Method for synthesis of solution-polymerized styrene butadiene rubber through two-component regulator

A technology for solution-polymerizing styrene-butadiene rubber and a conditioner, applied in the rubber field, can solve problems such as uneven distribution of styrene, and achieve the effects of completely uniform and random distribution, simple process and mature technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Under the protection of nitrogen, add 100ml of cyclohexane, 7.6g of butadiene, 2.4g of styrene, 0.40ml of tetrahydrofuran, 0.0056g of potassium tert-butyl oxide into a purified 250ml polymerization bottle with electromagnetic stirring, and use n-butyllithium Residual impurities in the system were removed, and 0.10 mmol of n-butyllithium was added to carry out polymerization reaction at 50°C. Samples were taken at different reaction times, and the reaction was stopped and samples were taken after 3 hours. All samples were flocculated with ethanol, and then placed in a vacuum oven for extraction and drying. Determination of conversion rate by mass method, test by nuclear magnetic resonance spectrometer 1 H-NMR spectrum. Calculate the styrene content in the polymer and the 1,2-structure content in the copolymer at different reaction times.

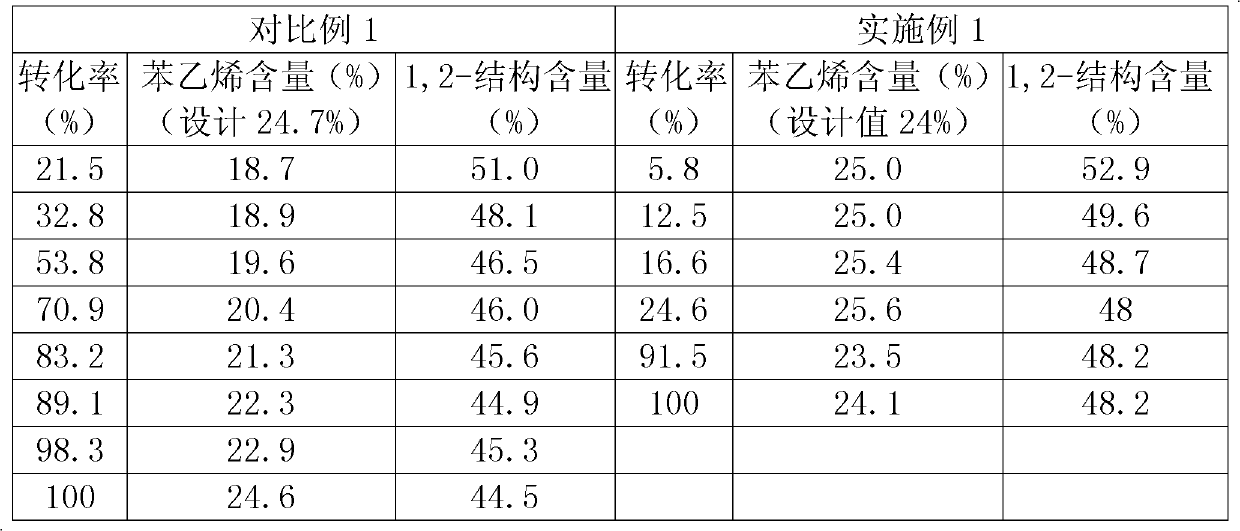

[0035] Copolymer composition and 1,2-structure content under different conversion ratios of Table 1 Comparative Example 1 and Examp...

Embodiment 2

[0039] Under the protection of nitrogen, add 100ml of cyclohexane, 7.6g of butadiene, 2.4g of styrene, 0.24ml of tetrahydrofuran, 0.0051g of potassium tert-butyl oxide into a purified 250ml polymerization bottle with electromagnetic stirring, and use n-butyl Lithium was used to remove residual impurities in the system, and 0.10 mmol of n-butyllithium was added to carry out polymerization reaction at 50°C. Samples were taken at different reaction times, and the reaction was stopped and samples were taken after 3 hours. All samples were flocculated with ethanol, and then placed in a vacuum oven for extraction and drying. Determination of conversion rate by mass method, test by nuclear magnetic resonance spectrometer 1 H-NMR spectrum. Calculate the styrene content in the polymer and the 1,2-structure content in the copolymer at different reaction times.

[0040] Copolymer composition and 1,2-structure content under different conversion ratios of Table 2 Example 2

[0041] ...

Embodiment 3

[0044] Under nitrogen protection, add 70ml of cyclohexane, 30ml of hexane, 8.0g of butadiene, 2.0g of styrene, 0.40ml of tetrahydrofuran, 1,1-dimethylpropyl Oxypotassium 0.0057g, use n-butyllithium to remove residual impurities in the system, add n-butyllithium 0.10mmol to carry out polymerization reaction at 50°C, take samples at different reaction times, stop the reaction and take samples after 3 hours. All samples were flocculated with ethanol, and then placed in a vacuum oven for extraction and drying. Determination of conversion rate by mass method, test by nuclear magnetic resonance spectrometer 1 H-NMR spectrum. Calculate the styrene content in the polymer and the 1,2-structure content in the copolymer at different reaction times.

[0045] Copolymer composition and 1,2-structure content under different conversion ratios of Table 3 Example 3

[0046] Conversion rate(%)

[0047] As can be seen from Table 3, adding THF and potassium tert-butyl oxide into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com