Method and device for preparing cadmium selenide sulfide nano material with monotonous and continuous variable band gap

A technology of cadmium sulfur selenide and nanomaterials, which is applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of limited application, difficulty in achieving continuous adjustment and continuous wide spectrum, and achieve wide application range and preparation Simple method and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 is the method for preparing the cadmium sulfide selenide nanoribbon that bandgap changes monotonously continuously, and the steps of this method are as follows:

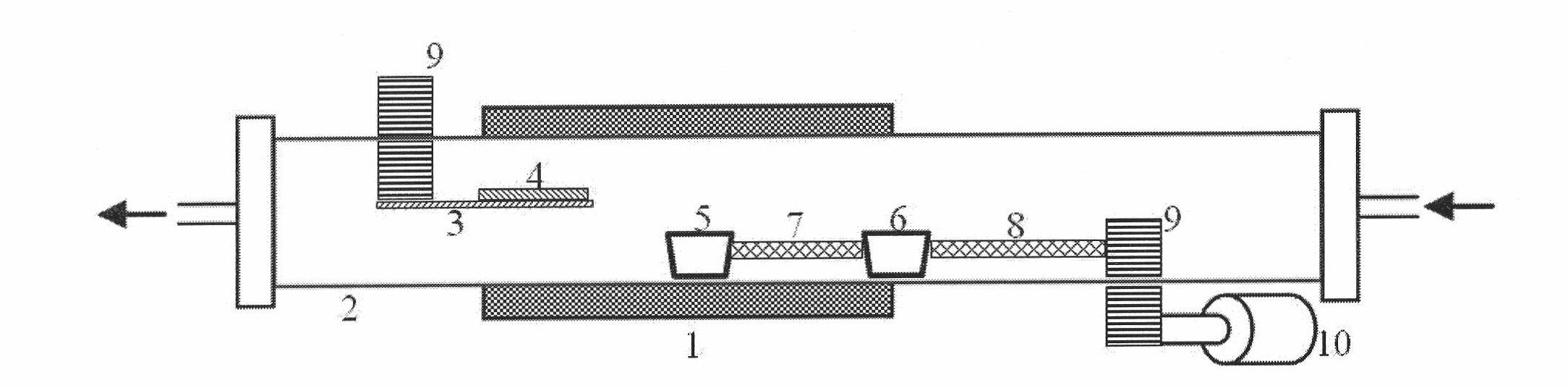

[0031] 1. The experimental equipment is a tube-type high-temperature furnace 1 heated by resistance wire. Prepare a silicon chip 4 with a gold-plated thickness of 10 nm and place it on the quartz chip 3. The quartz chip is placed in the cooling zone of the high-temperature furnace. The bottom of the quartz chip can be just Accommodate the quartz boat 5, 0.5g of cadmium sulfide and cadmium selenide materials are placed in the quartz boat, the cadmium sulfide quartz boat 5 is placed in the middle of the tube-type high-temperature furnace, that is, the area with the highest temperature, and the cadmium selenide quartz boat 6 is placed in the tube Type high-temperature furnace 1 outside is close to the low-temperature zone of nitrogen inlet, a section of quartz rod 7 is placed between the two boats, an...

Embodiment 2

[0036] Embodiment 2 is a method for preparing cadmium sulfide selenide nanowires with monotonous and continuous band gap changes. The steps of the method are as follows:

[0037] The difference between the steps of this method and the steps of preparing nanobelts is that the growth temperature is 850° C., and other steps and parameters are the same as in Example 1.

