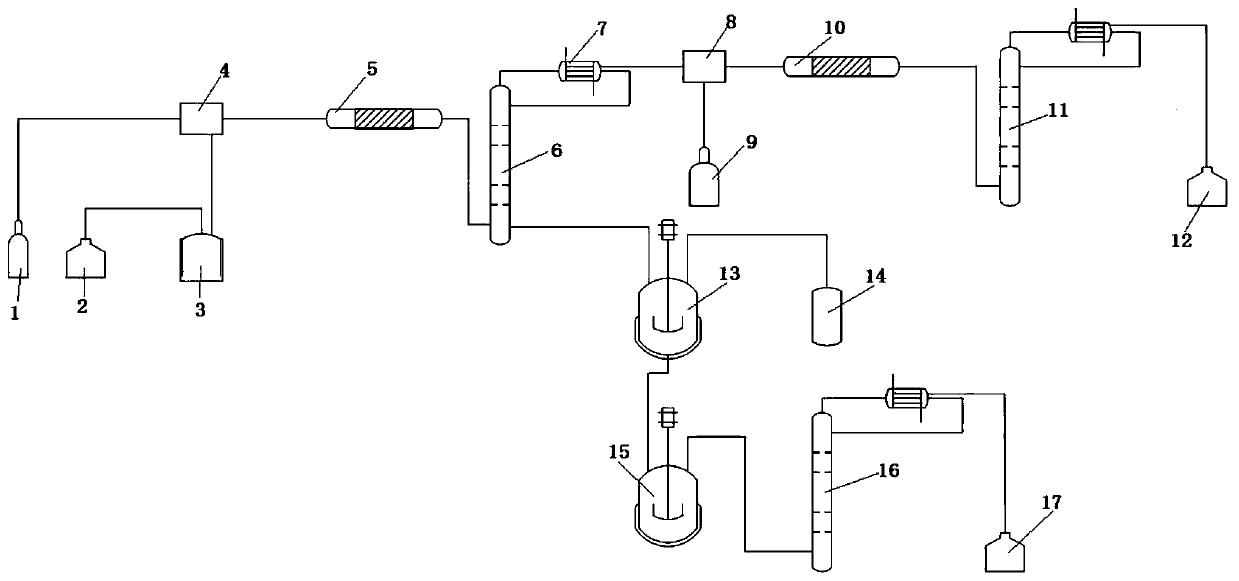

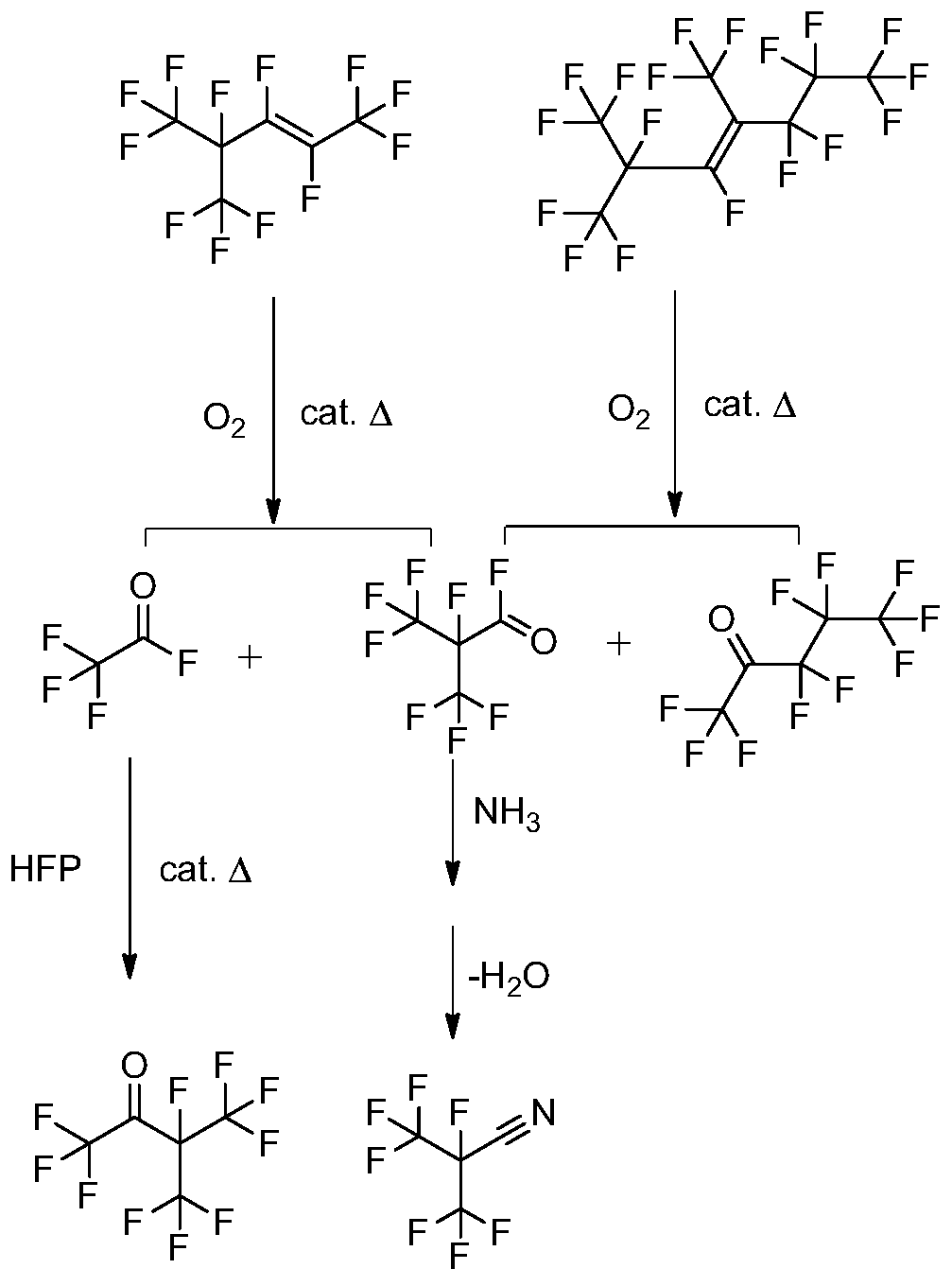

Economical and efficient perfluoronitrile and perfluoroketone co-production process and device

A perfluoroketone and perfluoronitrile technology, which is applied in the field of insulating gas preparation, can solve the problems of inability to realize large-scale application, high production cost, harsh preparation conditions of perfluoronitrile and perfluoroketone, and achieve cheap and efficient catalysts , easy separation and purification, short reaction route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The length of the first tubular fixed-bed reactor 5 is 80 cm, the pipe diameter is 1 inch, and the temperature of reaction is 150° C., and the silver oxide with a gac load of 5% is used as the catalyst, and the catalyst filling ratio in the first tubular fixed-bed reactor 5 is: 75%, the O 2 and hexafluoropropylene dimer in a molar ratio of 0.5:1 into the first tubular fixed-bed reactor 5 for reaction, the reaction pressure is 3 bar, and the reaction time is 60 s. As detected by gas chromatography, perfluoroisobutyryl fluoride accounts for 15.5% and trifluoroacetyl fluoride accounts for 16.3% in the product composition;

[0059] The length of the second tubular fixed bed reactor 10 is 80cm, the pipe diameter is 1 inch, and the reaction temperature is 100°C. The CsF with an activated carbon load of 5% is the catalyst, and the catalyst filling ratio in the second tubular fixed bed reactor 10 is 75% %, the obtained trifluoroacetyl fluoride and hexafluoropropylene are passe...

Embodiment 2

