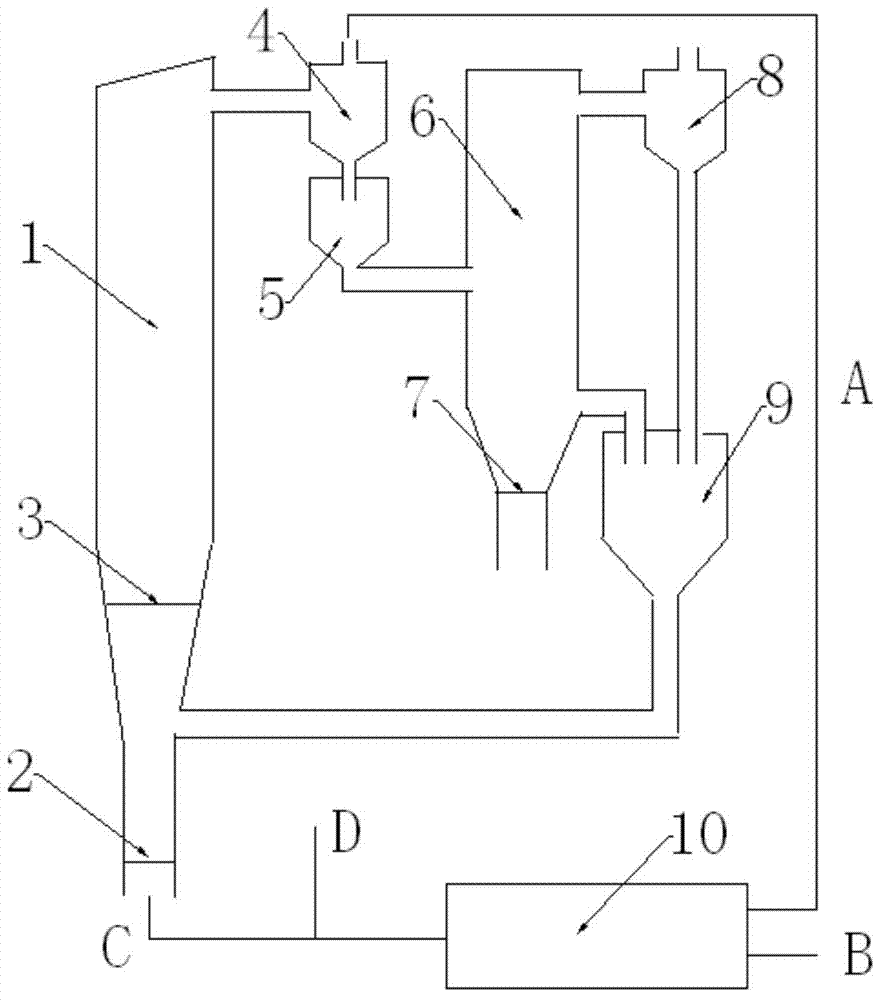

Device and process for preparing O2-CO2 mixed gas based on chemical-looping technology

A technology of O2-CO2 and mixed gas, which is applied in the direction of oxygen preparation, carbon compounds, inorganic chemistry, etc., can solve the problems of complex operation, high energy consumption, low efficiency, etc., achieve high heat and mass transfer efficiency, improve production efficiency, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The oxygen carrier particles used are CuO / TiO prepared by spray drying method 2 Particles, in which the mass fraction of CuO is 60%, the particle size of the particles is 100μm~150μm, and the feed rate of the oxygen carrier is 100g / min, the recycled flue gas introduced into the fluidized bed reactor from the oxygen-enriched burner The flow rate is 5 L / min, the reaction temperature in the fluidized bed reactor is 1000~1200℃, and the operating pressure is 0.1~0.2MPa. O was measured at the outlet of the fluidized bed reactor 2 -CO 2 O in the mixed gas 2 The content is 31.4%. The reaction temperature of the bubbling bed reactor is 600~700°C, the air flow rate input from the gas inlet of the bubbling bed reactor is 1L / min, and the operating pressure is 0.1MPa.

Embodiment 2

[0033] The oxygen carrier particle used is Mn 2 o 3 and Co 2 o 3 Composite oxygen carrier, where Mn 2 o 3 The mass fraction is 50%, Co 2 o 3 The quality fraction is 50%. The particle size of the particles is 200μm~300μm, the feed rate of the oxygen carrier is 200g / min, the flow rate of the recirculated flue gas introduced from the oxygen-enriched burner into the fluidized bed reactor is 5 L / min, and the fluidized bed The reaction temperature in the reactor is 750~850℃, and the operating pressure is 0.1~0.2MPa. O was measured at the outlet of the fluidized bed reactor 2 -CO 2 O in the mixed gas 2 The content is 21.9%. The reaction temperature of the bubble bed reactor is 400~500°C, the air flow rate input from the gas inlet of the bubble bed reactor is 1L / min, and the operating pressure is 0.1MPa.

Embodiment 3

[0035] The oxygen carrier used is PbO 2 Particles, the particle size of the particles is 450 μm~500 μm, the feed rate of the oxygen carrier is 500 g / min, and the flow rate of the recirculated flue gas introduced from the oxygen-enriched burner into the fluidized bed reactor is 5 L / min. The reaction temperature in the bed reactor is 300~350℃, and the operating pressure is 0.1~0.2MPa. O was measured at the outlet of the fluidized bed reactor 2 -CO 2 O in the mixed gas 2 The content is 7.2%. The reaction temperature of the bubbling bed reactor is 300~350°C, the air flow rate input from the gas inlet of the bubbling bed reactor is 1L / min, and the operating pressure is 0.1MPa.

[0036] The present invention and existing preparation O 2 -CO 2 Compared with the mixed gas process, the recirculated flue gas is used to directly produce O 2 -CO 2 The mixed gas simplifies the two-step process of first producing oxygen and then mixing in cryogenic air separation and other processes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com