Low temperature resistant and oil proof nitrile butadiene rubber-modified butadiene rubber (BR) blend material and preparation method thereof

A technology of nitrile rubber and butadiene rubber, which is applied in the field of rubber to achieve the effect of improving compatibility, good mechanical properties and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

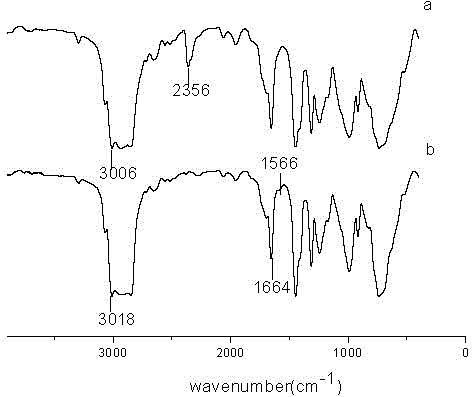

Image

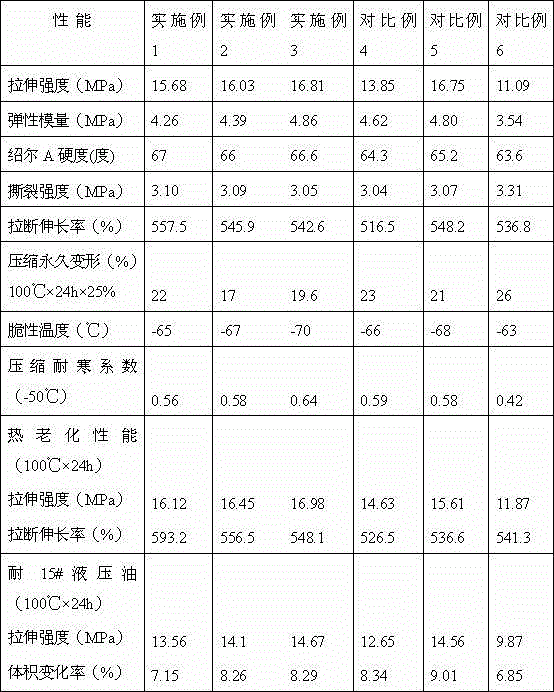

Examples

preparation example Construction

[0025] Weigh each component according to the formula, masticate the nitrile rubber on the double-roller mill, add maleic anhydride grafted butadiene rubber according to the formula ratio, and after the two are blended and covered with rolls, add zinc oxide and stearic acid in turn , anti-aging agent, 1 / 2 carbon black, accelerator, 1 / 2 carbon black, plasticizer, sulfur, temperature 45°C-55°C, after mixing evenly, thin-pass 6 times of filming, park at room temperature for 24 hours, and place on a plate Vulcanize on a vulcanizing machine at a temperature of 160°C for 20 minutes and a pressure of 10Mpa.

[0026] The formula of the present invention will be further described below in conjunction with specific examples:

Embodiment 1

[0029] The preparation process of Example 1 is as follows: masticating nitrile rubber on a double-roller mill, and adding maleic anhydride grafted butadiene rubber after rolling, and adding zinc oxide, hard Fatty acid, anti-aging agent, 1 / 2 carbon black, accelerator, 1 / 2 carbon black, plasticizer, sulfur, the temperature of the front roll is 45°C, and the temperature of the back roll is 55°C. Park at room temperature for 24 hours, and vulcanize on a flat vulcanizing machine at a temperature of 160°C for 20 minutes and a pressure of 10Mpa.

[0030] Example 2

Embodiment 2

[0032] Example 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com