Method for quality conditioning of industrial combustion natural gas

A natural gas, quenching and tempering technology, applied in the petroleum industry, fuel, gas fuel and other directions, to achieve the effect of saving resources, wide control range and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

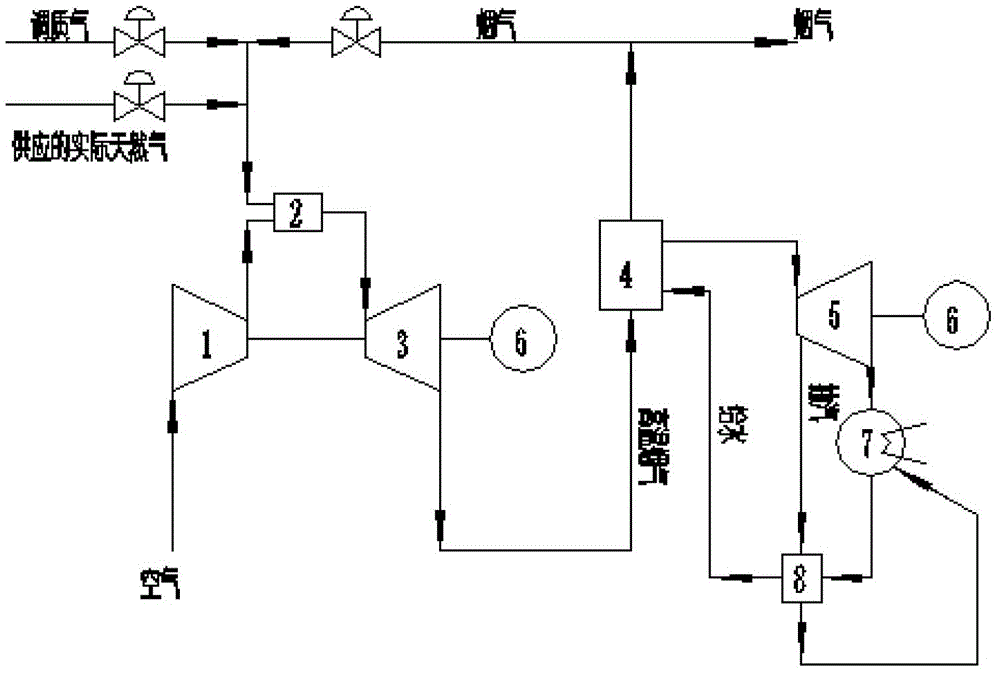

Embodiment Construction

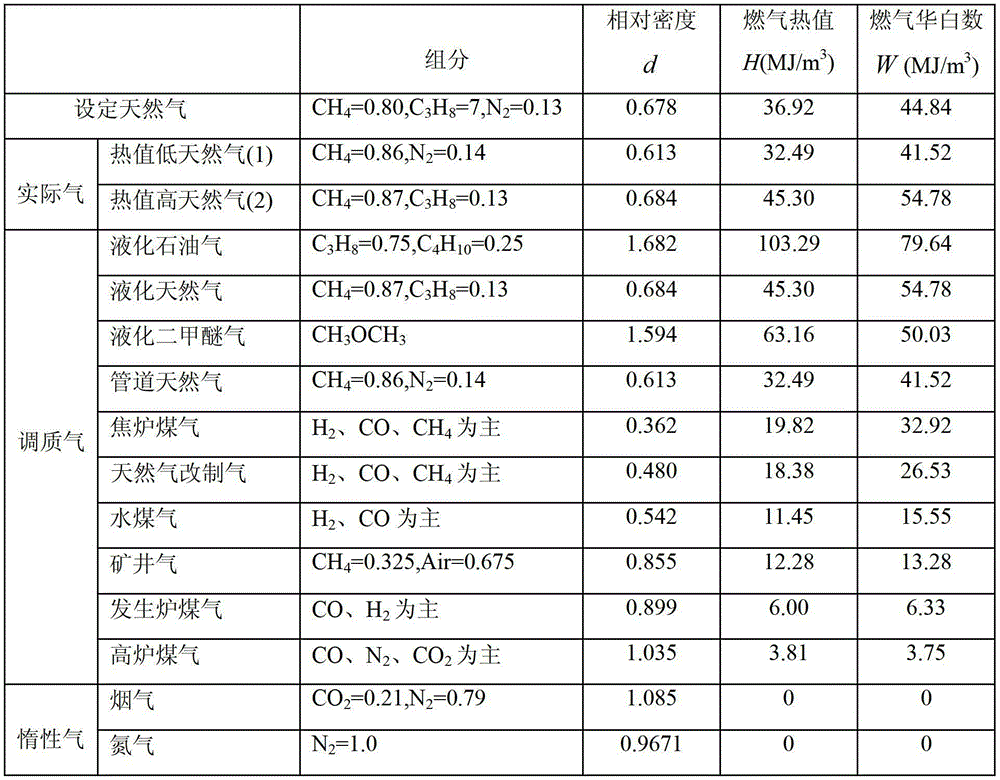

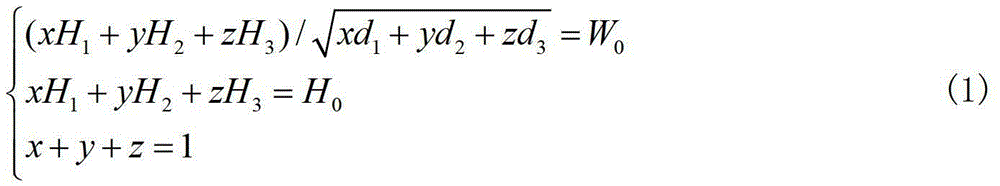

[0018] The blending target is to set natural gas, and the main body of blending is actual natural gas. The tempered gas used for blending includes liquefied petroleum gas, liquefied natural gas, dimethyl ether, pipeline natural gas, natural gas reformed gas, coke oven gas, water gas, mine gas, generator gas Coal gas, blast furnace gas, etc. are mixed with inert gas (flue gas, nitrogen, etc.) in order to meet the requirements of heat load. When the Wobbe number of the actual natural gas is lower than the Wobbe number of the set natural gas, use high calorific value gas (liquefied petroleum gas, liquefied dimethyl ether gas, liquefied natural gas, etc.) . When the Wobbe number of the actual natural gas is higher than the Wobbe number of the set natural gas, according to the conditions of the gas source, the gas with medium and low calorific value (pipeline natural gas, natural gas reformed gas, coke oven gas, water gas, mine gas, producer gas, etc.) can be selected. Coal gas, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com