Halogen-free flame-retardant fiberglass-reinforced PA (Polyamide)/ASA (Acrylonitrile Styrene Acrylate Copolymer) composite material and preparation method thereof

A composite material and glass fiber technology, applied in the field of polymer materials, can solve the problems of insufficient low temperature and dry toughness, poor dimensional stability, poor weather resistance, etc., to reduce material shrinkage performance, good mechanical properties, improve compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

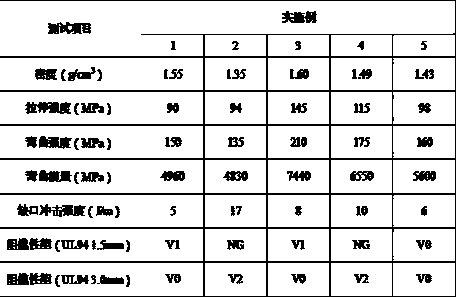

Examples

Embodiment 1

[0028] A halogen-free flame-retardant, glass fiber-reinforced PA / ASA composite material is provided, the components and parts by mass of the halogen-free flame-retardant, glass fiber-reinforced PA / ASA composite material are as follows: polyamide: 30 wt. Parts; Graft copolymer of acrylate rubber body and acrylonitrile, styrene: 18 parts by weight; Flame retardant: 25 parts by weight; Compatibilizer: 4 parts by weight; Glass fiber: 18 parts by weight; Toughener: 5 parts by weight; nucleating agent: 0.1 parts by weight; lubricant: 0.1 parts by weight; antioxidant: 0.1 parts by weight.

[0029] The polyamide is PA6, and the relative ratio of the polyamide is 2.45.

[0030] The melt index of said ASA is 15g / 10min.

[0031] The flame retardant is compounded by organic hypophosphite, aluminum hypophosphite and ammonium polyphosphate APP.

[0032] The compatibilizer is a mixture of polystyrene-acrylonitrile-GMA copolymer SAG and ABS grafted maleic anhydride ABS-g-MAH.

[0033] The ...

Embodiment 2

[0044] A halogen-free flame-retardant, glass fiber-reinforced PA / ASA composite material is provided, the components and parts by weight of the halogen-free flame-retardant, glass fiber-reinforced PA / ASA composite material are as follows: polyamide: 45 wt. Graft copolymer of acrylate rubber body and acrylonitrile, styrene: 20 parts by weight; Flame retardant: 18 parts by weight; Compatibilizer: 3.5 parts by weight; Glass fiber: 20 parts by weight; Toughener: 5 parts by weight; nucleating agent: 0.1 parts by weight; lubricant: 0.1 parts by weight; antioxidant: 0.1 parts by weight.

[0045] The polyamide is PA66, and the relative viscosity of the polyamide is 2.8P·S.

[0046] The melt index of the graft copolymer of the acrylic rubber body, acrylonitrile and styrene is 20g / 10min.

[0047] The flame retardant is melamine cyanurate MCA.

[0048] The compatibilizer is a mixture of polystyrene-maleic anhydride copolymer SMA and polyethylene-methyl acrylate copolymer EMA.

[0049] ...

Embodiment 3

[0060] A halogen-free flame-retardant, glass fiber-reinforced PA / ASA composite material is provided, the components and parts by mass of the halogen-free flame-retardant, glass fiber-reinforced PA / ASA composite material are as follows: polyamide: 20 wt. Parts; Graft copolymer of acrylate rubber body and acrylonitrile, styrene: 30 parts by weight; Flame retardant: 15 parts by weight; Compatibilizer: 2 parts by weight; Glass fiber: 30 parts by weight; Toughener: 3 parts by weight; nucleating agent: 0.5 parts by weight; lubricant: 0.5 parts by weight; antioxidant: 0.5 parts by weight.

[0061] The polyamide is PA66, and the relative viscosity range of the polyamide is 2.6 P·S.

[0062] The melt index of the graft copolymer of the acrylic rubber, acrylonitrile and styrene is 18g / 10min.

[0063] The flame retardant is compounded by aluminum hypophosphite, ammonium polyphosphate APP and melamine cyanurate MCA.

[0064] The compatibilizer is a mixture of ABS grafted maleic anhydrid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com