Inside cooling film dehumidifier and air dehumidification purification device using same

A membrane dehumidifier and internal cooling technology, applied in application, air quality improvement, membrane technology, etc., can solve the problems of air affecting the purification effect, cooling of difficult-to-dehumidify solutions, and reduced dehumidification efficiency, so as to improve heat and mass transfer efficiency, Improved dehumidification efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

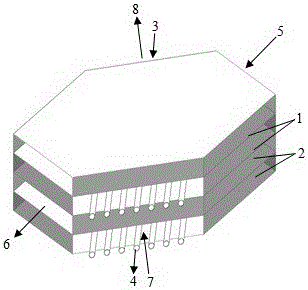

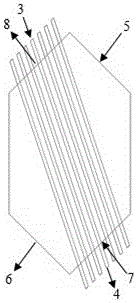

[0039] like figure 1 and figure 2 As shown, a membrane dehumidifier with internal cooling is in the shape of a straight hexagonal prism, and the isolation membrane 1 is hexagonal, and the isolation membrane 1 only allows the water vapor in the air in the air flow channel to enter the solution flow channel through the isolation membrane; the multilayer Isolation films 1 are stacked in parallel at equal intervals to form solution channels and air channels arranged in parallel and alternately; The sides of the prismatic membrane dehumidifier are the first side, the second side, the third side, the fourth side, the fifth side and the sixth side in the counterclockwise direction. The air flow channel includes the air inlet 5 and the air outlet 6, and the solution flow The channel includes a solution inlet 7 and a solution outlet 8 thereof, and the cooling pipe includes a cooling water inlet 3 and a cooling water outlet 4, the air inlet 5 of the air flow channel is opened on the t...

Embodiment 2

[0046] The main technical solutions of this embodiment are the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

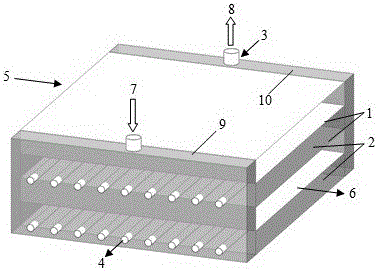

[0047] like image 3 and Figure 4 As shown, a membrane dehumidifier with internal cooling is in the shape of a cuboid, that is, the isolation membrane 1 is a rectangle, and the sides of the cuboid are the first side, the second side, the third side and the fourth side in the counterclockwise direction, and the air flow The inlet of the channel is opened on the fourth side, the outlet of the air flow is opened on the second side, the first side and the third side are respectively equipped with a liquid inlet head 9 and a liquid outlet head 10, and the inlet 7 of the solution channel is opened on the liquid inlet head. The outlet 8 of the solution flow channel is set on the top of the liquid outlet head, the cool...

Embodiment 3

[0050] The main technical solutions of this embodiment are the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0051] like Figure 5 and Figure 6 As shown, a membrane dehumidifier with internal cooling is in the shape of a cuboid, that is, the isolation membrane 1 is a rectangle, and the sides of the cuboid are the first side, the second side, the third side and the fourth side in the counterclockwise direction, and the air flow The inlet 5 of the channel is opened on the fourth side, the outlet 6 of the air flow channel is opened on the second side, a liquid inlet head 9 is installed on the end of the first side close to the second side, and a liquid inlet head 9 is installed on the end of the third side close to the fourth side. There is a liquid outlet head 10, the inlet 7 of the solution flow channel is opened at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com