Design of high-manganese medium-thickness plate applied to LNG (Liquefied Natural Gas) storage tanks and production method thereof

A technology of high manganese and storage tanks, applied in the field of steel materials, can solve the problems of reducing ultra-low temperature impact energy absorption, weakening grain boundary strength, cracking, etc., and achieve excellent resistance to temperature difference deformation performance, fatigue cracking resistance, and excellent plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

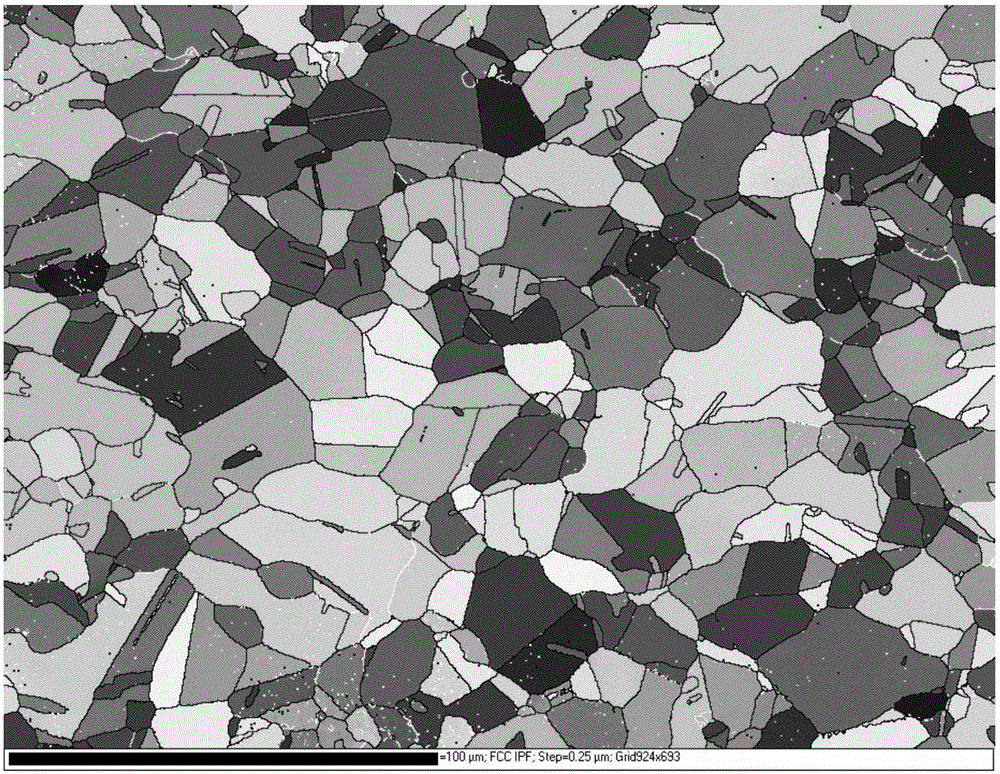

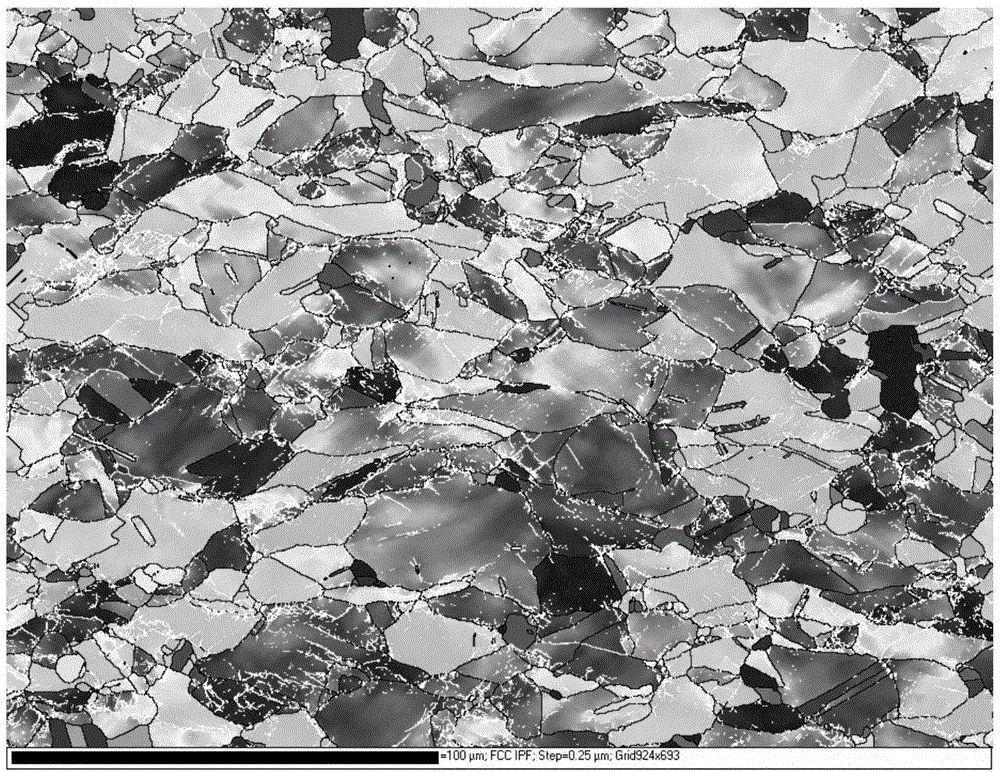

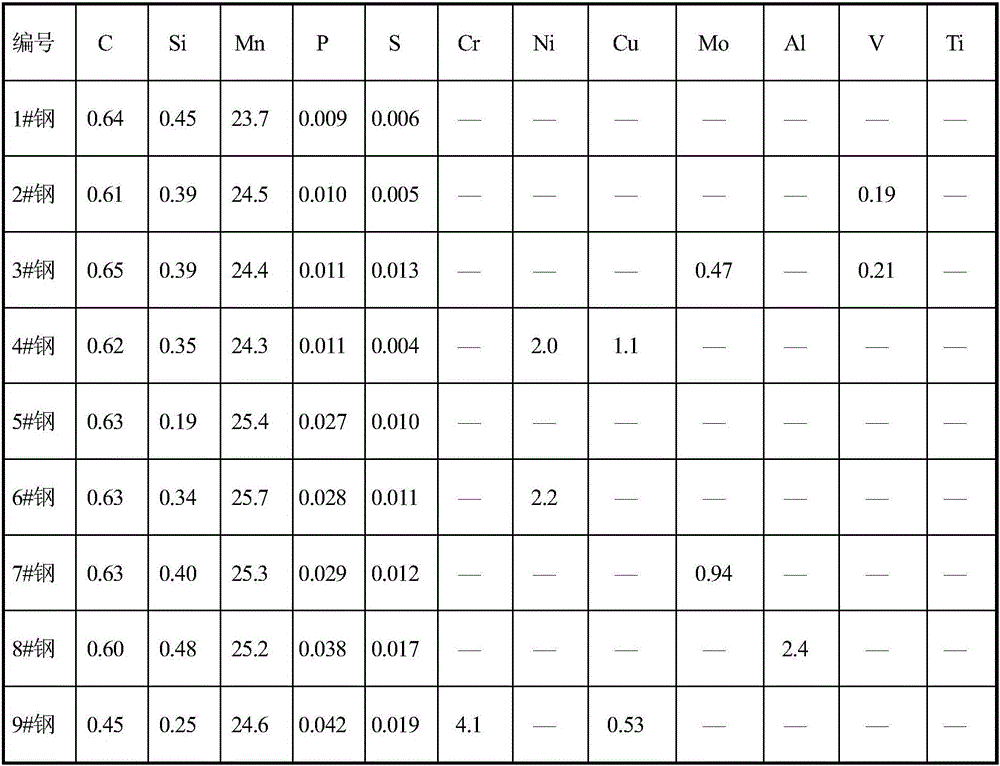

[0037] In the specific implementation process, the smelting is smelted in a vacuum induction furnace. After smelting, it is poured into a copper mold with a diameter of about 100 mm, and the shrinkage cavity is cut to obtain an ingot; the riser is cut off, and the ingot is heated to 1200 ° C for 2 hours. It is forged into a steel billet with a section of 80mm×80mm. The billets were reheated to 1200°C and held for 2 hours, and rolled in one or two stages on a 450mm two-roll reversing hot rolling experimental rolling mill. One-stage controlled rolling, the starting rolling temperature is 1083-1185°C, the final rolling temperature is 990-1116°C, and the starting and cooling temperature is 935-1080°C; two-stage controlled rolling, the first-stage rolling temperature is 1155-1170°C, The temperature of the first-stage finish rolling is 1090-1113°C, the second-stage start-rolling temperature is 931-962°C, the second-stage finish rolling temperature is 900-934°C, and the start-cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com