Stretch yarns and fabrics with multiple elastic yarns

a technology applied in the field of fabric manufacturing of stretch composite yarns and fabrics, can solve the problems of high recovery, low shrinkage performance, and difficult to obtain fabrics with easy stretch, and achieve the effects of low shrinkage performance, high recovery, and easy stretch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

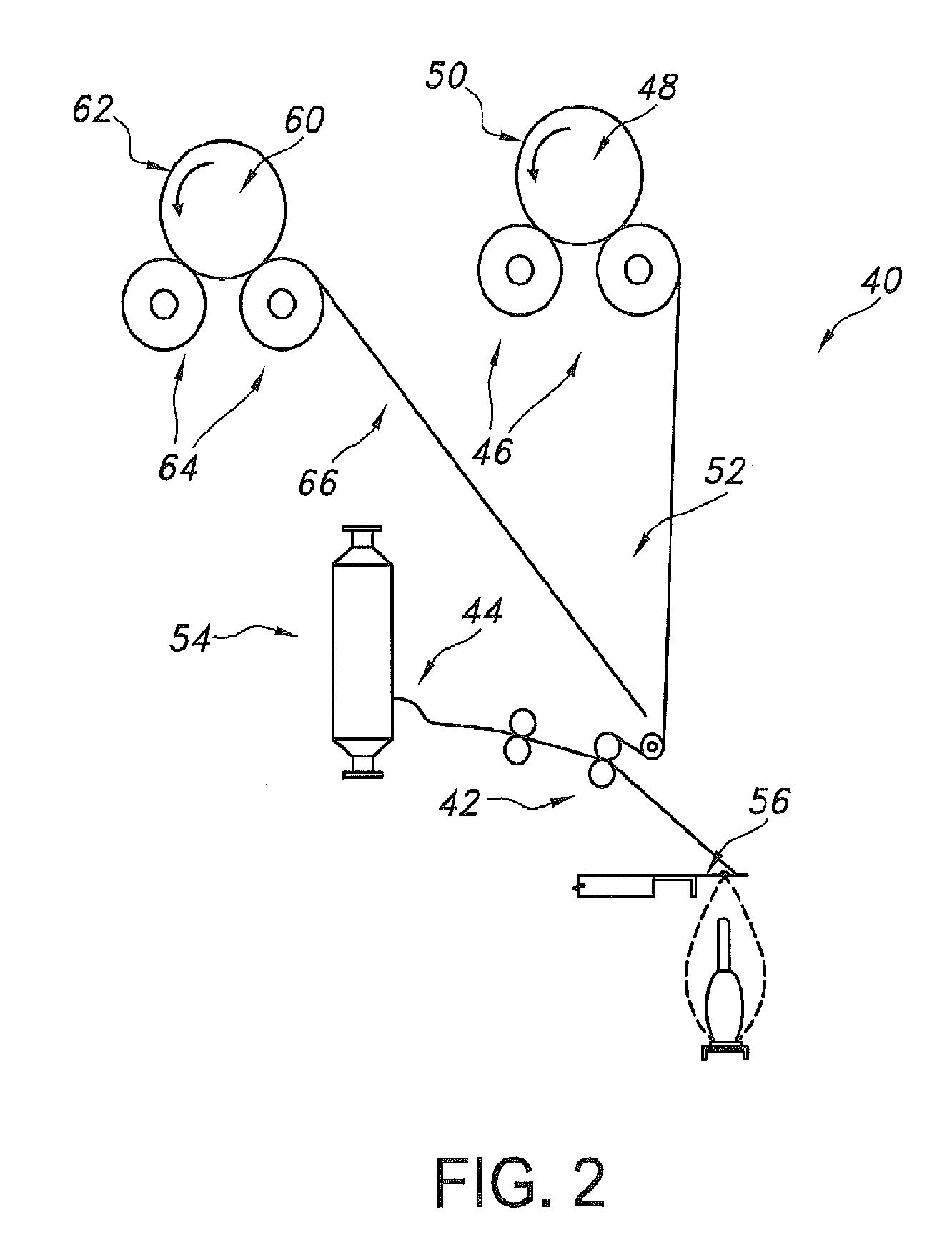

Method used

Image

Examples

examples

[0067]The following examples demonstrate the present invention and its capability for use in manufacturing a variety of fabrics. The invention is capable of other and different embodiments, and its several details are capable of modifications in various apparent respects, without departing from the scope and spirit of the present invention. Accordingly, the examples are to be regarded as illustrative in nature and not as restrictive.

[0068]For each of the following denim fabric examples, 100% cotton open end spun yarn or ring spun was used as warp yarn. For denim fabrics, they included two count yarns: 7.0 Ne OE yarn and 8.5 Ne OE yarn with irregular arrangement pattern. The yarns were indigo dyed in rope form before beaming. Then, they were sized and made the weaving beam. For bottom weight fabrics, the warp yarn are 20Ne 100% cotton ring spun yarn. They were sized and made the weaving beam.

