Polyurethane foam product and preparation method and application thereof

A polyurethane foam and product technology, applied in the field of polyurethane foam products and its preparation, can solve the problems of poor resilience and poor mechanical strength of microcellular polyurethane foam, which cannot be satisfied, and achieve excellent mechanical strength, no environmental pollution, and low compression deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

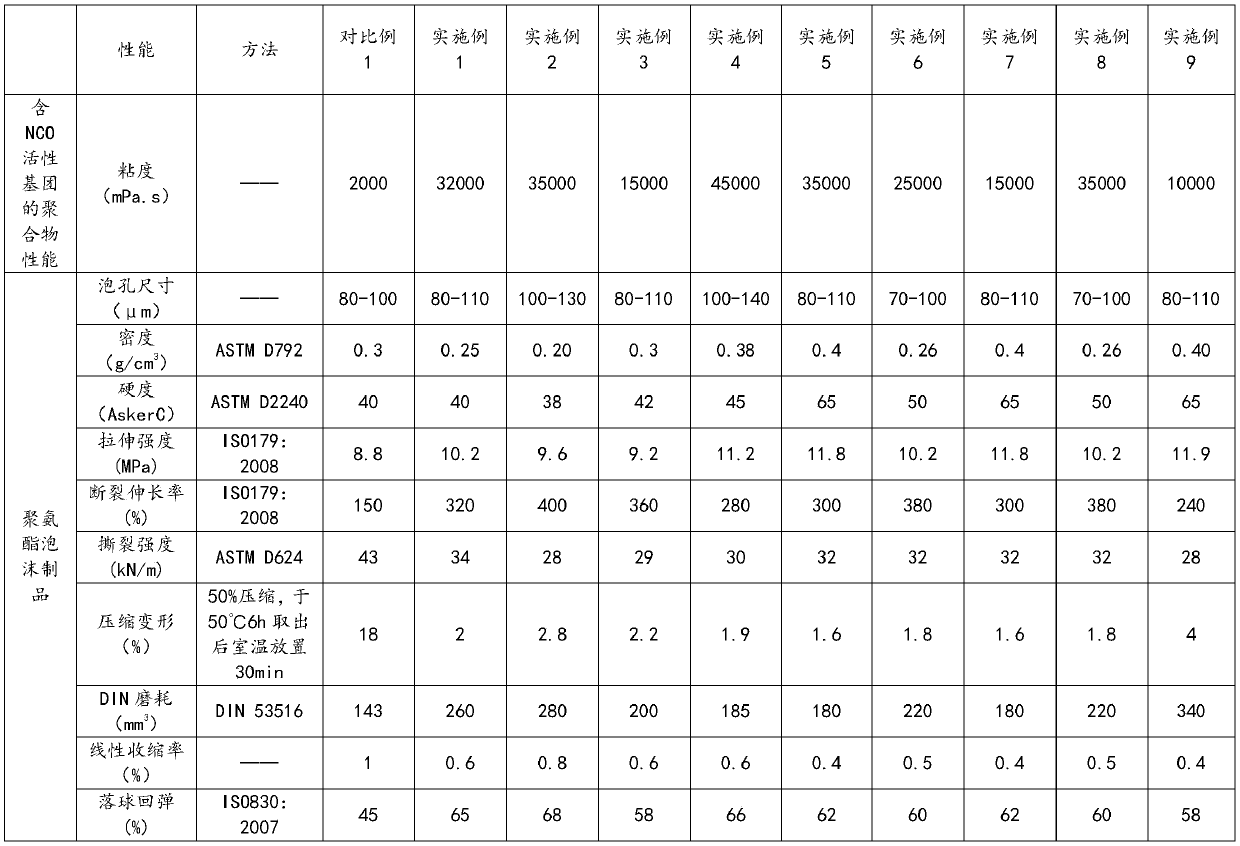

Examples

Embodiment 1

[0049] 1. Preparation of polymers containing NCO active groups

[0050] Add 100 parts by weight of 1800 g / mol polytetrahydrofuran polyether polyol with a functionality of 2 and 1 part by weight of antioxidant 1010 (purchased from Klein Company) into a glass reactor, heat it to 80°C and turn it on after the material melts Stir and heat up to 130°C, vacuum dehydrate to less than 200ppm, then cool down to 80°C, then add 30 parts by weight of MDI into the glass reactor, heat up to 110°C for 1.5h, and then add 0.3 parts by weight of Catalyst bismorpholine ethyl ether (DMDEE), continue to stir and react for 20 minutes, and finally discharge to obtain a polymer containing NCO active groups, which is sealed and stored. At the same time, the technical indicators of the product were tested as shown in Table 1.

[0051] 2. Preparation of polyurethane foam products

[0052] Take 100 parts by weight of the above-prepared polymer containing NCO active groups and 5 parts by weight of water...

Embodiment 2

[0054] 1. Preparation of polymers containing NCO active groups

[0055] Add 60 parts by weight of 2000g / mol polytetrahydrofuran polyol with a functionality of 2, 40 parts by weight of 2000g / mol, polybutylene adipate with a functionality of 2 and 0.5 parts by weight of inorganic filler talcum powder Put it into a glass reactor, heat it to 80°C and start stirring after the material melts, and raise the temperature to 130°C, vacuumize and dehydrate to less than 200ppm, then cool down to 80°C, then add 25 parts by weight of MDI into the glass reactor, and heat up React at 110°C for 1.5 hours, then add 0.2 parts by weight of the catalyst bismorpholine ethyl ether (DMDEE), continue to stir and react for 20 minutes, and finally discharge the material to obtain a polymer containing NCO active groups, keep it sealed and test at the same time The technical indicators of the product are shown in Table 1.

[0056] 2. Preparation of polyurethane foam products

[0057] Mix 100 parts by we...

Embodiment 3

[0059] 1. Preparation of polymers containing NCO active groups

[0060] Add 100 parts by weight of 1000 g / mol polytetrahydrofuran polyether polyol with a functionality of 2 and 2 parts by weight of OB-1 fluorescent agent into a glass reactor, heat to 80 ° C and start stirring after the material melts, and raise the temperature to 130 ℃, vacuum dehydration to less than 200ppm, then lower the temperature to 80°C, then add 50 parts by weight of MDI into the glass reactor, heat up to 110°C for 1.5h, and then add 1 part by weight of catalyst bismorpholine ethyl Ether (DMDEE), continue to stir and react for 20min, and finally discharge to obtain a polymer containing NCO active groups, which is sealed and stored, and the technical indicators of the product are shown in Table 1.

[0061] 2. Preparation of polyurethane foam products

[0062] Put 100 parts by weight of the polymer containing NCO active groups prepared above into the extruder, then inject 2 parts by weight of water into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| molar mass | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com