Rubber composition, V belt wrapper glue with adoption of rubber composition and preparation method of V belt wrapper glue

A technology of rubber composition and wrapping glue, which is applied in the field of V-belt wrapping glue and its preparation, and rubber composition. It can solve the problems of heat and oxygen aging resistance, poor durability, and high cost, and achieve heat resistance and heat and oxygen aging resistance. The effect of improving, improving compatibility and processing performance, and reducing overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

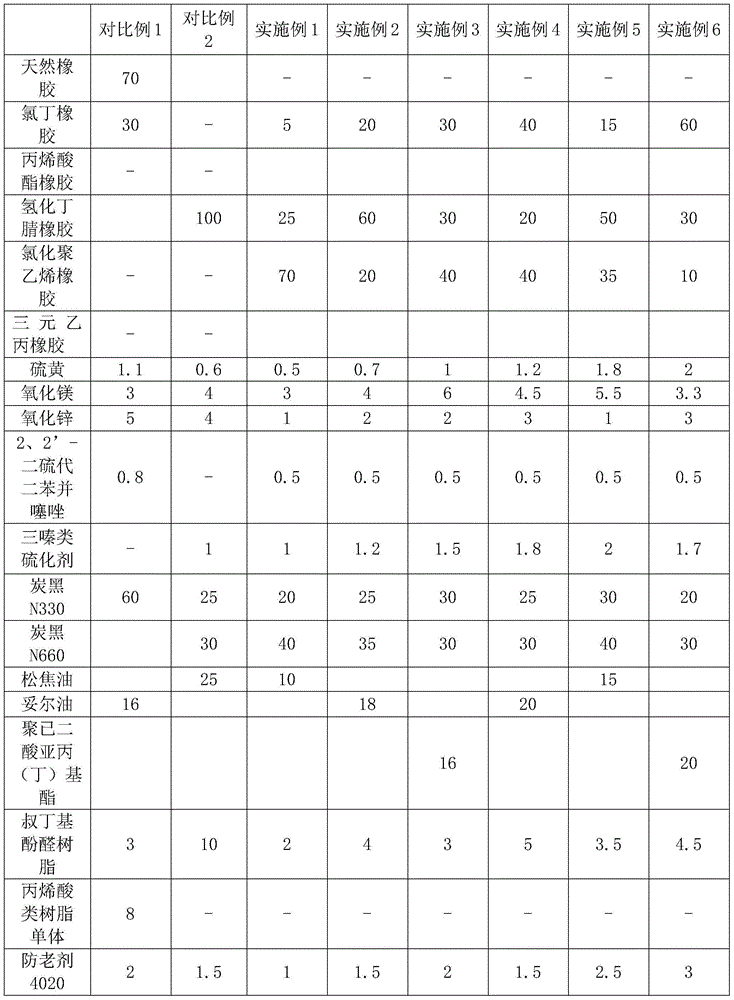

Embodiment 1

[0047] A V-belt wrapped cloth glue, characterized in that its composition includes the following components by weight: 5 parts of acrylate rubber, 25 parts of chlorinated polyethylene rubber, 70 parts of EPDM rubber, 0.5 part of sulfur, zinc oxide 1 part, 3 parts of magnesium oxide, 0.5 part of 2,2'-dithiodibenzothiazole, 1 part of triazine vulcanizing agent, 20 parts of carbon black N33020 parts, 40 parts of carbon black N66040 parts, 10 parts of pine tar, tert-butylphenol aldehyde 2 parts of resin, 1 part of 4020 anti-aging agent;

[0048] First, the acrylic rubber and EPDM rubber are kneaded together on the open mill, and the kneading is uniform before use;

[0049] Put the compound rubber into the internal mixer, add zinc oxide, magnesium oxide, 2,2'-dithiodibenzothiazole, triazine vulcanizing agent, carbon black N330, carbon black N660, pine tar, tert-butyl Phenolic resin, 4020 anti-aging agent, mixing evenly, deglue, the degumming temperature is controlled below 80 ℃; ...

Embodiment 2

[0055] A V-belt wrapped cloth glue is characterized in that its composition comprises the following components by weight:

[0056] 20 parts of acrylate rubber, 60 parts of chlorinated polyethylene rubber, 20 parts of EPDM rubber, 0.7 parts of sulfur, 4 parts of magnesium oxide, 2 parts of zinc oxide, 0.5 parts of 2,2'-dithiodibenzothiazole , 1.2 parts of triazine vulcanizing agent, 25 parts of carbon black N33025, 35 parts of carbon black N6603, 18 parts of tall oil, 4 parts of tert-butyl phenolic resin, 1.5 parts of 4020 anti-aging agent. First, the acrylic rubber and EPDM rubber are kneaded together on the open mill, and the kneading is uniform before use;

[0057] Put the compound rubber into the internal mixer, and then add magnesium oxide, zinc oxide, 2,2'-dithiodibenzothiazole, triazine vulcanizing agent, carbon black N330, carbon black N660, tall oil, tert-butyl Base phenolic resin, 4020 anti-aging agent, mixing evenly, degumming, degumming temperature is controlled at...

Embodiment 3

[0063] A V-belt wrapped cloth glue is characterized in that its composition comprises the following components by weight:

[0064] 30 parts of acrylate rubber, 30 parts of chlorinated polyethylene rubber, 40 parts of EPDM rubber, 1 part of sulfur, 6 parts of magnesium oxide, 2 parts of zinc oxide, 0.5 part of 2,2'-dithiodibenzothiazole , 1.5 parts of triazine vulcanizing agent, 30 parts of carbon black N33030, 30 parts of carbon black N66030, 16 parts of tall oil, 3 parts of tert-butyl phenolic resin, 2 parts of 4020 anti-aging agent.

[0065] First, the acrylic rubber and EPDM rubber are kneaded together on the open mill, and the kneading is uniform before use;

[0066] Put the compound rubber into the internal mixer, and then add magnesium oxide, zinc oxide, 2,2'-dithiodibenzothiazole, triazine vulcanizing agent, carbon black N330, carbon black N660, tall oil, tert-butyl Base phenolic resin, 4020 anti-aging agent, mix evenly, degumming, degumming temperature is controlled a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com