Patents

Literature

80results about How to "Reduce ignition voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

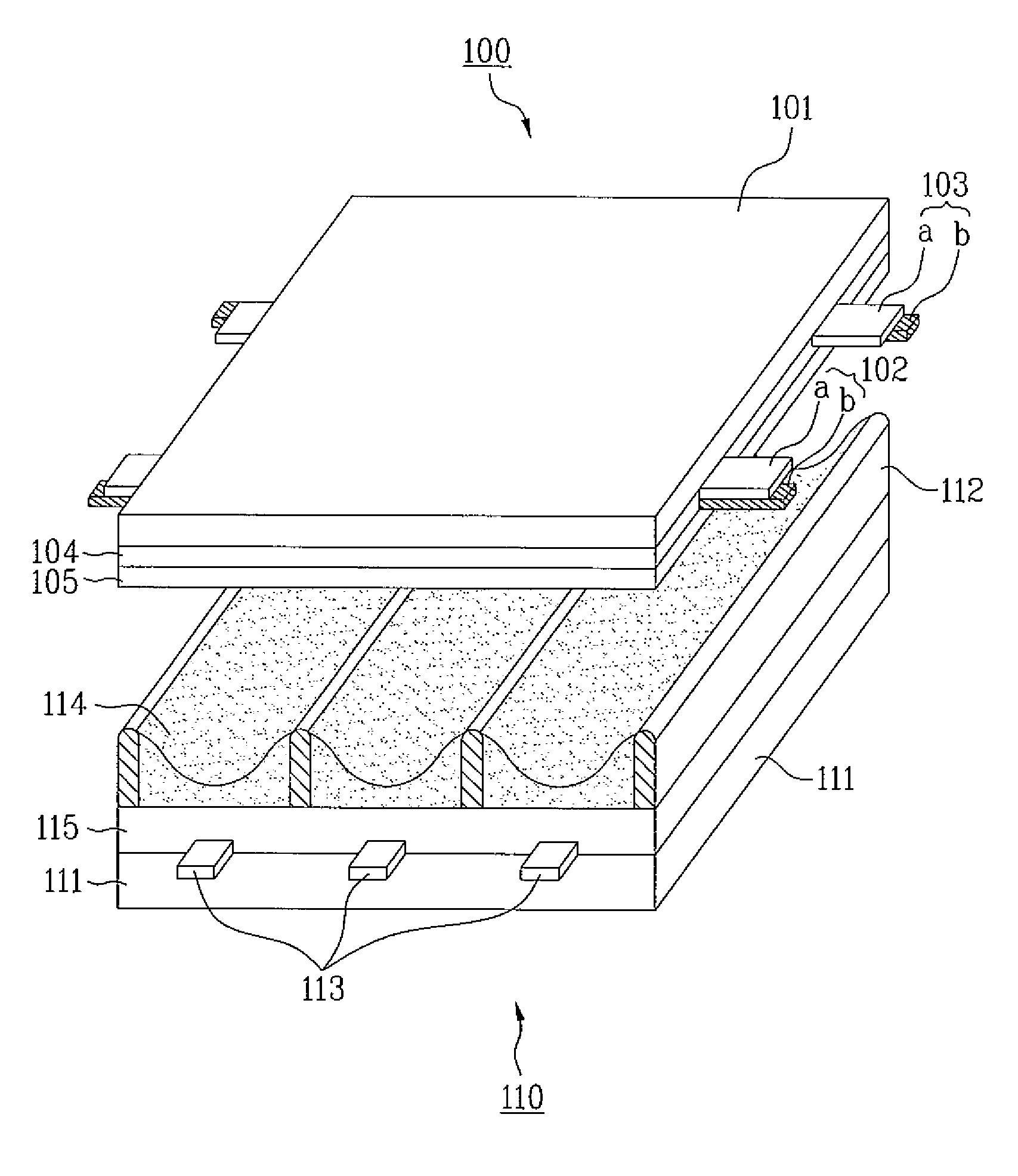

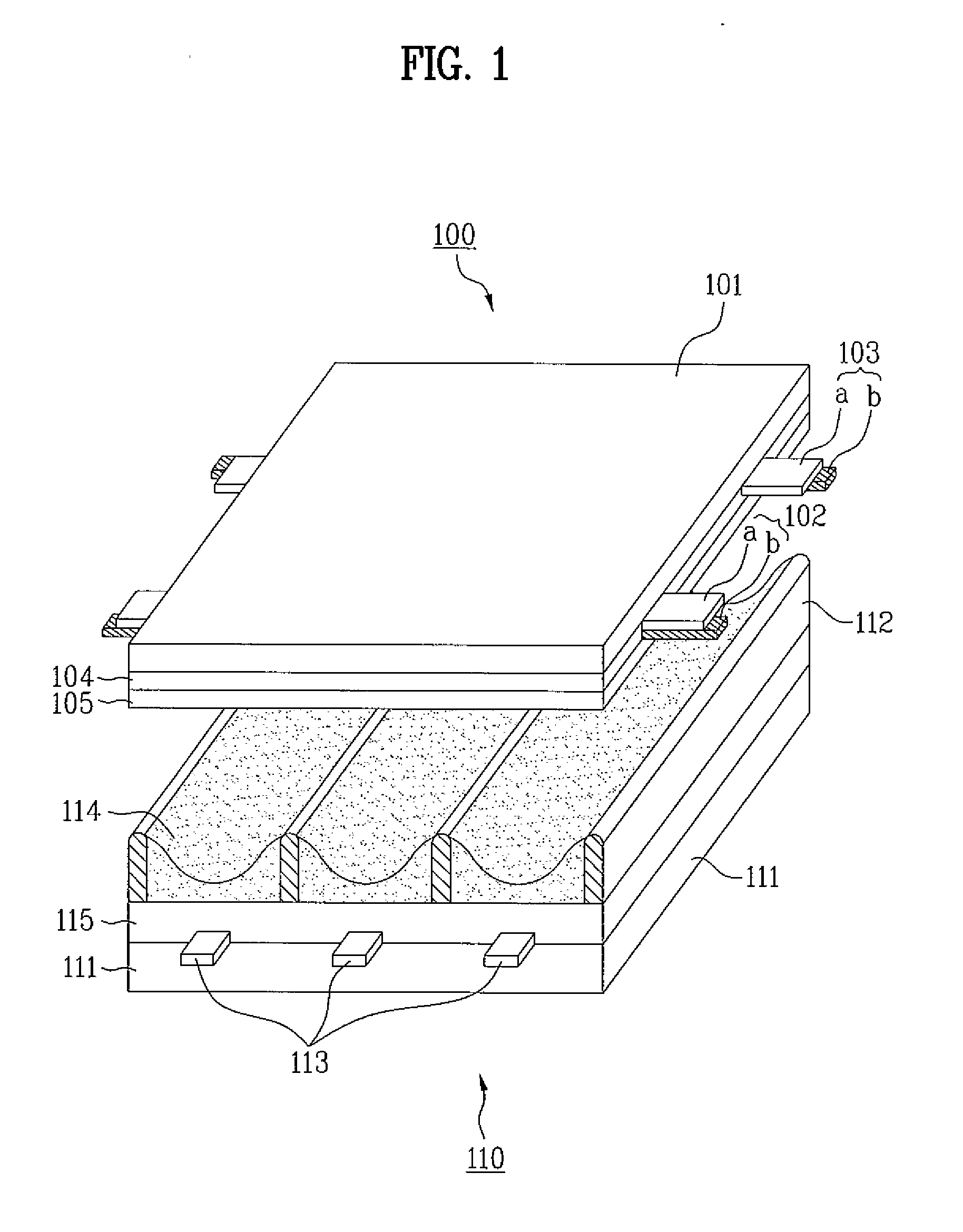

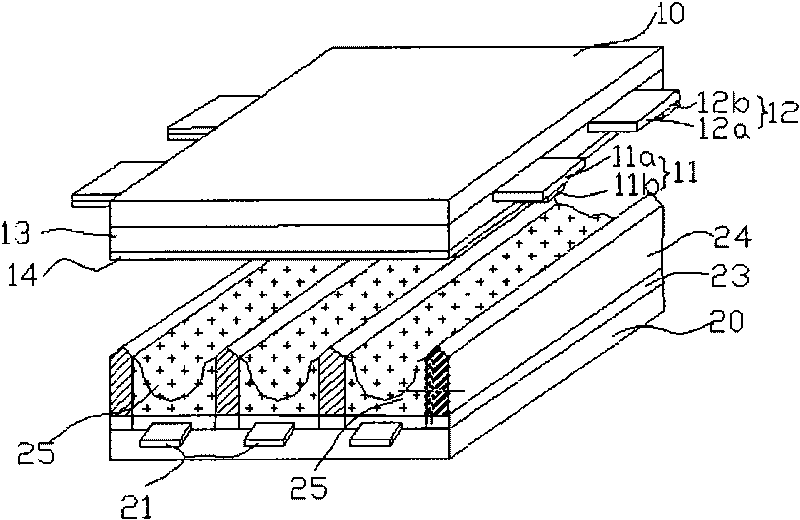

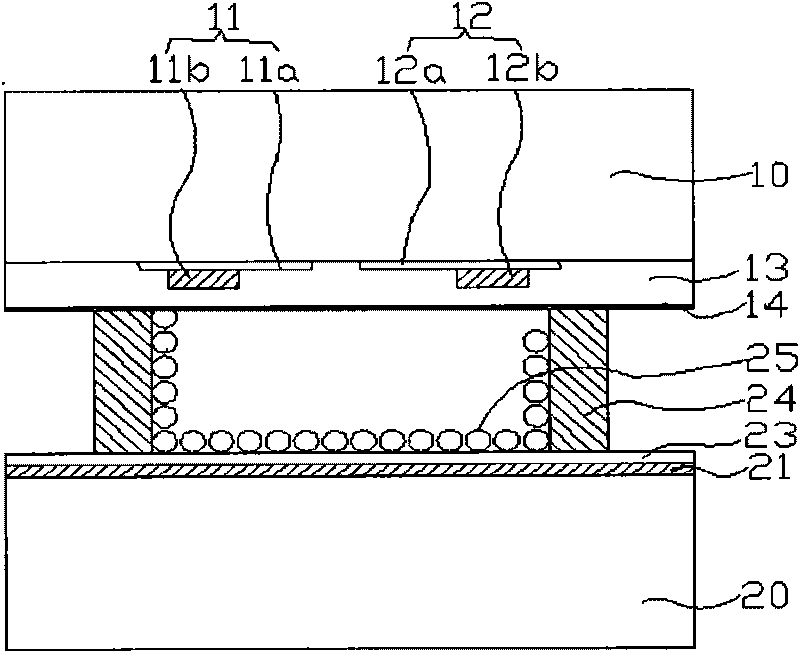

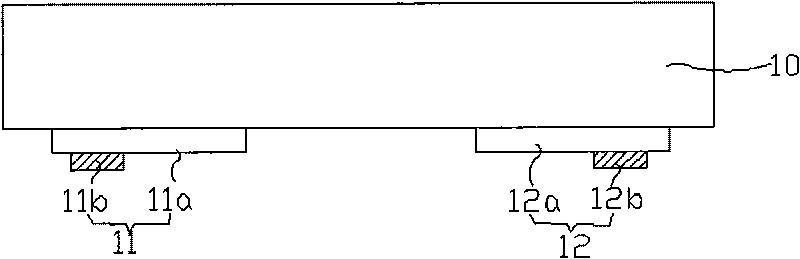

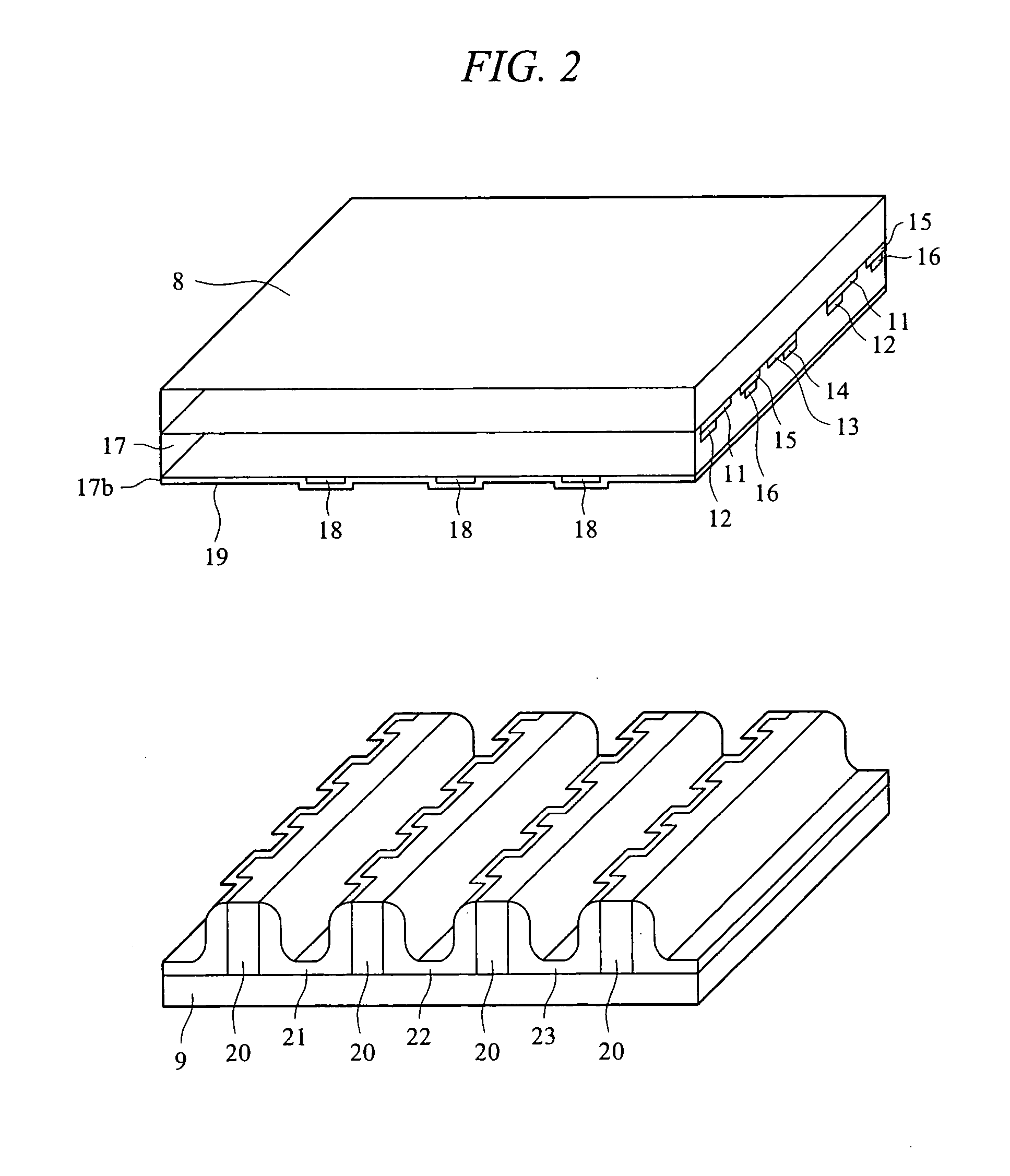

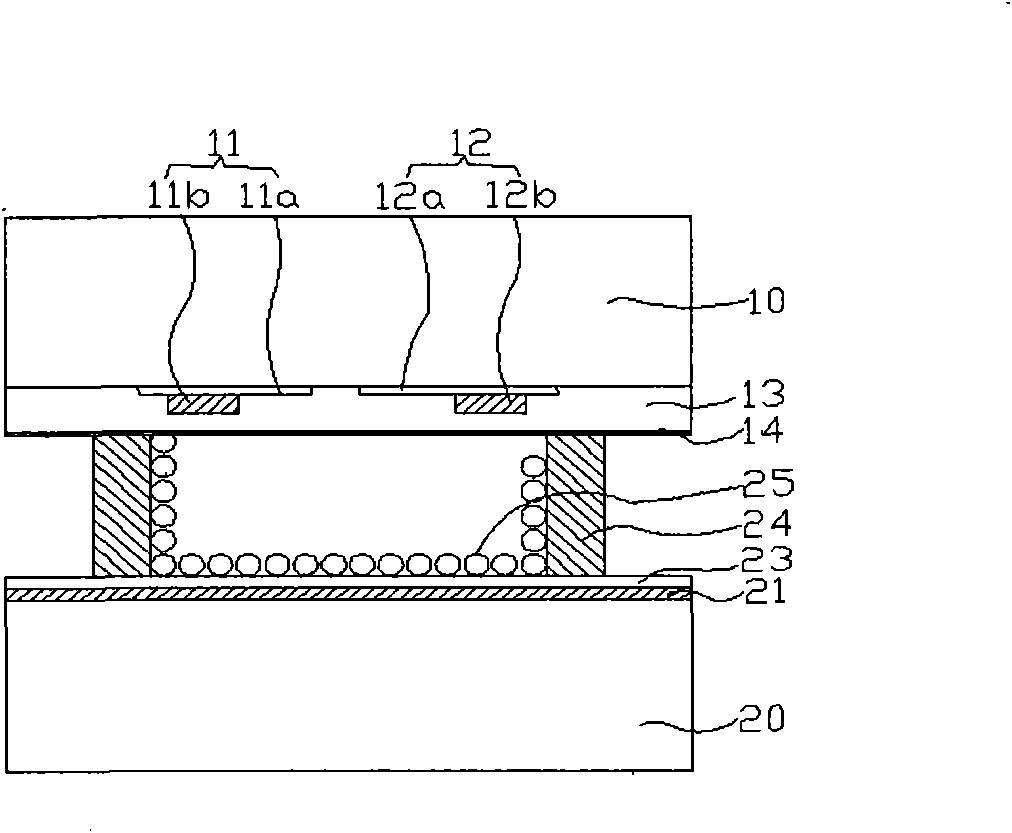

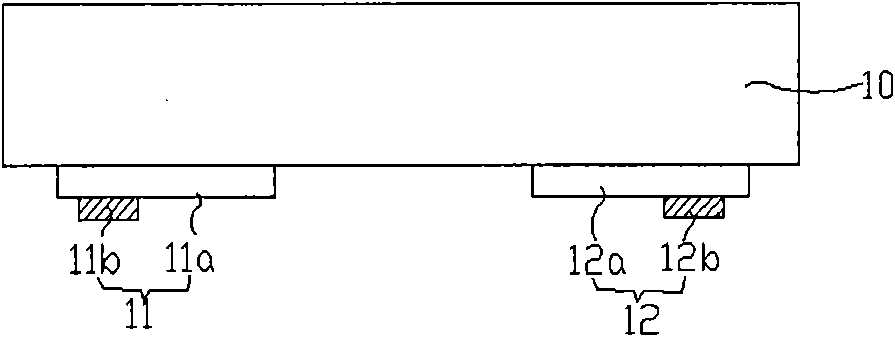

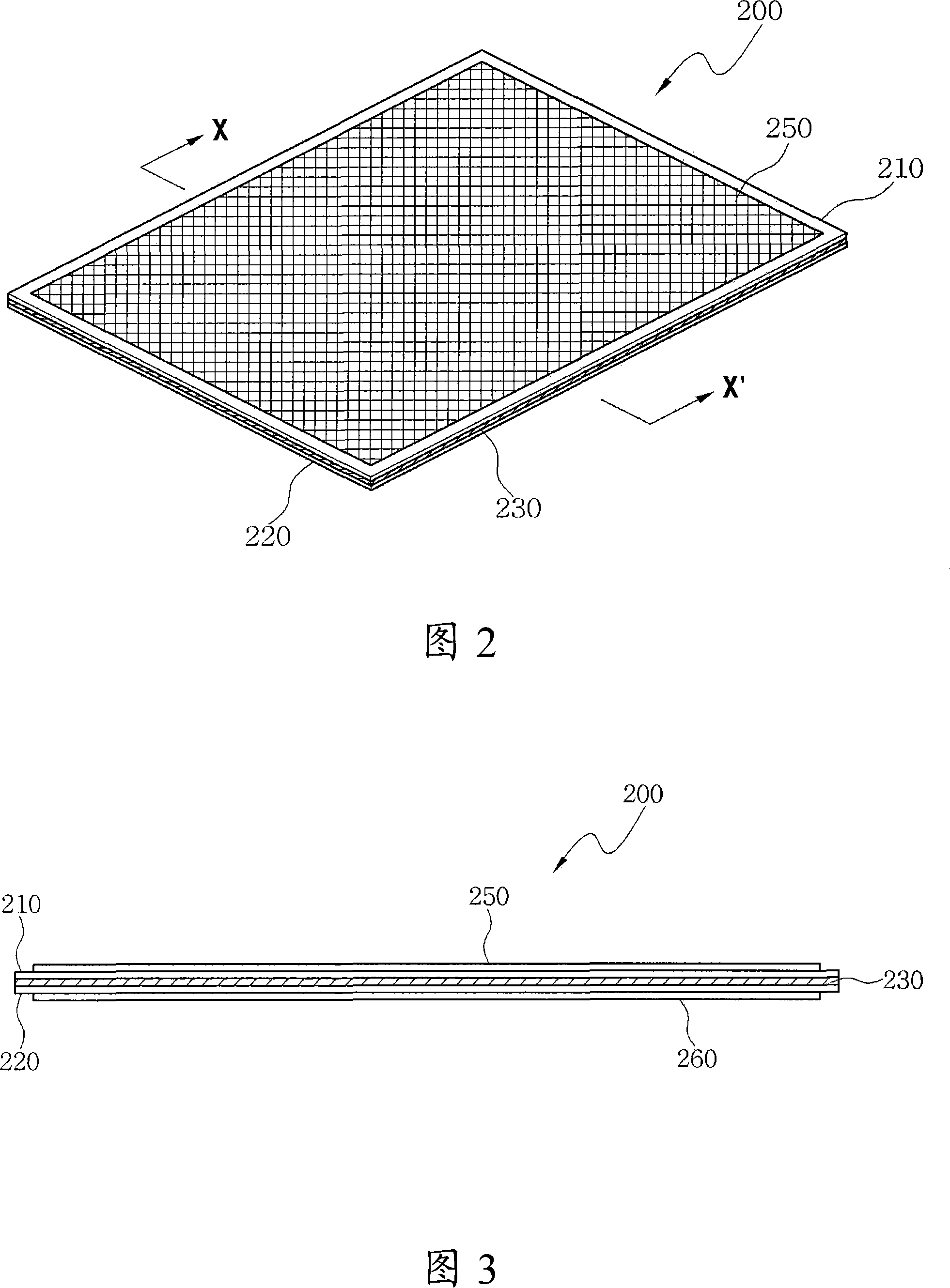

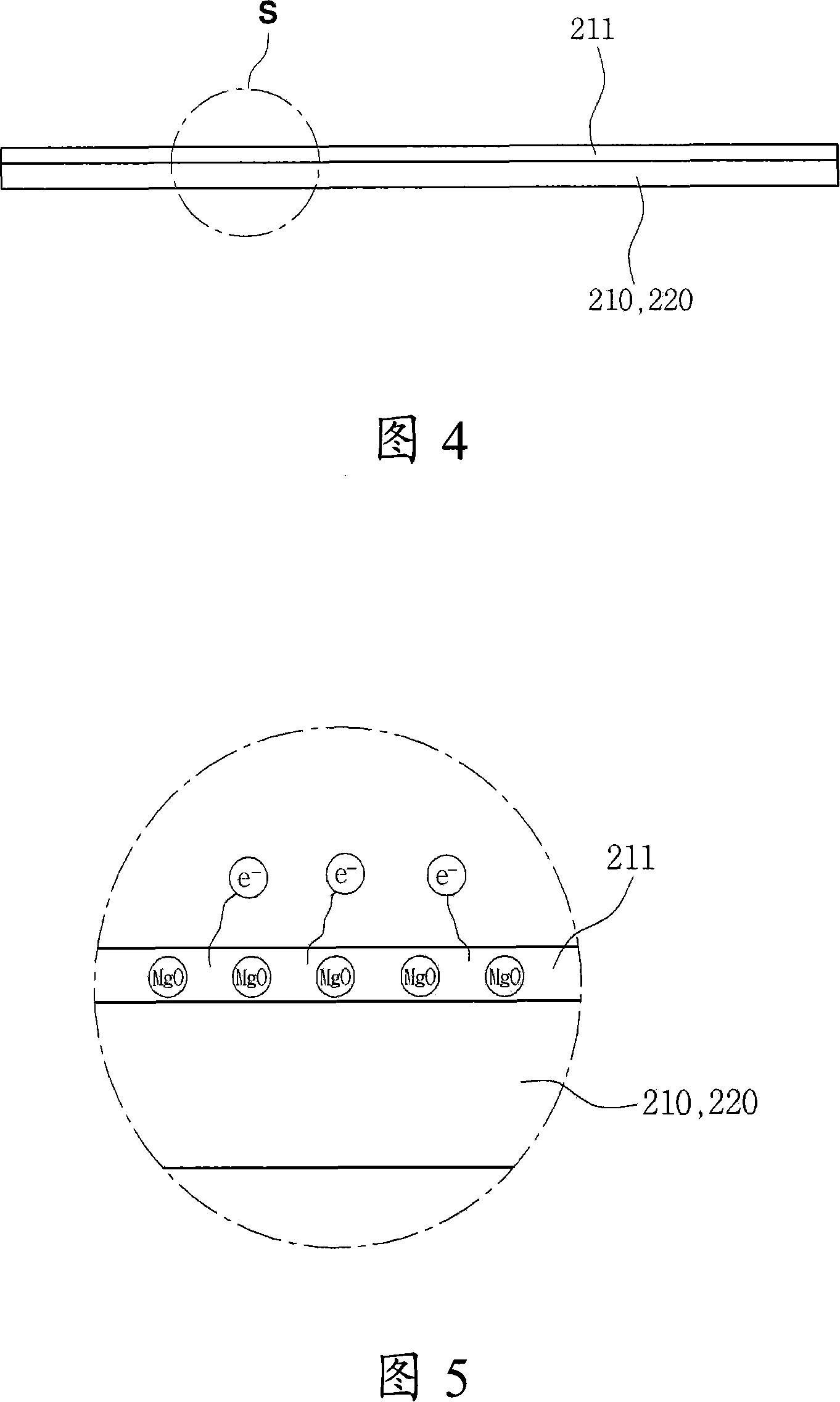

Plasma display panel and method for producing the same

InactiveUS20070152593A1Improved secondary electron emission characteristicReduce ignition voltageAddress electrodesSustain/scan electrodesEngineeringSecondary electrons

A plasma display panel with low firing voltage is disclosed. The plasma display panel includes an upper panel and a lower panel facing each other through barrier ribs wherein the upper panel includes a first protective film composed of magnesium oxide and a second protective film formed on the first protective film and composed of a secondary electron-emitting material.

