Thermoplastic light-duty composite plate and preparing method thereof

A composite sheet and thermoplastic material technology, applied in sheet/board, building components, etc., can solve problems such as damage to human health, pollution of the environment, waste of resources, etc., to improve the quality of breaking strength, minimize fiber damage, and reduce warpage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Materials: unsealed glass fiber (density: 2.28g / cm 3 100kg length: 300mm diameter: 10um), PP fiber (density: 0.92g / cm 3 100kg, length: 150mm diameter: 6um)

[0050] The materials are mixed at 1:1, and the width is 2M.

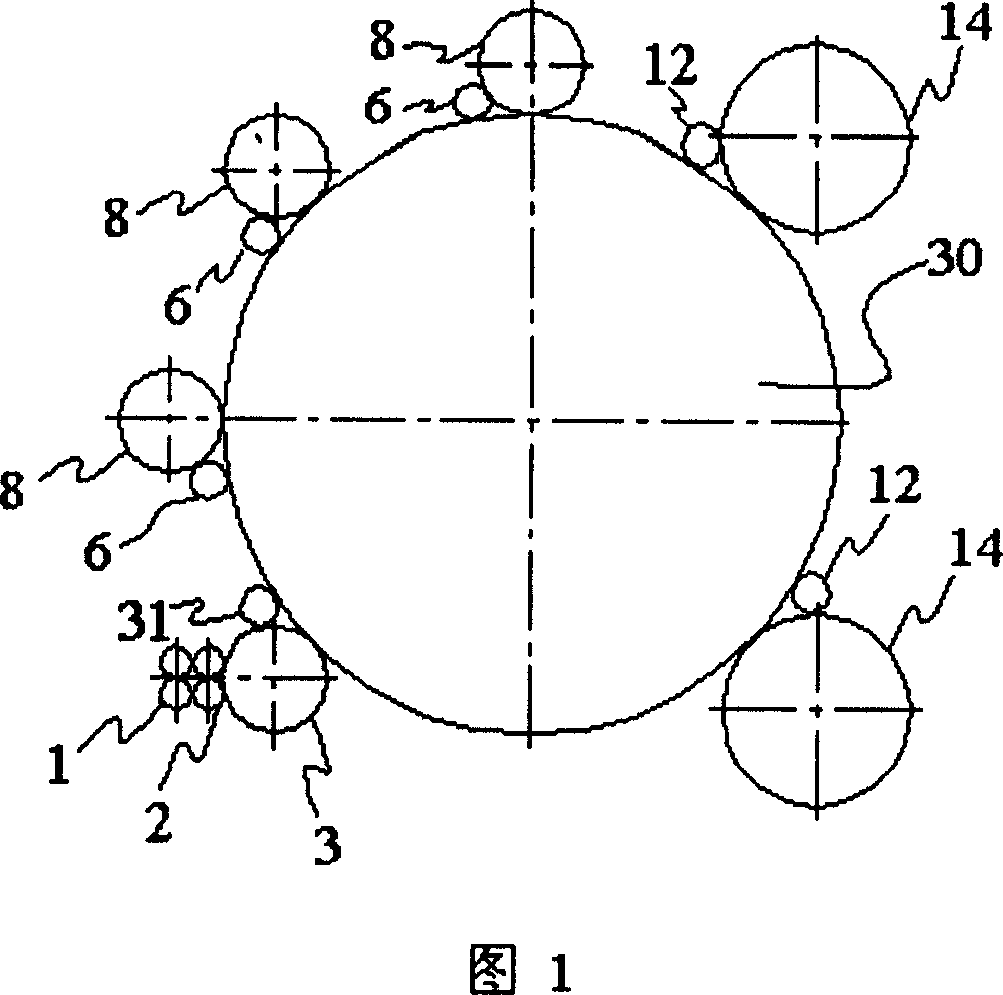

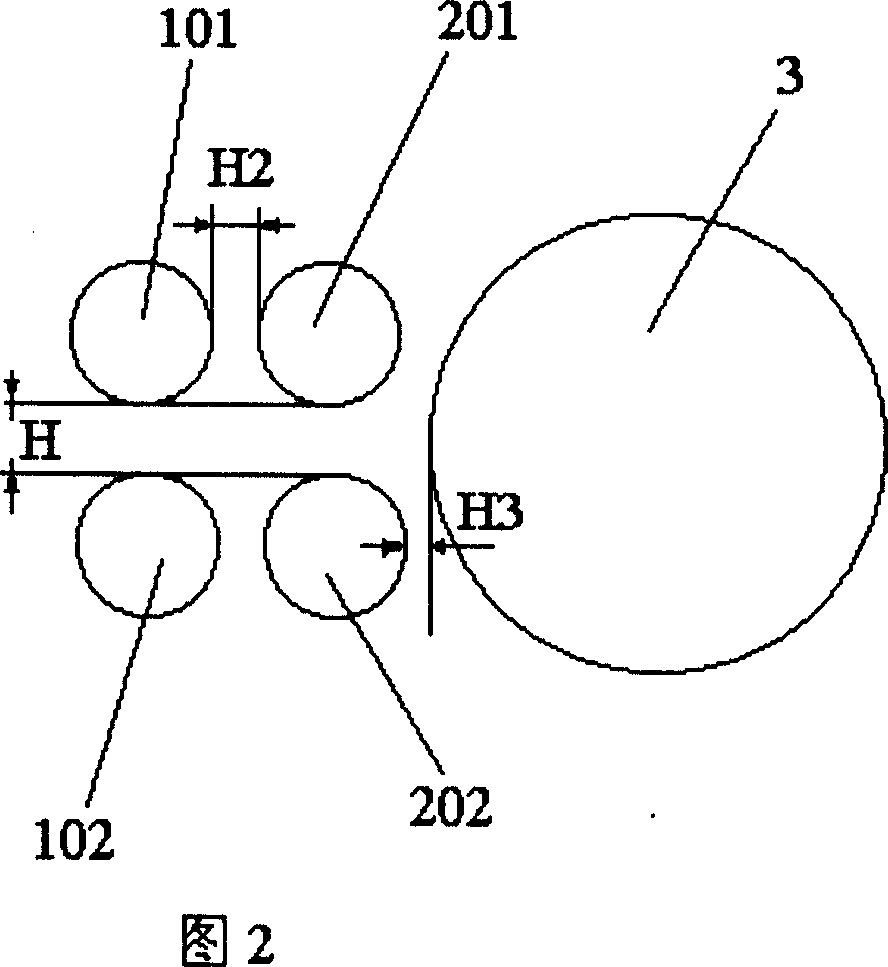

[0051] The above-mentioned raw materials are opened, and then carded with a carding machine with the feeding and carding system shown in Figure 1, and then reinforced into a web to obtain a long-cut glass fiber needle felt.

[0052] Foam impregnation: the needle-punched felt made by the above steps is double-sided sizing by a foaming machine, and the thermoplastic glue adopts acrylate glue (acrylic ester weight content 40%, and the weight content of coupling agent orthosilicate is 1 %, the solvent is water), the foaming ratio is 3:8, the foaming amount is 200kg / h, the viscosity is 18000 centipoise, the pressure is controlled at 500kg, pneumatically applied, the mechanical speed is 2M / min, and the double-sided impregnation acupuncture is pressed at 25...

Embodiment 2

[0058] Materials: unsealed glass fiber (density: 2.28g / cm 3 100kg Length: 300mm Diameter: 10um)

[0059] PP fiber (density: 0.92g / cm3 100kg, length: 55~65mm diameter: 6um)

[0060] The materials are mixed according to 4:6, and the width is 2.5M.

