Catalyst as well as preparation method and application thereof

A technology of catalysts and fluorides, applied in chemical instruments and methods, physical/chemical process catalysts, preparation of halogenated hydrocarbons, etc., can solve the problems of high reaction temperature and low selectivity of target products, and achieve lower reaction temperature and less side effects Reaction occurs and the effect with high reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

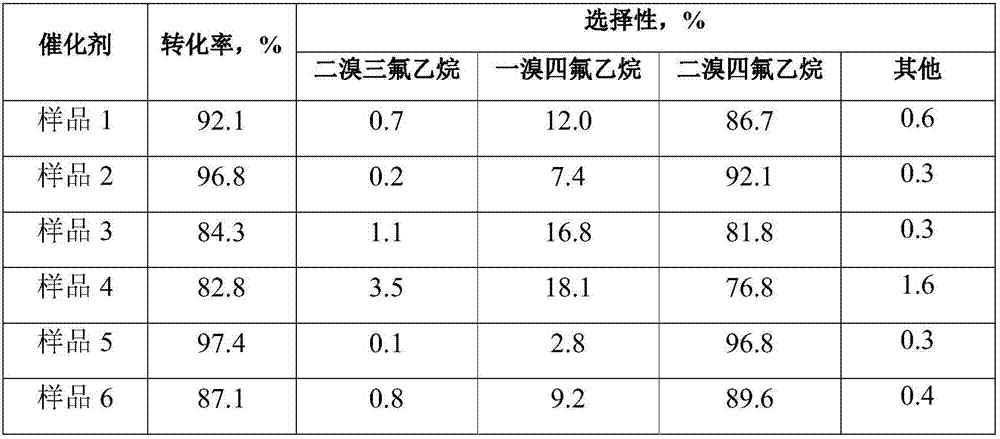

Examples

Embodiment 1

[0025] Embodiment 1 (sample 1)

[0026] Weigh 300g of coconut shell charcoal, add 10% nitric acid solution, boil and reflux for 6h, filter and wash with deionized water until pH = 7, dry at 80°C for 12h, and set aside;

[0027] Weigh 17.3g FeCl 3 and 12.7g ZnCl 2 Dissolve with deionized water, stir until the solution is clear, add pretreated coconut shell charcoal and let stand for 12 hours. After the impregnated catalyst was filtered, it was dried at 80°C for 24 hours, and then used.

Embodiment 2

[0028] Embodiment 2 (sample 2)

[0029] Weigh 300g of aluminum fluoride, add 10% nitric acid solution, boil and reflux for 6h, filter and wash with deionized water until pH = 7, dry at 80°C for 12h, and set aside;

[0030] Weigh 17.3g FeCl 3 and 12.7g ZnCl 2 Dissolve in deionized water, stir until the solution becomes clear, add pretreated aluminum fluoride and let stand for 12 hours. After the impregnated catalyst was filtered, it was dried at 80°C for 24 hours, and then used.

Embodiment 3

[0031] Embodiment 3 (sample 3)

[0032] Weigh 300g of magnesium fluoride, add 10% nitric acid solution, boil and reflux for 6h, filter and wash with deionized water until pH = 7, dry at 80°C for 12h, and set aside;

[0033] Weigh 17.3g FeCl 3 and 12.7g ZnCl 2 Dissolve in deionized water, stir until the solution is clear, add pretreated magnesium fluoride and let stand for 12 hours. After the impregnated catalyst was filtered, it was dried at 80°C for 24 hours, and then used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com