Owner:LG ELECTRONICS INC

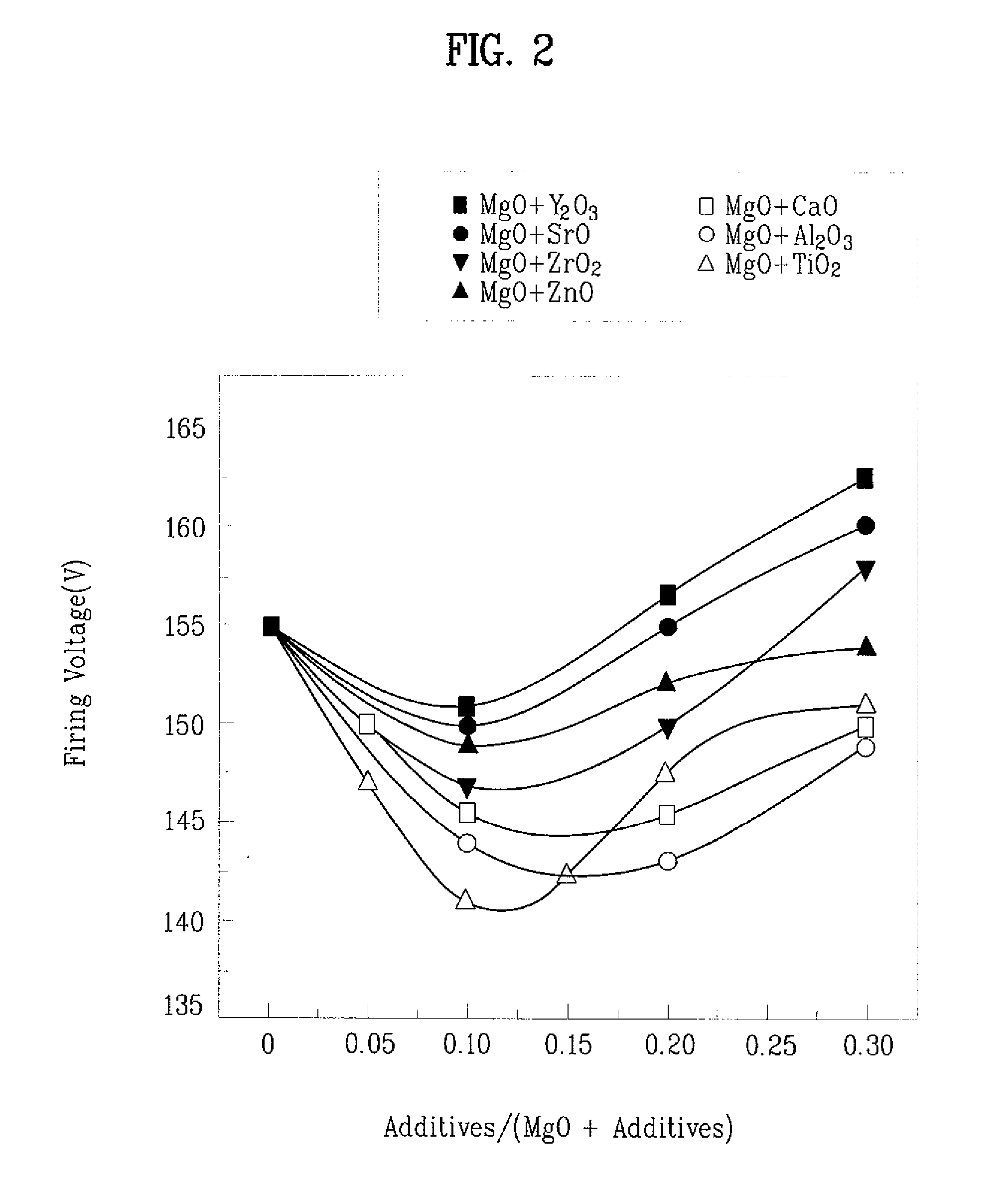

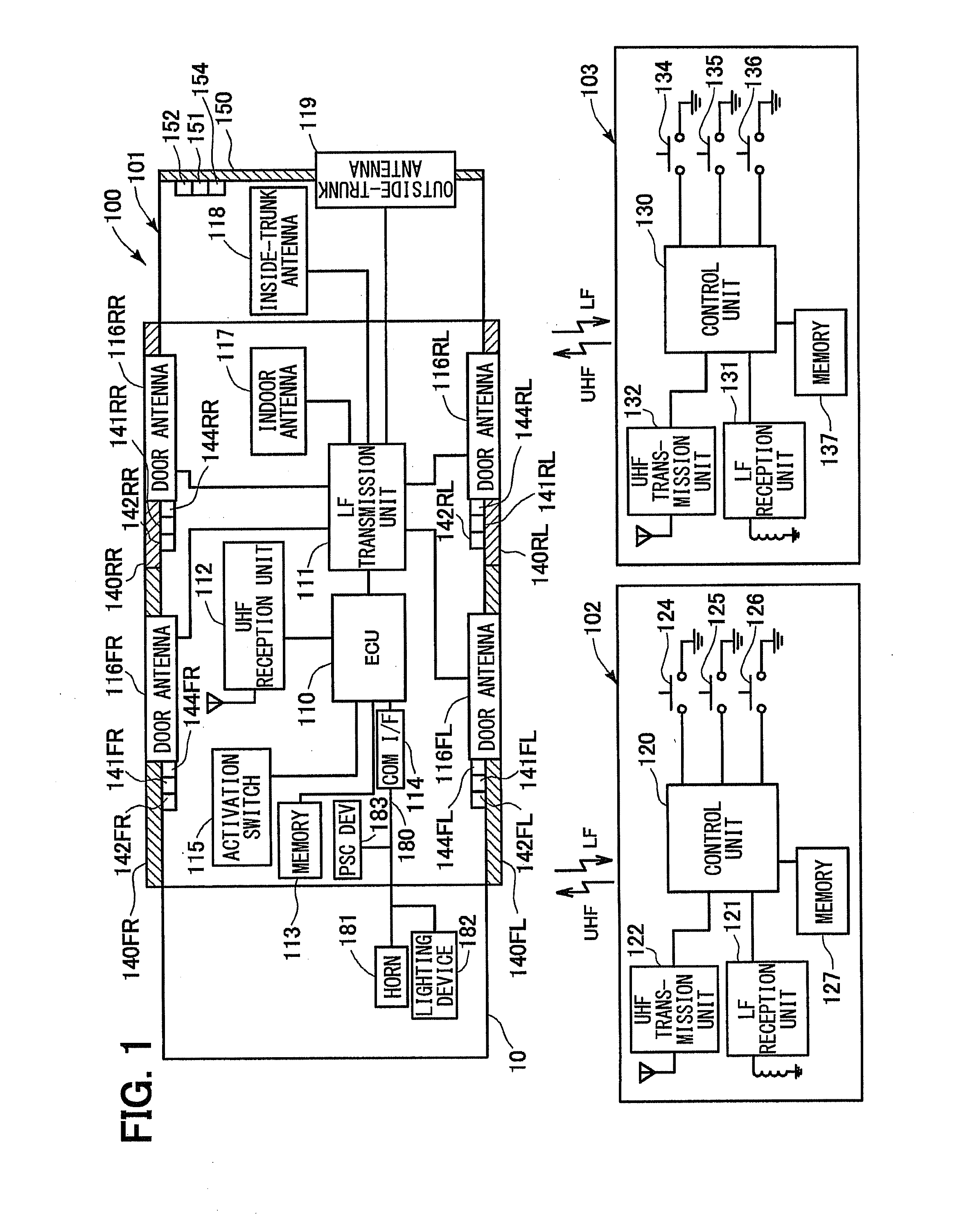

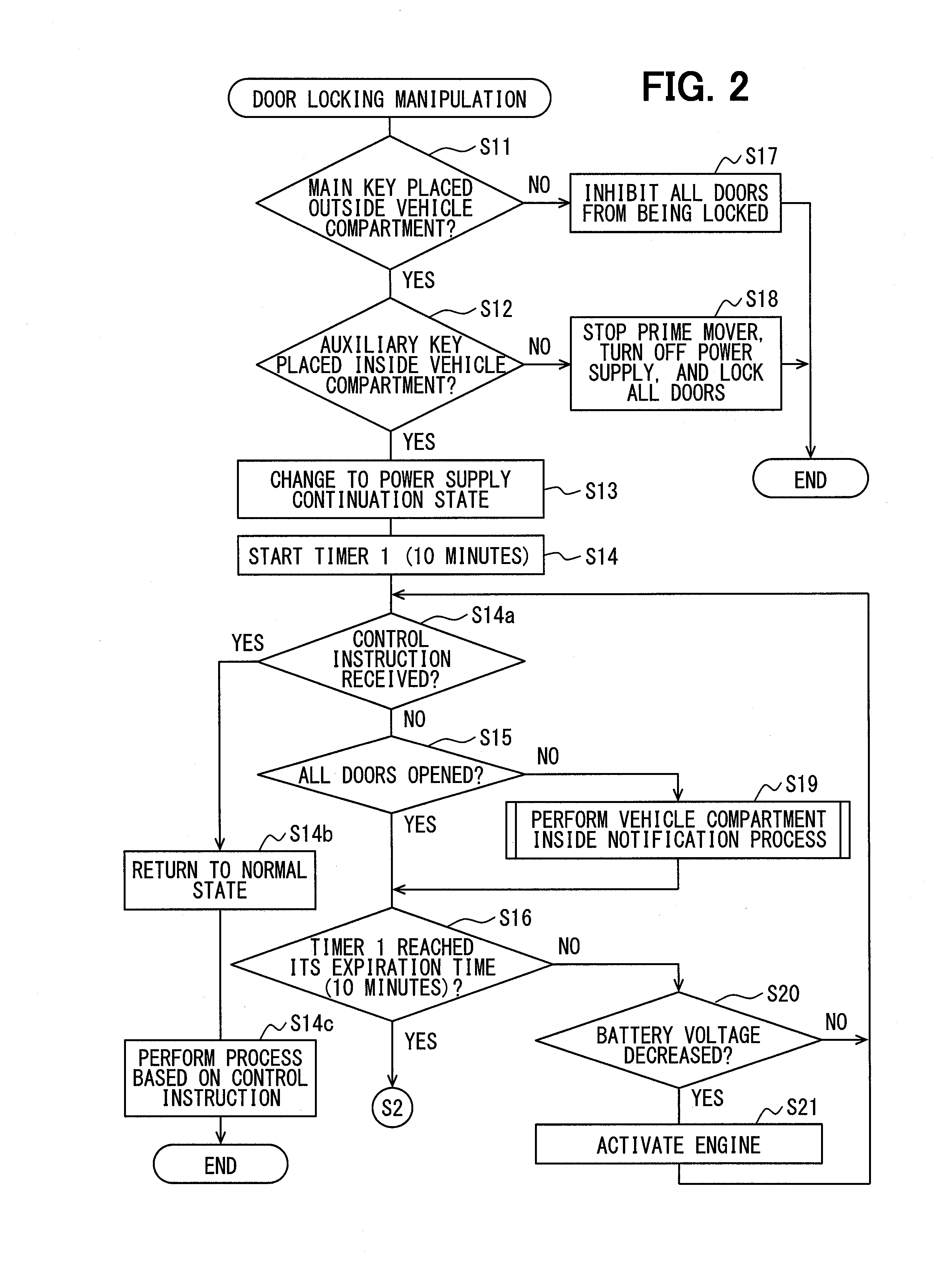

Smart entry system

InactiveUS20160005250A1Disables adjustmentDegrades interior environmentDigital data processing detailsAnti-theft devicesEngineeringSmart system

A smart system locks a door of a vehicle when there is a user's instruction to lock the door when a first portable device in which first identification information is stored is outside the vehicle and a second portable device in which second identification information is stored is inside the vehicle, and controls the power supply state from a normal state to a power supply continuation state in which power continues to be supplied only to a predetermined power supply continuation device in the vehicle.

