positive displacement pump

A technology of positive displacement pump and pump assembly, applied in the direction of pump, rotary piston pump, pump element, etc., can solve the problem of cover and control board wear, etc., and achieve the effect of preventing slight movement and avoiding end-side wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

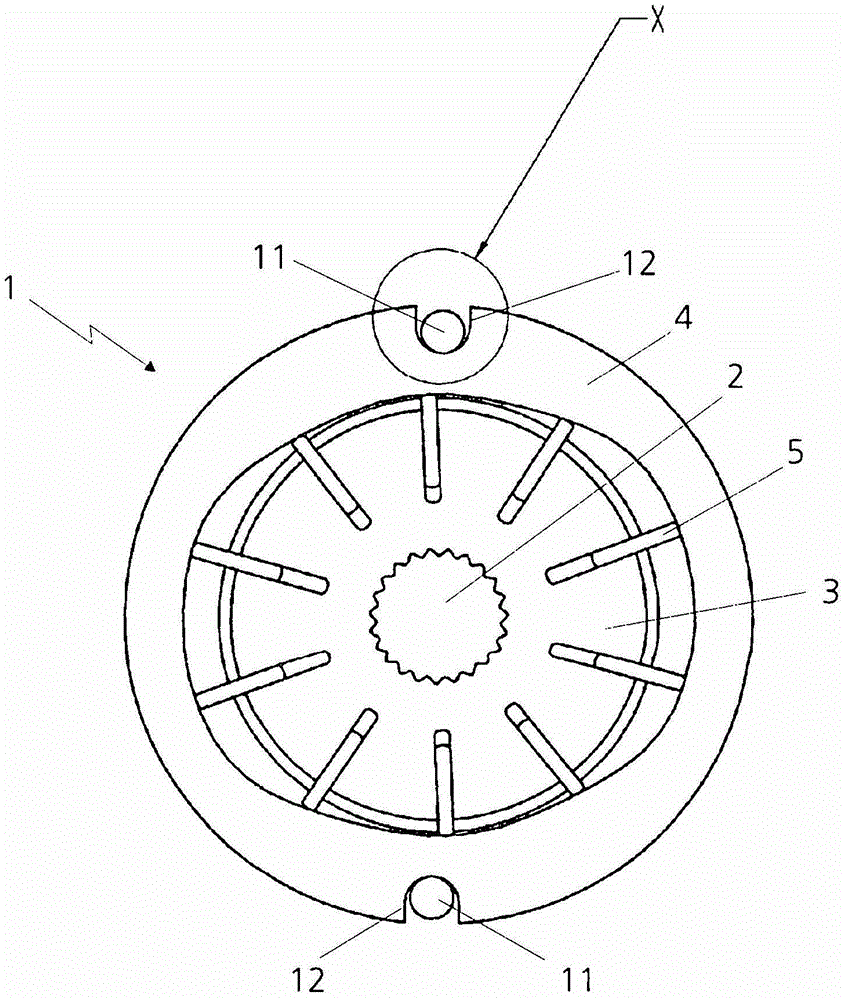

[0020] The invention will be described below on the basis of a two-stroke vane pump. However, the invention can of course also be used for roller vane pumps.

[0021] Sliding vane pumps are well known. For this purpose, reference is made, for example, to the aforementioned patent documents, so only the components relevant to the invention will be described in detail below.

