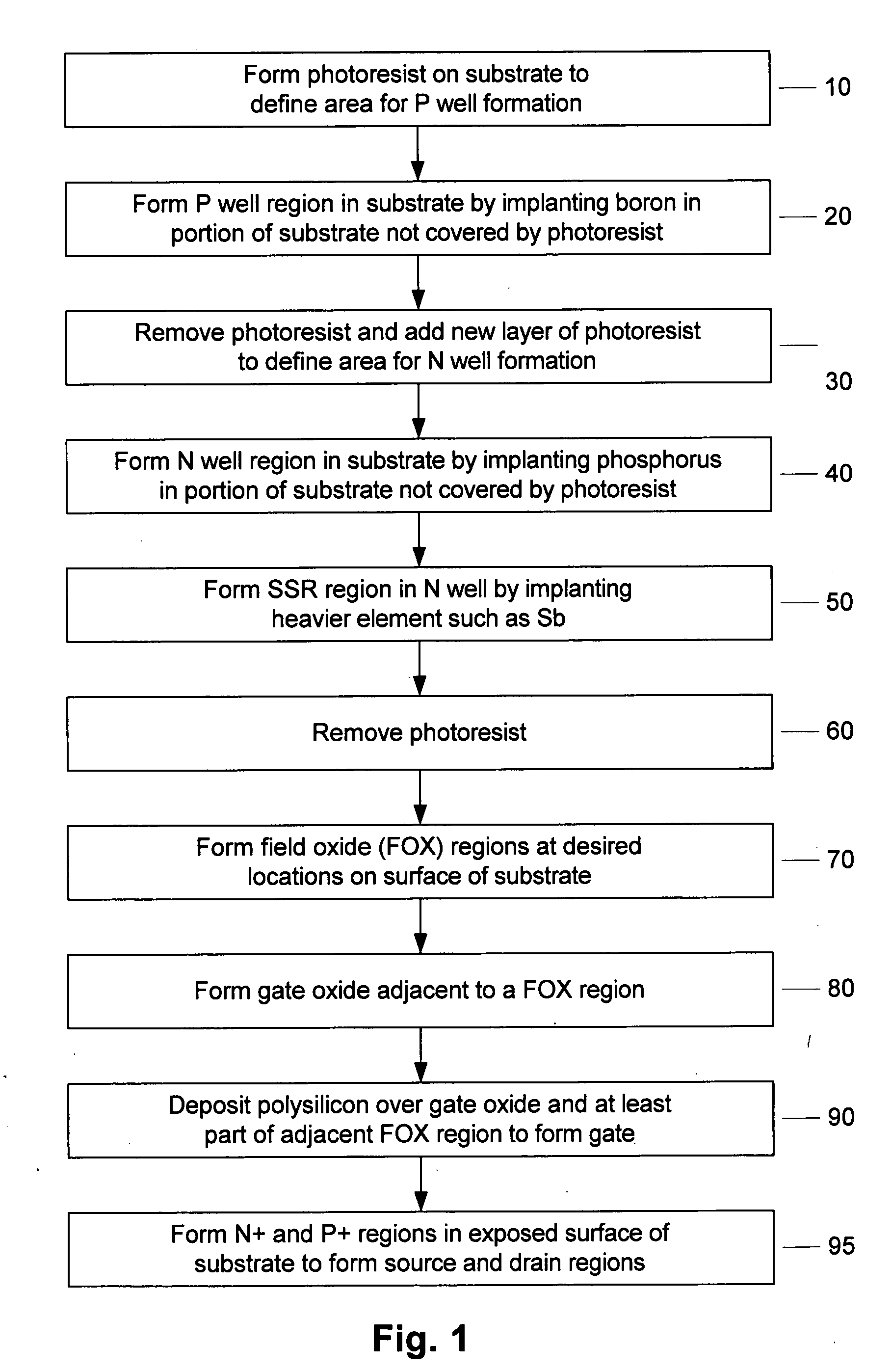

LDMOS device and method of fabrication of LDMOS device

ActiveUS20060189081A1Improve breakdown voltageReduce RONSemiconductor/solid-state device manufacturingSemiconductor devicesLDMOSElectrical resistance and conductance