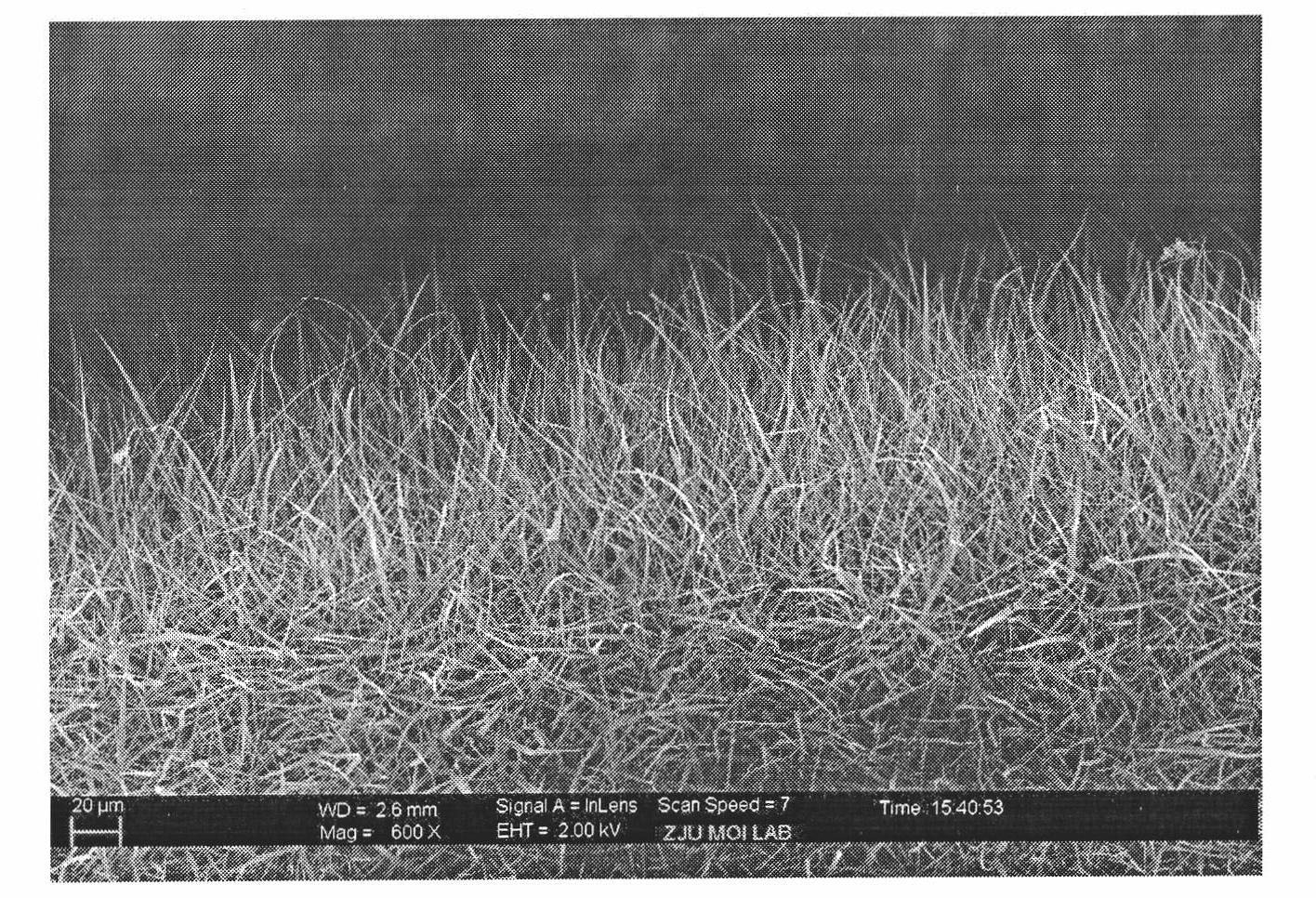

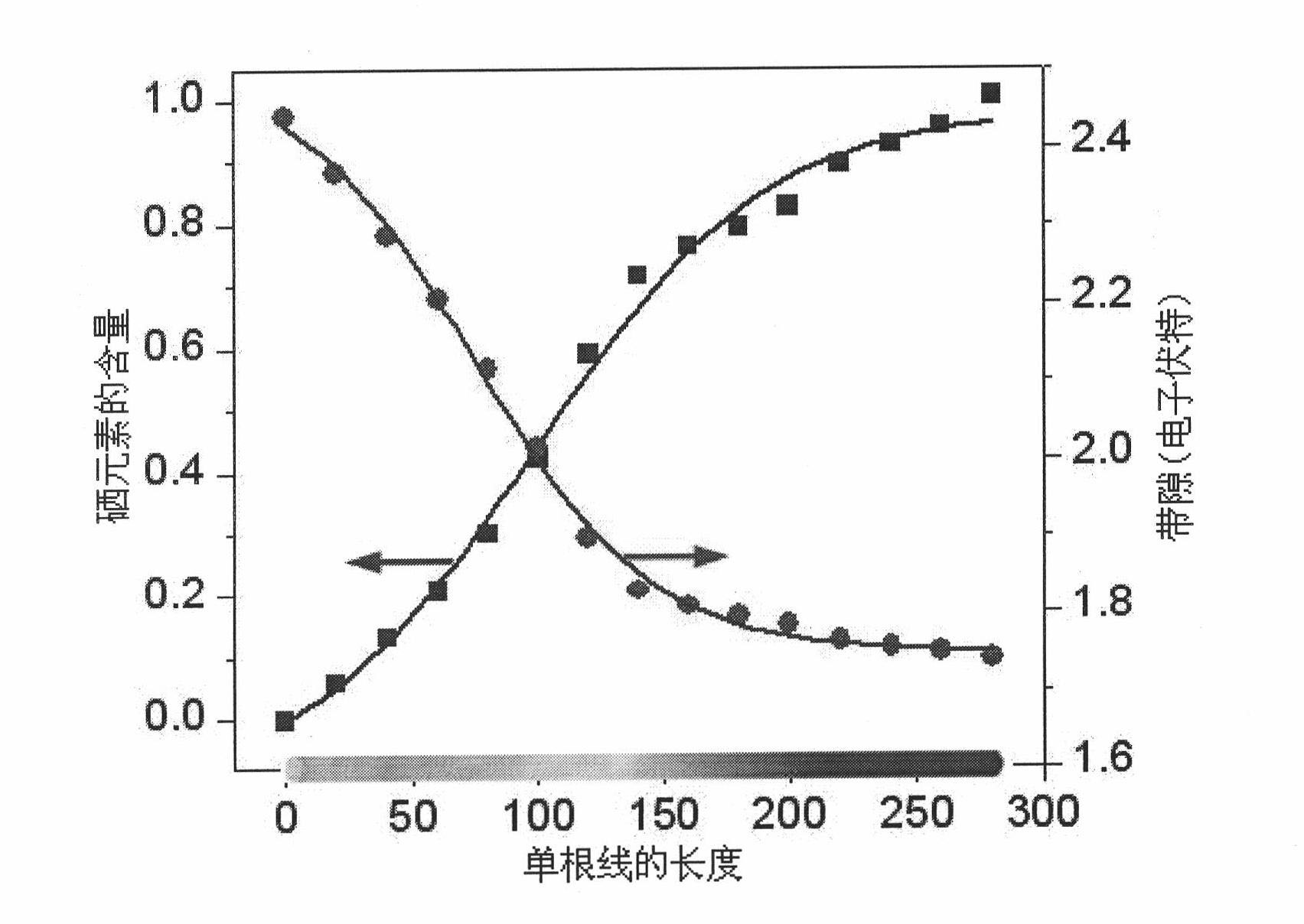

[0038] The length of the nanomaterial prepared in the above embodiment is on the order of hundreds of microns, the diameter of the nanowire is from 200nm to 2μm, the width of the nanoribbon is from 200nm to 5μm, and the thickness is less than 100nm. Depend on image 3 It can be seen that along a single nanoribbon, the content of selenium element and the band gap change monotonously and continuously, and the corresponding band gap of selenium element from 0 to 100% is 2.4ev to 1.7ev. Depend on Figure 4 It can be seen that the prepared nanoribbons are single crystals with good crystallinity, growing along the 001...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com