EVA/POE supercritical foaming composite shoe material and preparation method thereof

A supercritical, shoe technology, applied in applications, footwear, apparel, etc., can solve problems such as affecting the application field, having a slight odor, and reducing the mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

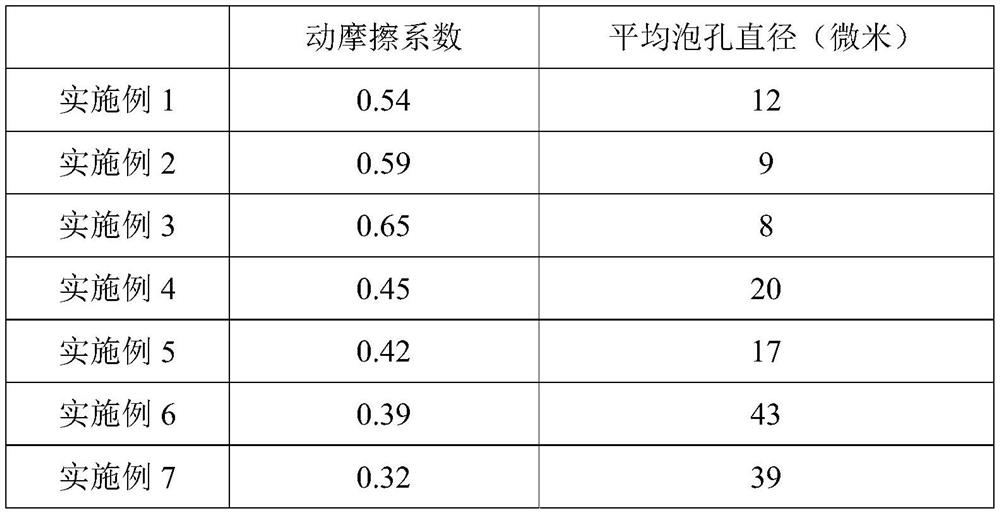

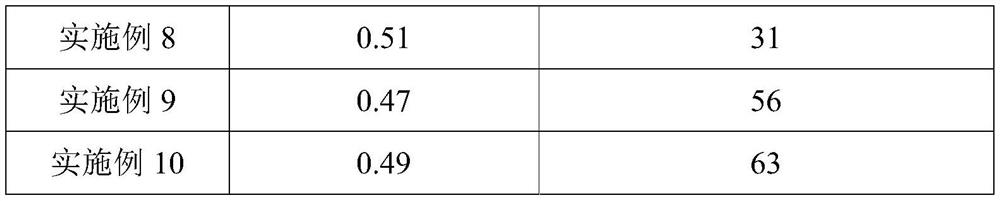

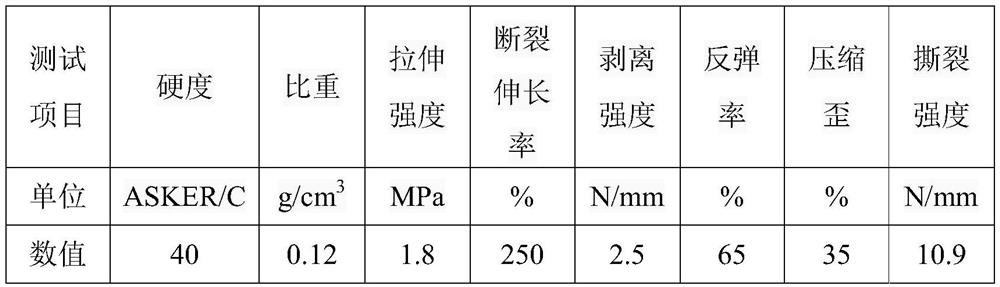

Examples

preparation example Construction

[0047] In one embodiment, the preparation method of described polyethylene glycol monomethyl ether grafted polyethylene maleic anhydride copolymer comprises the steps:

[0048] (1) Add polyethylene glycol monomethyl ether and polyethylene maleic anhydride copolymer into a three-necked flask with a stirring bar, use xylene as solvent, add p-toluenesulfonic acid, heat, reflux reaction, water separator removes water;

[0049] (2) cooling after the reaction is over, adding methanol to precipitate, suction filtration, washing, and drying;

[0050] The mass ratio of described polyethylene glycol monomethyl ether, polyethylene maleic anhydride copolymer is 4:1; Described p-toluenesulfonic acid accounts for polyethylene glycol monomethyl ether, polyethylene maleic anhydride copolymer gross mass 4wt%; the temperature of the reflux reaction is 160°C, and the reaction time is 8h;

[0051] The polyethylene glycol monomethyl ether is purchased from Beijing Bailingwei Chemical Co., Ltd.; ...

Embodiment 1

[0068] Embodiment 1 provides a kind of EVA / POE supercritical foaming composite shoe material, by weight, the preparation raw material of described supercritical foaming composite shoe material is: ethylene-vinyl acetate copolymer 30 parts, ethylene - 20 parts of octene copolymer, 10 parts of styrene-butadiene block copolymer, 1 part of peroxide, 1.2 parts of nucleating agent, 5 parts of modifier, 1 part of stearic acid;

[0069] The ethylene-vinyl acetate copolymer is a composite of an ethylene-vinyl acetate copolymer with a vinyl acetate content of 26wt% and an ethylene-vinyl acetate copolymer with a vinyl acetate content of 28wt%; the vinyl acetate The mass ratio of the ethylene-vinyl acetate copolymer with the ester content of 26wt% to the ethylene-vinyl acetate copolymer with the vinyl acetate content of 28wt% is 1:1.2; the ethylene-acetic acid with the vinyl acetate content of 26wt% The grade of the vinyl ester copolymer is EVA 7470K, purchased from Taiwan Formosa Plastic...

Embodiment 2

[0085] Embodiment 2 provides a kind of EVA / POE supercritical foaming composite shoe material, by weight, the preparation raw material of described supercritical foaming composite shoe material is: ethylene-vinyl acetate copolymer 40 parts, ethylene - 30 parts of octene copolymer, 20 parts of styrene-butadiene block copolymer, 3 parts of peroxide, 1.6 parts of nucleating agent, 8 parts of modifier, 3 parts of stearic acid;

[0086] The ethylene-vinyl acetate copolymer is the same as in Example 1, except that the ethylene-vinyl acetate copolymer with a vinyl acetate content of 26 wt%, and the ethylene-vinyl acetate copolymer with a vinyl acetate content of 28 wt% The mass ratio of the substance is 1:1.6;

[0087] Described ethylene-octene copolymer is with embodiment 1;

[0088] Described styrene-butadiene block copolymer is with embodiment 1;

[0089] The peroxide is bis-tert-butylperoxycumene (CAS No. 2212-81-9);

[0090] Described nucleating agent is with embodiment 1;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com