A lateral double diffused metal oxide semiconductor (LDMOS) device, and method of fabricating such a device, are provided. The method comprises the steps of: (a) providing a substrate of a first conductivity type; (b) forming within the substrate a well region of a second conductivity type, the well region having a super steep retrograde (SSR) well profile in which a doping concentration changes with depth so as to provide a lighter doping concentration in a surface region of the well region than in a region below the surface region of the well region; (c) forming a gate layer which partly overlies the well region and is insulated from the well region; and (d) forming one of a source region and a drain region in the well region. The presence of the SSR well region provides a lighter surface doping to enable a higher breakdown voltage to be obtained within the LDMOS device, and heavier sub-surface doping to decrease the on-resistance.

Owner:MACRONIX INT CO LTD

Backlight structure

InactiveUS20060250542A1Surface lightPlanar/plate-like light guidesNon-linear opticsLight guideOptoelectronics

A backlight structure is provided. The backlight structure includes a light guide, a light source module and a reflector. The light guide has a groove which is positioned on one side of the bottom of the light guide. The reflector is disposed below the light guide and extended to the groove for a light mixing zone to be formed in the groove. The light source module corresponds to the groove.

Owner:AU OPTRONICS CORP

Surface light source device

InactiveUS20120020079A1Improve directionalityIncrease the light areaPlanar light sourcesNon-electric lightingLight beamOptoelectronics

A surface light source device includes a number of light sources, a first prism sheet and a second prism sheet. The light sources are distributed on a bottom plate of a housing. The first prism sheet and the second prism sheet are arranged above the light sources in that order. The light sources and the first prism sheets are spaced by a first predefined distance, and the first prism sheets and the second prism sheets are spaced by a second predefined distance. The light emitting surface of the first prism sheet includes a number of substantially parallel elongated protrusions, and the light emitting surface of the second prism sheet includes a number of elongated V-shaped ridge structures extending along different directions. Light beams emitted by the light sources are substantially diffused after passing through the first and the second prism sheet and become surface light beams.