Owner:DENSO CORP

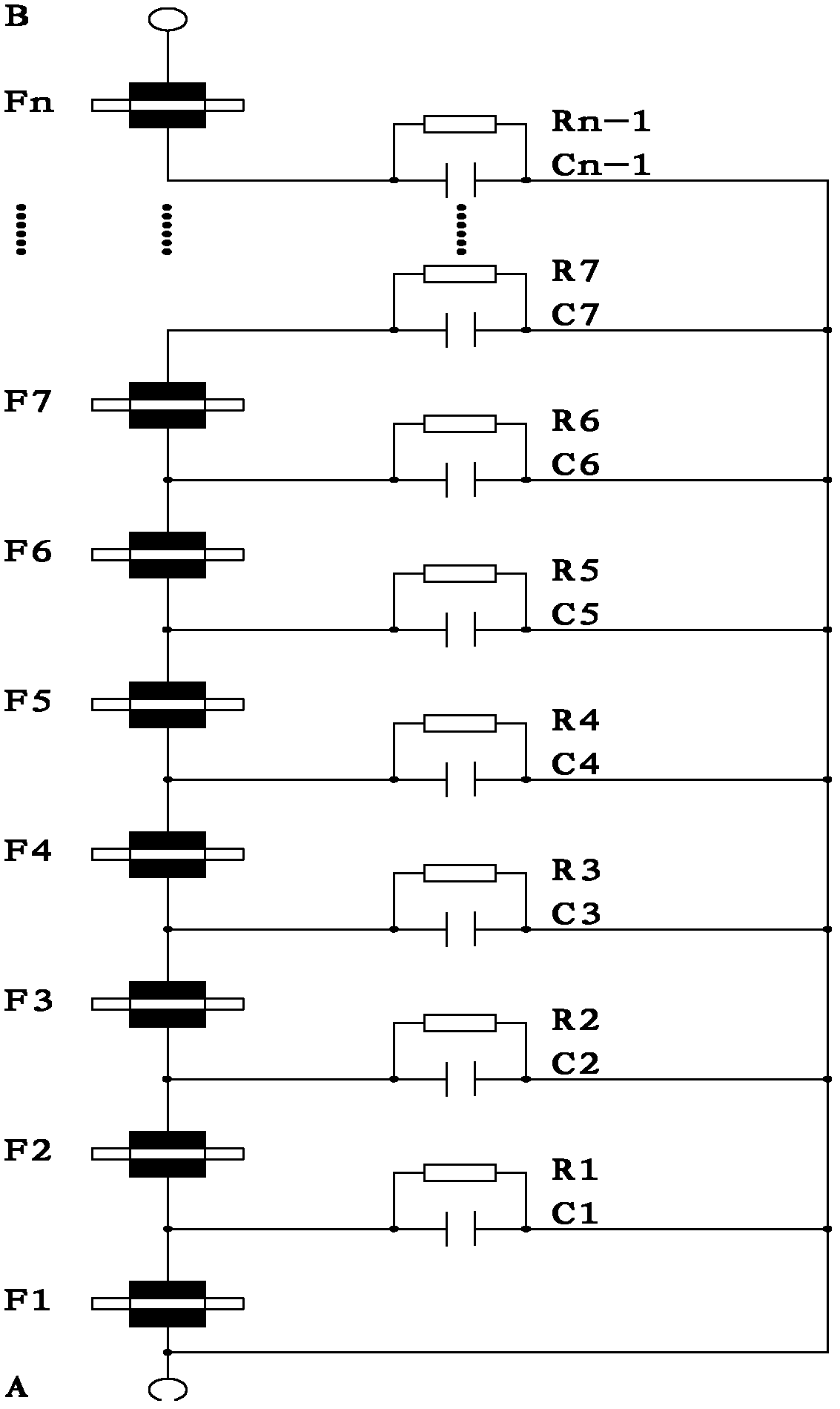

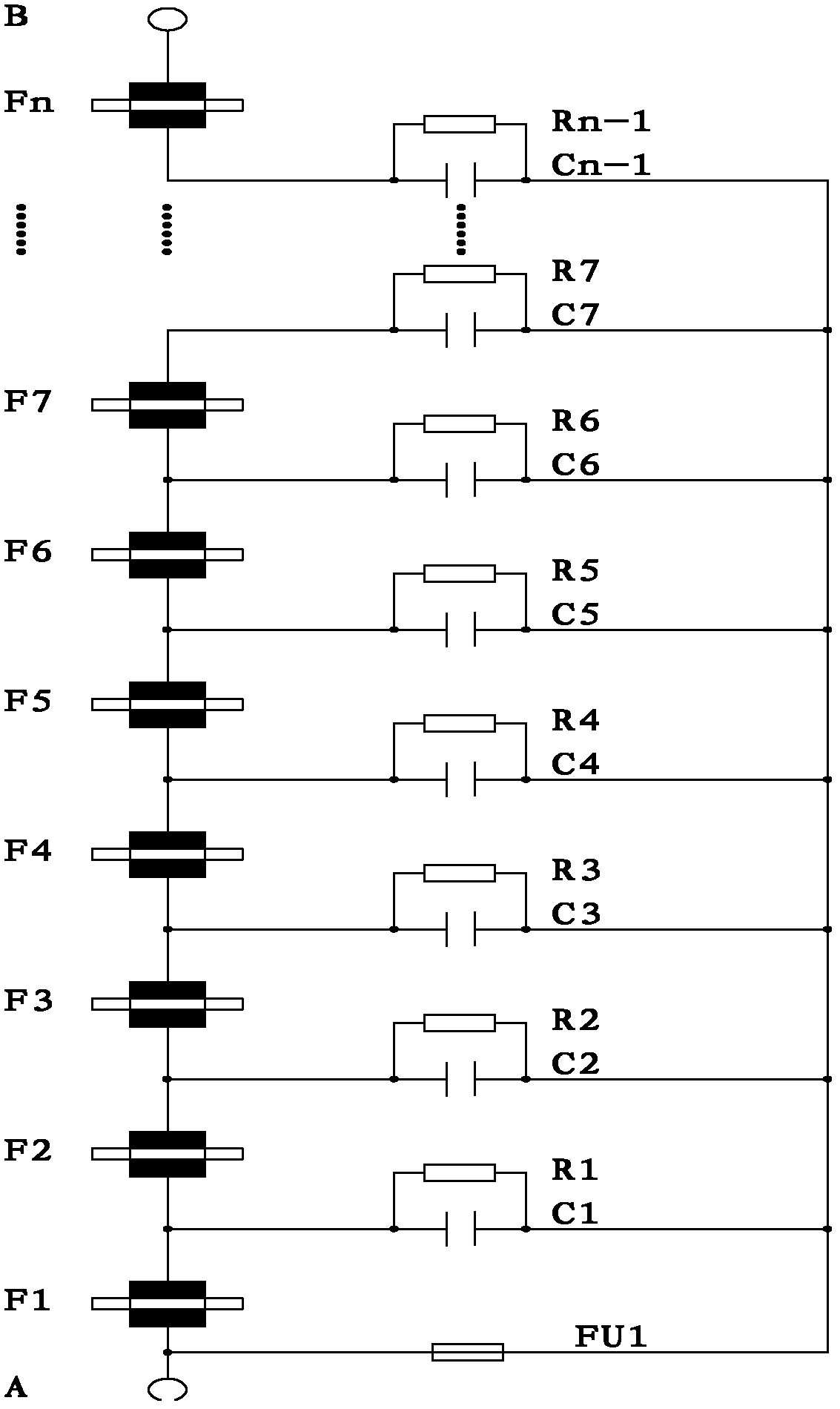

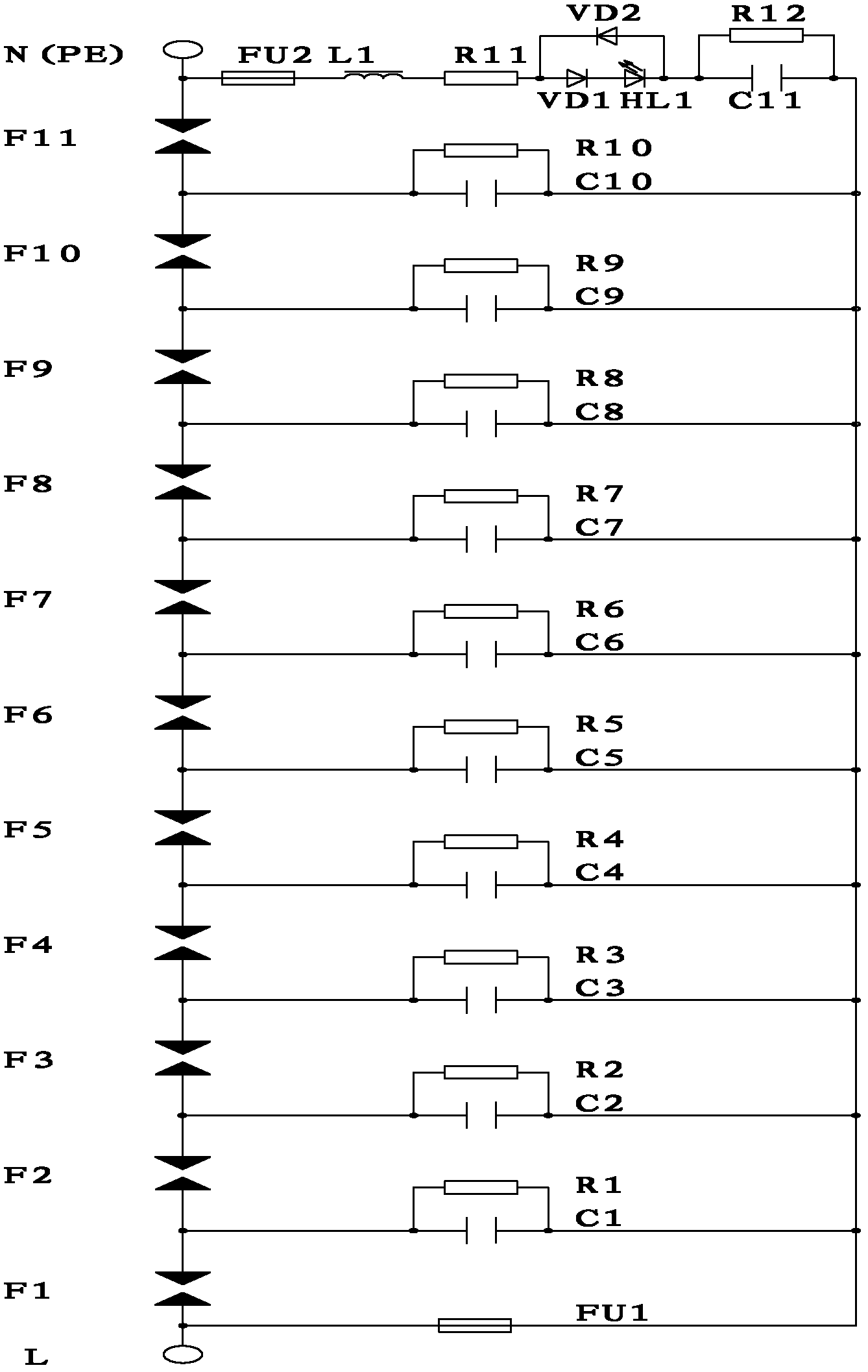

Multilayer discharge gap type surge protection device

ActiveCN102545196AStable auxiliary discharge gap re-ignitionNo retriggering effectEmergency protective arrangements for limiting excess voltage/currentOvervoltageEngineering

The invention relates to a multilayer discharge gap type surge protection device, which is suitable for overvoltage protection on an alternating-current or direct-current circuit. The multilayer discharge gap type surge protection device comprises n discharge gaps and n-1 trigger circuits, wherein n is an integer of being more than or equal to 2; the n discharge gaps are connected in series to form an overvoltage bleeder circuit; two ends of the overvoltage bleeder circuit are provided with connecting terminals, and the overvoltage bleeder circuit is used for connecting with a protected alternating-current or direct-current circuit; one end of each of the n-1 trigger circuits is respectively connected with a conductive member between the corresponding discharge gaps, and other ends of the n-1 trigger circuits are connected together and connected with the outer end part of the first discharge gap F1; and all the trigger circuits have same structure and are connected in parallel through a capacitor and a resistor to form an RC (Resistor-Capacitor) circuit.

Owner:SICHUAN ZHONGGUANG LIGHTNING PROTECTION TECH

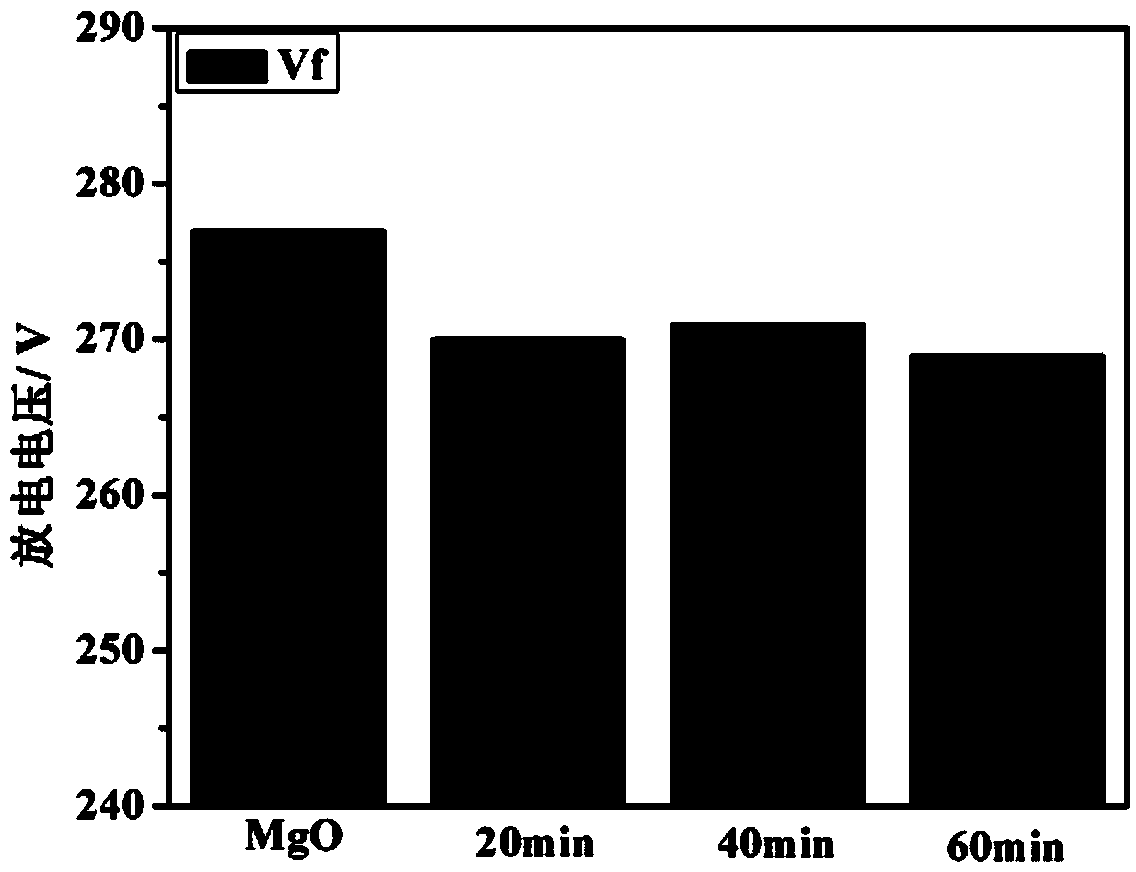

Magnesia coated fluorescent powder and its coating method

InactiveCN1664051AImprove resistance to thermal deteriorationWork lessLuminescent compositionsMagnesium saltSupersonic waves

Disclosed is the magnesia integument phosphor powder covered with magnesia on the surface of the phosphor powder.The method of integument comprising: preparing pH buffer with the concentration between 0.1-0.2M by employing conjugate acid and base system with the pH value between 8.0-12.0, weighing relevant quantity of water-soluble magnesium salt according to the proportion between magnesia and phosphor powder by weight (0.25~15): 100, preparing water-soluble magnesium salt volumetric solution with the concentration between 0.01~1M; preparing phosphor powder suspension with the concentration 0.2~5% by adding the phosphor powder into the buffer, stirring, dispersing with supersonic wave to make the phosphor powder dispersed in the buffer; heating the phosphor powder suspension to 20~70 DEG C and keeping the temperature, stirring with speed 100r / m~ 300r / m and dropping the water-soluble magnesium salt volumetric solution into the phosphor powder suspension at the speed of 2~15ml / min, then keeping the temperature and stirring for 30~180 minutes and getting the integument phosphor powder suspension, separating, washing, dewatering and drying at 60-120DEG C, making the integument phosphor powder moisture percentage below 0.25%,incandescing at 200~400 DEG C for 1~3 hours and air cooling in the furnace.

