Method for operation of a burner in particular a burner for a gas turbine and device for carrying out said method

A technology of burner and fuel characteristics, applied in gas turbine installations, combustion methods, combustion air/fuel supply, etc., can solve problems such as increased nitrogen oxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

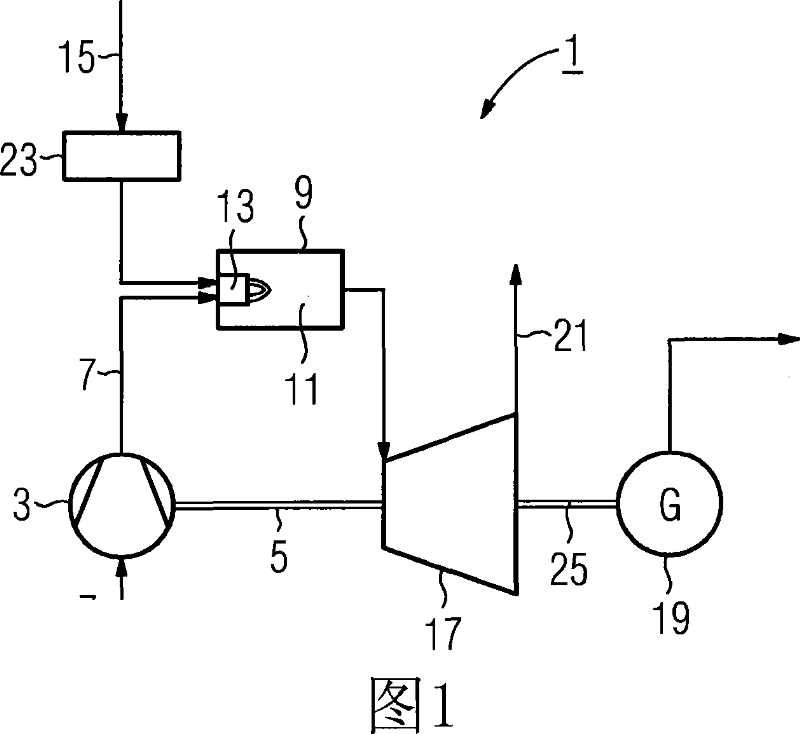

[0034] The gas turbine system shown in FIG. 1 has a gas turbine 1 with a compressor 3 , a combustion chamber 9 and a turbine 17 downstream of the combustion chamber 9 . Compressor 3 and turbine 17 are optionally coupled via a common rotor shaft 5 . A generator 19 is connected downstream of the turbine 17 and is coupled to the turbine 17 , for example via a generator shaft 25 . The combustion chamber 9 comprises a combustion zone 11 and a burner 13 protruding into the combustion zone 11 for burning a liquid or gaseous fuel 15 . When the gas turbine 1 is working, the air 7 is sucked into the compressor 3, where the air is compressed. The compressed air 7 is fed to the burner 13 as combustion air and mixed with fuel 15 . The fuel-air mixture thus formed is combusted in the combustion zone 11 , producing very hot combustion gases. The high-temperature combustion gas is delivered to the turbine 17, where it expands to perform work, thereby driving the rotor shaft 5 on the compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com