Owner:HON HAI PRECISION IND CO LTD

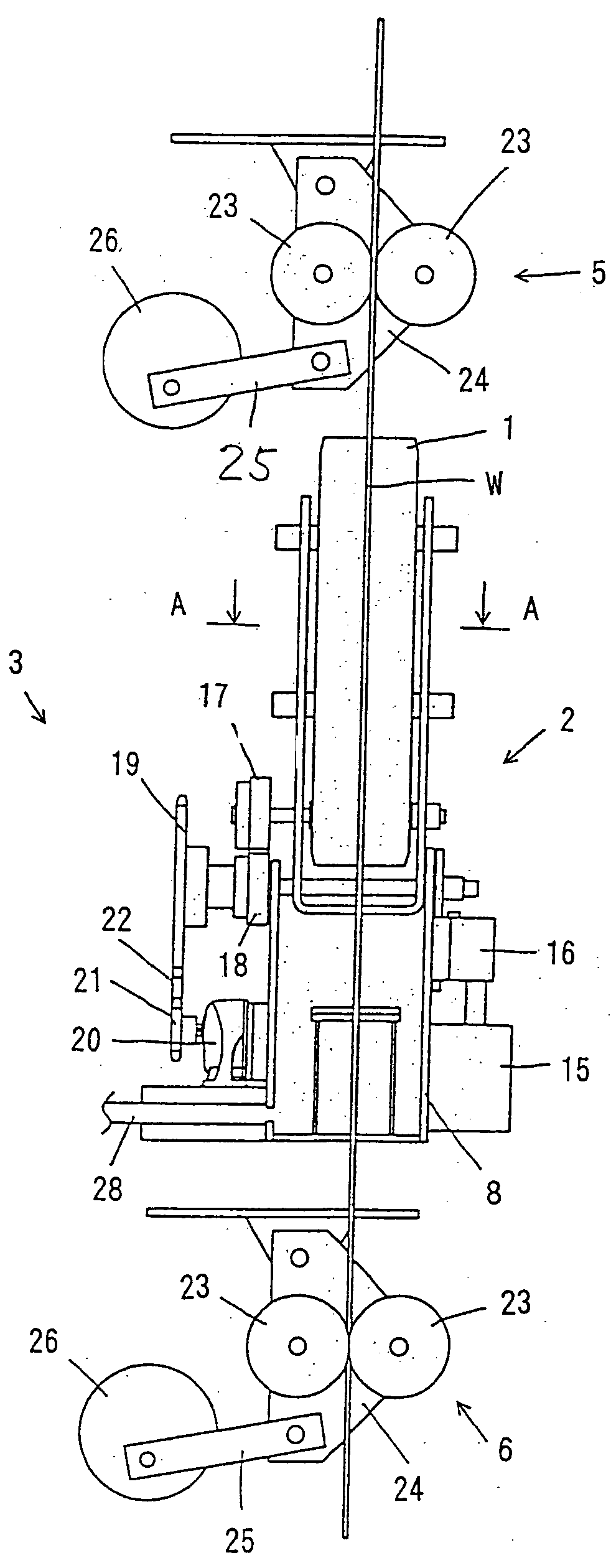

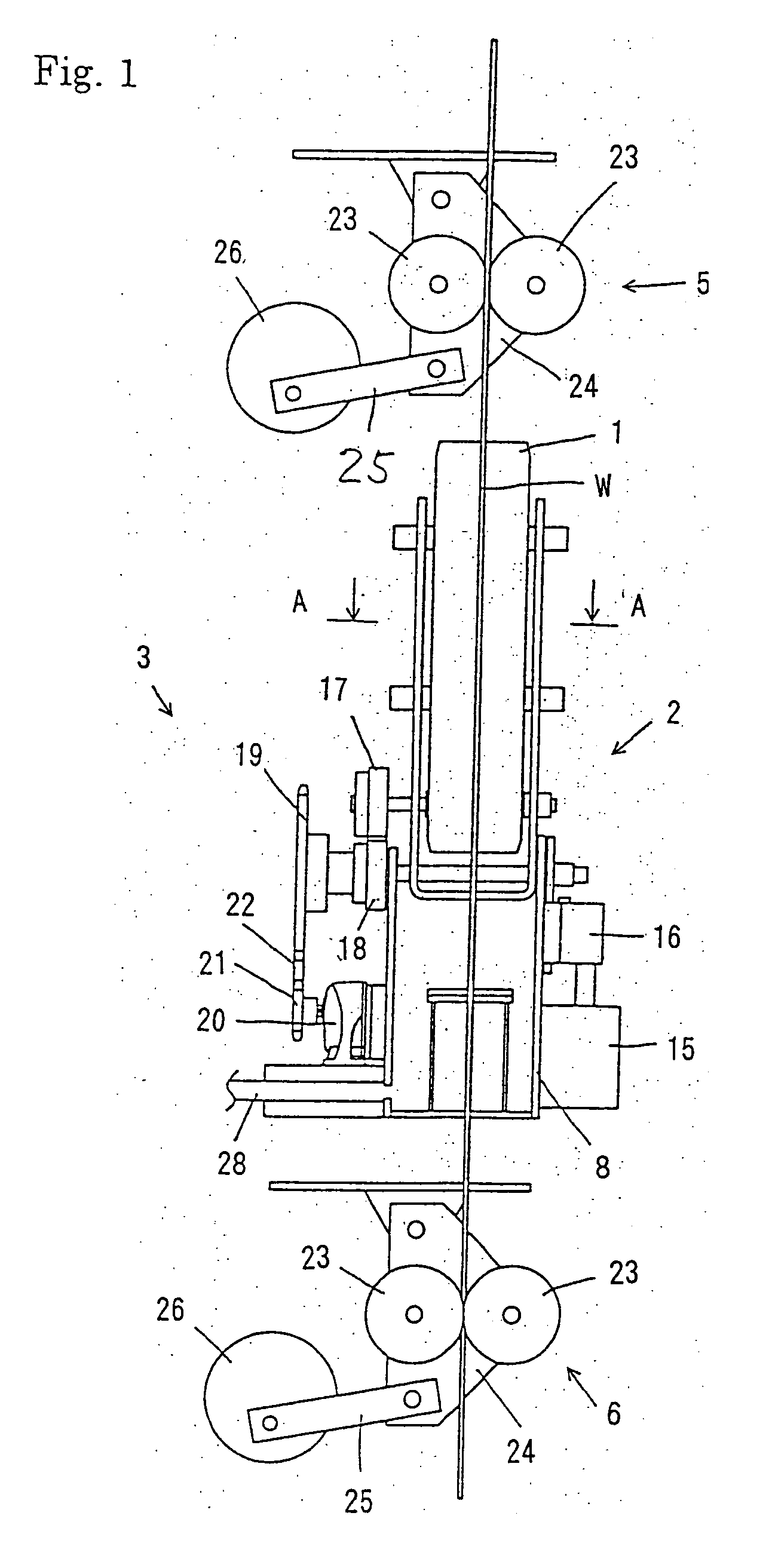

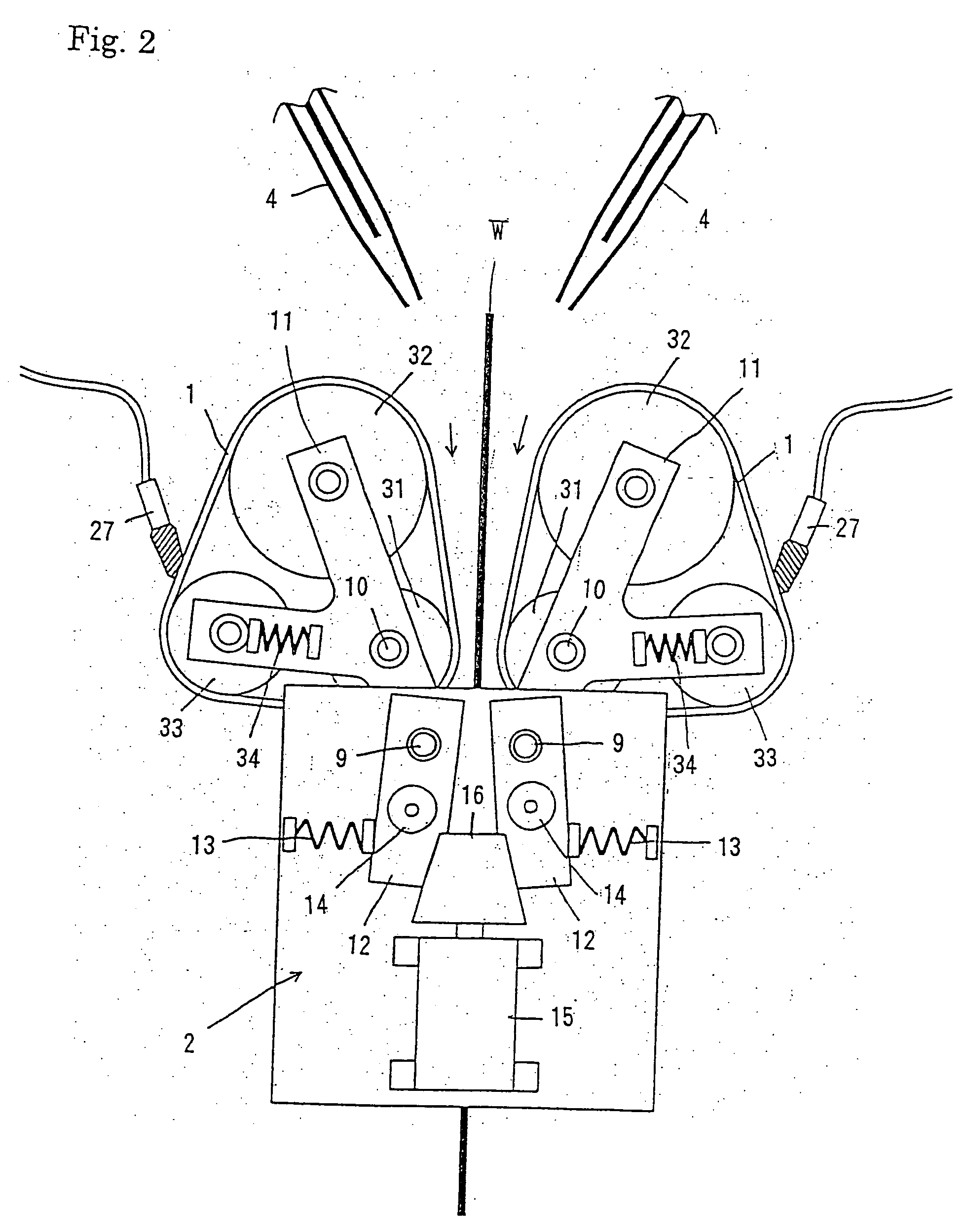

Method and apparatus for surface treatment of a long piece of material

InactiveUS20050191950A1Efficient continuous processingSurface lightPolishing machinesBelt grinding machinesMechanical propertyAbrasive

An inline-ready method of finishing the surface of a long material (W) capable of preventing any environmental problem from occurring and the mechanical properties of the long material from deteriorating, comprising the steps of holding the long material (W) by two or more elastic endless belts (1) with a specified force, rotating the elastic endless belts (1) in the same direction as or in the reverse direction to the moving direction of the long material by moving the long material (W) and increasing or decreasing the rotating speed of the elastic endless belts (1) more than or less than the moving speed of the long material, and loading powder and granular grinding material (S) between the elastic endless belts (1), characterized in that the grinding material (S) is moved relative to the long material (W) to rub the grinding material (S) against the long material (W) so as to finish the surface of the long material (W).

Owner:SINTOKOGIO LTD

Flat light source

InactiveUS7543970B2Easy constructionDecrease in degradationShow cabinetsImpedence networksLight guideOptoelectronics

