Method for producing a discharge lamp, in particular a flat lamp

A technology of discharge lamps and discharge chambers, which is applied in the field of flat panel lamps, can solve problems such as labor-intensive and time-consuming removal, and achieve the effects of lower ignition voltage, high luminous efficiency, and good dimmability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

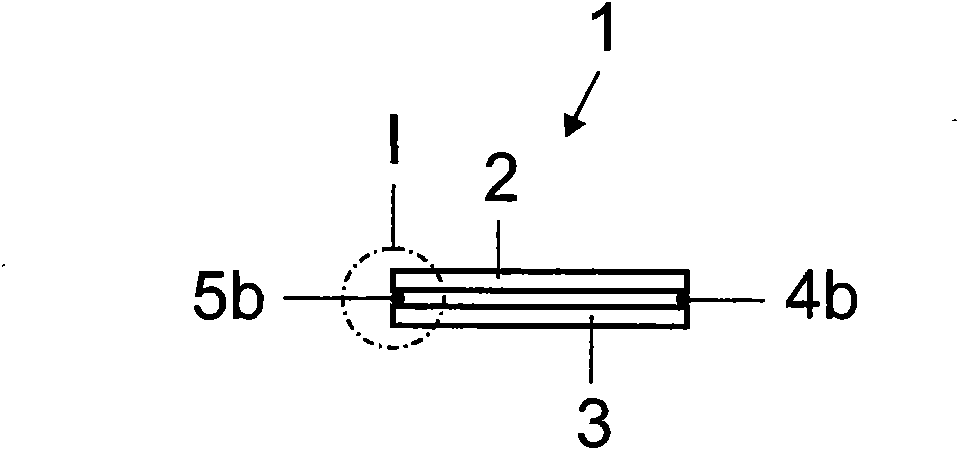

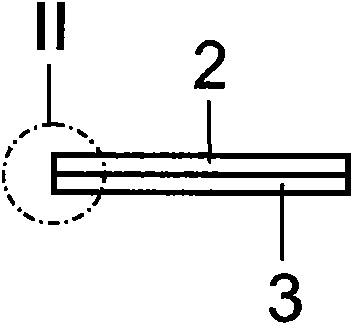

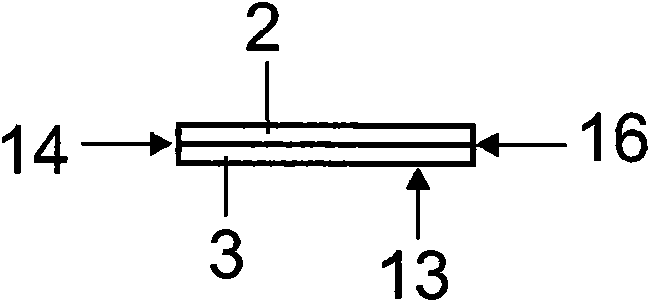

[0036] For producing a discharge lamp 1 designed as a panel lamp, a plate-shaped upper part 2 and a plate-shaped lower part 3 are provided. In this embodiment, the upper part 2 and the lower part 3 are constructed of glass material. The lower part 3 is designed as a rectangular plate, which is substantially planar. The upper part 2 can be constructed similarly to the lower part 3 . However, it can also preferably be provided that the upper part 2 has a corresponding rectangular shape to the lower part 3 and also includes a wave-shaped structuring in cross section.

[0037] A layer of luminescent material is then applied to the surface of the upper part 2 and the lower part 3 respectively. It is also conceivable to additionally apply a reflective layer to the lower part. The upper part 2 and the lower part 3 are then introduced into a first device (not shown) in which the organic constituents of the phosphor paste of the phosphor layer are burned out by a heat treatment. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com