Fuel heater system including hot and warm water sources

一种燃料加热、燃料的技术,应用在涡轮/推进装置的燃料加热、涡轮/推进燃料输送系统、装料系统等方向,能够解决燃烧器损坏、发动机操作降级、发动机性能低效等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

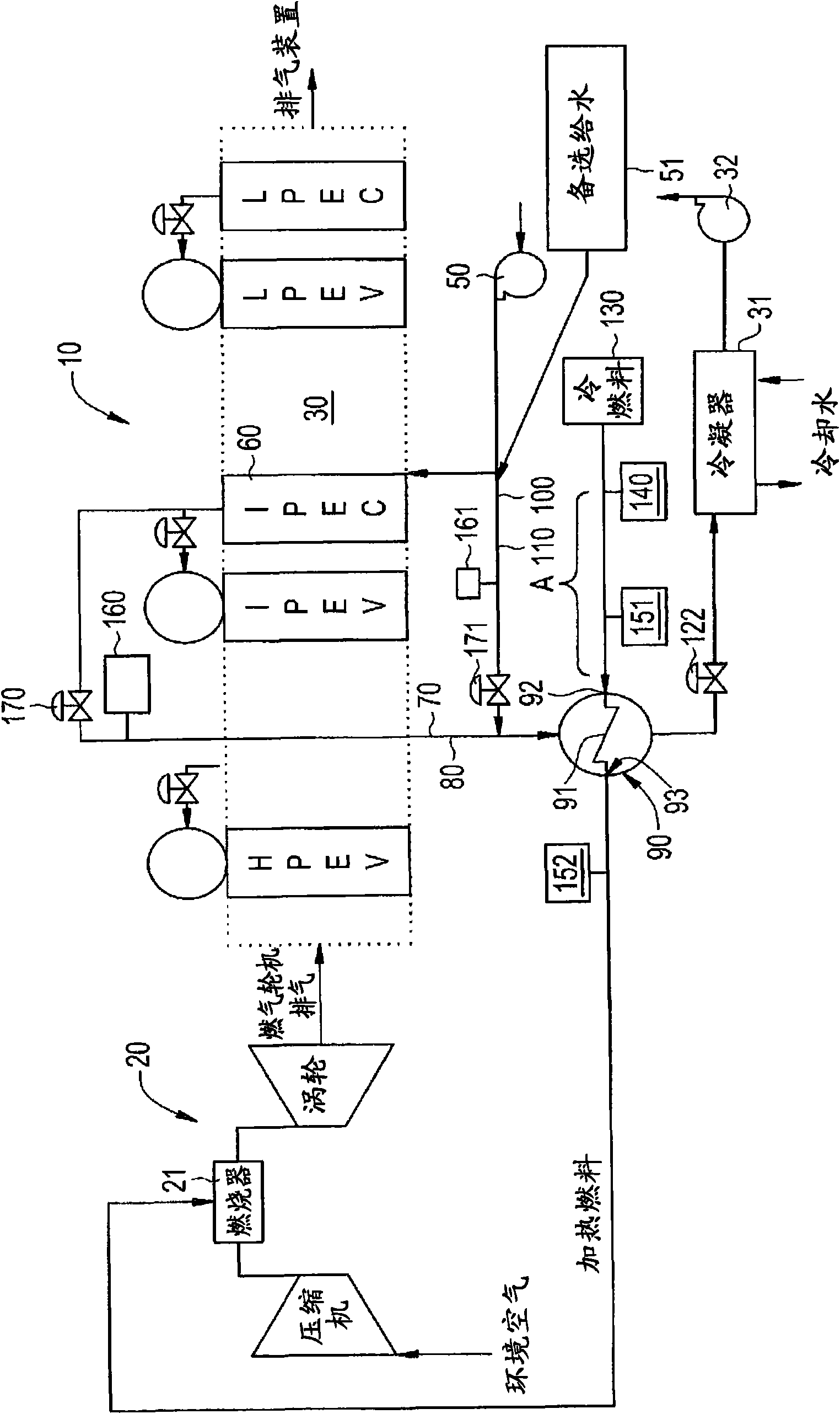

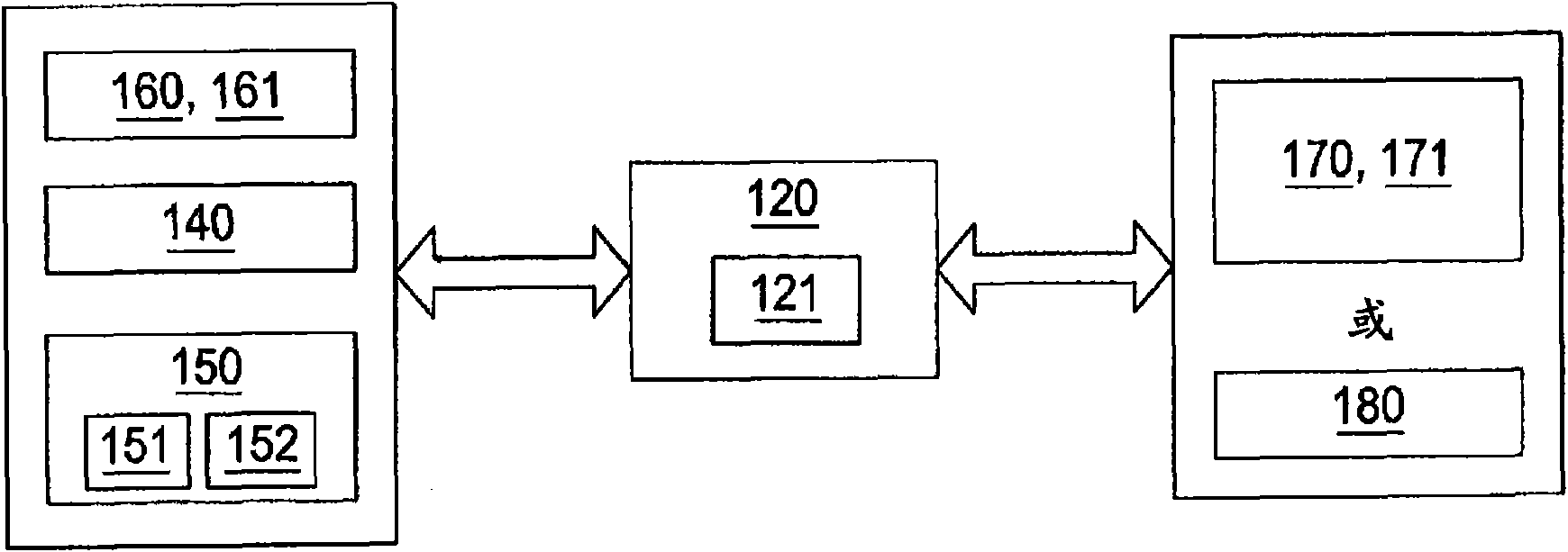

[0051] see Figure 1 to Figure 3 , in a combined cycle power plant (or power plant) 10, fuel and air are combusted in a gas turbine engine 20 to produce mechanical energy, thermal energy, and electricity. A portion of the thermal energy is transferred to a heat recovery steam generator (HRSG) 30 where it is used to generate steam, eg from water condensed in a condenser 31 and pumped by a condensate pump 32 . A portion of the steam is then used to generate additional mechanical energy and / or electricity.

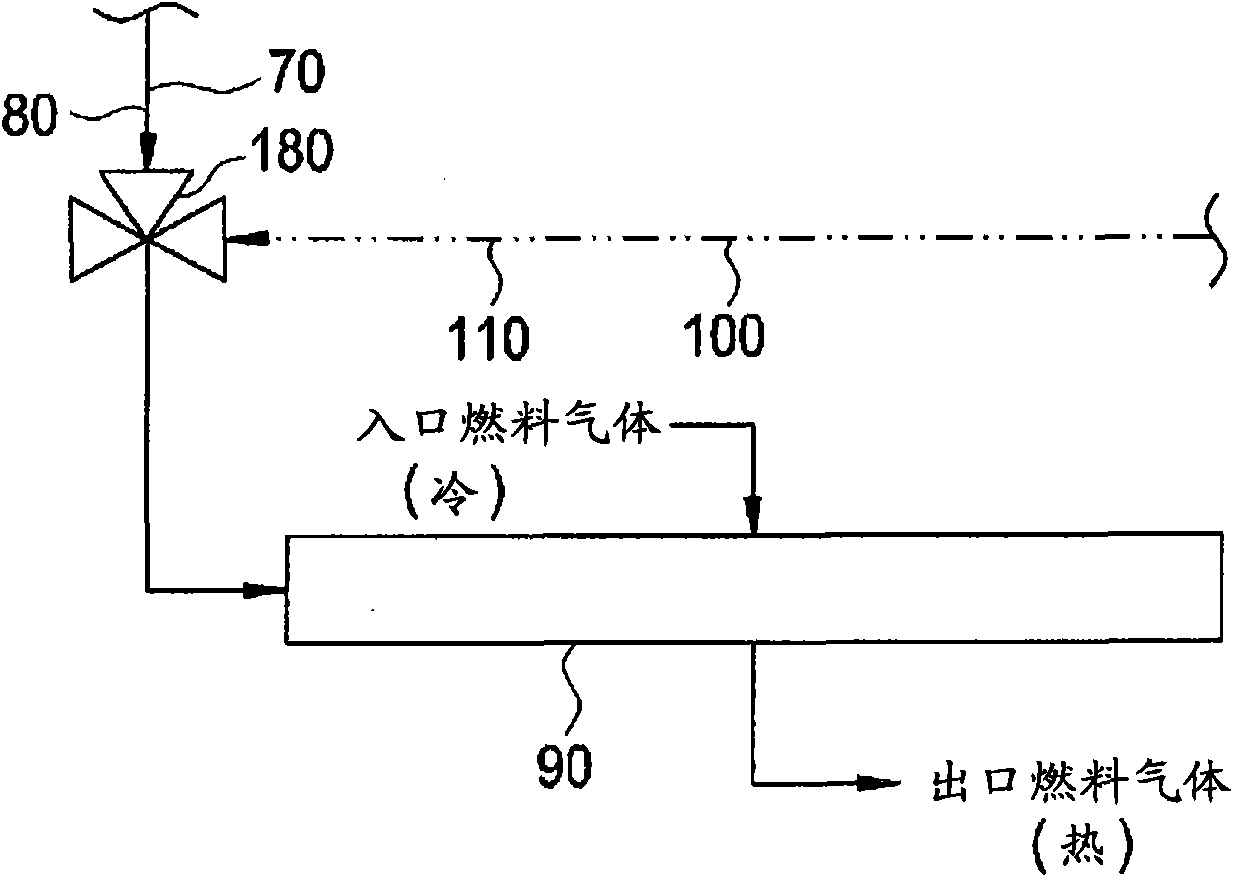

[0052] According to an exemplary embodiment, water recirculated (or regenerated) by HRSG 30 may be directed to feed water pump 50 , which pumps a portion of the recirculated water to, for example, IP economizer 60 of HRSG 30 . This water is heated and output as first feed water 70 at a temperature of approximately 440°F. This first feed water 70 , which is relatively hot, is then fed via a first line 80 towards a heat exchanger 90 where the water can be used to heat the fue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com