Owner:SOUTHEAST UNIV

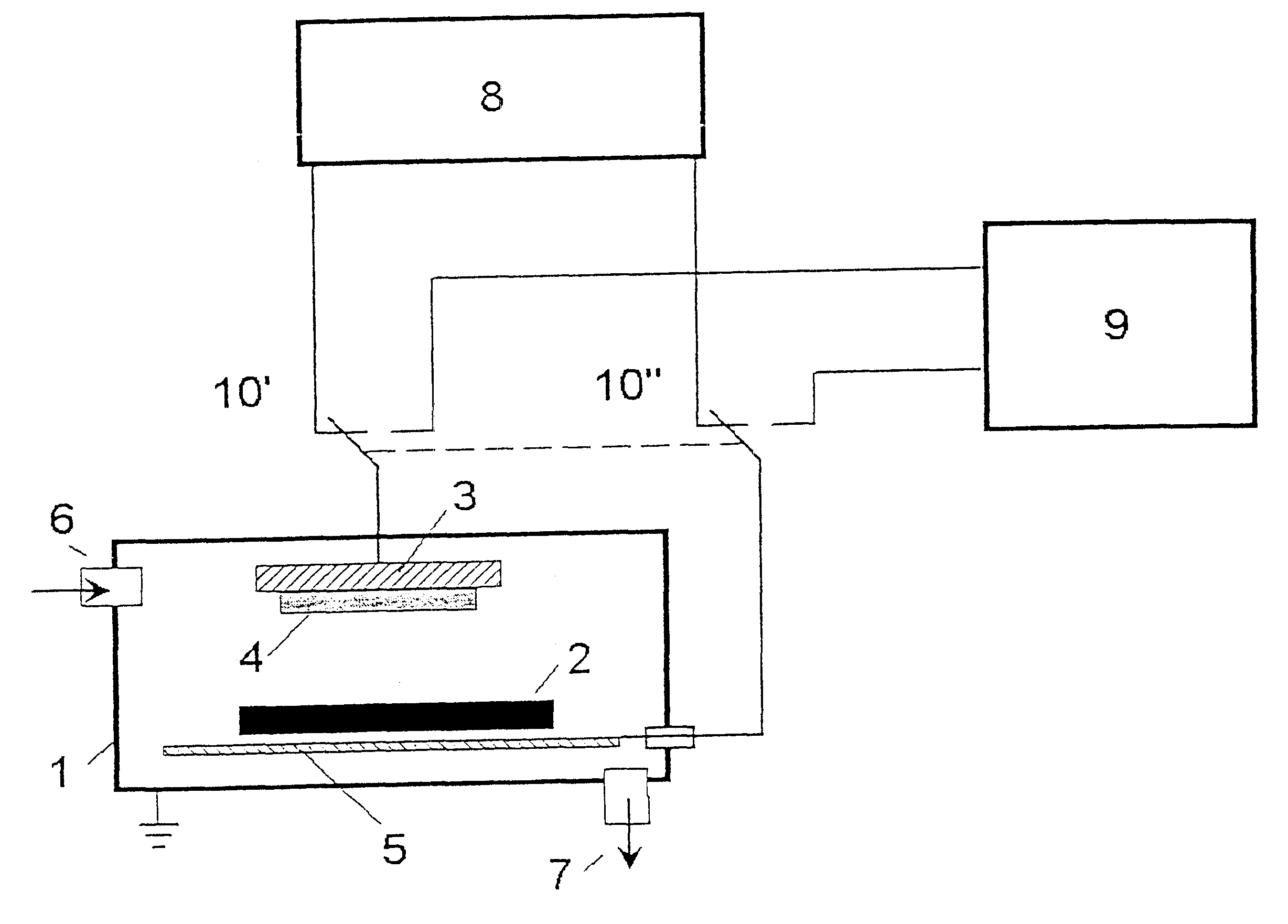

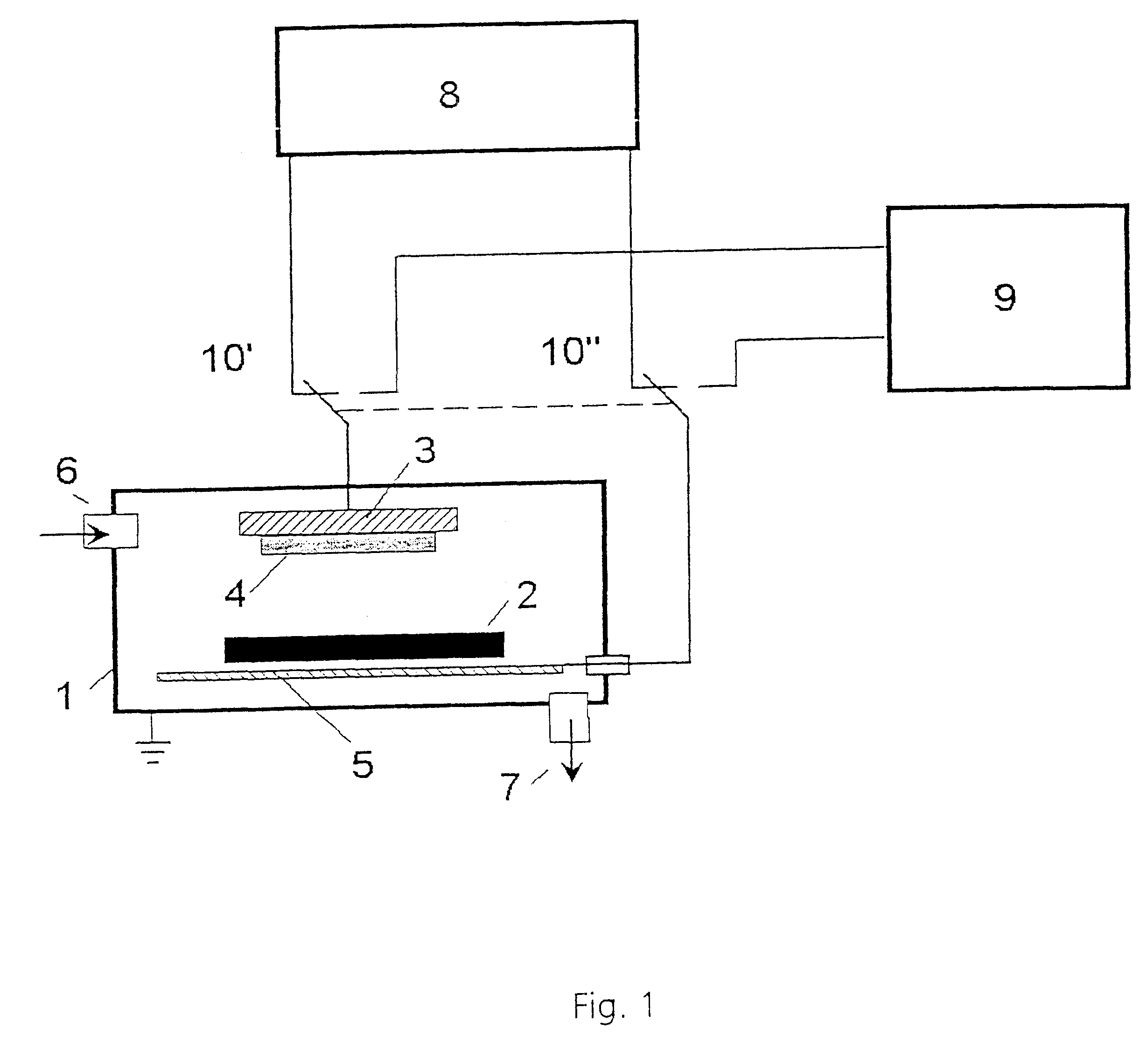

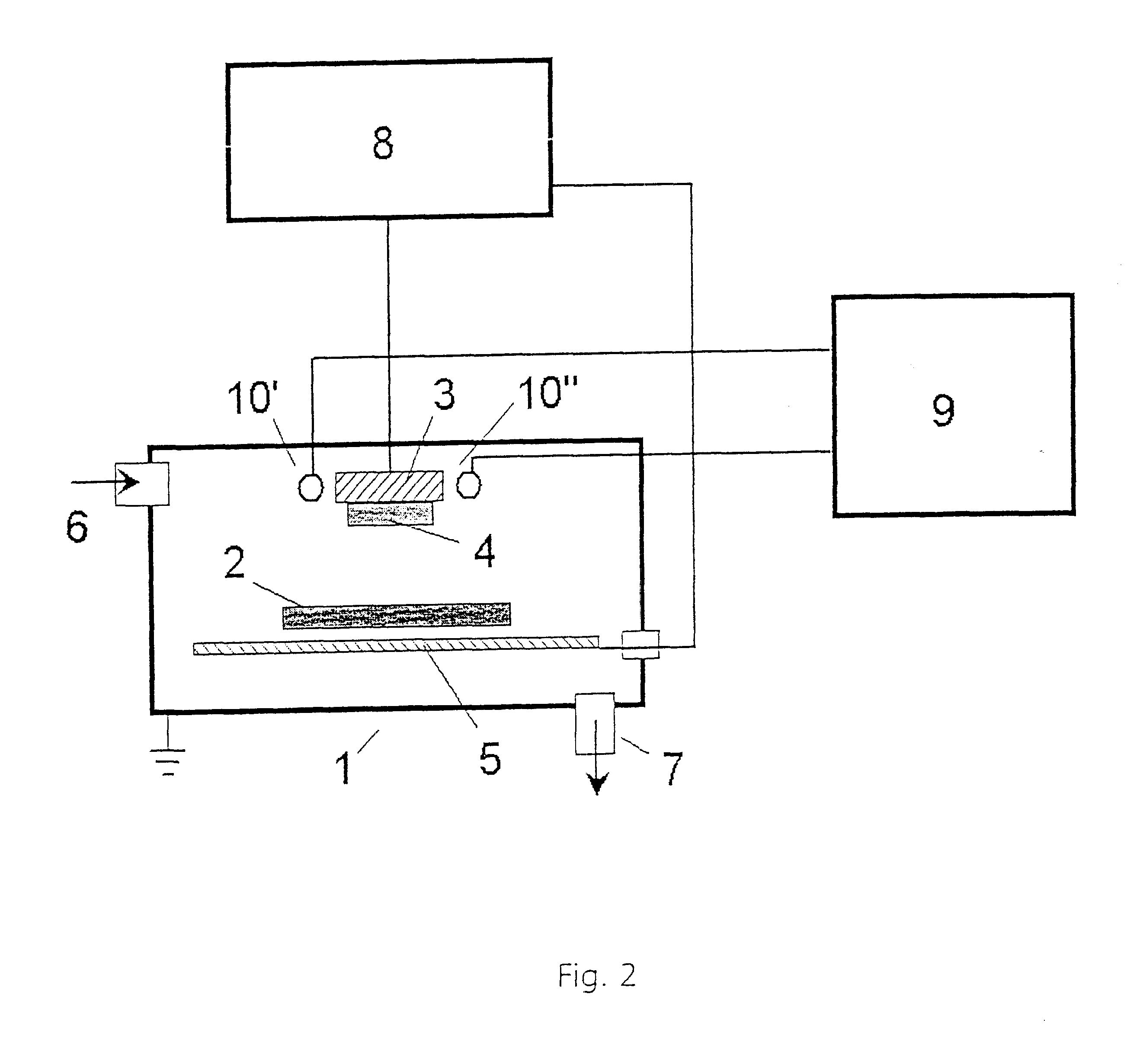

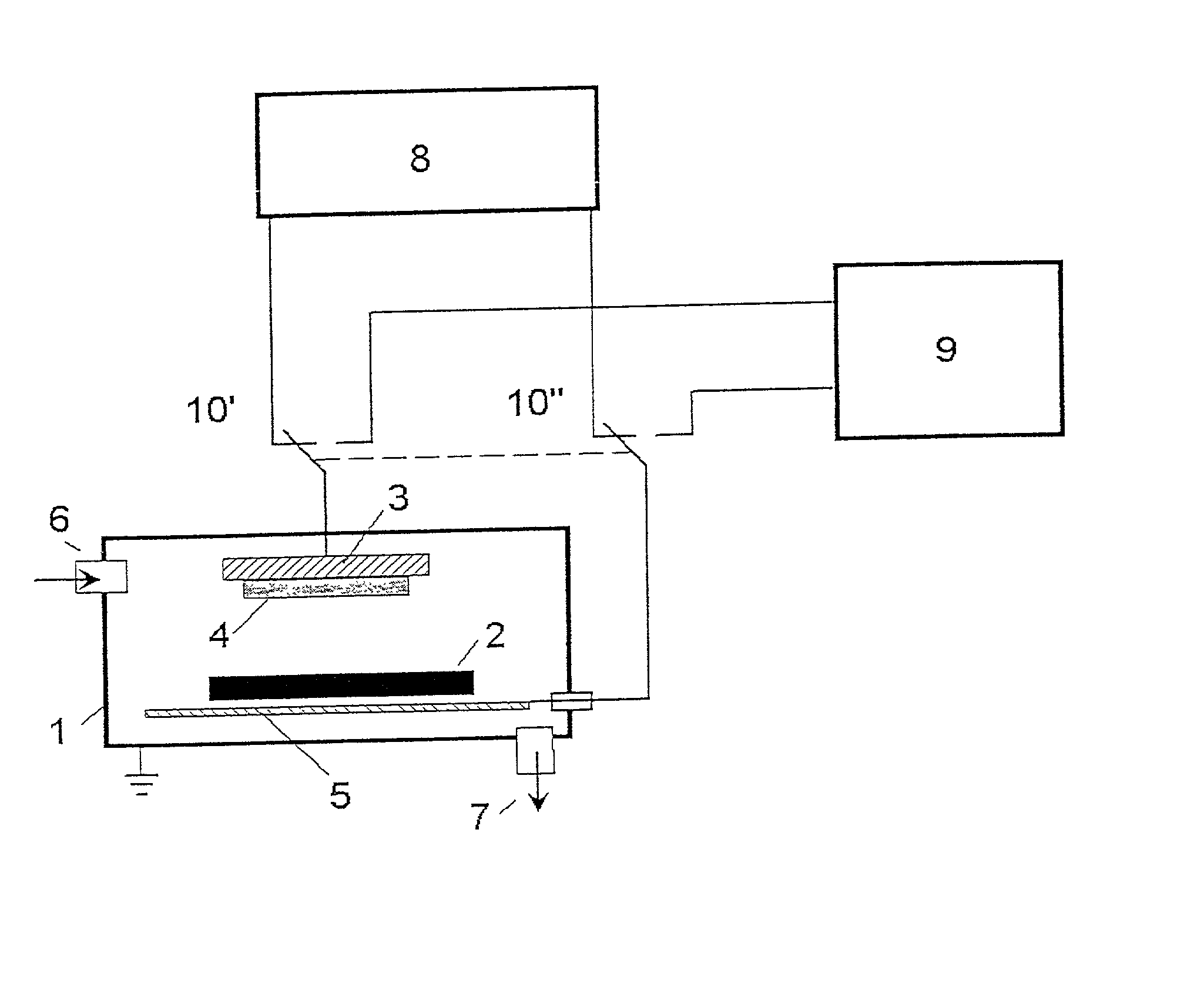

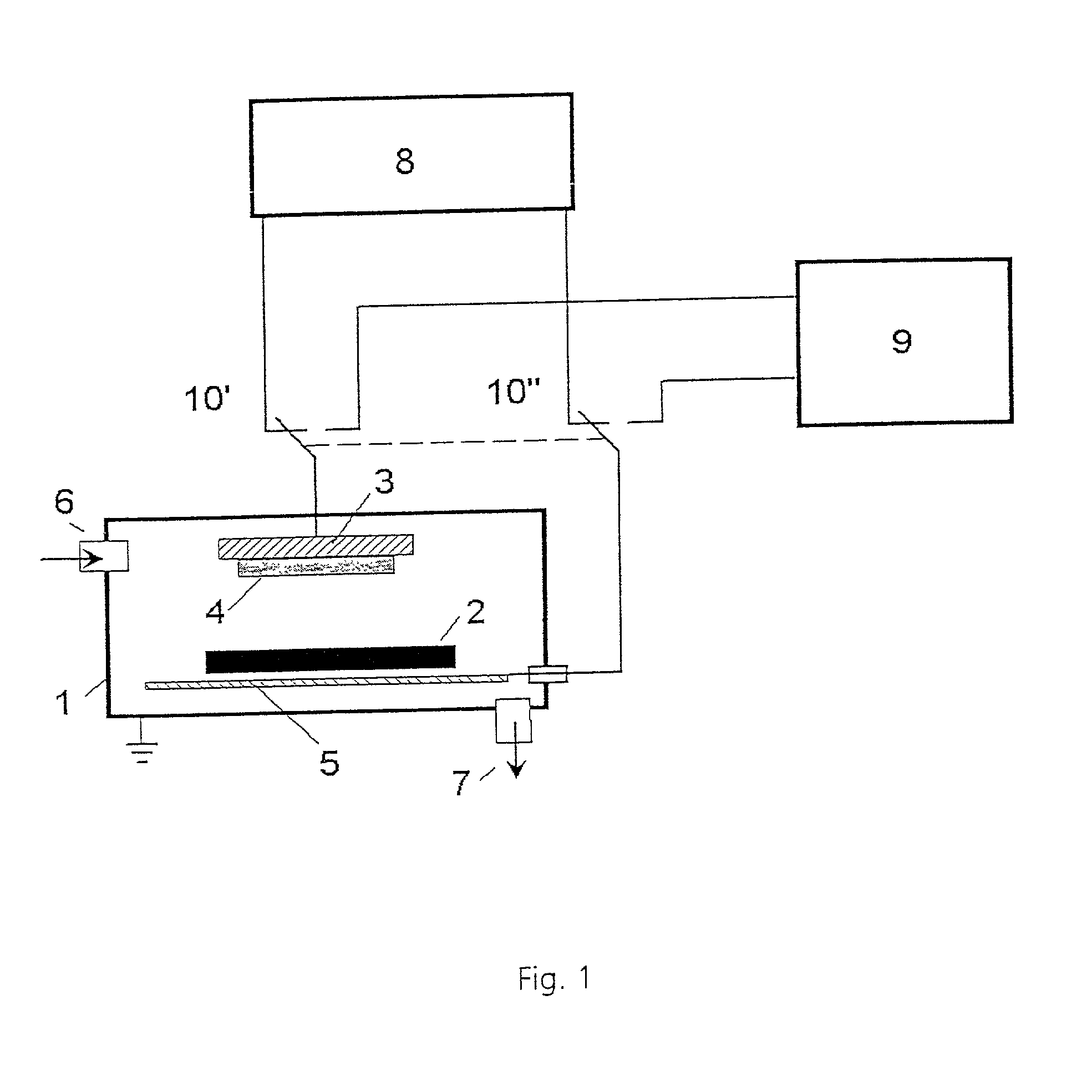

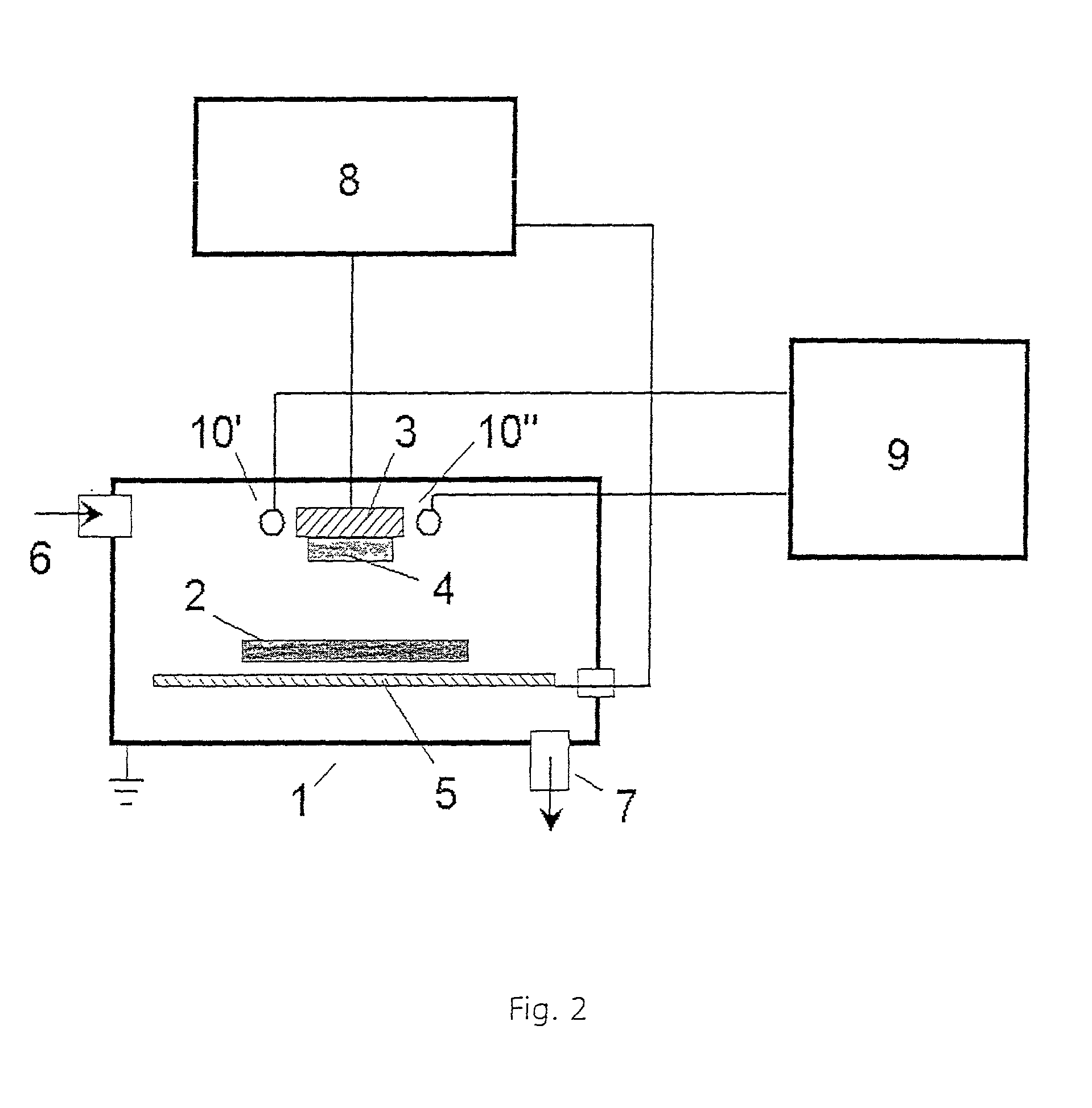

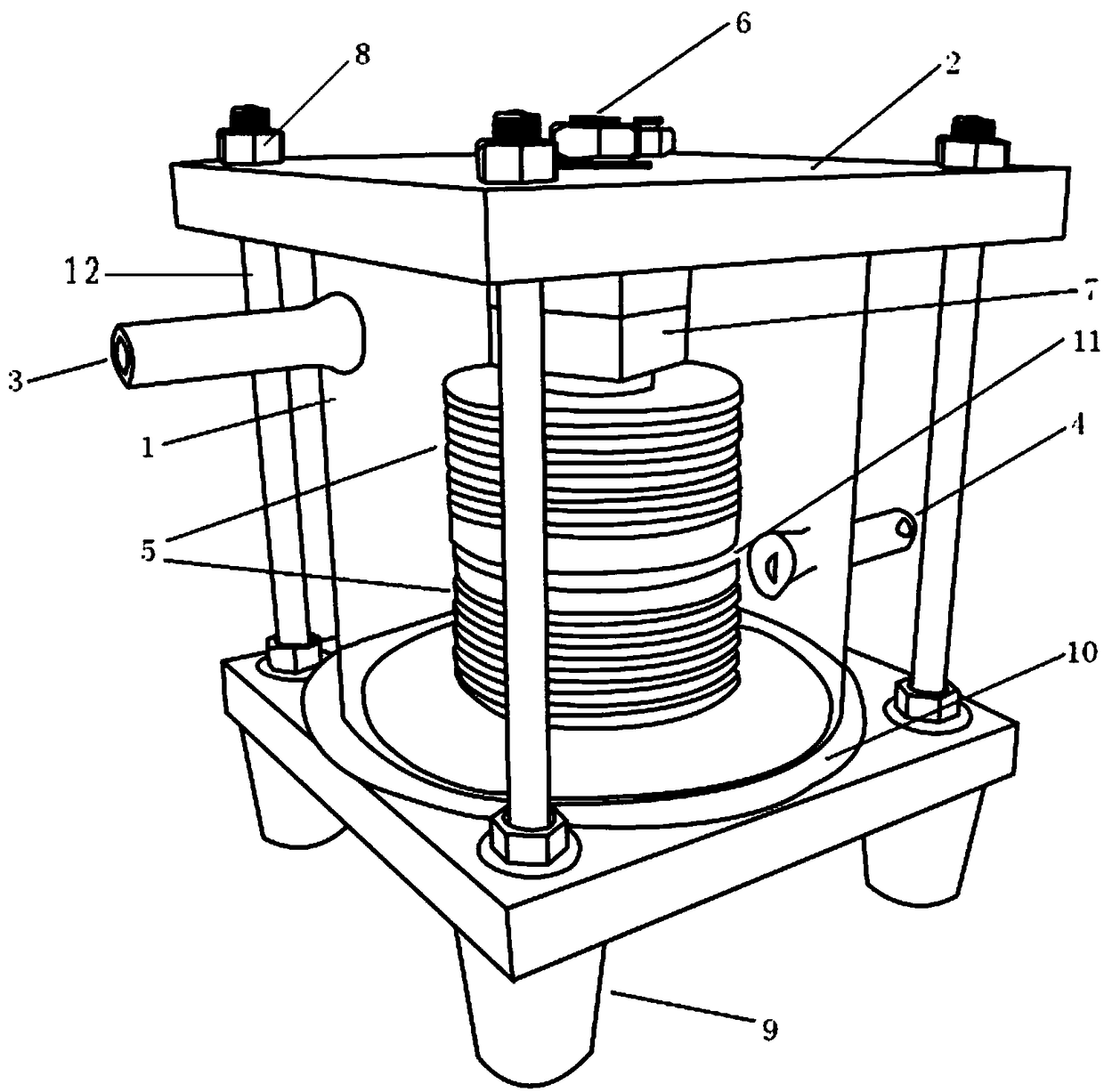

Process and device for reducing the ignition voltage of plasmas operated using pulses of pulsed power

InactiveUS6582566B2Low powerPrevent defective operating stateCellsLiquid surface applicatorsCharge carrierEngineering

Process and device for reducing an ignition voltage of power pulses in plasmas operated in a pulsed manner with long pulse-off times. The process includes generating a power pulsed plasma at a pulse duty factor, the pulse duty factor being a ratio of pulse-on time to pulse-off time, and at least before the beginning of the pulse-on time of the power pulses, producing charge carriers using an additional plasma discharge at a lower power than that of the power pulses. The device includes a vacuum chamber including at least one pump system, an arrangement for producing plasma, the arrangement including at least one anode and at least one cathode, an energy source connected to the cathode and the anode which can be pulsed in the frequency range of between approximately 10 Hz to approximately 1 MHZ, and a mechanism for one of producing an additional plasma discharge.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

