Preparation method of auxiliary water reducing agent for cement-based building material

A water-reducing agent and infrastructure technology, applied in the field of building admixtures, can solve the problems of by-products affecting performance and harsh preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

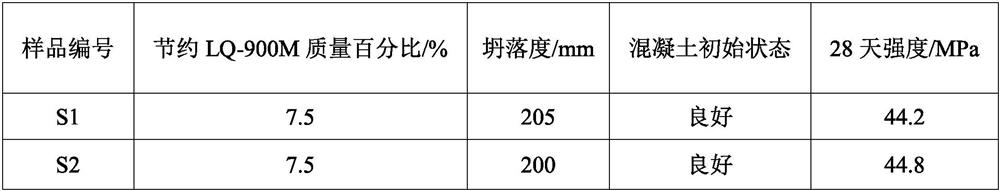

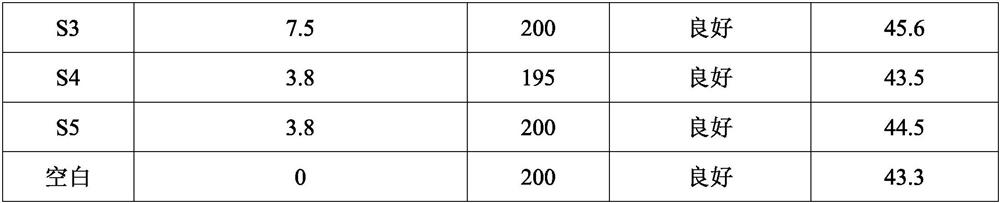

Examples

Embodiment 1

[0025] 100g of TPEG (number average molecular weight 2300-2500), 5.4g of acrylic acid and deionized water were added to the reactor. Under continuous stirring, the temperature of the reactor was raised to 60±5°C. When the reaction kettle is stabilized at 60±5°C, add 1.8 g of potassium persulfate at one time under continuous stirring. Then, the reaction kettle was kept warm at 60±5°C, and a deionized aqueous solution containing 0.9 g of ammonium persulfate was added dropwise, and the drop was completed within 1 to 2 hours. After dropping, keep warm at 60±5°C for 1-2h. Finally, after cooling down to 50°C, liquid caustic soda was added into the reaction kettle, and the final pH was adjusted to 5-6 to obtain auxiliary water reducer for cement-based building materials. Record the sample as S-1.

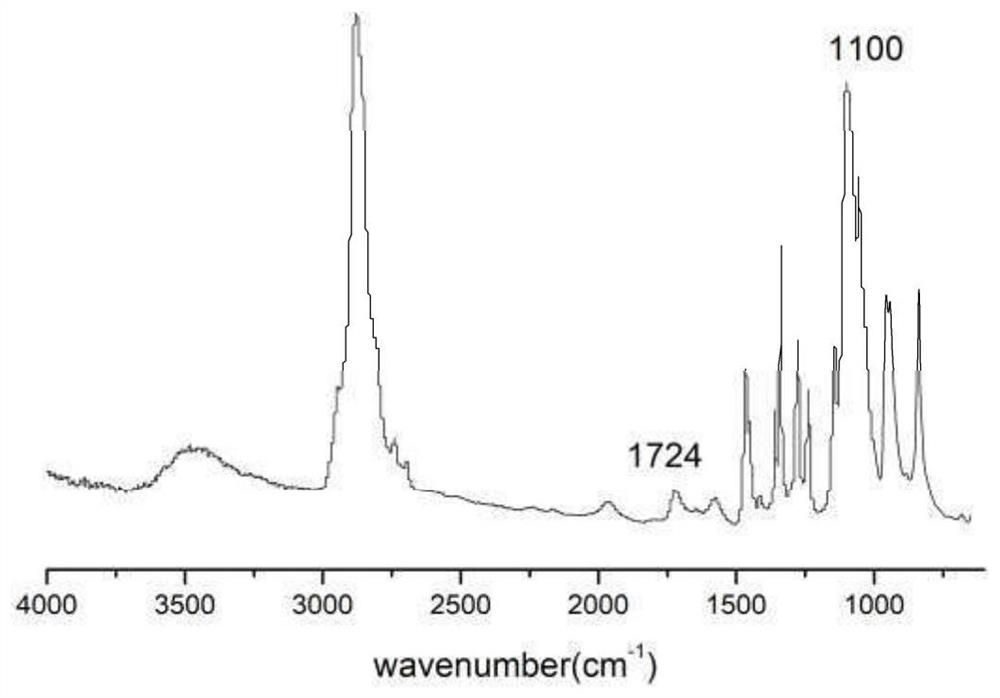

[0026] Purify S-1, and then characterize the S1 sample with a Nicholas Fourier transform infrared spectrometer IS5, the spectrum is as follows figure 1 shown. figure 1 1109cm in the in...

Embodiment 2

[0028] 100g of TPEG (number average molecular weight 2300-2500), 2.7g of acrylic acid and deionized water were added to the reactor. Under continuous stirring, the temperature of the reactor was raised to 60±5°C. When the reaction kettle is stabilized at 60±5°C, add 0.9 g of ammonium persulfate at one time under continuous stirring. Then, the reaction kettle was kept warm at 60±5°C, and a deionized aqueous solution containing 0.45 g of ammonium persulfate was added dropwise, and the drop was completed within 2 to 3 hours. After dropping, keep warm at 60±5°C for 1-2h. Finally, after cooling down to 50°C, liquid caustic soda was added to the reaction kettle, and the final pH was adjusted to 5-6 to obtain cement-based building material auxiliary water reducer, and the recorded sample was S-2.

Embodiment 3

[0030] 100 g of TPEG (number average molecular weight 2300-2500), 3.6 g of acrylic acid and deionized water were added to the reactor. Under continuous stirring, the temperature of the reactor was raised to 60±5°C. When the reaction kettle is stabilized at 60±5°C, add 0.63 g of potassium persulfate at one time under continuous stirring. Then, the reaction kettle was kept warm at 60±5°C, and the deionized aqueous solution containing 0.27g VC was added dropwise, and the drop was completed within 3 to 4 hours. After dropping, keep warm at 60±5°C for 1-2h. Finally, after cooling down to 50°C, liquid caustic soda was added to the reaction kettle, and the final pH was adjusted to 5-6 to obtain cement-based building material auxiliary water reducer, and the recorded sample was S-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com