Mud-proof slump-retaining type polycarboxylate superplasticizer with low shrinkage and high adaptability and low-temperature preparation method thereof

An adaptable, polycarboxylic acid technology, applied in the field of water reducing agent improvement, can solve the problems of reduced concrete work performance, high mud content in sand and gravel aggregates, easy bleeding, bottom scratching, etc., to reduce sensitivity, High polymerization activity, improved workability and bleeding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

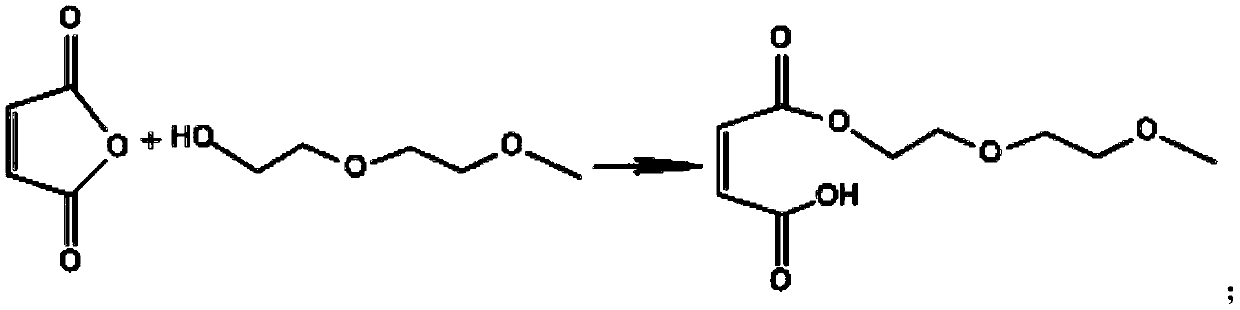

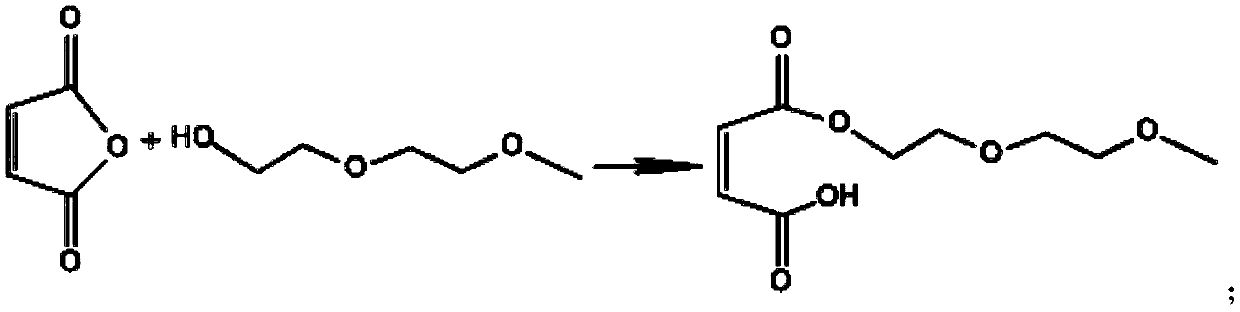

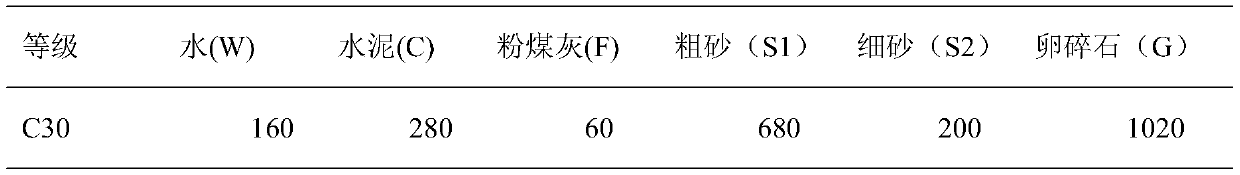

[0033]A low-shrinkage and high-adaptability mud-retaining polycarboxylate water-reducer, said low-shrinkage and high-adaptability mud-resistance polycarboxylate water-reducer is prepared by reacting the following raw materials in parts by mass : 300 parts of 4-hydroxybutyl vinyl polyoxyethylene ether, 16 parts of unsaturated carboxylic acid, 3.6 parts of unsaturated amide monomer, 12 parts of unsaturated carboxylic acid ester, diethylene glycol monomethyl ether maleate 7.2 parts, 2.33 parts of unsaturated quaternary ammonium salt monomers, 4.5 parts of oxidants, 0.016 parts of catalysts, 1.35 parts of reducing agents, 1.5 parts of chain transfer agents, 470 parts of deionized water; the 4-hydroxybutyl vinyl polyoxyethylene Ether, unsaturated carboxylic acid, unsaturated amide monomer, unsaturated carboxylic acid ester, diethylene glycol monomethyl ether maleate and unsaturated quaternary ammonium salt monomer, their material ratio is: 1.0 : 2.96: 0.23: 1.38: 0.44: 0.16; the co...

Embodiment 2

[0039] A low-shrinkage and high-adaptability mud-retaining polycarboxylate water-reducer, said low-shrinkage and high-adaptability mud-resistance polycarboxylate water-reducer is prepared by reacting the following raw materials in parts by mass : 330 parts of 4-hydroxybutyl vinyl polyoxyethylene ether, 17.5 parts of unsaturated carboxylic acid, 2.4 parts of unsaturated amide monomer, 15.6 parts of unsaturated carboxylic acid ester, diethylene glycol monomethyl ether maleate 7.5 parts, 2.12 parts of unsaturated quaternary ammonium salt monomers, 4.64 parts of oxidants, 0.018 parts of catalysts, 1.5 parts of reducing agents, 1.8 parts of chain transfer agents, 525 parts of deionized water; the 4-hydroxybutyl vinyl polyoxyethylene Ether, unsaturated carboxylic acid, unsaturated amide monomer, unsaturated carboxylic acid ester, diethylene glycol monomethyl ether maleate and unsaturated quaternary ammonium salt monomer, their material ratio is: 1.0 : 2.94: 0.41: 1.45: 0.42: 0.19; t...

Embodiment 3

[0045] A low-shrinkage and high-adaptability mud-retaining polycarboxylate water-reducer, said low-shrinkage and high-adaptability mud-resistance polycarboxylate water-reducer is prepared by reacting the following raw materials in parts by mass : 300 parts of 4-hydroxybutyl vinyl polyoxyethylene ether, 18.2 parts of unsaturated carboxylic acid, 1.6 parts of unsaturated amide monomer, 13.5 parts of unsaturated carboxylic acid ester, diethylene glycol monomethyl ether maleate 6.9 parts, 2.82 parts of unsaturated quaternary ammonium salt monomers, 4.8 parts of oxidants, 0.015 parts of catalysts, 1.6 parts of reducing agents, 1.96 parts of chain transfer agents, 470 parts of deionized water; the 4-hydroxybutyl vinyl polyoxyethylene Ether, unsaturated carboxylic acid, unsaturated amide monomer, unsaturated carboxylic acid ester, diethylene glycol monomethyl ether maleate and unsaturated quaternary ammonium salt monomer, their material ratio is: 1.0 : 2.82: 0.21: 1.38: 0.42: 0.18; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com