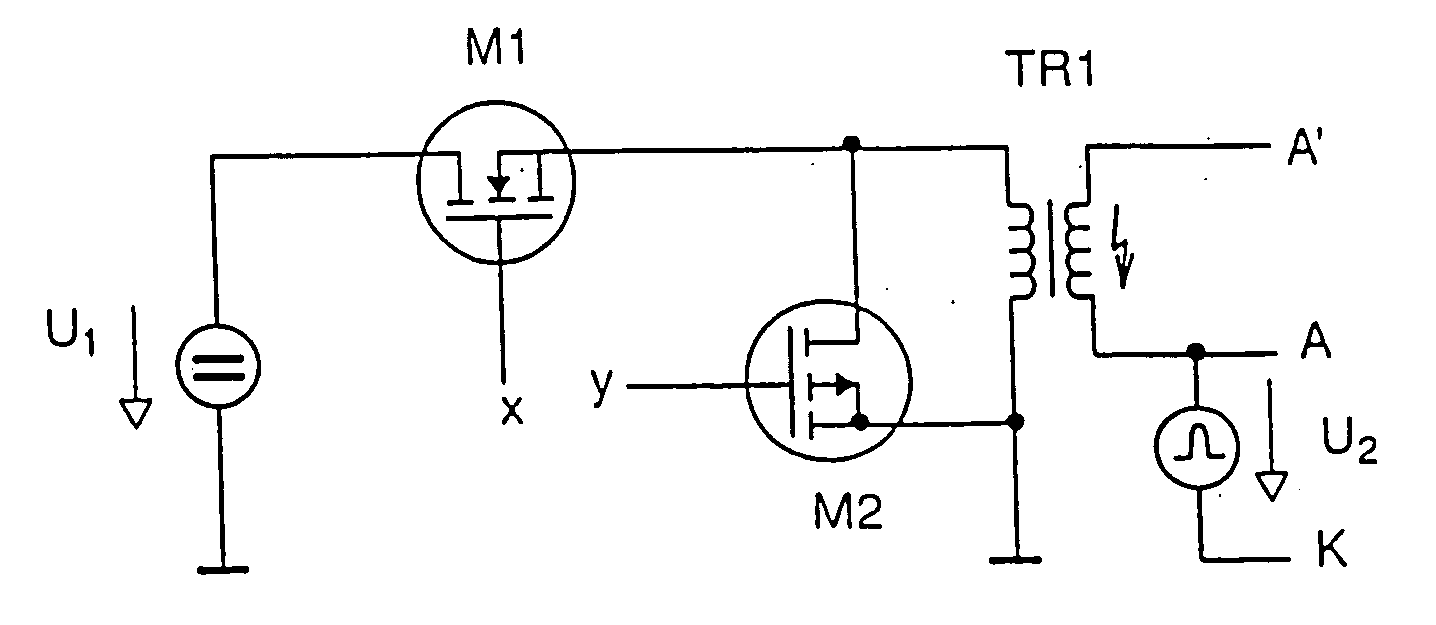

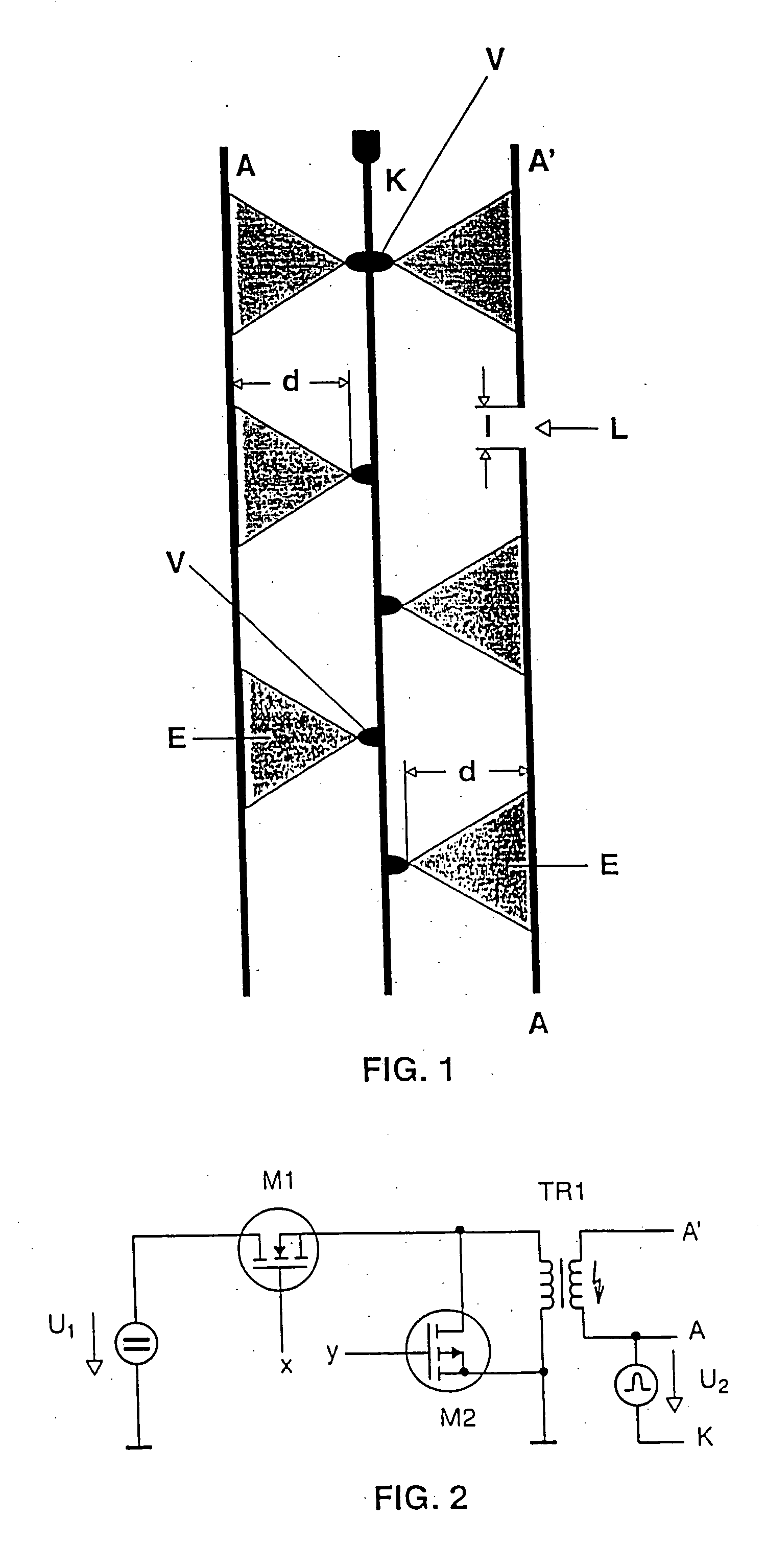

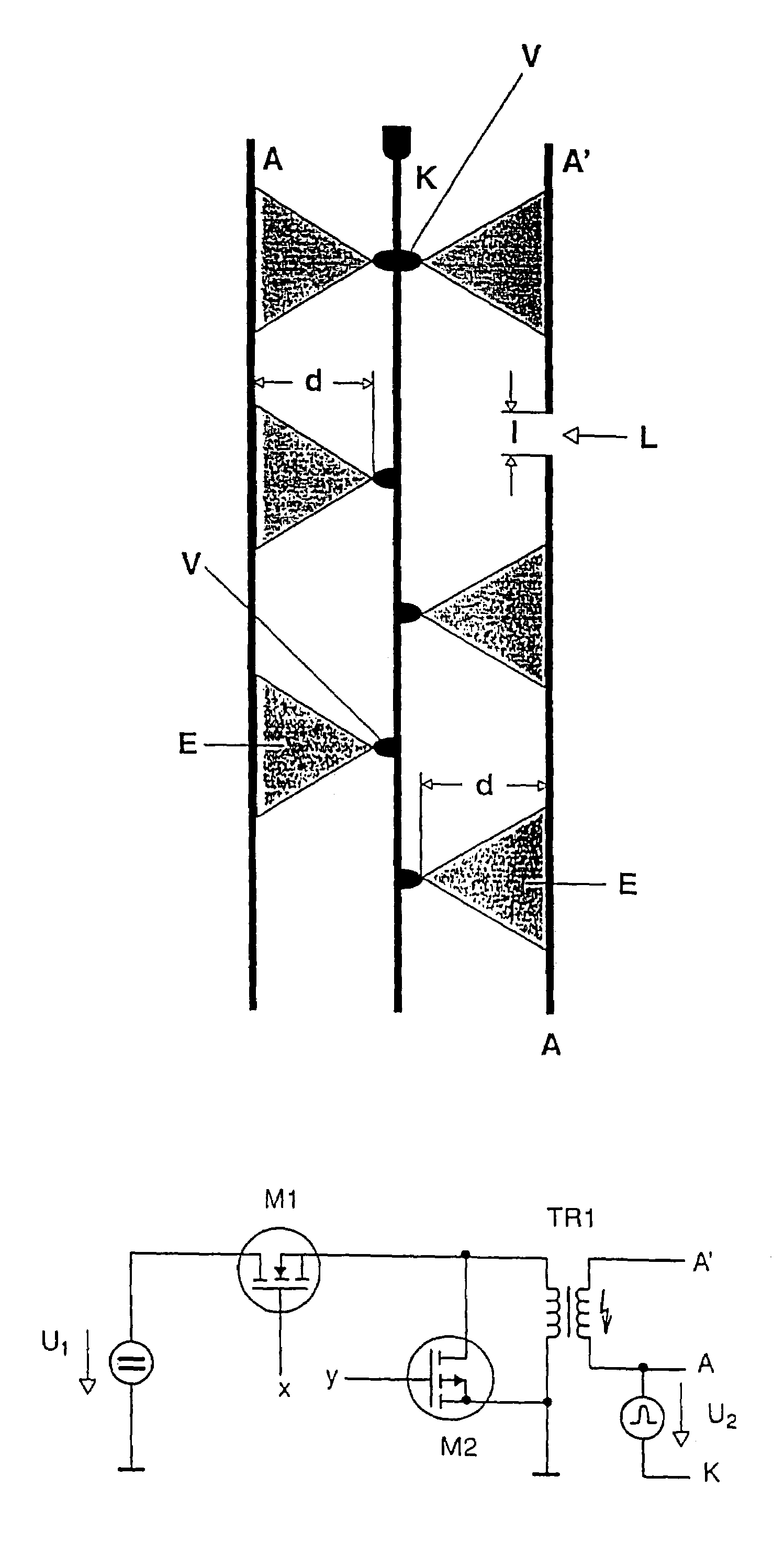

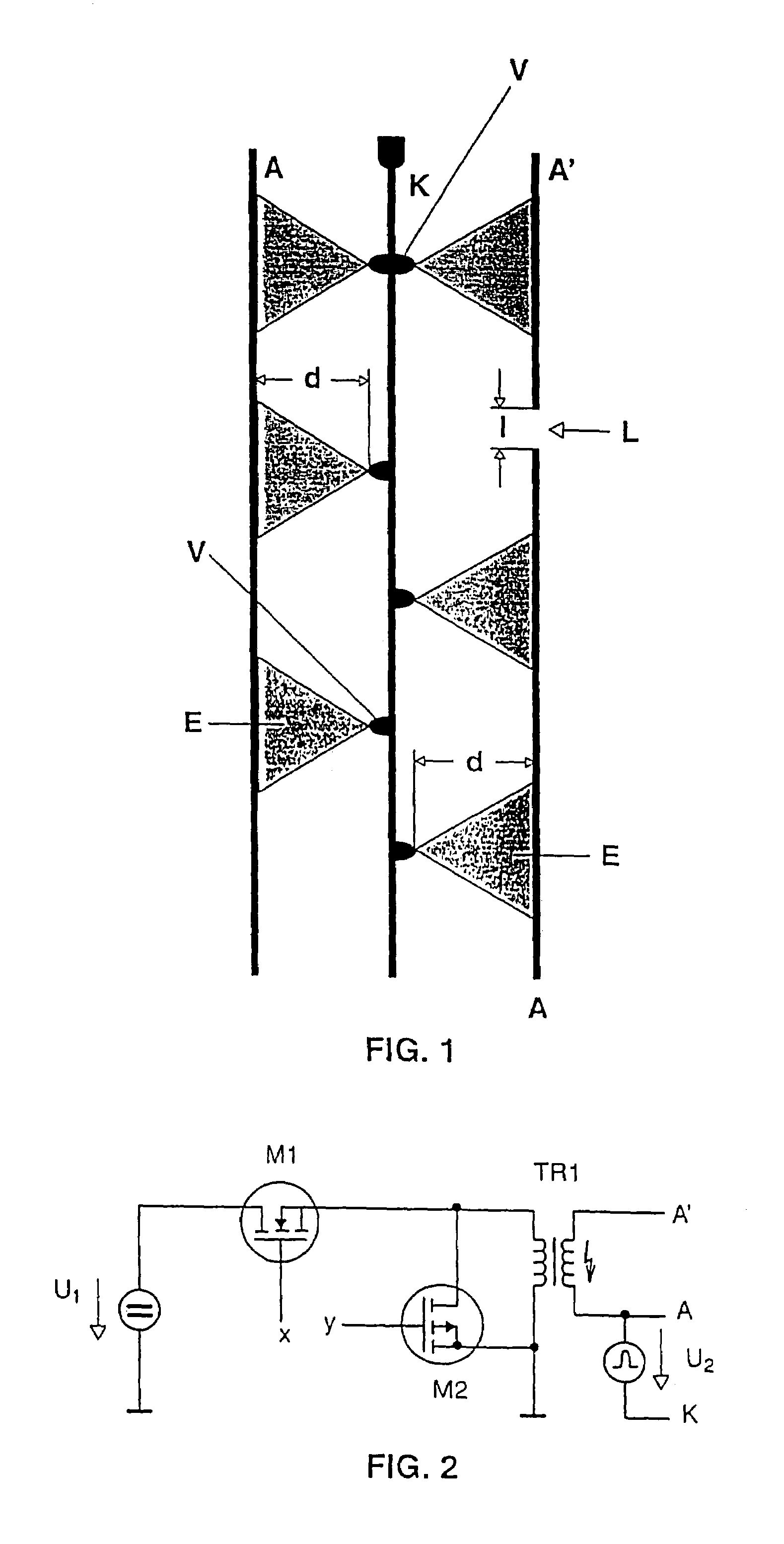

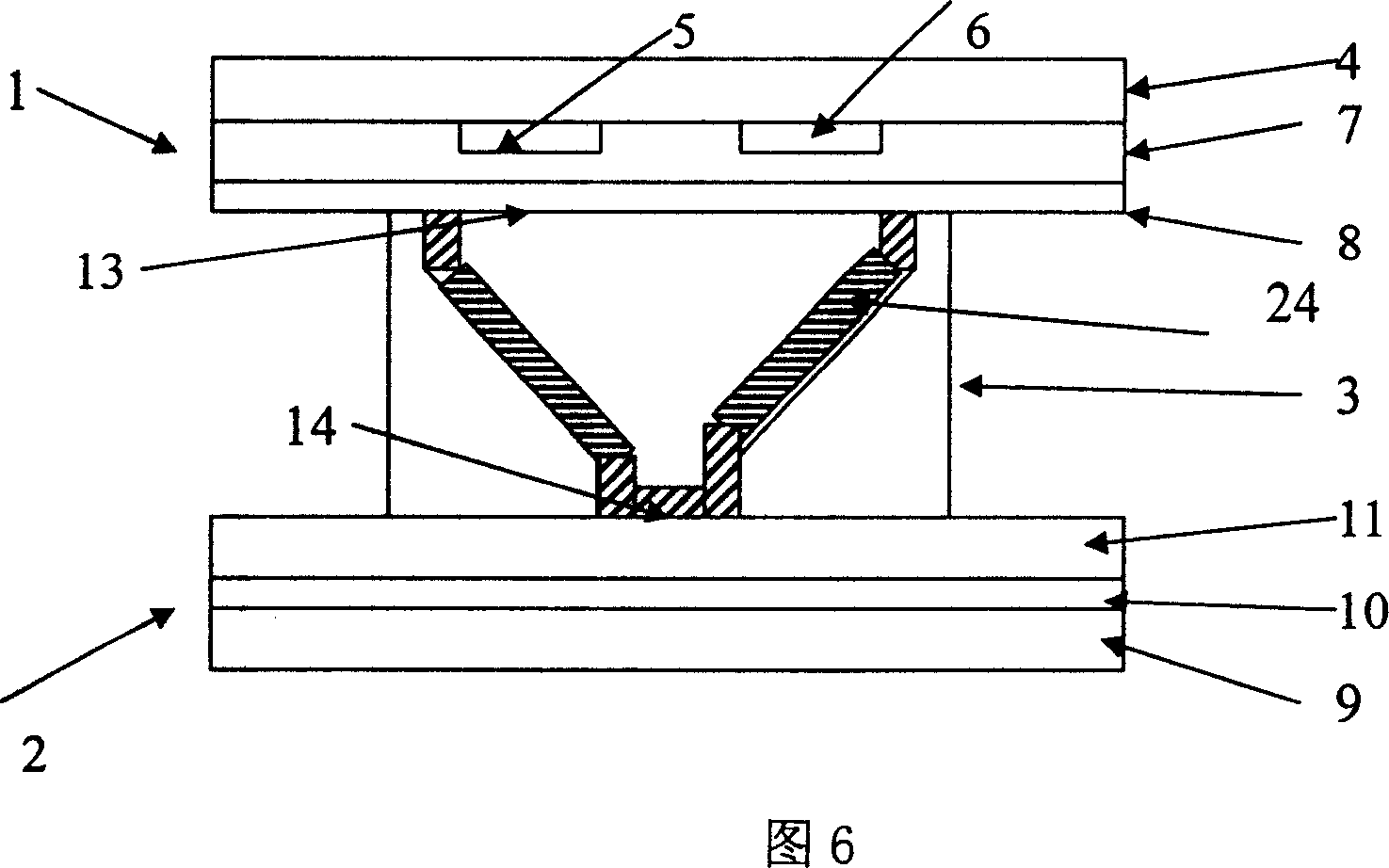

Dielectric barrier discharge lamp and method and circuit for igniting and operating said lamp

InactiveUS20040183455A1High strengthReduce needElectric light circuit arrangementGas discharge lamp usageEngineeringDielectric barrier discharge

An elongated electrode of a dielectric barrier discharge lamp is divided into two component electrodes (A, A') by a gap (L). The two component electrodes (A, A') are driven in an ignition phase in such a way that an auxiliary discharge that facilitates the ignition of the main discharge (E) in the region of the electrode gap (L), in particular when the lamp is in the dark. In normal operation, the component electrodes (A, A') are driven in such a way that they contribute to the generation of the main discharge (E).