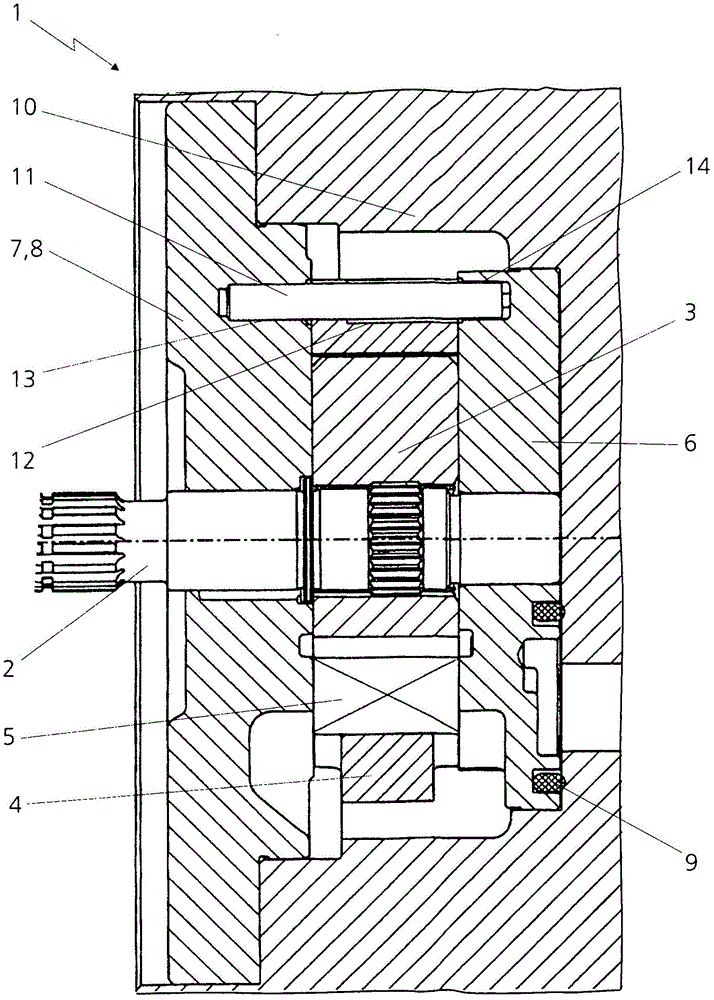

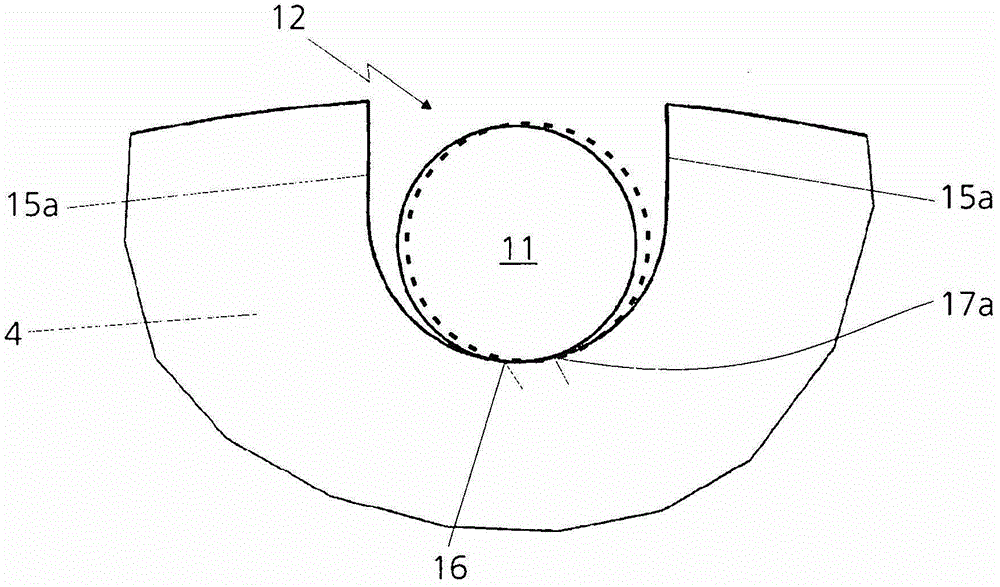

[0022] The sliding vane pump 1 has a rotor 3 arranged on a drive shaft 2 , a cam ring 4 surrounding the rotor 3 and a plurality of working slides 5 in the form of vanes arranged in slots on the periphery of the rotor 3 . Control plates 6 and 7 are provided on both sides of the rotor 3 and the cam ring 4 . In the exemplary embodiment shown, the control board 7 is integrated in the cover 8 or forms the cover. In the control plates 6 and 7 supply and rear slide supply bends (not shown) are formed in known manner. The seal 9 is used to ensure a seal against the pressure medium, usually oil, to the outside....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com