High-speed processing-oriented surface quality preferred spline real-time interpolation method

A real-time interpolation and surface quality technology, applied in the direction of instruments, computer control, simulators, etc., can solve the problem that there is no separate control of processing areas with different speeds, and achieve the effect of reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

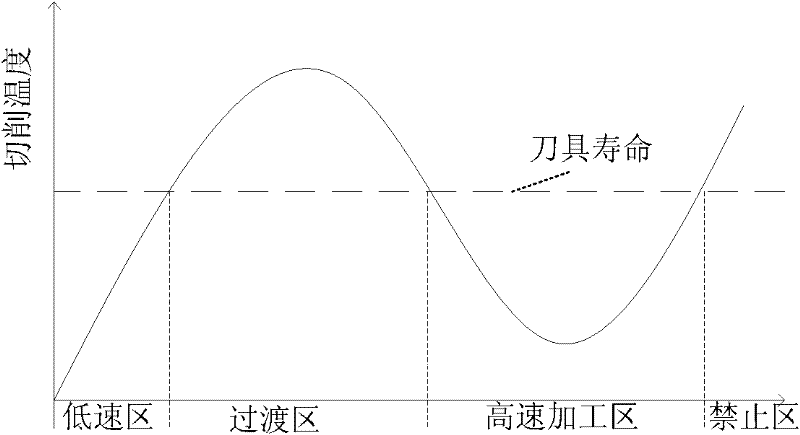

[0038] Such as figure 1 As shown, according to the Salomon curve, the entire machining process can be divided into low-speed machining area, transition area, high-speed machining area and forbidden area according to the speed value. The processing characteristics of the low-speed processing area are basically the same as those of the traditional processing area. Due to the low processing speed, the main factor affecting the quality of the processed surface is the change of the output force of the spindle motor. Therefore, as long as the continuous transition of the acceleration is ensured in this interval, the maximum combined acceleration that the machine tool can provide can be fully utilized.

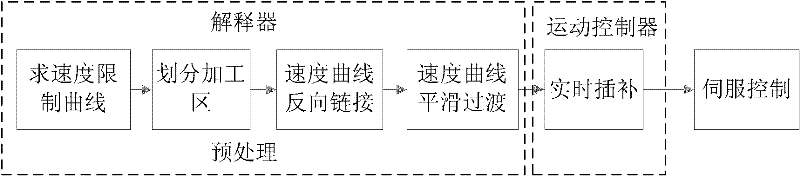

[0039] The spline curve real-time interpolation method oriented to high-speed machining with priority of surface quality comprises the following steps:

[0040] P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com