Gas drying process and device

A technology of gas drying and process, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of environmental pollution, waste, high cost, etc., and achieve the advantages of avoiding powdering of adsorbent, convenient operation and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

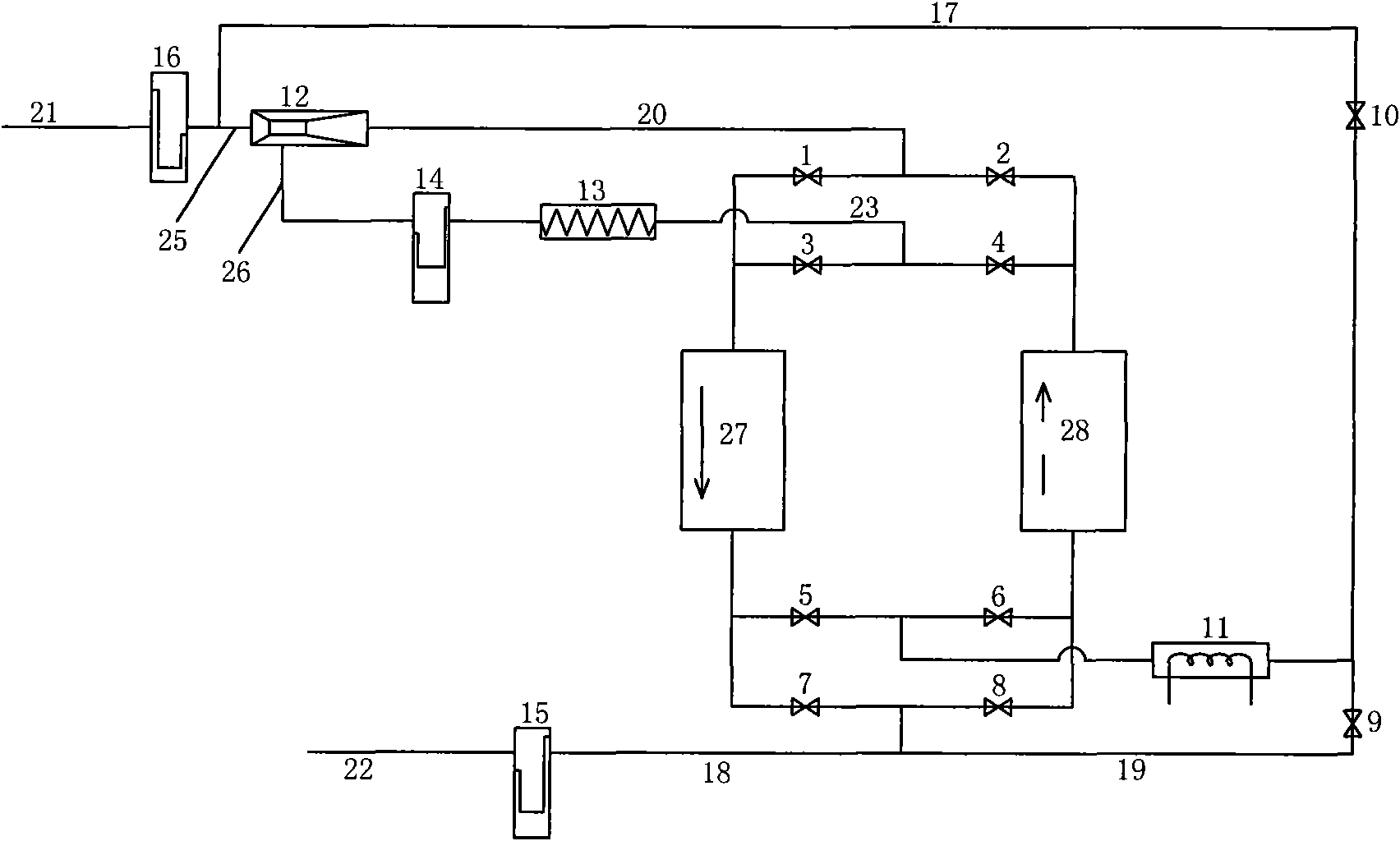

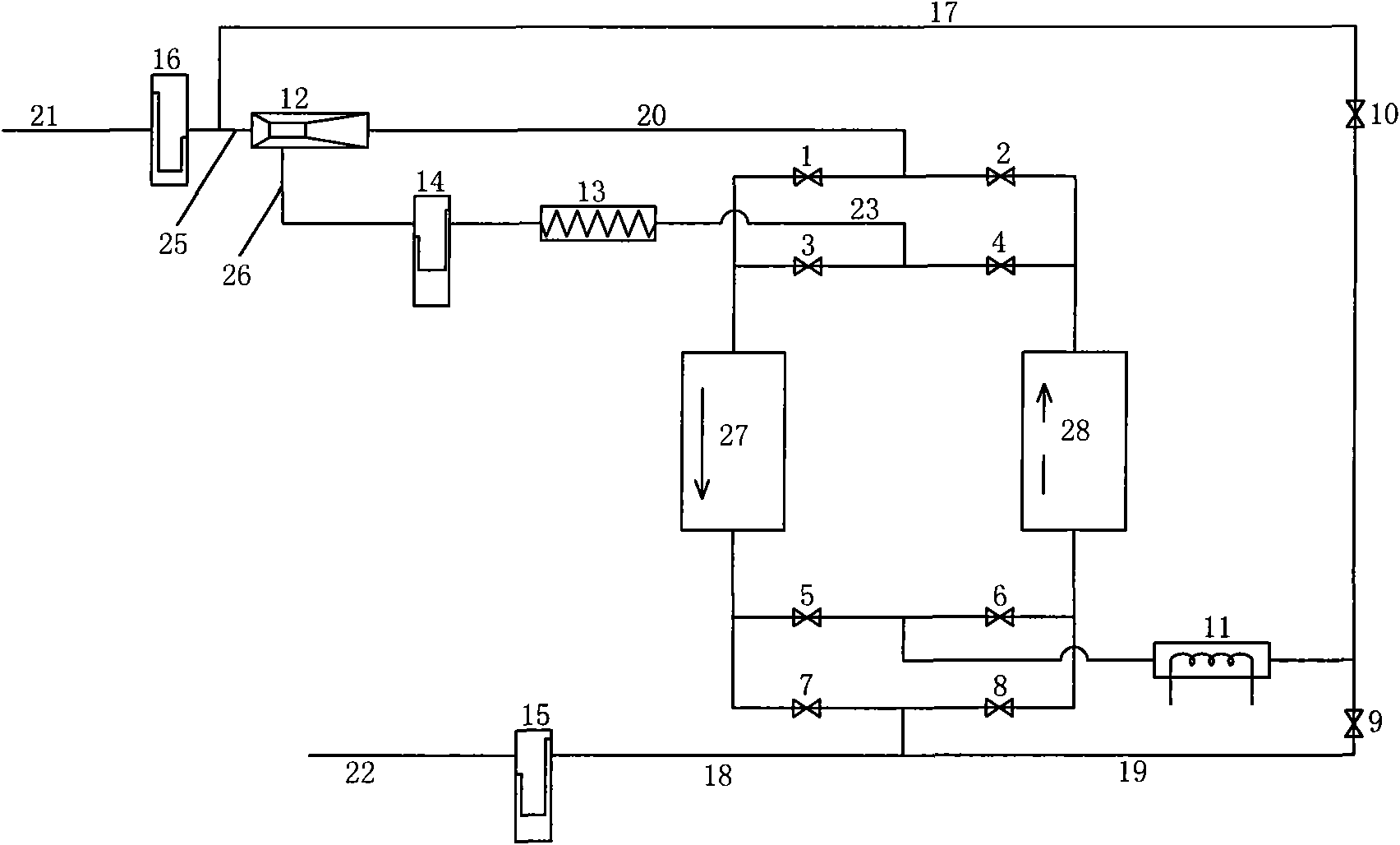

[0046] Gas drying process of the present invention is as follows:

[0047] (1) Adsorption

[0048] (1.1) Filtration and separation of the free liquid contained in the raw gas;

[0049] (1.2) A part of the gas obtained after the treatment of step (1.1) is pressurized and introduced into a tower for adsorption and drying; the adsorbent in the adsorption tower can be silica gel, aluminum glue or molecular sieves;

[0050] (1.3) Another part of the gas obtained after the treatment of step (1.1) is delivered to step (2) for regeneration;

[0051] (1.4) filtering the gas obtained after the treatment in step (1.2) to separate the solid dust particles in the gas;

[0052] (1.5) Part of the gas obtained after the treatment in step (1.4) is introduced into the gas utilization system, and the other part is introduced into the step (2.5);

[0053] (2) regeneration

[0054] (2.1) Heating the gas introduced through step (1.3), so that the temperature rises to the temperature required fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com