Splicing and connectorization of photonic crystal fibres

a technology of photonic crystal fibres and connectors, applied in the field of optical fibers, can solve the problems of poor mechanical strength, high splice loss, and difficult transition from small core pcfs to standard optical fibers, and achieve the effect of low loss and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

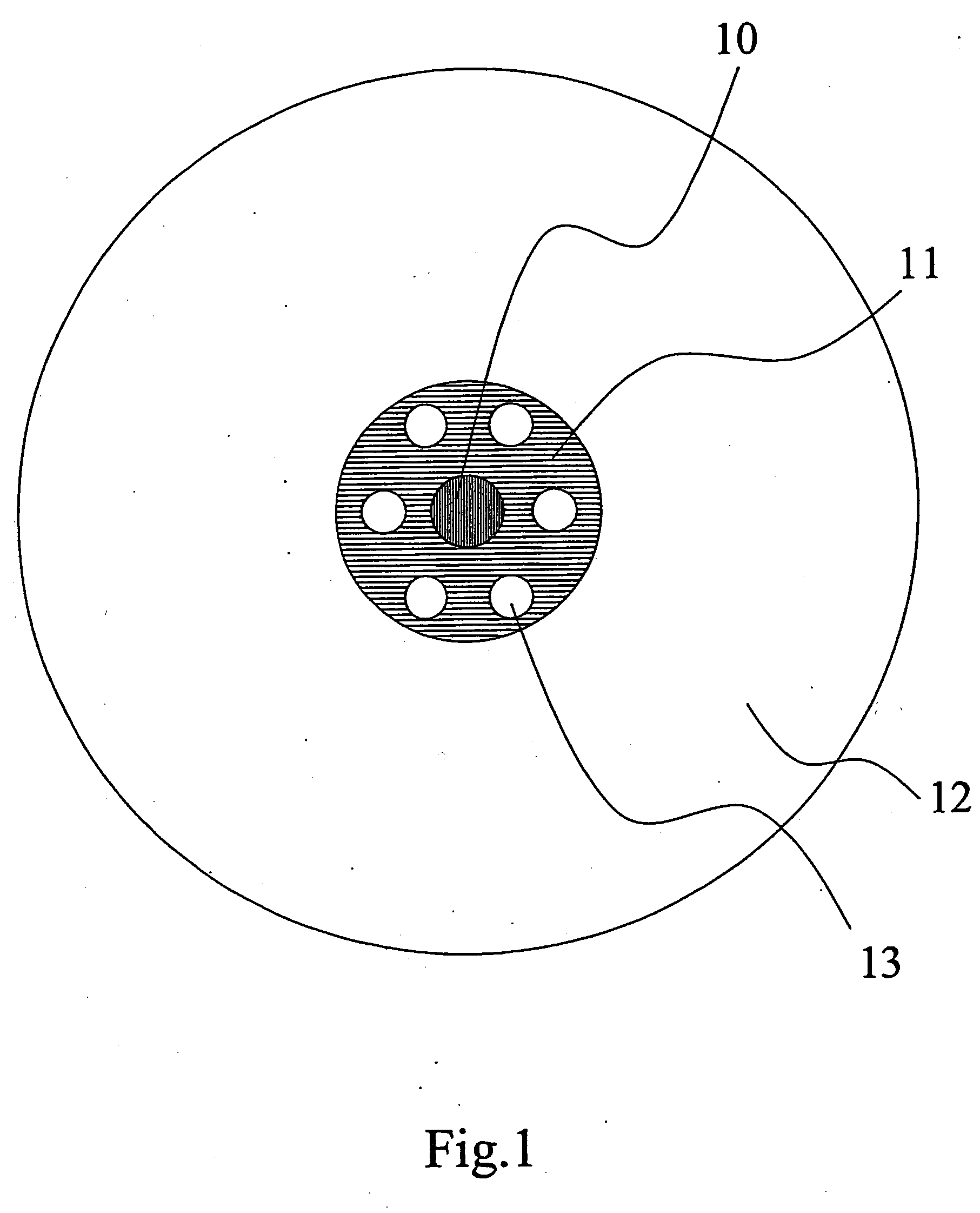

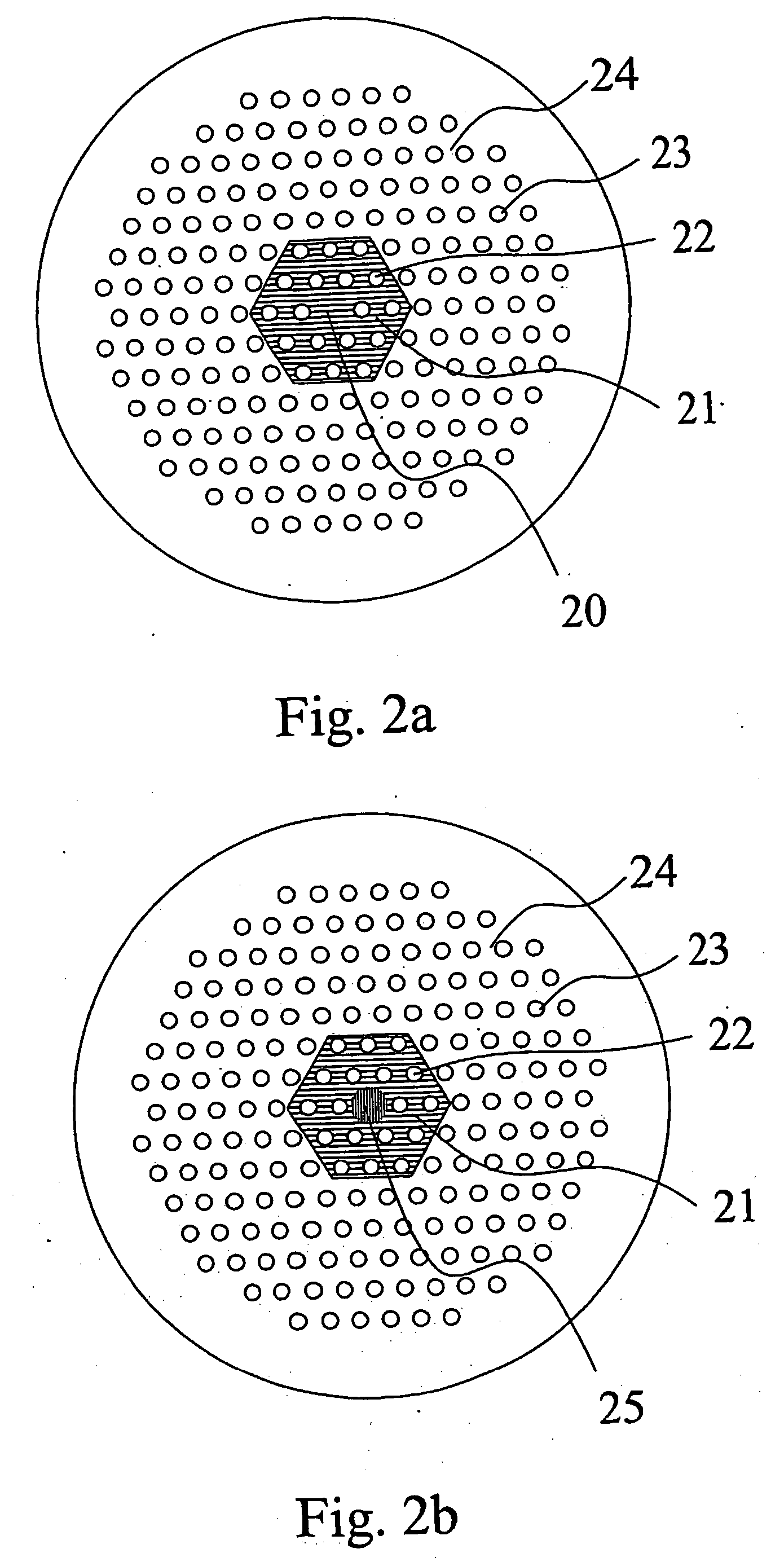

[0116] According to one aspect of the present invention, these objects are fulfilled by providing an optical fibre having an axial direction and a cross section perpendicular to said axial direction, said optical fibre comprising a core region, an inner cladding region and an outer cladding region, wherein said inner cladding region comprises inner cladding features and an inner background material of refractive index n1, and said outer cladding region comprises an outer background material of refractive index n2, and n1 is larger than n2.

[0117] In a preferred embodiment, said core region comprises material with a refractive index ncore, and ncore is equal to n1. This provides for example to use similar background material for the inner cladding region and the core region.

[0118] In a preferred embodiment, said core region comprises material with a refractive index ncore, and ncore is larger than n1. This allows for example to design an optical fibre with a high nonlinear coefficie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com