Internal cooling, heating type apparatus for dehumidifying and regenerating solution, and dehumidifying and regenerating method

A solution dehumidification and regeneration device technology, applied in heating methods, separation methods, chemical instruments and methods, etc., can solve the problems of poor dehumidification/regeneration effect, decrease, dehumidification/regeneration solution temperature rise, etc., to achieve high efficiency and performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

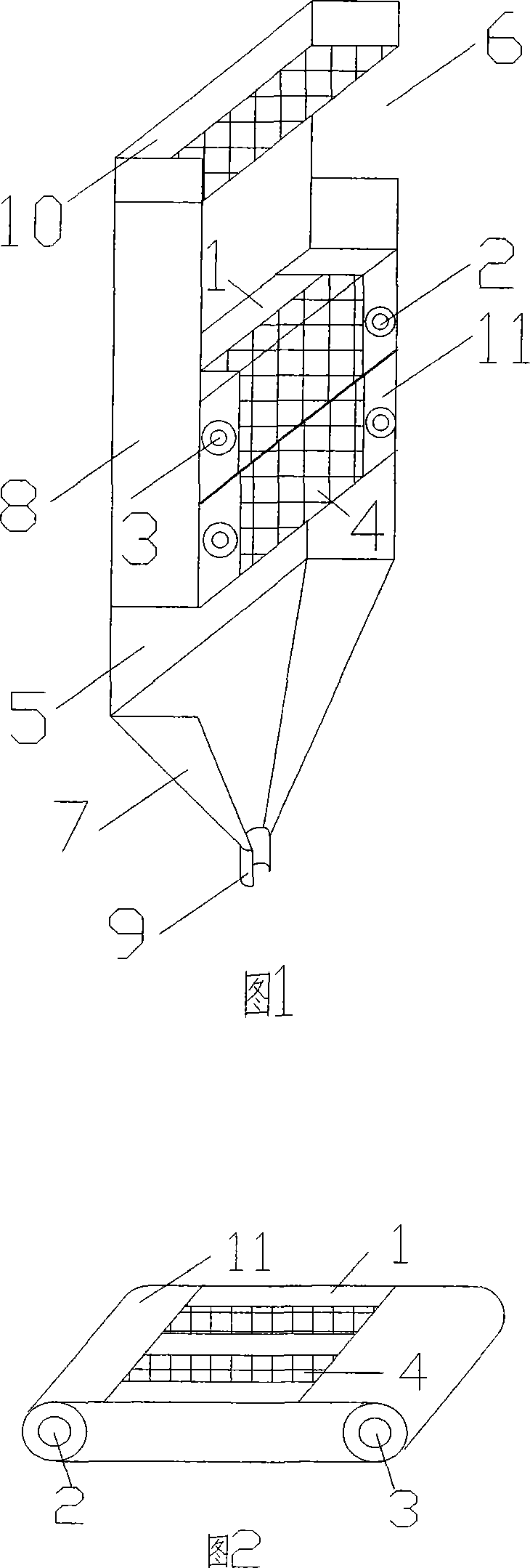

[0018] Example 1: LiCl solution regeneration process. Dehumidification and regeneration unit 11 has a channel height of 1m and a width of 0.3m. A plate-fin heat exchanger is selected as the core of the regenerator, and the plate-fin expansion coefficient is 5. When the cold / heat medium channel has no internal heat When the working fluid is flowing, the regenerator is an adiabatic regenerator. The dehumidification regeneration method is divided into the flow of the solution, the flow of the air, and the flow of the cold / heat medium, among which,

[0019] 1) The process of the solution: the solution first enters the liquid distribution tank 10, which makes the solution uniformly distributed and then falls to the heat and mass exchange bed 4 due to the action of gravity, forming a falling film on the surface of the heat and mass exchange bed 4 of the dehumidification regeneration unit 11, and in the The surface of the heat-mass exchange bed 4 exchanges heat and mass with the coun...

Embodiment 2

[0023] Example 2: LiCl solution dehumidification process. The structure of the internal cooling type dehumidification device is similar to the structure of the regeneration device mentioned above. The channel flow rate of the wet air unit is 0.0098kg / s, the temperature is 25.0°C, and the moisture content is 11.5g / kg dry air; The mass flow rate of the dehumidification solution is 0.016kg / s, the temperature is 27°C, the mass percentage concentration is 40.0%, the mass flow rate of the internal cooling working medium is 0.04kg / s, and the temperature is 25°C. In the adiabatic dehumidifier, both the solution temperature and the air temperature increase gradually, the solution temperature rises from 27°C to 28.7°C, and the air temperature rises from 25°C to 26.2°C. In the internal cooling type dehumidification device, the solution temperature gradually decreases due to the internal cooling water, and the outlet temperature is only 26.1°C, and the air temperature has a small increase,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com