Carboxy nitrile rubber high-performance damping material and method for producing the same

A carboxyl nitrile rubber and damping material technology, which is applied in the field of carboxy nitrile rubber-based high-performance damping materials and their preparation, can solve problems such as non-controllability, and achieve the effects of large loss factor and improved damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

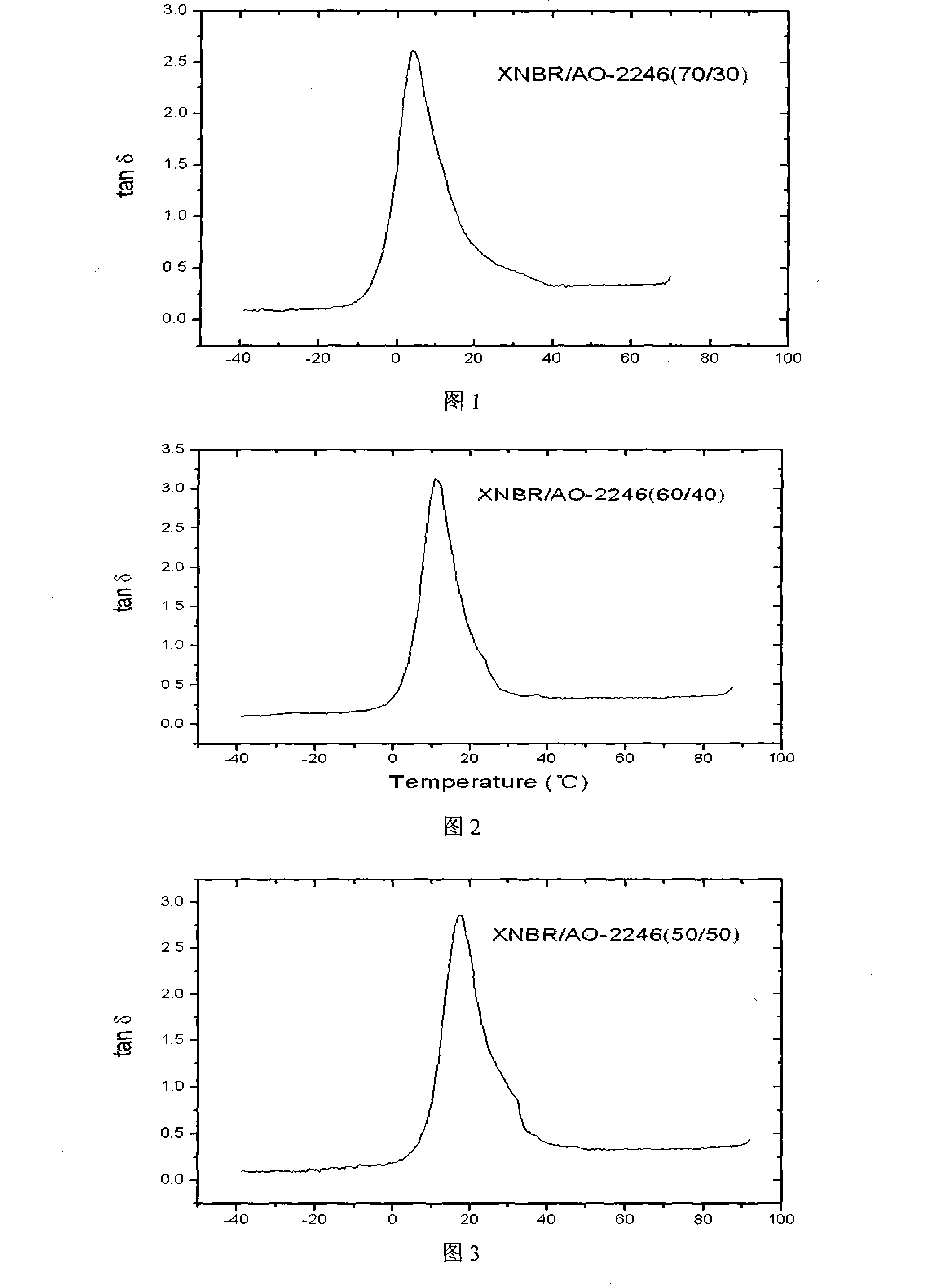

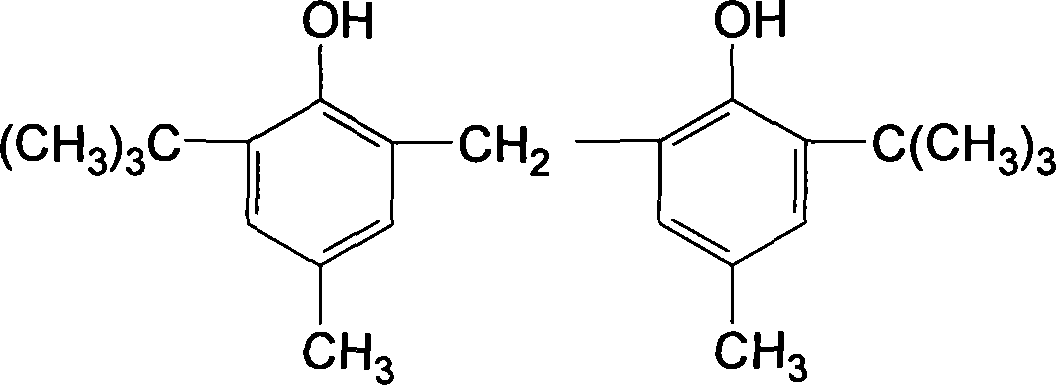

[0033] With the formula carboxybutyl rubber (XNBR) as 70 parts by mass and hindered phenol antioxidant (AO-2246) as 30 parts by mass, a 1mm thin sheet sample was prepared strictly according to the above preparation method, and a dynamic mechanical analyzer (DMA- 7, Perkin Elmer) conducted dynamic mechanical tests on it. Test conditions: frequency 1Hz, temperature -50-100°C, heating rate 5°C / min, tensile mode, test results shown in Figure 1. It can be seen from Figure 1 that the peak loss factor of this material can reach 2.62, and the peak value is located at 3.9°C; the temperature range corresponding to tanδ≥0.3 is -7~67.2°C, that is, the effective damping temperature range can reach 74.2°C.

Embodiment 2

