Fuel gas supply system and method of ship

A gas supply and ship technology, applied in the container discharge method, container filling method, transportation and packaging, etc., can solve the problems of excess, complex gas supply system, etc., achieve the effect of reducing power requirements, preventing pressure increase, and simplifying configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

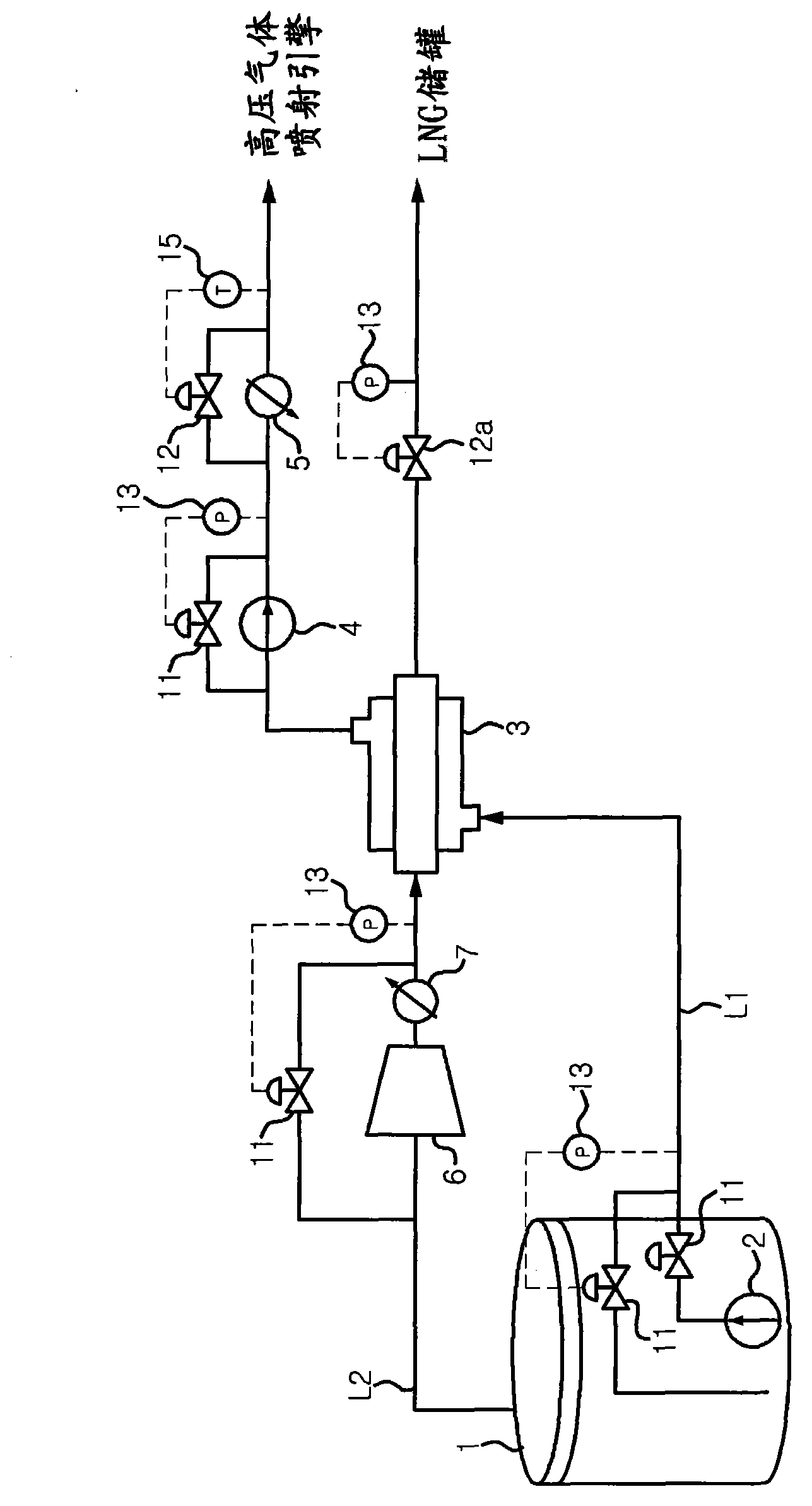

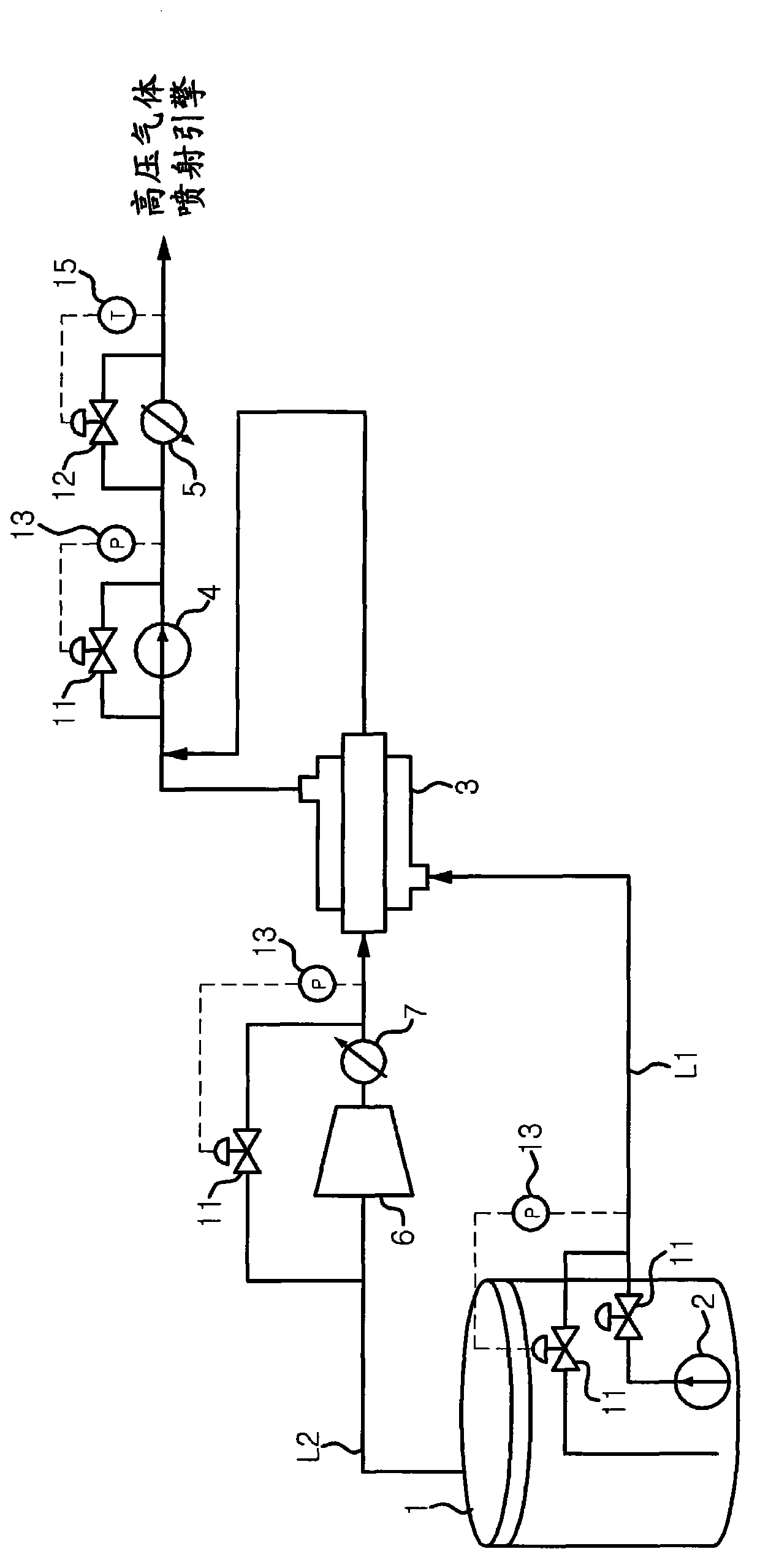

