Catalyst for sec-butyl acetate hydrogenation reaction, and preparation method and application thereof

A technology of sec-butyl acetate and hydrogenation reaction, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve problems such as poor low temperature performance of catalysts, and achieve thermal stability High performance, avoid activity reduction, high anti-sintering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of the catalyst that is used for sec-butyl acetate hydrogenation reaction, comprises the following steps:

[0027] Will Al 2 o 3 Add the metal salt solution and the precipitating agent solution to the suspension of the precursor, precipitate reaction, age, and obtain precipitation; the Al 2 o 3 The precursors are selected from dry aluminum hydroxide, pseudoboehmite and γ-Al 2 o 3 One or more of the powders; the metal salt solution includes soluble copper salts and soluble additives; the soluble additives are selected from one of soluble zinc salts, soluble magnesium salts, soluble calcium salts and soluble barium salts or more; the precipitant solution includes sodium carbonate, sodium hydroxide and water with a mass ratio of 3.0 to 8.0:1.0:3.5 to 10.0;

[0028] The precipitate is filtered, washed with water, dried and roasted to obtain a catalyst for the hydrogenation reaction of sec-butyl acetate;

[0029] Al i...

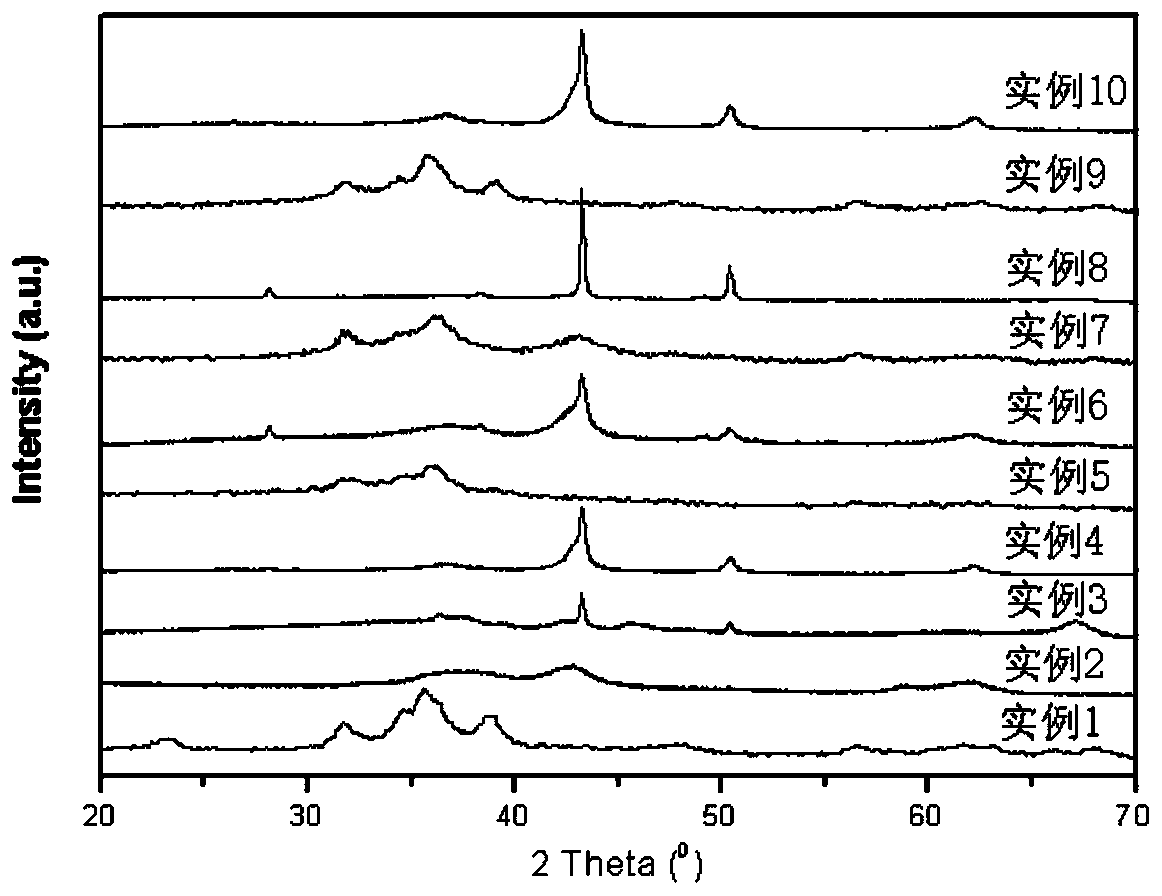

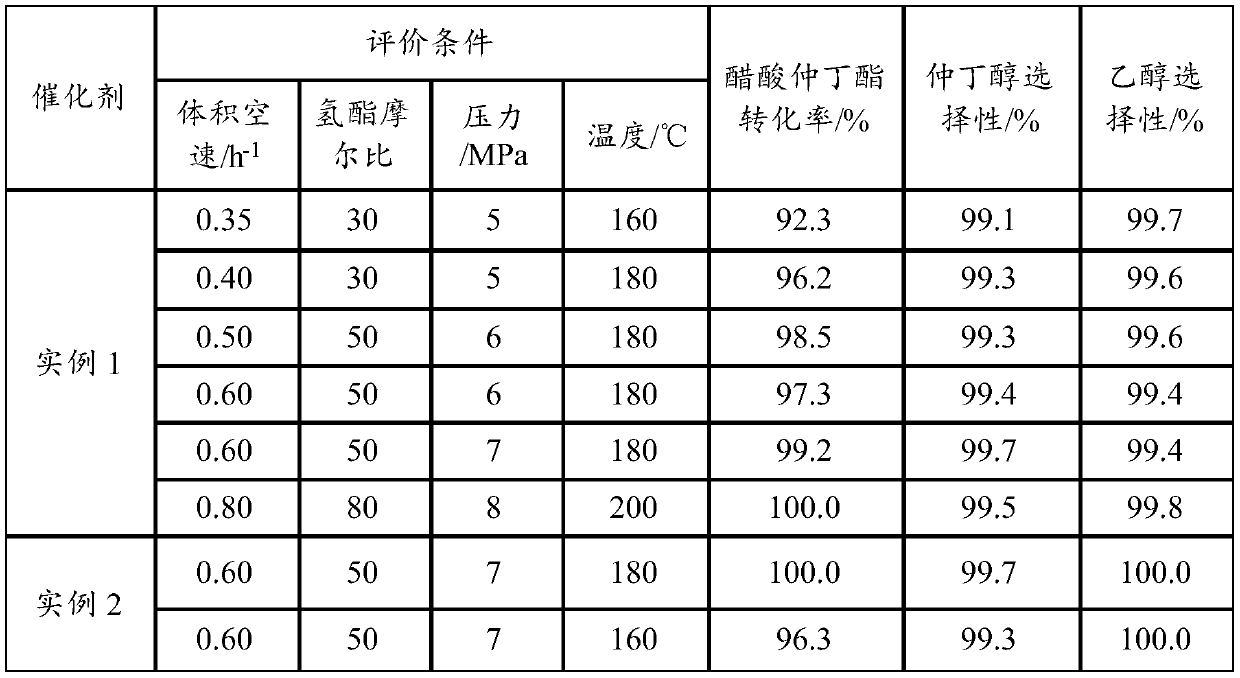

Embodiment 1

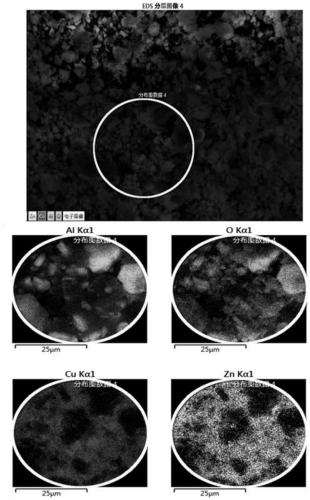

[0044] This embodiment provides a CuO-ZnO-Al 2 o 3 Catalyst, comprises the steps:

[0045] Weigh 459g of aluminum hydroxide dry glue, add 5L of water to prepare aluminum hydroxide dry glue suspension, stir at 70°C and make it uniformly dispersed. Weigh 608g copper nitrate and 1462g parts by weight of zinc nitrate, mix with 12.5L water and stir evenly. Weigh 16.33kg parts by weight of sodium carbonate and 3.08kg parts by weight of sodium hydroxide, mix them with 12.5L of water and stir evenly. Under the condition of stirring, nitrate solution and alkali solution are simultaneously added to the aluminum hydroxide dry gel suspension, and the whole process is controlled for 4 hours, and the pH is controlled at 7-8. After the precipitation reaction is completed, keep stirring at 80°C for 5 hours to carry out the aging process; the final precipitate is filtered, washed, dried at 100°C for 10 hours, roasted at 500°C for 4 hours, and shaped to obtain the hydrogenation production of...

Embodiment 2

[0047] This embodiment provides a CuO-MgO-Al 2 o 3 Catalyst, comprises the steps:

[0048] Weigh 345g of aluminum hydroxide dry glue, add 5L of water to prepare aluminum hydroxide dry glue suspension, stir at 70°C and make it uniformly dispersed. Weigh 608g of copper nitrate and 3176g of magnesium nitrate, mix them with 12.5L of water and stir evenly. Weigh 16.33kg parts by weight of sodium carbonate and 3.08kg parts by weight of sodium hydroxide, mix them with 12.5L of water and stir evenly. Under the condition of stirring, nitrate solution and alkali solution are simultaneously added to the aluminum hydroxide dry gel suspension, and the whole process is controlled for 4 hours, and the pH is controlled at 7-8. After the precipitation reaction is completed, keep stirring at 80°C for 5 hours to carry out the aging process; the final precipitate is filtered, washed, dried at 100°C for 10 hours, roasted at 500°C for 4 hours, and shaped to obtain the hydrogenation production of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com