[0061] The above-mentioned raw materials are opened, and then carded with a carding machine with the feeding and carding system shown in Figure 1, and then reinforced into a web to obtain a long-cut glass fiber needle felt.

[0062] Foam impregnation: the needle-punched felt made by the above steps is double-sided sizing by a foaming machine, and the thermoplastic glue adopts vinyl acetate glue (35% by weight of vinyl acetate, coupling agent methacryloxypropyl trimethoxy The weight content of silane is 2%, the solvent is water), the foaming ratio is 2:7, the foaming amount is 100kg / h, the viscosity is 18000 centipoise, the pressure is controlled at 500kg, applied pneumatically, the mechanical speed is 2M / min, and 250g double-side...

Embodiment 3

[0066] Materials: hemp fiber (100kg, length: 150-200mm, diameter: 8um) PP fiber (100kg, length: 120-150mm, diameter: 6um)

[0067] The materials are mixed at 1:1, and the width is 2M.

[0068] The above-mentioned raw materials are opened, and then carded with a carding machine with the feeding and carding system shown in Figure 1, and then reinforced into a web to obtain a long-cut glass fiber needle felt.

[0069] Foam impregnation: the needle felt made by the above steps is double-sided sizing by a foaming machine, and the thermoplastic glue adopts acrylate glue (acrylic ester weight content 40%, coupling agent methacryloxypropyl triethoxy The weight content of silane is 3%, the solvent is water), the foaming ratio is 3:8, the foaming amount is 100kg / h, the viscosity is 20000 centipoise, the pressure is controlled at 500kg, applied pneumatically, and the mechanical speed is 2M / min. Square 250g double-sided impregnated needle felt.

[0070] The surface of the above-mentione...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com