High attenuating earmuff device

a high-attenuation, earmuff technology, applied in the direction of earmuffs, hats, headwear caps, etc., can solve the problems of increasing attenuation, earmuffs not being achieved, annoying or impractical to continue insertion and removal of earplugs,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

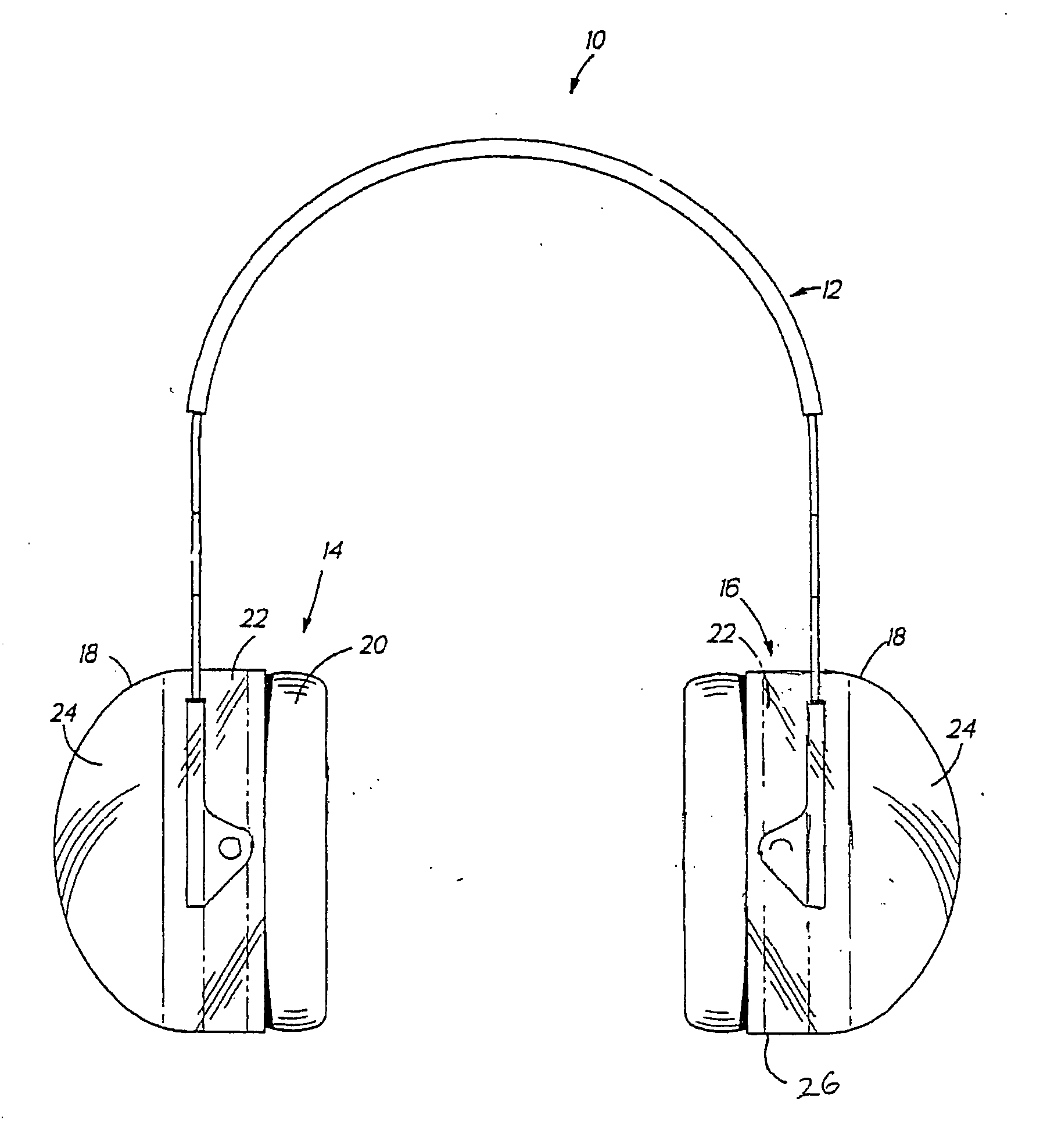

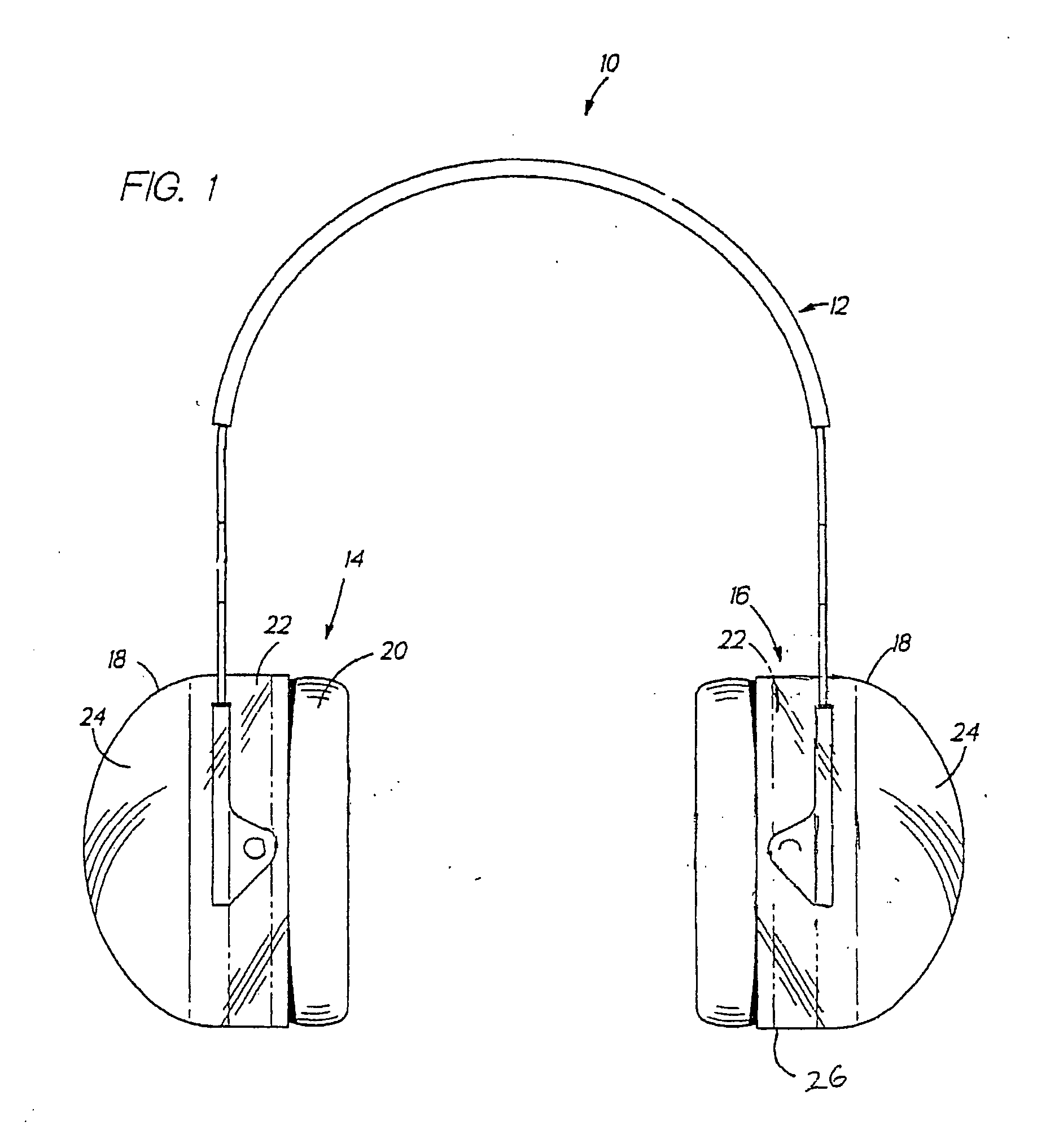

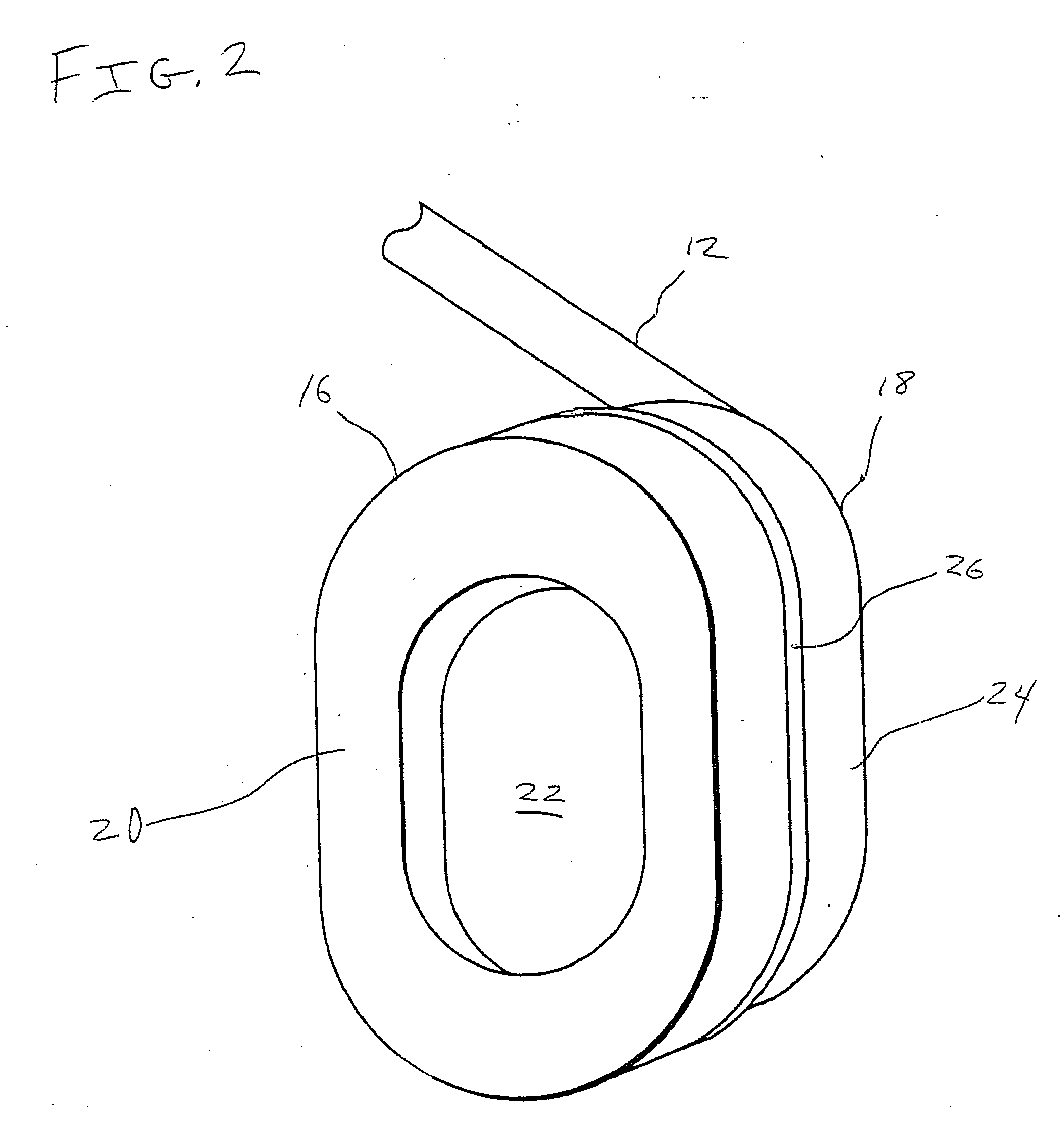

[0015] An earmuff device 10 is shown in FIGS. 1 and 2 in an exemplary embodiment of the invention. The earmuff device 10 broadly comprises a generally U-shaped, resilient connecting band 12 and a pair of earmuff cup assemblies 14 and 16 connected to opposite ends of connecting band 12.

[0016] The ear muff cup assemblies 14 and 16 are affixed to the connecting band 12 in any desired manner. Most preferably, earmuff cup assemblies 14 and 16 may be connected to an adapter which, in turn, is connected to the band 12. The adapter may be configured to allow the ear muff cup assemblies 14 and 16 to pivot or rotate relative the band 12 or, alternatively, the adapter may hold the assemblies 14 and 16 fixedly on the band 12, etc.

[0017] Each of the earmuff cup assemblies 14 and 16 comprises a rigid earmuff cup 18, a cushion 20, and an earmuff cup liner 22. Rigid cup 18 is generally formed of two pieces, a cup shaped portion 24 and a cushion seal plate 26, which are fixed together at an interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com