Flue-gas processing technique based on adsorbent-polymer composite material

A technology of composite materials and adsorbents, applied in air quality improvement, other chemical processes, separation methods, etc., can solve problems such as consumption of activated carbon, complex and expensive desulfurization devices, and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

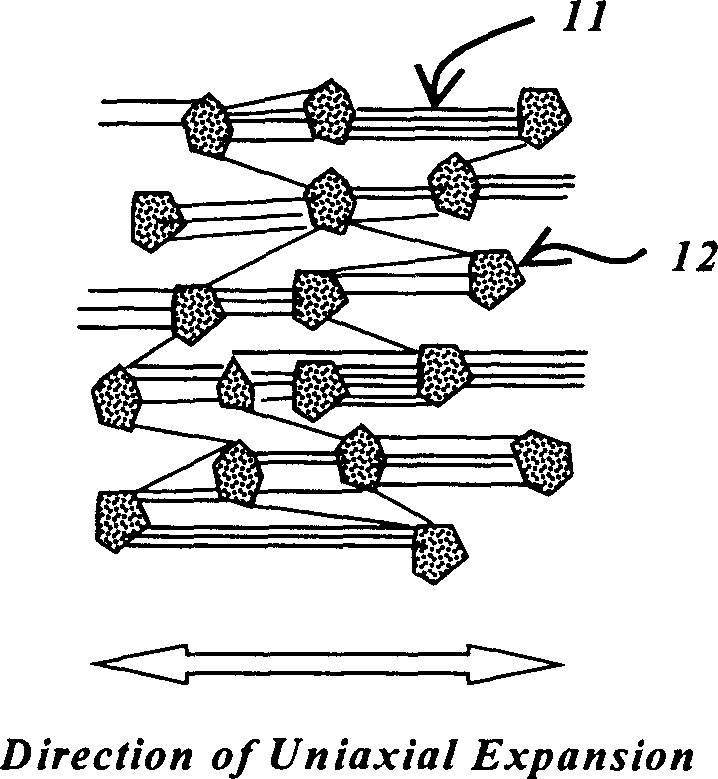

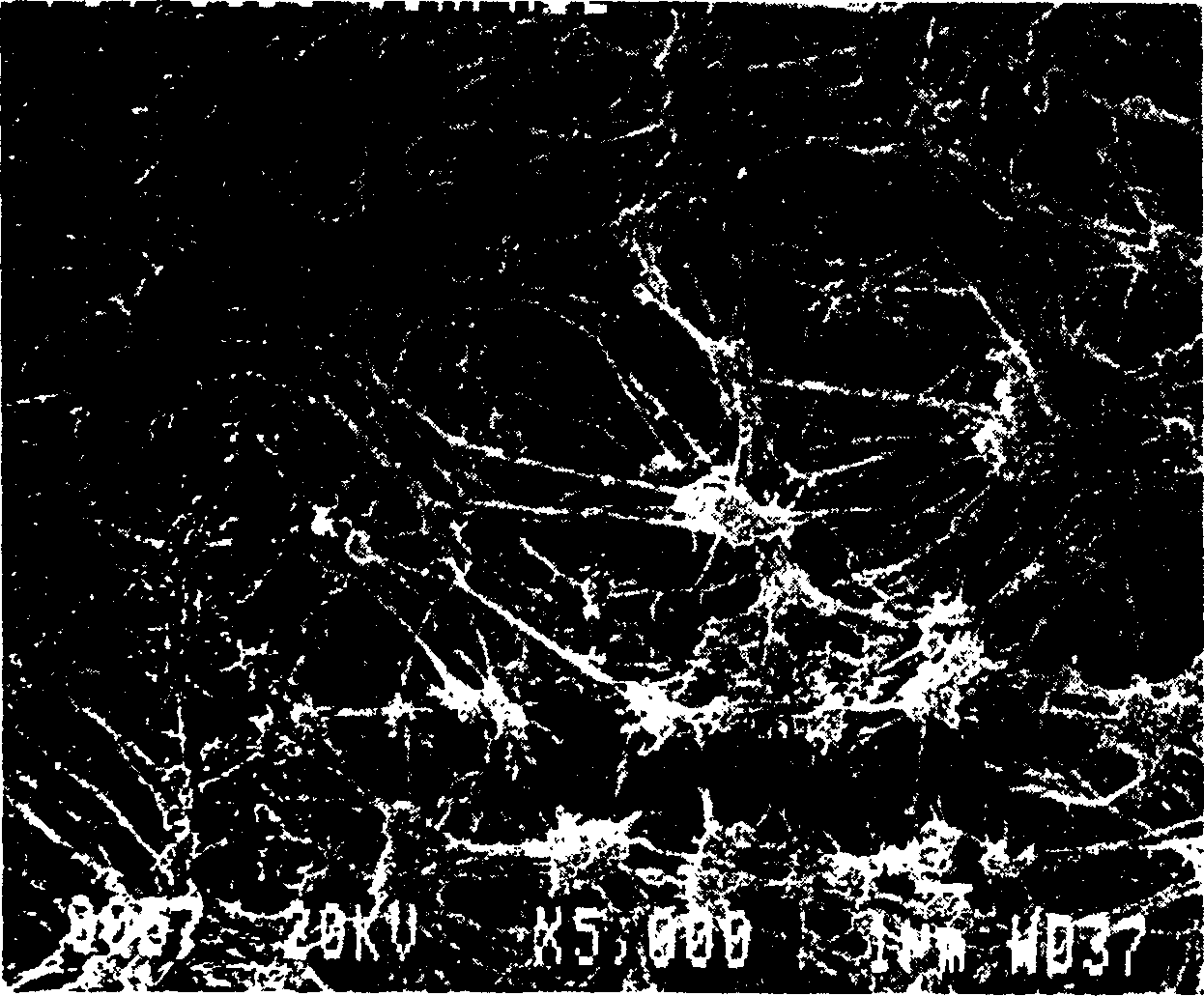

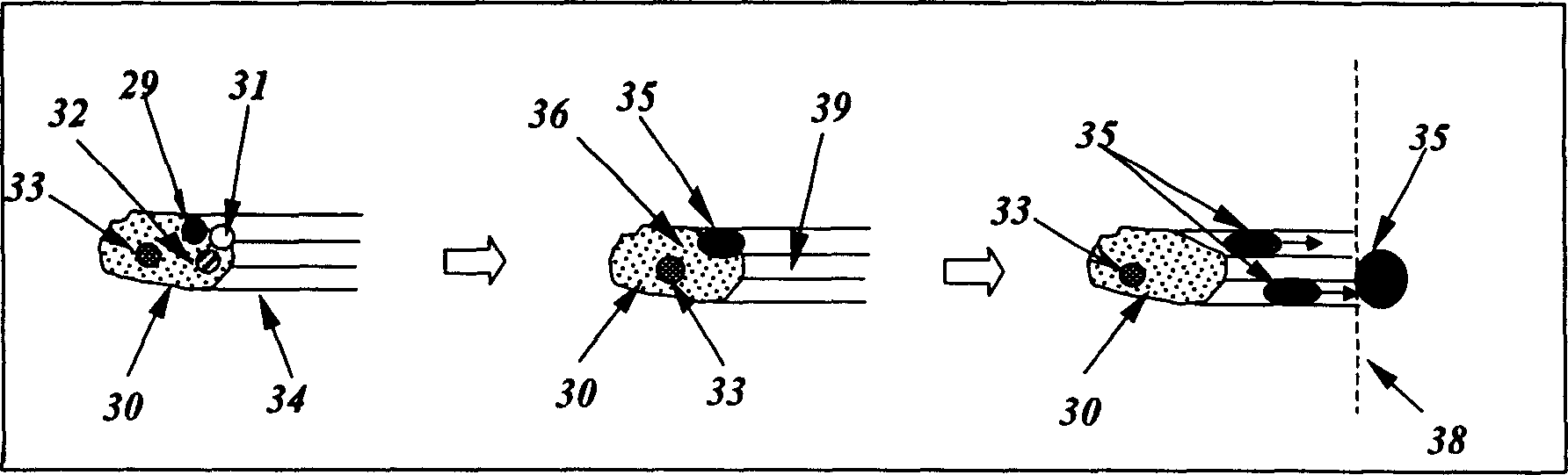

[0040] DETAILED DESCRIPTION OF THE INVENTION: The present invention involves a process for simultaneously removing sulfur oxides, mercury vapor, and fine dust from flue gas using a sorbent-polymer composite (SPC). The present invention includes the SPC material itself. The process of the present invention converts sulfur oxide into a sulfuric acid solution, which has a relatively high concentration of sulfuric acid and can be used as a salable product. The process of the invention fixes mercury molecules inside the material by means of chemical adsorption, and captures dust particles on the porous polytetrafluoroethylene film layer on the outer surface of the SPC by means of surface filtration.

[0041] SO x Scavenging: Adsorbent materials, especially activated carbon, have proven to be a viable material for scavenging sulfur oxides from flue gases. In a typical sorbent-based desulfurization process, flue gas is introduced and passed through a sorbent bed, where sulfur oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com