Method and device for sludge filter cake aerobic air drying

An air-drying device and sludge technology, applied in the directions of sludge drying, sludge treatment, sludge treatment, etc., can solve the problems of difficult sludge drying tail gas treatment, poor equipment operation stability, and high energy consumption of sludge drying. Resource utilization, low drying energy consumption, and the effect of reducing drying energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

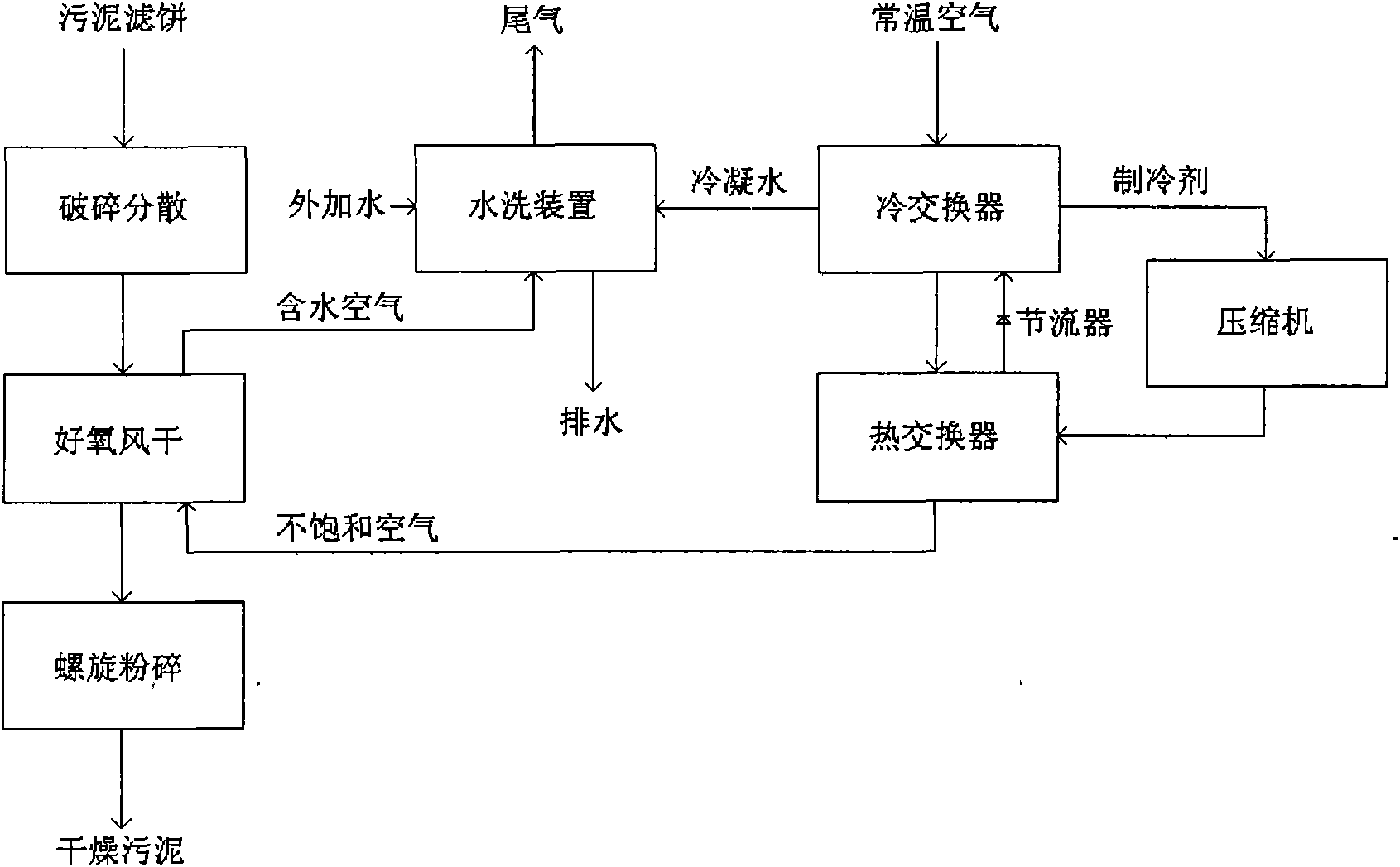

[0037] A kind of sludge filter cake aerobic air-drying method, it comprises the following steps:

[0038] (1) The sludge filter cake with a moisture content of 70-50% is broken into sludge particles and then dropped to the conveyor belt to disperse into a sludge particle layer. The sludge filter cake can be broken by the corresponding sludge filter cake crushing device. accomplish.