Each point light source includes an overhang projecting perpendicularly to a light emitting surface from one side of the light emitting surface, and the overhang has its main surface made in contact with a light outgoing surface of a light guide plate with the light emitting surface facing a light incident surface of the light guide plate. Engagement of the overhang with the light outgoing surface of the light guide plate prevents a displacement of the light emitting surface of the point light source and the light incident surface of the light guide plate even when the light guide plate suffers from deformation such as warpage. Even if a displacement occurs, the presence of the overhang reflects leaked light to guide it to the light incident surface of the light guide plate.

Owner:MITSUBISHI ELECTRIC CORP

Image capture apparatus

ActiveUS20190156096A1Avoid problemsSurface lightCoupling light guidesPrint image acquisitionLight guideLight beam

An image capturing apparatus includes a light transmitting cover, a display panel, a Light guiding member, a light emitting element, and an image capturing element. The light transmitting cover has a surface in contact with the environmental medium. The light emitting element is disposed on one side of the Light guiding member. The sensing light beam is transmitted to the light penetrating portion in the first light guiding portion to be projected to the display area of the light transmitting cover, and a portion of the sensing light beam is totally reflected by the surface to form a signal beam that enters the second light guiding portion from the light penetrating portion. The image capturing element is disposed on the other side of the Light guiding member to receive the signal light beam that is transmitted in the second light guiding portion.

Owner:GINGY TECH

Solid-state imaging device and production method of the same

InactiveUS20050145905A1Reduce harmImprove operating characteristicsTelevision system detailsSolid-state devicesSemiconductorSurface cover

A solid-state imaging device is provided, which comprises unit pixel portions. Each unit pixel portion comprises a first conductivity type substrate, a second conductivity type semiconductor layer, a first conductivity type well region, a light receiving region for generating electric charges when irradiated with light, an electric charge accumulation region for accumulating the electric charges from the light receiving region, and a transistor capable of reading out a signal corresponding to an amount of the electric charges accumulated in the electric charge accumulation region. A surface of the light receiving region is covered with an insulating film made of the same material as that of a gate insulating film of the transistor.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com