[0062] The length of the first tubular fixed-bed reactor 5 is 80 cm, the pipe diameter is 1 inch, and the temperature of reaction is 150° C., and the silver oxide with a gac load of 5% is used as the catalyst, and the catalyst filling ratio in the first tubular fixed-bed reactor 5 is: 75%, the O 2 and hexafluoropropylene dimer in a molar ratio of 1:1 into the first tubular fixed-bed reactor 5 for reaction, the reaction pressure is 3bar, and the reaction time is 60s. As detected by gas chromatography, perfluoroisobutyryl fluoride accounts for 21.3% and trifluoroacetyl fluoride accounts for 23.8% in the product composition;

[0063] The length of the second tubular fixed bed reactor 10 is 80cm, the pipe diameter is 1 inch, and the reaction temperature is 100°C. The CsF with an activated carbon load of 5% is the catalyst, and the catalyst filling ratio in the second tubular fixed bed reactor 10 is 75% %, the obtained trifluoroacetyl fluoride and hexafluoropropylene are passed in...

Embodiment 3

[0066] The length of the first tubular fixed-bed reactor 5 is 80 cm, the pipe diameter is 1 inch, and the temperature of reaction is 170 DEG C. With activated carbon loading, silver oxide of 5% is used as the catalyst. In the first tubular fixed-bed reactor 5, the catalyst filling ratio is: 75%, the O 2 and hexafluoropropylene dimer in a molar ratio of 1:1 into the first tubular fixed-bed reactor 5 for reaction, the reaction pressure is 3bar, and the reaction time is 60s. As detected by gas chromatography, perfluoroisobutyryl fluoride accounts for 26.2% and trifluoroacetyl fluoride accounts for 27.6% in the product composition;

[0067] The length of the second tubular fixed bed reactor 10 is 80 cm, the pipe diameter is 1 inch, and the reaction temperature is 120° C., and the CsF with an active carbon load of 5% is the catalyst, and the catalyst filling ratio in the second tubular fixed bed reactor 10 is 75 %, the obtained trifluoroacetyl fluoride and hexafluoropropylene are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com