[0039] (2) Dry air at a certain temperature is positively pressured into the sludge particle layer on the slow-moving conveyor belt; the dry air is formed by condensing and separating moisture in the cold exchanger and heating up in the heat exchanger. ; The temperature of the dry air can be between 0 and 90°C. The dry air is transported through the air duct to the dry air inlet between the upper and lower steel meshes of the conveyor belts of each layer. When passing through the bottom and surface sludge particles, it provides oxygen for the aerobic reaction of the sludge and absorbs the sludge ...

Embodiment 2

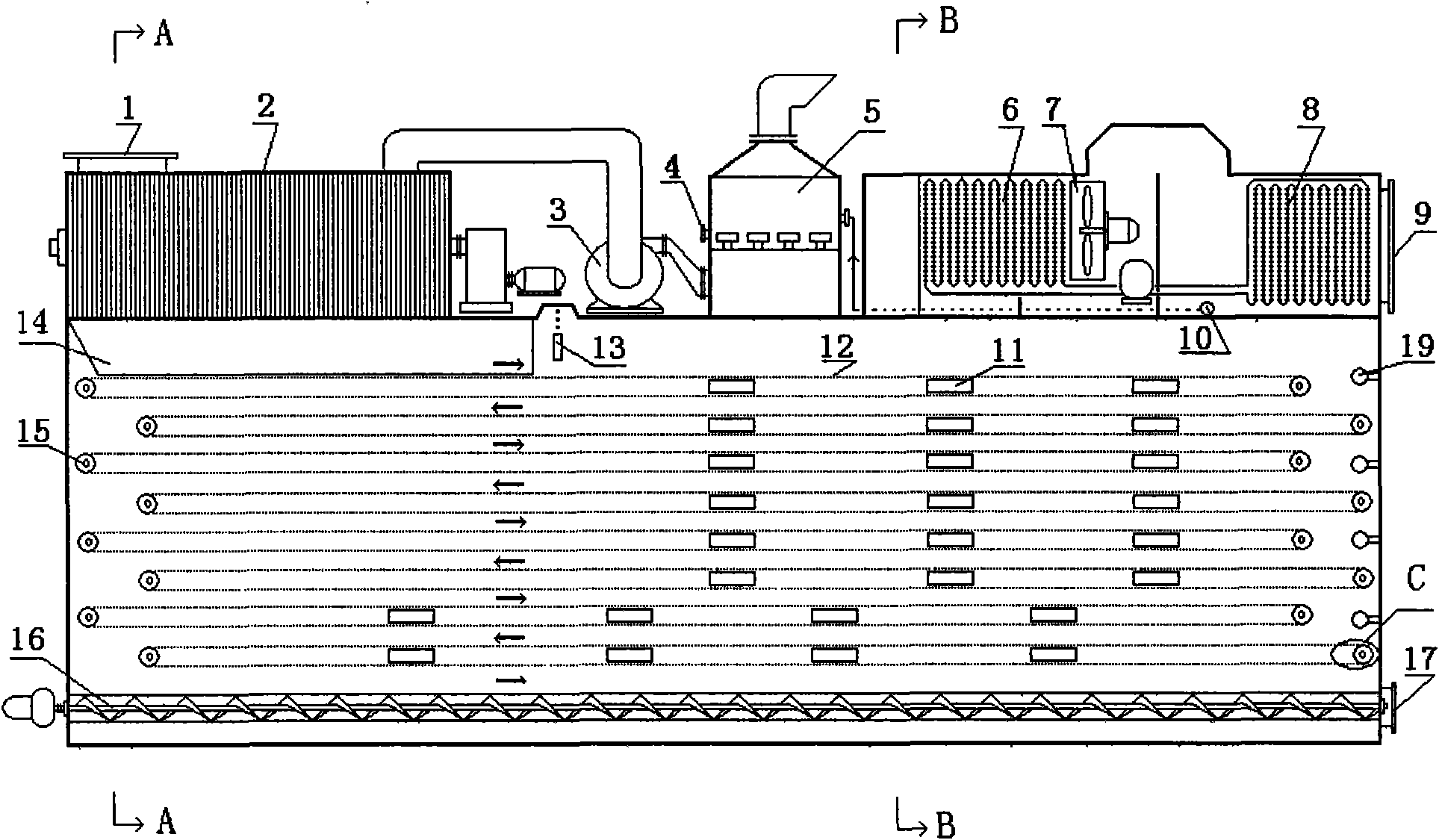

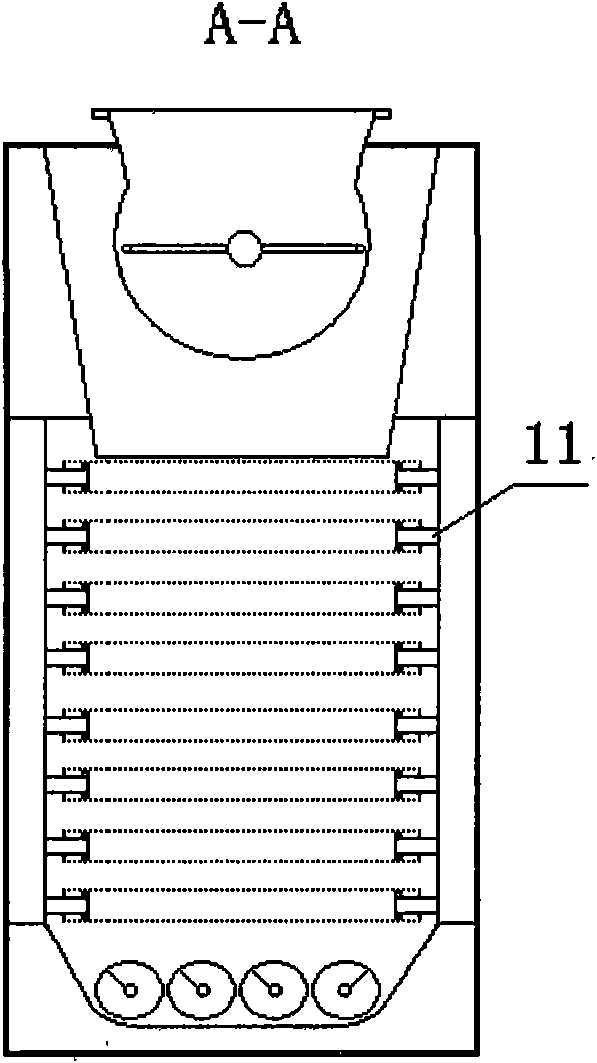

[0051] The sludge filter cake with a moisture content of 70% enters the sludge filter cake crushing and dispersing device 2 from the feed port, and the crushed sludge particles fall onto the conveyor belt 12 of the sludge aerobic air-drying mechanism. The linear speed of the conveyor belt 12 is 1.5mm / s, the sludge thickness on the conveyor belt 12 is about 50mm. When the sludge is transported to the end of the conveyor belt 12, the sludge will automatically fall on the next layer of conveyor belt 12 moving in the opposite direction, and the sludge will be sterilized by ultraviolet light 19 during the sludge stirring process, and so forth. The temperature of the dry air is 62°C, and it is transported through the air duct to the dry air inlet 11 between the upper and lower steel meshes of each steel mesh conveyor belt to provide drying air to the sludge particles on the upper and lower mesh belts. The dried sludge falls on the discharge crushing mechanism 16 placed at the bottom...

Embodiment 3

[0053] The sludge filter cake with a moisture content of 62% enters the sludge filter cake crushing and dispersing device 2 from the feed port 1, and the crushed sludge particles fall to the conveyor belt 12 of the sludge aerobic air-drying mechanism. The linear speed of the conveyor belt 12 is 3mm / s, and the sludge thickness on the conveyor belt 12 is about 80mm. When the sludge is transported to the end of the conveyor belt 12, the sludge will automatically fall on the next layer of conveyor belt 12 moving in the opposite direction, and the sludge will be sterilized by ultraviolet light 19 during the sludge stirring process, and so forth. The temperature of the drying air is 55°C, and it is transported through the air duct to the drying air outlet 11 between the upper and lower mesh belts of each conveyor belt 12 to provide dry air to the sludge particles on the upper and lower mesh belts. The dried sludge falls on the discharge crushing mechanism 16 placed at the lower part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com