Method for synthesis of solution-polymerized styrene butadiene rubber through two-component regulator

A solution-polymerized styrene-butadiene rubber and regulator technology, applied in the field of rubber, can solve problems such as uneven distribution of styrene, and achieve the effect of completely uniform and random distribution, mature technology and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Under the protection of nitrogen, add 100ml of cyclohexane, 7.6g of butadiene, 2.4g of styrene, 0.40ml of tetrahydrofuran, 0.0056g of potassium tert-butyl oxide into a purified 250ml polymerization bottle with electromagnetic stirring, and use n-butyllithium Residual impurities in the system were removed, and 0.10 mmol of n-butyllithium was added to carry out polymerization reaction at 50°C. Samples were taken at different reaction times, and the reaction was stopped and samples were taken after 3 hours. All samples were flocculated with ethanol, and then placed in a vacuum oven for extraction and drying. Determination of conversion rate by mass method, test by nuclear magnetic resonance spectrometer 1 H-NMR spectrum. Calculate the styrene content in the polymer and the 1,2-structure content in the copolymer at different reaction times.

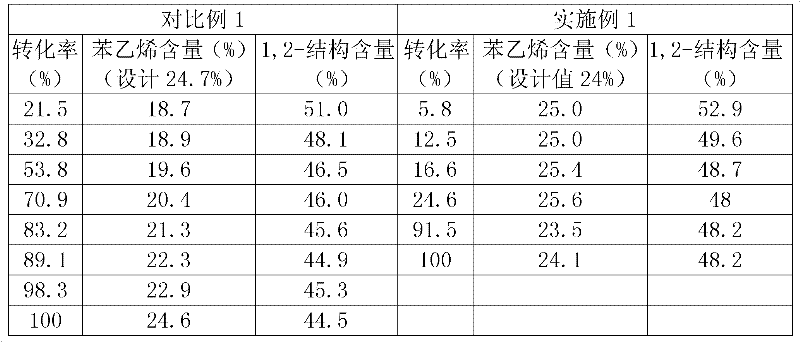

[0035] Copolymer composition and 1,2-structure content under different conversion ratios of Table 1 Comparative Example 1 and Examp...

Embodiment 2

[0039] Under the protection of nitrogen, add 100ml of cyclohexane, 7.6g of butadiene, 2.4g of styrene, 0.24ml of tetrahydrofuran, 0.0051g of potassium tert-butyl oxide into a purified 250ml polymerization bottle with electromagnetic stirring, and use n-butyl Lithium was used to remove residual impurities in the system, and 0.10 mmol of n-butyllithium was added to carry out polymerization reaction at 50°C. Samples were taken at different reaction times, and the reaction was stopped and samples were taken after 3 hours. All samples were flocculated with ethanol, and then placed in a vacuum oven for extraction and drying. Determination of conversion rate by mass method, test by nuclear magnetic resonance spectrometer 1 H-NMR spectrum. Calculate the styrene content in the polymer and the 1,2-structure content in the copolymer at different reaction times.

[0040] Copolymer composition and 1,2-structure content under different conversion ratios of Table 2 Example 2

[0041] ...

Embodiment 3

[0044] Under nitrogen protection, add 70ml of cyclohexane, 30ml of hexane, 8.0g of butadiene, 2.0g of styrene, 0.40ml of tetrahydrofuran, 1,1-dimethylpropyl Oxypotassium 0.0057g, use n-butyllithium to remove residual impurities in the system, add n-butyllithium 0.10mmol to carry out polymerization reaction at 50°C, take samples at different reaction times, stop the reaction and take samples after 3 hours. All samples were flocculated with ethanol, and then placed in a vacuum oven for extraction and drying. Determination of conversion rate by mass method, test by nuclear magnetic resonance spectrometer 1 H-NMR spectrum. Calculate the styrene content in the polymer and the 1,2-structure content in the copolymer at different reaction times.

[0045] Copolymer composition and 1,2-structure content under different conversion ratios of Table 3 Example 3

[0046] Conversion rates(%)

[0047] As can be seen from Table 3, adding THF and potassium tert-butyl oxide into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com