Reformate deolefination method without hydrogen

A reformed oil, non-hydrogen-prone technology, applied in chemical instruments and methods, molecular sieve catalysts, physical/chemical process catalysts, etc., can solve problems such as low activity, short life, and large loss of aromatics, and achieve good technical effects and prolong Lifespan, the effect of slowing down the speed of overlay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

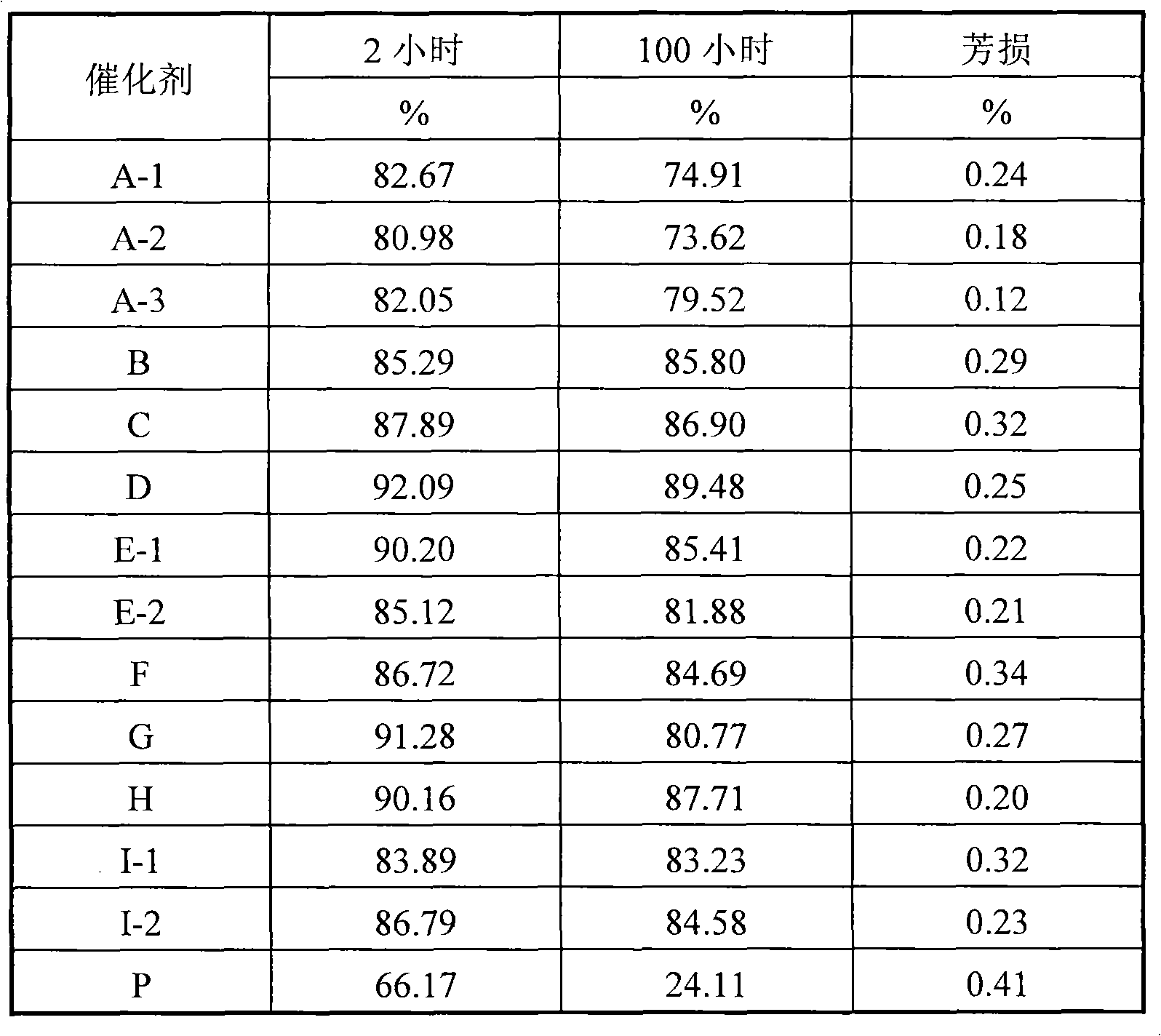

Embodiment 1

[0025] Take Na 2 O content is 0.15% (weight) pseudo-boehmite 10 grams, and K 2 90 grams of MCM-41 molecular sieves with an O content of 0.30% (weight) were mixed evenly. A solution was prepared with 4.95 grams of chemically pure nickel nitrate, 0.10 grams of 10% hydrochloric acid, 13.02 grams of 85% phosphoric acid, 2.5 milliliters of chemically pure nitric acid and 63 milliliters of water. Add this mixed solution to the mixture, mix well, knead and extrude to shape, dry and bake at 550°C for 3 hours to obtain a composition of Ni / Cl / P / molecular sieve / alumina=1.0 / 0.01 / 3.5 / 90 / 10 of Catalyst A-1.

Embodiment 2

[0027] Take SiO 2 Content is 40% (weight) of silica sol 50 grams, and K 2 80 grams of MCM-41 molecular sieves with an O content of 0.30% (weight) were mixed evenly. 0.18 grams of chemically pure ammonium molybdate, 0.73 grams of 10% ammonium bromide, 9.30 grams of 85% phosphoric acid, 4.87 grams of chemically pure ammonium fluoride, 2.5 milliliters of chemically pure nitric acid and 33 milliliters of water were used to form a solution. Add this mixed solution to the mixture, mix evenly, knead and extrude to shape, dry and bake at 550°C for 3 hours to obtain a composition of Mo / Br / F / P / molecular sieve / alumina=0.1 / 0.05 / 2.5 / 2.5 / 90 / 10 Catalyst A-2.

Embodiment 3

[0029] Take Na 2 O content is 80 grams of pseudo-boehmite of 0.15% (weight), and K 2 20 grams of TS-1 molecular sieves with an O content of 0.30% (weight) were mixed evenly. A solution was prepared with 17.23 grams of chemically pure niobic acid, 4.95 grams of chemically pure nickel nitrate, 0.94 grams of 98% sulfuric acid, 0.19 grams of 85% phosphoric acid, 2.5 milliliters of chemically pure nitric acid and 63 milliliters of water. Add this mixed solution to the mixture, mix well, knead and extrude to shape, dry and bake at 550°C for 3 hours to obtain a composition of Nb / Ni / S / P / molecular sieve / alumina=9.0 / 1.0 / 0.3 / 0.05 / 20 / 80 Catalyst A-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com