Rapid fuel gas condensation system with double-tower direct spray

A condensing system and direct technology, applied in direct contact heat exchangers, indirect heat exchangers, petroleum industry, etc., can solve the problem of insufficient condensation of condensable gases, reduce bio-oil yield, increase process difficulty and cost, etc. problems, to achieve the effect of meeting the requirements of rapid cooling, speeding up the condensation speed, and fast cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

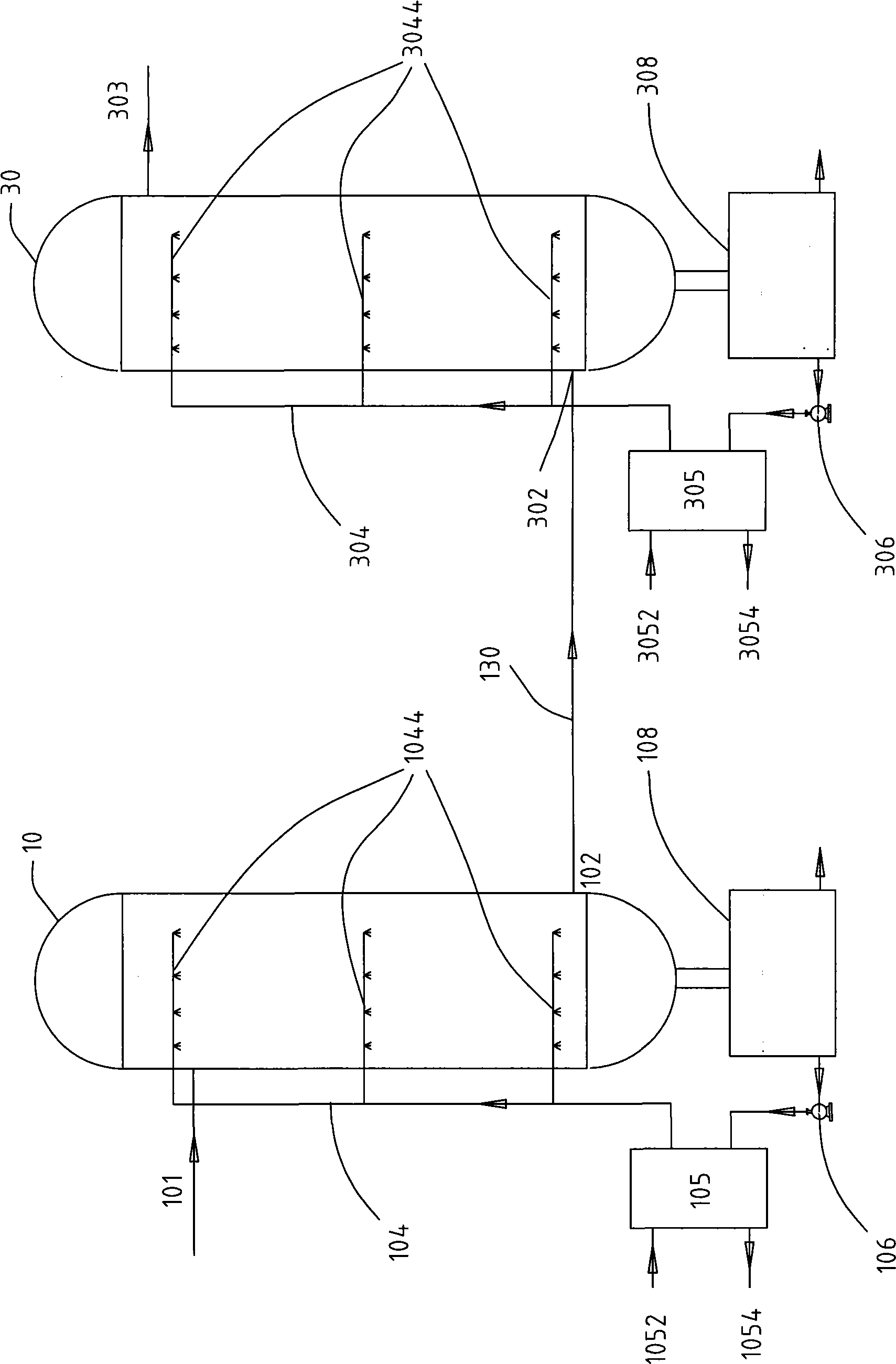

[0023] Please refer to figure 1 , the double-tower direct spray cracking gas rapid condensation system of the present invention comprises a first-stage spray tower 10 provided with a high-temperature pyrolysis gas inlet 101 and a pyrolysis gas outlet 102, a pyrolysis gas inlet 302 and a non-condensable gas The second-stage spray tower 30 of the outlet 303, the connecting pipe 130 connecting the pyrolysis gas outlet 102 of the first-stage spray tower 10 and the pyrolysis gas inlet 302 of the second-stage spray tower 30, and the first-stage spray The bio-oil storage tank 108 connected to the condensed bio-oil outlet of the tower 10, the bio-oil storage tank 308 connected to the condensed bio-oil outlet of the second-stage spray tower 30, the first atomized spraying subsystem (in this embodiment Including a first atomizing spray unit 104, a first circulating oil pump 106 connected to a first bio-oil storage tank 108, and a first heat exchange unit connected between the first circ...

Embodiment 2

[0031] As another kind of scheme of the present invention, other parts are identical with embodiment 1, and difference is:

[0032] The condensing medium used for the first atomizing spray unit 10 and the second atomizing spray unit 30 can come from outside the system, that is, the bio-oil generated by the system itself is not used, so the system can not be provided with the first heat exchanger 10 and the second heat exchanger 30.

[0033] Moreover, the high-temperature pyrolysis gas inlet 101 of the first-stage spray tower 10 is arranged below the pyrolysis gas outlet 102, that is, the first-stage spray tower also adopts a reverse spraying path with the gas.

Embodiment 3

[0035] As another kind of scheme of the present invention, other parts are identical with embodiment 1, and difference is:

[0036] Using a heat exchanger, a circulating oil pump and a bio-oil storage tank, the bio-oil produced by the first-stage spray tower 10 and the second-stage spray tower 30 all enters the same bio-oil storage tank, and part of the bio-oil is produced by the same bio-oil storage tank. A circulating oil pump is sent to the same heat exchanger for cooling and then sent to the first atomizing spray unit 104 and the second atomizing spray unit 304 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com