3D curved display TPU protective film and preparation method thereof

A technology of curved screen and protective film, applied in chemical instruments and methods, lamination, coating, etc., can solve problems such as the inflexibility of protective film, the inability to fit the curved screen, and the inability to fully protect the touch screen or display module, etc. , to achieve the effect of being conducive to wide popularization and application, good protection effect and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

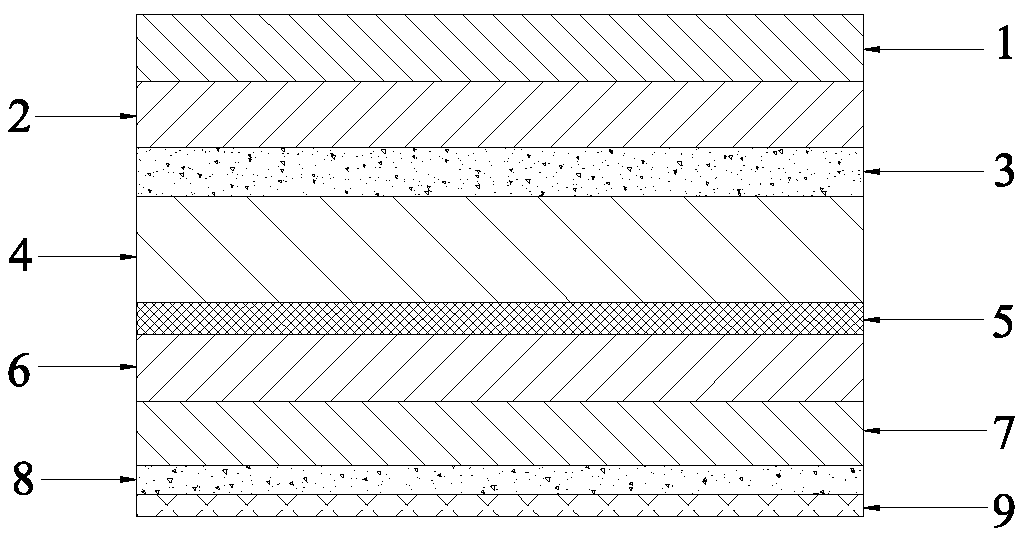

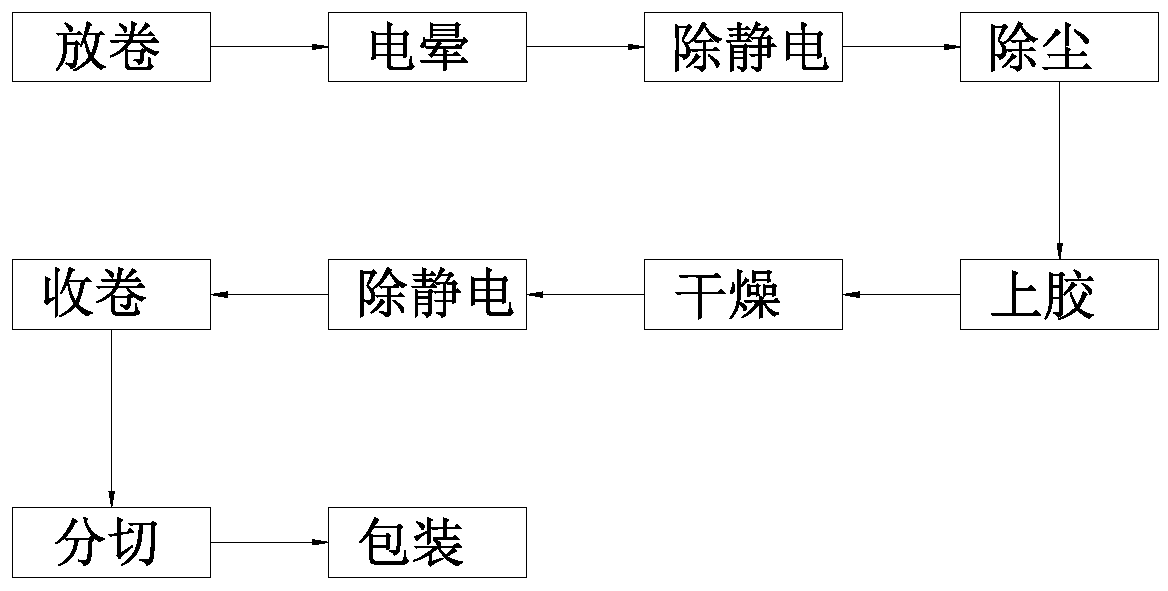

[0033] Example: see Figure 1 to Figure 4 , the embodiment of the present invention provides a 3D curved screen TPU protective film, which includes a dumb film layer 1, a first OCA adhesive layer 2, a self-healing layer 3, a TPU film layer 4, a primer layer 5, and a second OCA adhesive layer 6 , a transparent PET layer 7, a high-viscosity and low-peeling silica gel layer 8 and a fluorine film layer 9, the dumb film layer 1, the first OCA adhesive layer 2, the self-healing layer 3, the TPU film layer 4, the primer layer 5, the second Two OCA adhesive layer 6, transparent PET layer 7, high-viscosity and low-peeling silicone layer 8 and fluorine film layer 9 are laminated sequentially from top to bottom.

[0034] Specifically, the self-healing layer 3 is formed by mixing the following raw materials in parts by weight: 90-95 parts of nano-silicon dioxide, 1-5 parts of nano-graphite, 5-10 parts of nano-copper, and 10-10 parts of magnesium hydroxysilicate. 15 parts, 8-12 parts of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com