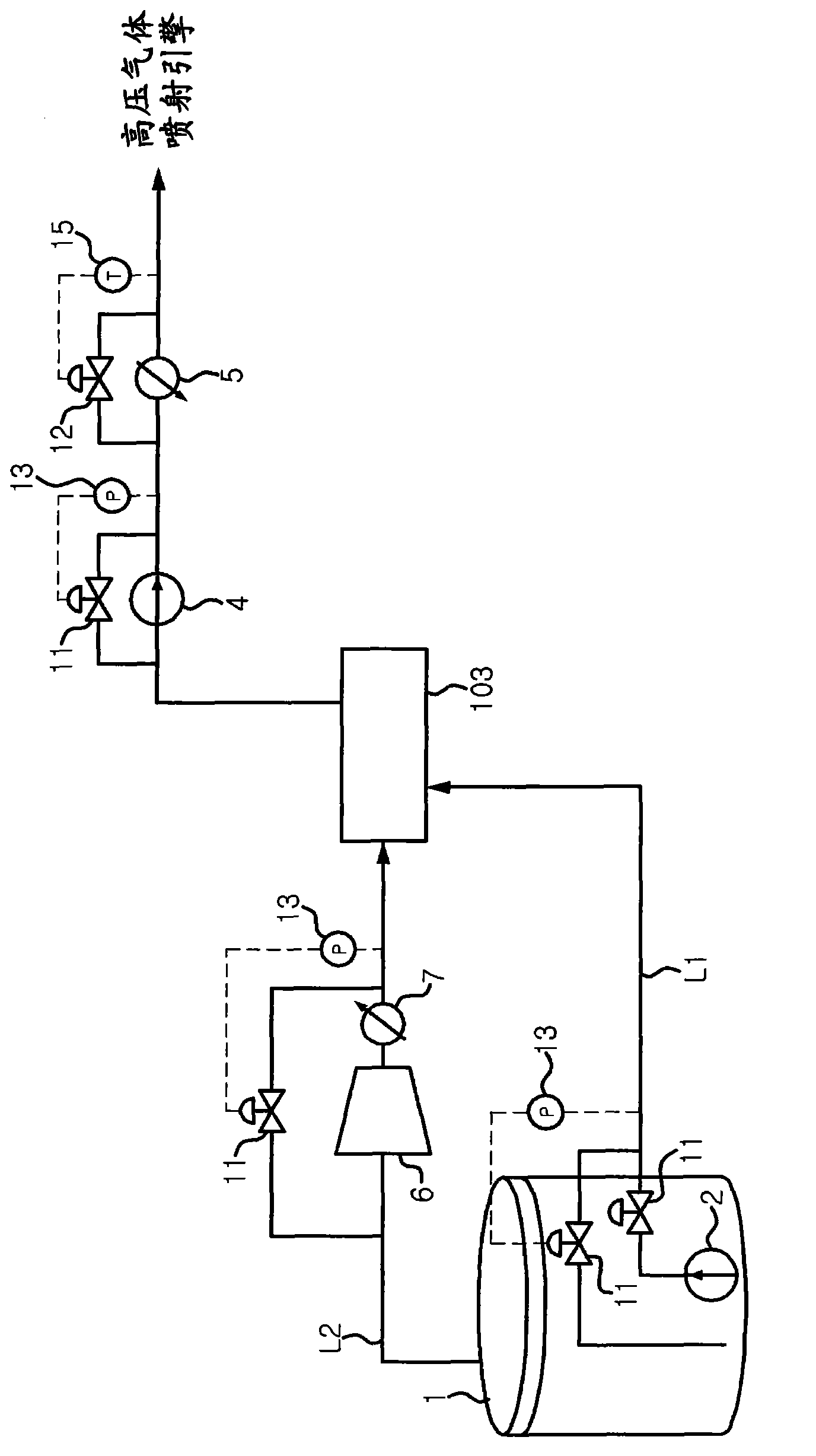

[0021] figure 1 It is a schematic diagram of a gas supply system of a ship according to an embodiment of the present invention. like figure 1 As explained in , the ship's gas supply system supplies gas to the ship's high-pressure gas injection engines.

[0022] figure 1 The gas supply system includes: a gas supply line L1, which is used to supply the LNG extracted from the LNG storage tank 1 of the ship to the high-pressure gas injection engine of the ship; and a heat exchanger 3, which is installed in the middle of the gas supply line L1 In order to exchange heat between the LNG and the boil-off gas extracted from the LNG storage tank 1 .

[0023] The ship may be an LNG carrier. The LNG carrier has an LNG storage tank for storing LNG. In this case, the LNG storage tank 1 is an LNG storage tank.

[0024] In addition, the ship may be a sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com