Suspension magnetizing roasting cyanide breakage-weak magnetic separation iron extraction device for high-iron cyanide tailings

A technology of cyanidation tailings and magnetization roasting, applied in magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of large sewage production, long process and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

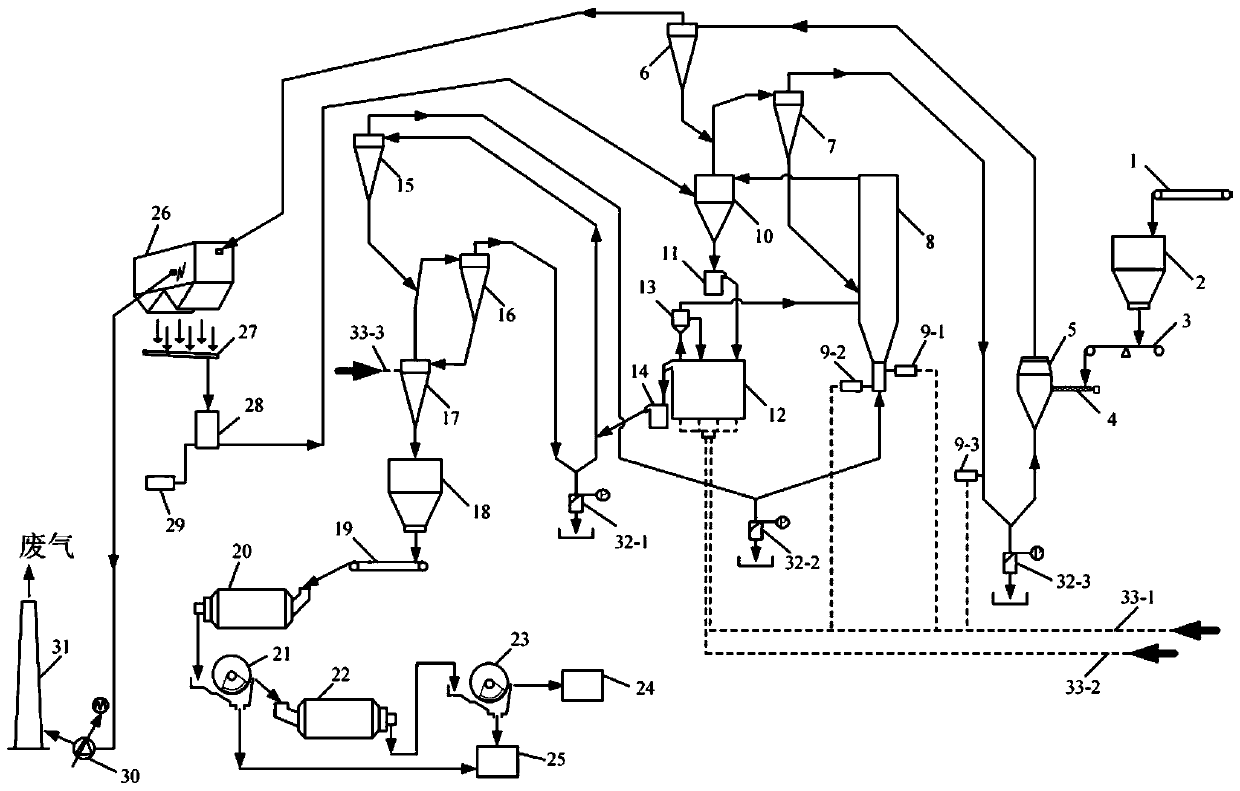

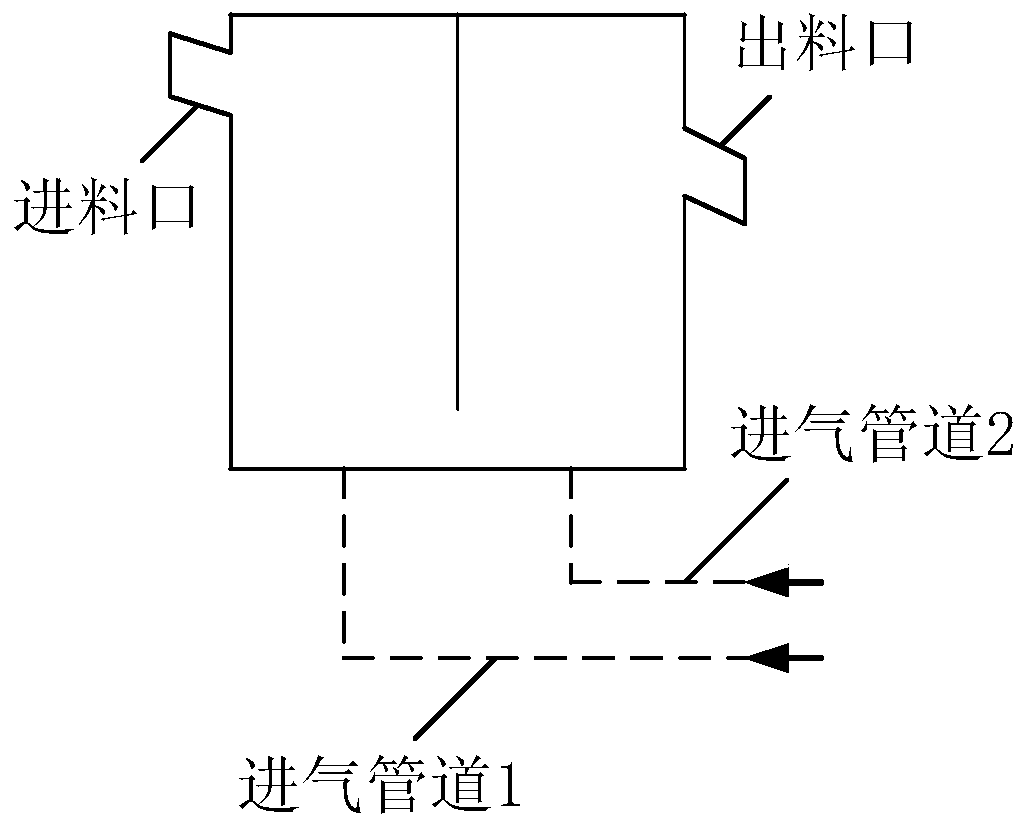

[0073] Suspension magnetization roasting of high ferricyanide tailings cyanide breaking-weak magnetic separation and iron extraction device structure is as follows figure 1 As shown, it includes a feeding bin 2, a Venturi dryer 5, a first cyclone preheater 6, a second cyclone preheater 7, a pre-oxidation suspension roaster 8, a heat separation cyclone 10, a suspension reduction roaster 12, Collection bin 18, first stage grinding machine 20, first stage weak magnetic separator 21, second stage grinding machine 22, second stage weak magnetic separator 23, dust collector 26 and induced draft fan 30;

[0074]The outlet of the feeding bin 2 is opposite to the screw feeder 4, and the feed port of the screw feeder 4 is opposite to the inlet of the Venturi dryer 5; Feed port is communicated, and the discharge port of the first cyclone preheater 6 is communicated with the feed port of the second cyclone preheater 7, and the discharge port of the second cyclone preheater 7 is connected ...

Embodiment 2

[0104] Device structure is the same as embodiment 1;

[0105] The high ferricyanide tailings adopted are TFe 32.91% by mass percentage, SiO 2 29.45%, CN - Content 460mg / L, method is with embodiment 1, difference is:

[0106] (1) The part of ferricyanide tailings that is crushed and ground to a particle size of -0.038mm accounts for 70% of the total mass;

