Method for pipelined continuous production of n-n-propylacetamide

A n-propyl acetamide, pipeline technology, applied in the direction of chemical instruments and methods, carboxylic acid amide preparation, organic compound preparation, etc., can solve the problems of low yield and long time, and achieve high yield and high production capacity Big, backmixed small effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

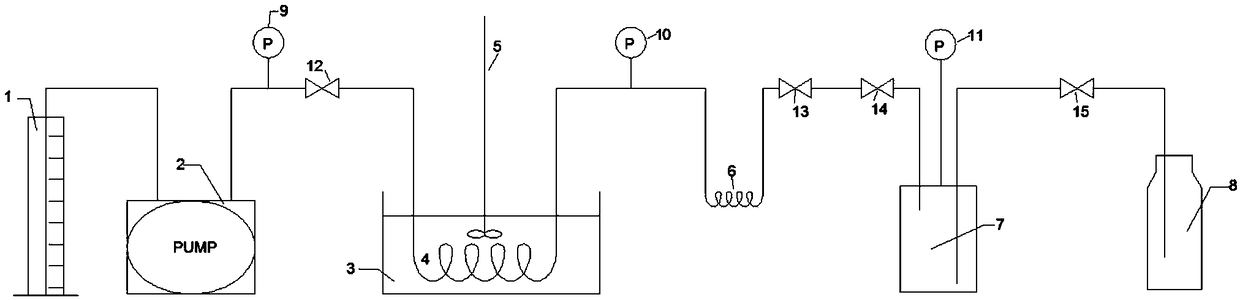

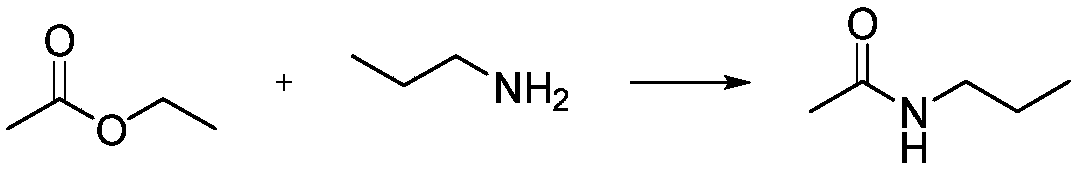

[0050] Example 1. A method for pipelined continuous production of N-n-propylacetamide using figure 1 The device shown in, takes ethyl acetate and n-propylamine as raw materials, and performs the following steps in sequence:

[0051] (1) Add 300 mL of ethyl acetate to the measuring cylinder 1, fully open the valves in the system (including needle valves 12-14 and valve 15), and use a large flow rate of 10 mL / min to fill the reaction coil 4 with ethyl acetate; The remaining ethyl acetate in 1 was recovered, and 450 mL of a mixed solution of ethyl acetate and n-propylamine was added as the raw material for the reaction. The molar ratio of ethyl acetate and n-propylamine was 1:1.

[0052] (2) Fill the system pressure (ie, the pressure in the reaction coil 4) to 3 MPa with nitrogen (at this time, the readings of the pressure gauge 9 and the pressure gauge 10 are both 3 MPa), and the valve 15 is closed. Turn on the oil bath 3, set the temperature to 170°C, turn on the stirring paddle 5,...

Embodiment 2

[0062] Example 2. A method for pipelined continuous production of N-n-propylacetamide,

[0063] The molar ratio of ethyl acetate and n-propylamine is 1:0.5;

[0064] Set the flow rate of 0.40-1.00mL / min at the plunger pump 2,

[0065] The rest is equivalent to Example 1.

[0066] Under different flow rate conditions, the reaction yield is shown in Table 2 below:

[0067] Table 2. Reaction results at 170℃, raw material ratio 1:0.5

[0068]

Embodiment 3

[0069] Example 3. A method for pipelined continuous production of N-n-propylacetamide,

[0070] The molar ratio of ethyl acetate and n-propylamine is 1:2;

[0071] Set the flow at the plunger pump 2 to 0.40-1.00mL / min;

[0072] The rest is equivalent to Example 1.

[0073] Under different flow rate conditions, the reaction yield is shown in Table 3 below:

[0074] Table 3. Reaction results at 170°C and 1:2 ratio of raw materials

[0075]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com