[0035] With the formulation of carboxybutyl rubber (XNBR) as 60 parts by mass and hindered phenol antioxidant (AO-2246) as 40 parts by mass, a 1mm thin sheet sample was prepared strictly according to the above preparation method, and a dynamic mechanical analyzer (DMA- 7, Perkin Elmer) conducted dynamic mechanical tests on it. Test conditions: frequency 1Hz, temperature -50-100°C, heating rate 5°C / min, tensile mode, test results shown in Figure 2. It can be seen from Figure 2 that the peak loss factor of this material can reach 3.14, and the peak value is located at 10.7°C; the temperature range corresponding to tanδ≥0.3 is -1.9~84.7°C, that is, the effective damping temperature range can reach 86.3°C.

Embodiment 3

[0037] With the formulation of carboxybutyl rubber (XNBR) as 50 parts by mass and hindered phenol antioxidant (AO-2246) as 50 parts by mass, a 1mm thin sheet sample was prepared strictly according to the above preparation method, and a dynamic mechanical analyzer (DMA- 7, Perkin Elmer) conducted dynamic mechanical tests on it. Test conditions: frequency 1Hz, temperature -50-100°C, heating rate 5°C / min, tensile mode, test results shown in Figure 3. It can be seen from Figure 3 that the peak loss factor of this material can reach 2.87, and the peak value is located at 17.4°C; the temperature range corresponding to tanδ≥0.3 is 4.9-91.8°C, that is, the effective damping temperature range can reach 86.7°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com