[0107](2) the temperature of the material at the outlet of the venturi drier 5 is controlled to be 130°C; the solid material is preheated to 400°C in the second cyclone preheater 7;

[0108] (3) cyanide breaking roasting temperature 700; The residence time of the solid material entering the pre-oxidation roaster in the pre-oxidation roaster is 10min;

[0109] (4) The reduction roasting temperature is 550°C; when coal gas and nitrogen are introduced from the bottom of the suspension reduction roaster 12, the amount of coal gas introduced is determined according to the amount of H in the coal gas. 2 / CO and Fe in oxide sla...

Embodiment 3

[0113] Device structure is the same as embodiment 1;

[0114] The high ferricyanide tailings adopted are TFe 36.39% by mass percentage, SiO 2 22.25%, CN - Content 420mg / L, method is with embodiment 1, difference is:

[0115] (1) The part of ferricyanide tailings that is crushed and ground to a particle size of -0.038mm accounts for 75% of the total mass;

[0116] (2) the temperature of the material at the outlet of the venturi drier 5 is controlled to be 135°C; the solid material is preheated to 500°C in the second cyclone preheater 7;

[0117] (3) cyanide breaking roasting temperature 750; The residence time of the solid material entering the pre-oxidation roaster in the pre-oxidation roaster is 5min;

[0118] (4) The reduction roasting temperature is 600°C; when feeding coal gas and nitrogen from the bottom of the suspension reduction roasting furnace 12, the amount of coal gas is calculated according to the amount of H in the coal gas. 2 / CO and Fe in oxide slag powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com