Manufacturing method of glass fiber cloth reinforced copper-clad plate

A technology of glass fiber cloth and manufacturing method, applied in printed circuit manufacturing, chemical instruments and methods, manufacturing printed circuit precursors, etc., can solve the problem of affecting the dielectric properties of CCL, high volume fraction of CCL, affecting the rigidity of CCL problems, to achieve the effect of improving peel strength, improving dielectric properties, and reliable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

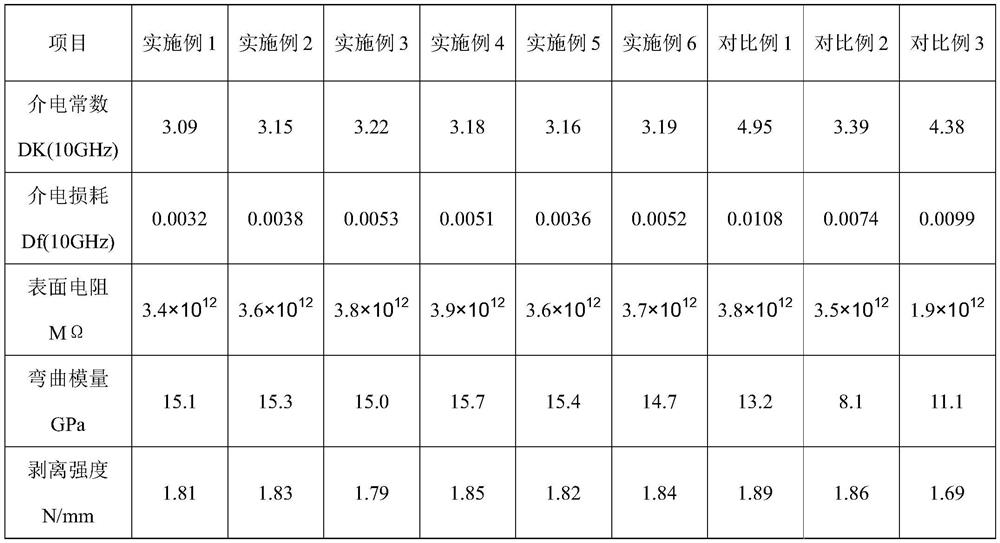

Examples

Embodiment 1

[0027] A method for manufacturing a glass fiber cloth reinforced copper clad laminate, comprising the following specific steps:

[0028] S1. Preparation of reinforcement material: choose glass fiber cloth as reinforcement material, weave glass fiber cloth with E-GLASS non-alkali glass roving, thickness is 0.01mm, grammage is 15g / m 2 , and then spray 4 parts by weight of polytetrafluoroethylene under the condition of air pressure of 0.3MPa, after standing for 8 minutes, spray 1 part by weight of epoxy resin, and dry at a temperature of 35 ° C for 30 minutes, and finally use vinyl three Surface treatment with ethoxysilane at 150°C to obtain reinforced materials;

[0029] S2. Preparation of modified resin: take epoxy resin as the basic body, carry out blending reaction with dicyclopentadiene, oligophenylene ether and styrene, and then add flame retardant and mix uniformly to obtain modified resin. Among them, the weight ratio of epoxy resin to dicyclopentadiene, oligophenylene e...

Embodiment 2

[0033] A method for manufacturing copper-clad laminates reinforced with glass fiber cloth, S1. Prepare glass fiber cloth in the reinforced material, with a thickness of 0.1mm and a grammage of 90g / m 2 . Others are with embodiment 1.

Embodiment 3

[0035] A method for manufacturing copper-clad laminates reinforced with glass fiber cloth, S1. Prepare glass fiber cloth in the reinforcement material, with a thickness of 0.2mm and a grammage of 180g / m 2 . Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com