Production technology of phycoerythrin and crystal and product thereof

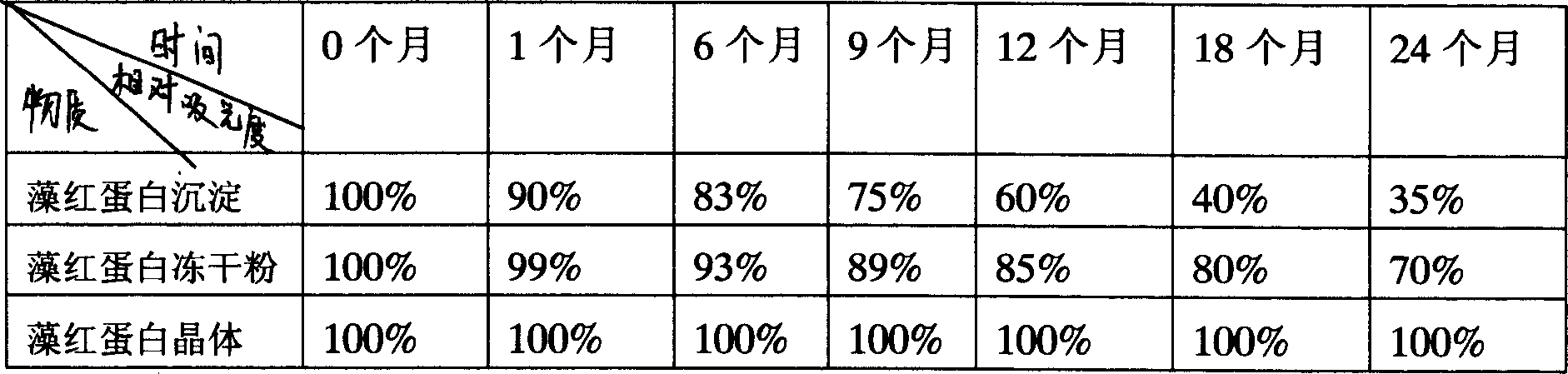

A phycoerythrin and crystal technology, applied in the field of crystal manufacturing process and products, and protein, can solve the problems of high fluorescence activity, can not be stored for a long time, easy to lose biological activity, etc., and achieve the effect of high fluorescence activity and small requirements for preservation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] 1. Preparation of phycoerythrin

[0118] cell disruption

[0119] Weigh an appropriate amount of phycoerythrin raw material (such as seaweed, polytubule and other algae), wash it twice with distilled water, grind it with a tissue crusher at 0°C, put it into a beaker, add pH value 6.5, concentration 0.005 mol / liters of phosphate-buffered saline (PBS), and stir well. Ultrasonic crushing at 1200W in an ice bath for 60 minutes, the crushed crude liquid was left to stand at low temperature (0°C) for 10 hours, and then filtered three times with at least three layers of gauze to remove large cell tissue fragments, and the filtrate was placed in a pre- In a cold high-speed refrigerated centrifuge, centrifuge at 8,000 rpm at 0°C for 60 minutes, remove the precipitate, and collect the supernatant;

[0120] Ammonium sulfate graded salting out

[0121] Add solid ammonium sulfate to the supernatant to make it reach 30% saturation, let stand at 10°C for 10 hours, centrifuge at 60...

Embodiment 2

[0142] 1. Preparation of phycoerythrin

[0143] cell disruption

[0144] Weigh an appropriate amount of phycoerythrin raw material (such as laver, polytubule and other algae), wash it twice with distilled water, grind it with a tissue crusher at 2°C, put it into a beaker, add pH value 6.8, concentration 0.005 mol / liters of phosphate-buffered saline (PBS), and stir well. Ultrasonic crushing at 1200W in an ice bath for 60 minutes, the crushed crude liquid was left to stand at low temperature (2°C) for 10 hours, and then filtered three times with at least three layers of gauze to remove large cell tissue fragments, and the filtrate was placed in a pre- In a cold high-speed refrigerated centrifuge, centrifuge at 8,000 rpm at 2°C for 60 minutes, remove the precipitate, and collect the supernatant;

[0145] Ammonium sulfate graded salting out

[0146] Add solid ammonium sulfate to the supernatant to make it reach 30% saturation, let stand at 2°C for 10 hours, centrifuge at 6000 ...

Embodiment 3

[0167] 1. Preparation of phycoerythrin

[0168] cell disruption

[0169] Weigh an appropriate amount of phycoerythrin raw material (such as laver, polytubule and other algae), wash it twice with distilled water, grind it with a tissue crusher at low temperature (5°C), put it into a beaker, add pH value 7.0, concentration 0.005 mol / L phosphate buffered saline (PBS), stir well. Ultrasonic crushing at 1500W in an ice bath for 45 minutes, the crushed crude liquid was left to stand at low temperature (5°C) for 18 hours, and then filtered three times with at least three layers of gauze to remove large cell tissue fragments, and the filtrate was placed in a pre- In a cold high-speed refrigerated centrifuge, centrifuge at 8,000 rpm at 4°C for 45 minutes, remove the precipitate, and collect the supernatant;

[0170] Ammonium sulfate graded salting out

[0171] Add solid ammonium sulfate to the supernatant to make it reach 25% saturation, let stand at 5°C for 18 hours, centrifuge at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com