Initiator complex for copolymerization of styrene and butadiene and polymerization method

A technology of butadiene and styrene is applied in the field of preparation of initiator complexes for initiating the copolymerization of styrene and butadiene to achieve the effect of mature technology and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

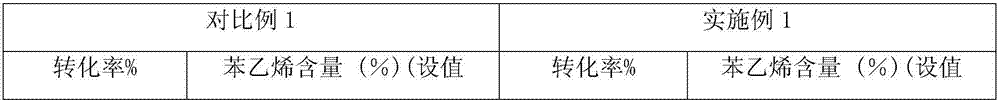

example 1

[0031] Under the protection of nitrogen, quickly add 100ml of 0.5M sec-butyl lithium hexane solution and 1ml of 0.05M t-BuOK THF solution to the dry initiator reactor successively, place it in a 60°C water bath and stir for 30min to obtain Initiator complexes for the copolymerization of styrene and butadiene.

[0032] Under the protection of nitrogen, add organic solvent, styrene and organic solvent dissolved in butadiene to the dry and deoxygenated autoclave, the total monomer concentration of styrene and butadiene is 30g / 100mL, in the total monomer Butadiene content is 70%, add A 8.0×10 -5 mol / 100mL polymerization solution, react at 50°C for 1 h, then add the initiator complex for preparing styrene and butadiene copolymerization, the ratio of the molar number of Li in the initiator complex to the gram number of monomer added is 7× 10 -6 mol / g, react at 50°C for 2 hours, stop with ethanol, condense the polymer with excess ethanol, wash and extrude with steam, and dry in vac...

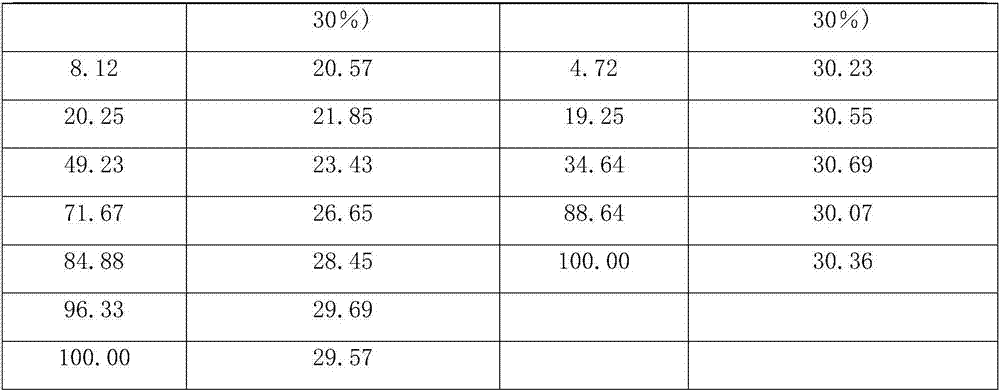

Embodiment 2

[0040] Under the protection of nitrogen, quickly add 100ml of 10M n-butyllithium hexane solution and 10ml of 0.1M t-BuOK THF solution to the dry initiator reactor successively, place it in a water bath at 10°C and stir for 60min to obtain the used Initiator complex for copolymerization of styrene and butadiene.

[0041] Under the protection of nitrogen, add organic solvent, styrene and organic solvent dissolved in butadiene to the dry and deoxygenated autoclave, the total monomer concentration of styrene and butadiene is 20g / 100mL, in the total monomer Butadiene content is 80%, add A 2.0×10 -4 mol / 100mL polymerization liquid, react at 30°C for 0.5h, then add the initiator complex for preparing styrene and butadiene copolymerization, the molar ratio of Li in the initiator complex to the gram number of monomer added is 2 ×10 -5 mol / g, react at 30°C for 4 hours, stop with ethanol, condense the polymer with excess ethanol, wash and extrude with steam, and dry in vacuum to obtain s...

example 3

[0046] Under the protection of nitrogen, quickly add 50ml of 2M sec-butyllithium hexane solution and 10ml of 0.1M t-BuOK THF solution to the dry initiator reactor successively, place it in a water bath at 30°C and stir for 240min to obtain the used Initiator complex for copolymerization of styrene and butadiene.

[0047] Under the protection of nitrogen, add organic solvent, styrene and organic solvent dissolved in butadiene to the dry and deoxygenated autoclave, the total monomer concentration of styrene and butadiene is 10g / 100mL, in the total monomer Butadiene content is 50%, add A 5.0×10 -5 mol / 100mL polymerization solution, react at 70°C for 20min, then add the initiator complex for preparing styrene and butadiene copolymerization, the ratio of the molar number of Li in the initiator complex to the gram number of monomer added is 4× 10 -6 mol / g, react at 70°C for 1 hour, stop with ethanol, coagulate the polymer with excess ethanol, wash and extrude with steam, and dry i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com