[0069]Table 1 lists four examples of core spun yarn with traditional one elastic core filamen...

example yarn a

Typical Core Spun Yarn with One Elastic Core Fiber

[0073]This is not an innovative yarn. This core spun yarn is 16Ne with one 40d LYCRA® spandex fiber covered by cotton sheath. The draft of the LYCRA® fiber is 3.5× during covering process. The cotton twist level TM is 18 twisters per inch. This yarn has 17.71% recoverable stretch after boil off.

example yarn b

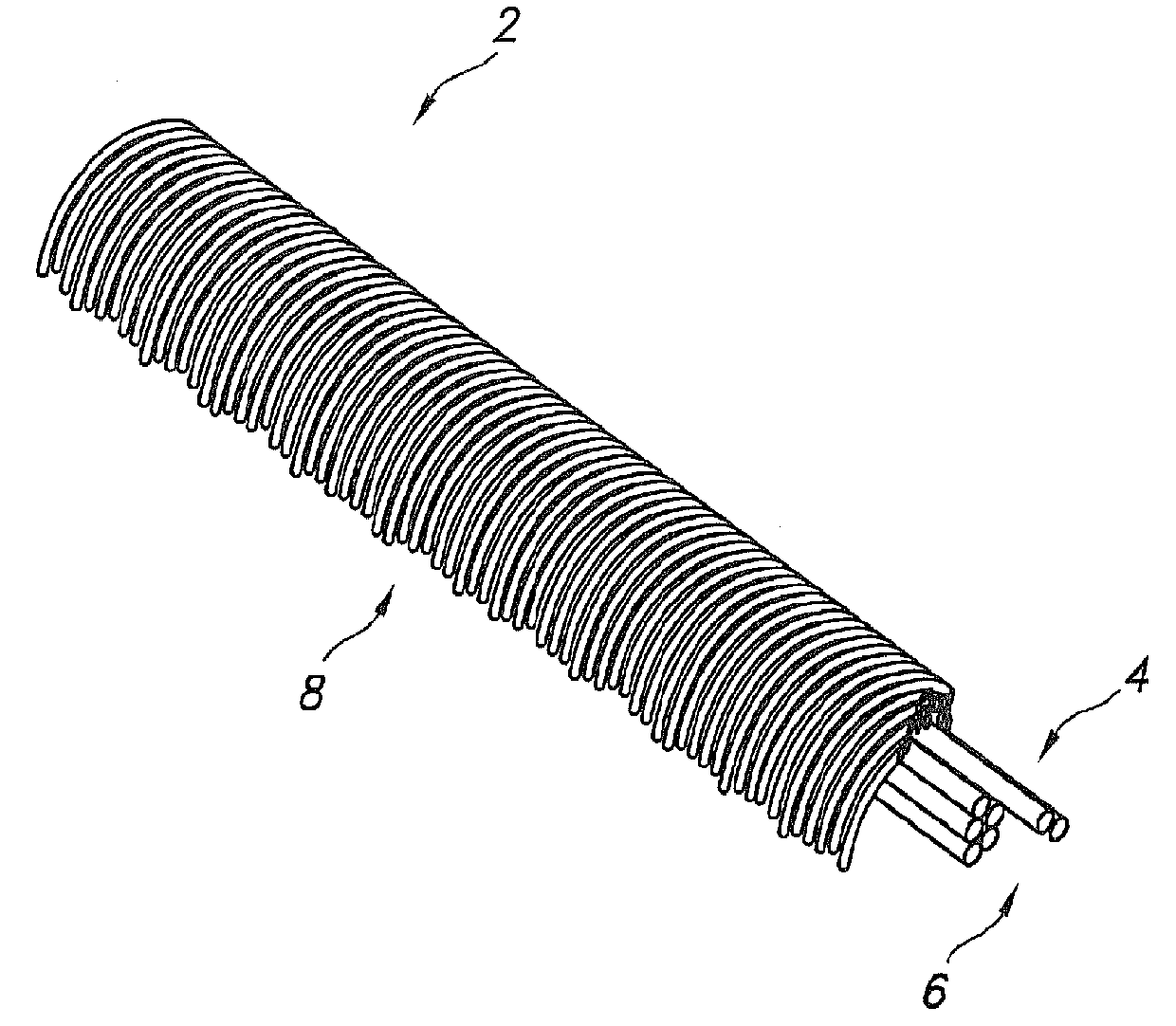

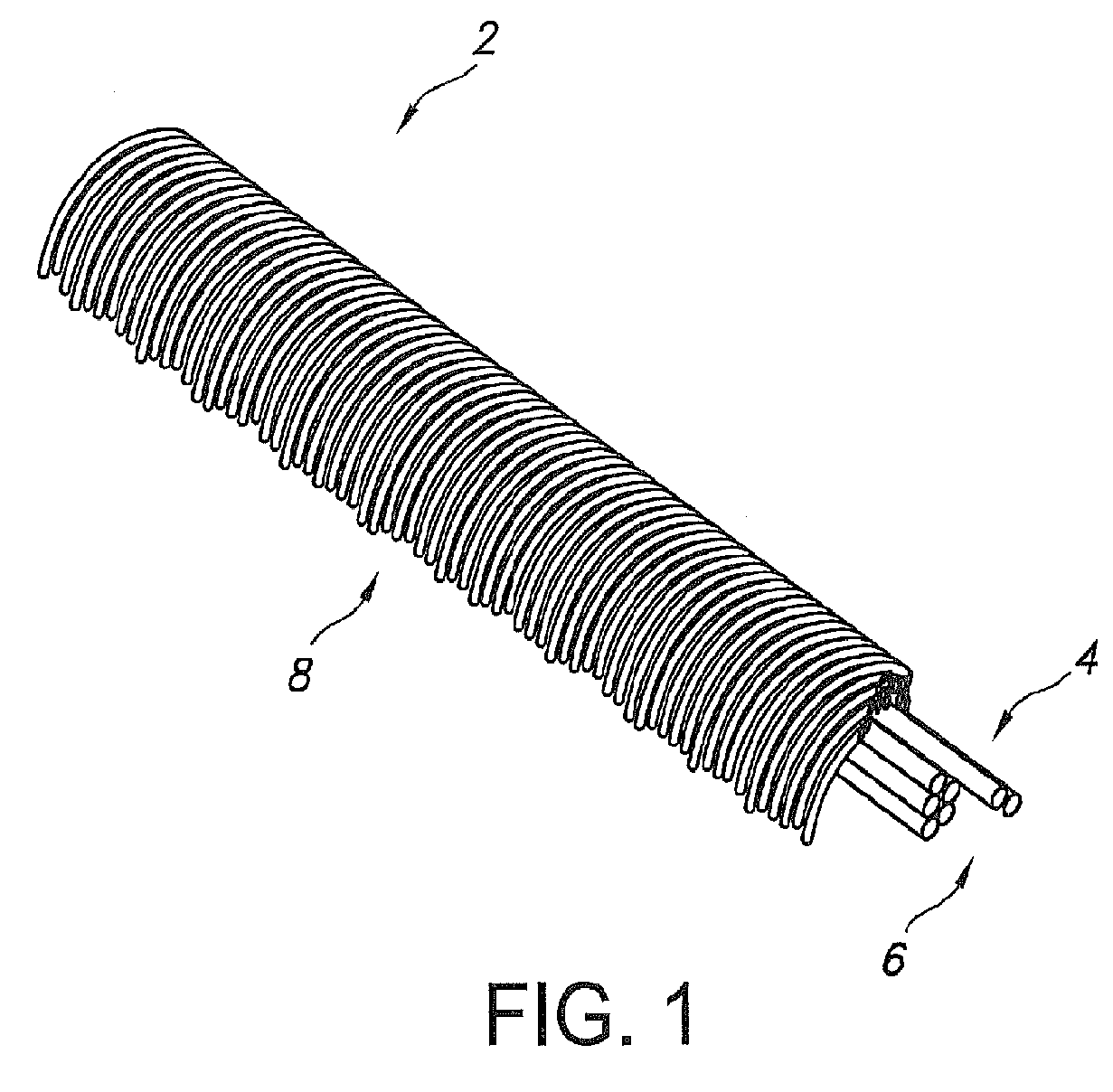

Core Spun Yarn with Two Core Elastic Fibers

[0074]The core spun yarn is 16Ne with two sets of LYCRA® spandex fiber covered by cotton sheath. Elastic core I fiber is 20D T162B and Elastic core II fiber is 20D T162B as well. The total denier of the elastic finer is 40 denier. The draft of the LYCRA® fiber is 3.5× during covering process. The cotton twist level TM is 18 twisters per inch. Therefore, this core spun yarn has the same structure with Example Yarn A, including in yarn count, LYCRA® fiber denier and yarn twist level, except with 2 sets of core elastic filaments instead of one end of core spun yarn. The recoverable stretch of this yarn is 20.63%, which has 2.92 unit percent higher than yarn in sample A. That means the yarn with two sets of filaments core has high recoverable stretch than the yarn with one set of filament core under the same content of spandex. In this way, the innovative yarn can provide high stretch and high recovery power for the fabrics by using the same am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com