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

Dielectric barrier discharge lamp and method and circuit for igniting and operating said lamp

InactiveUS6982526B2Improved ignition responseIncrease brightnessElectric light circuit arrangementGas discharge lamp usageEngineeringDielectric barrier discharge

An elongated electrode of a dielectric barrier discharge lamp is divided into two component electrodes (A, A′) by a gap (L). The two component electrodes (A, A′) are driven in an ignition phase in such a way that an auxiliary discharge that facilitates the ignition of the main discharge (E) in the region of the electrode gap (L), in particular when the lamp is in the dark. In normal operation, the component electrodes (A, A′) are driven in such a way that they contribute to the generation of the main discharge (E).

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

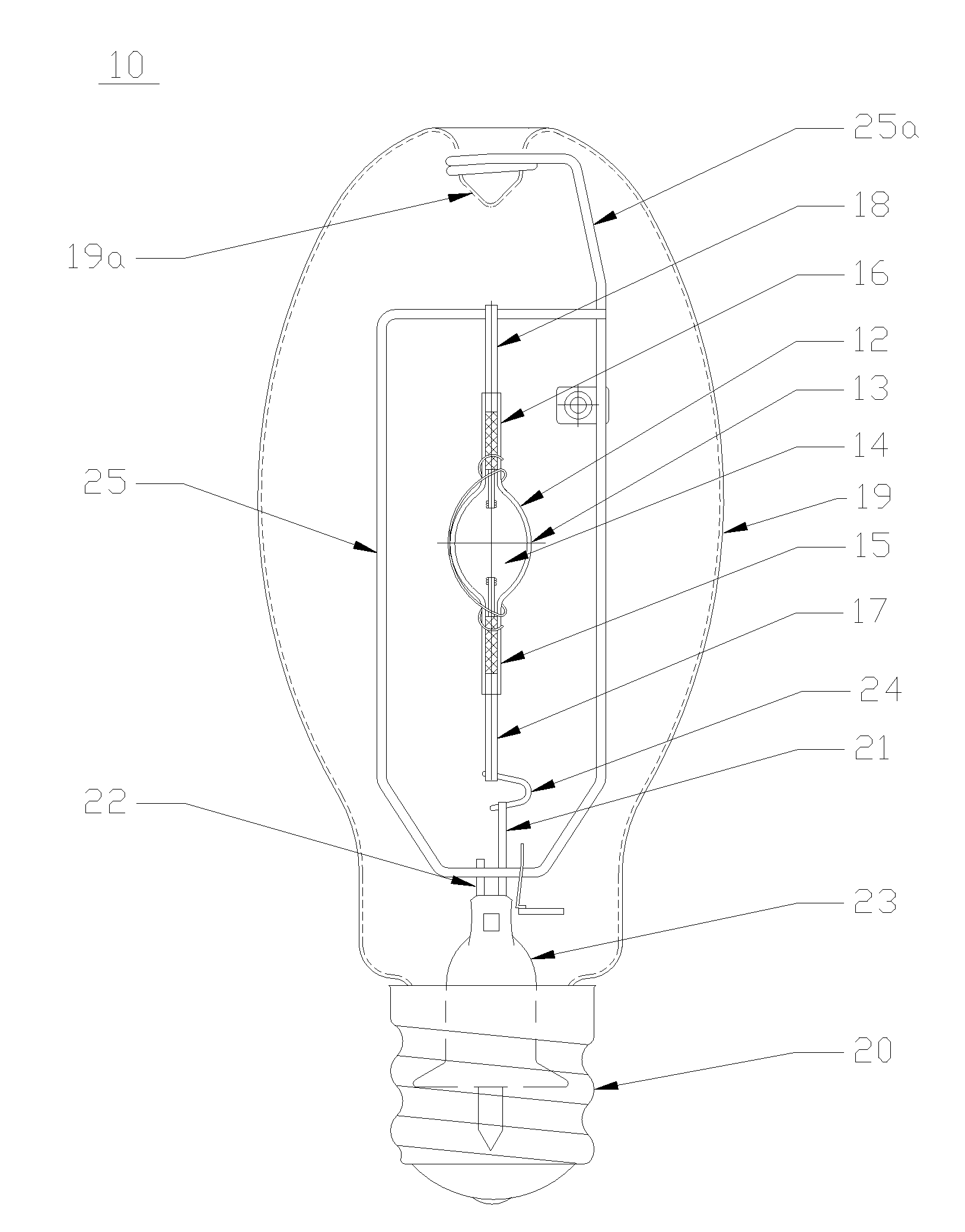

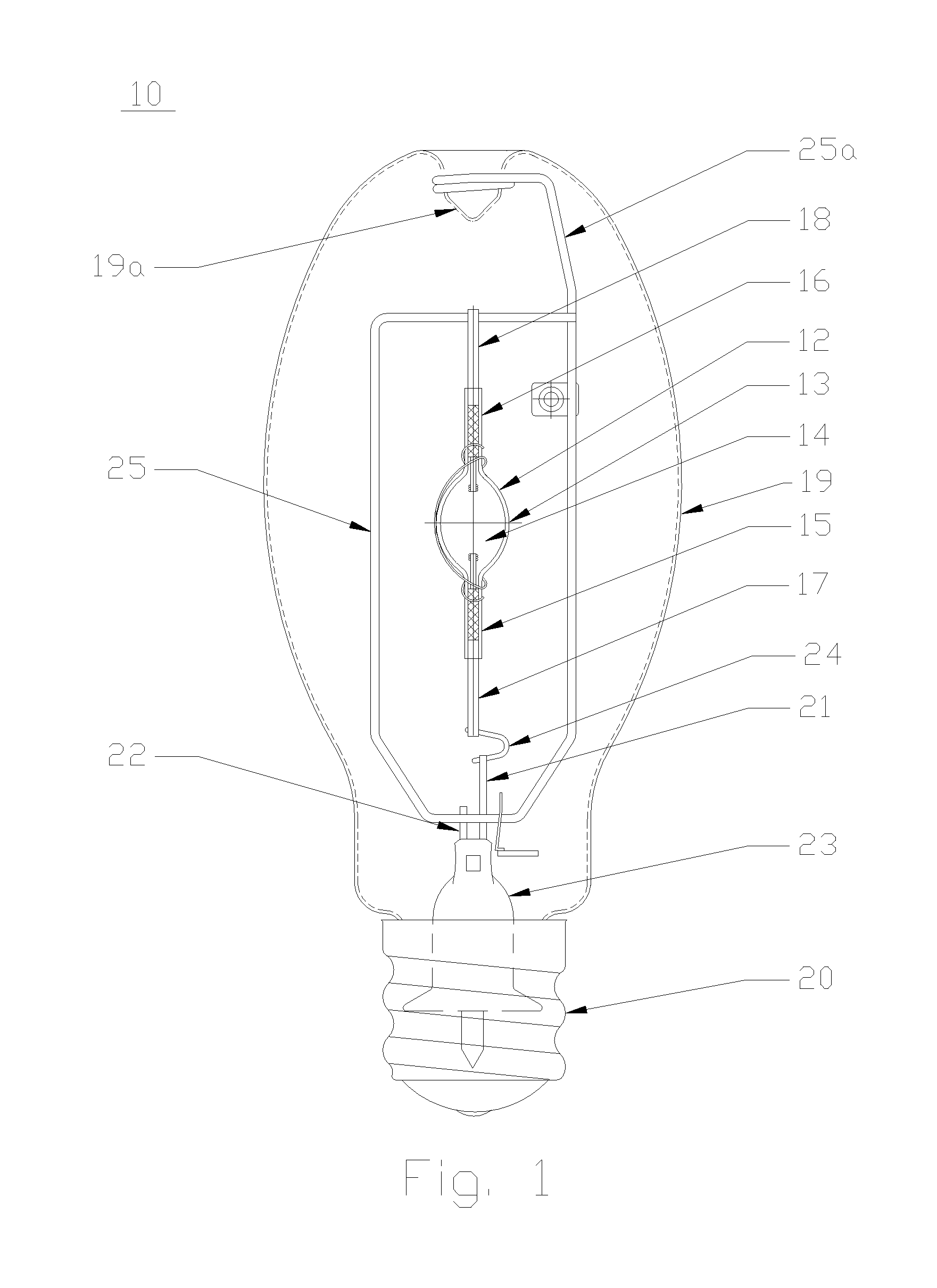

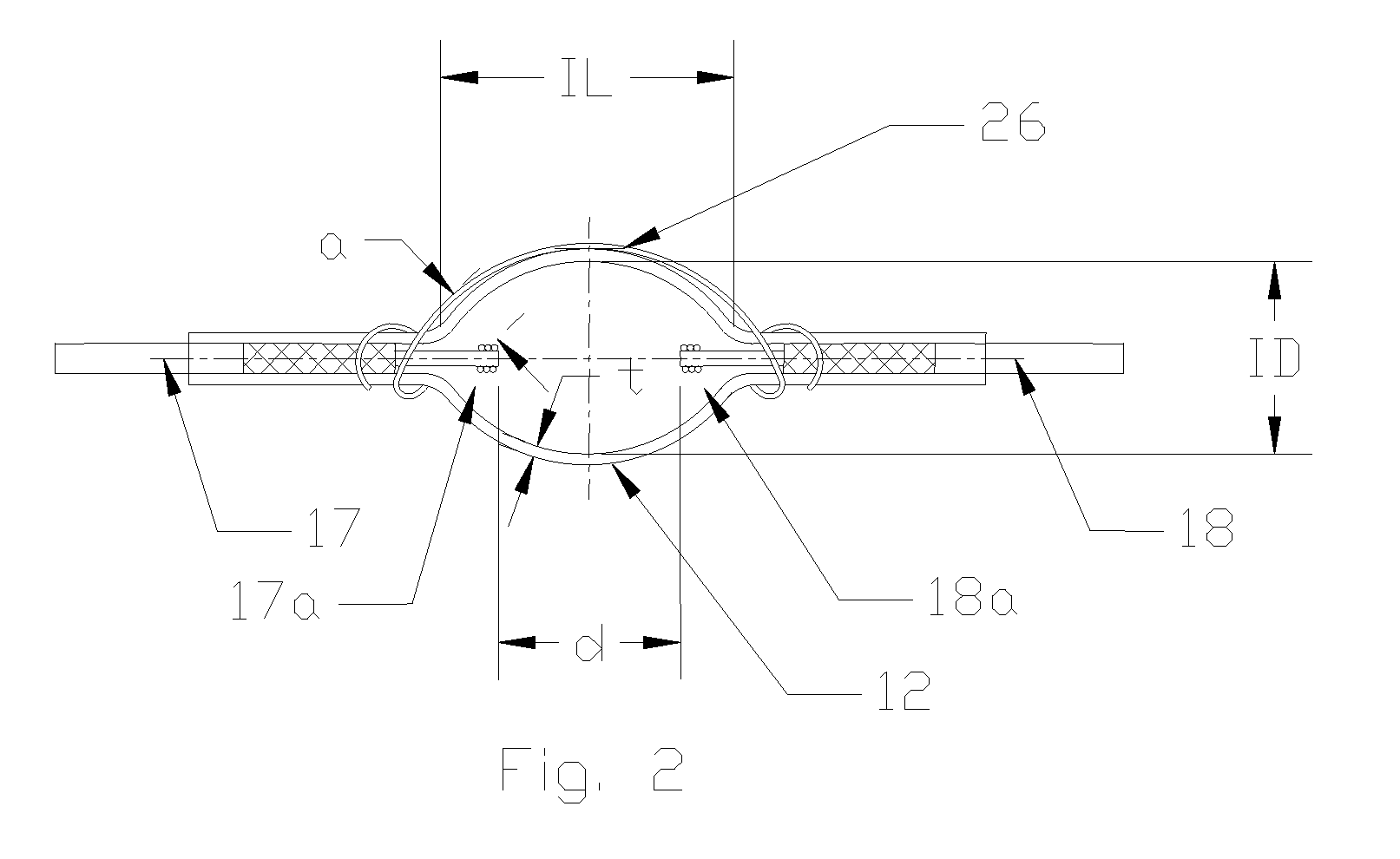

Ceramic gas discharge metal halide lamp

InactiveUS20110266947A1Reliable ignitionReduce ignition voltageSolid cathode detailsGas discharge lamp detailsNoble gasIodide

A ceramic gas discharge metal halide (CDM) lamp (10) capable of retrofitting into existing high pressure iodide (HPI) metal halide and high pressure mercury vapor (HP) lamp fixtures for significient energy savings, the CDM lamp (10) having a ceramic discharge vessel (12) containing a pair of discharge electrodes (17, 18), a Penning mixture of the rare gases neon and argon, and a chemical fill which includes an oxygen dispenser and which restricts strong oxygen binders to 5 mole percent or less. In a preferred embodiment, the discharge vessel (12) has an aspect ratio R of less than 2, a wall thickness t of up to 1.2 mm, a spacing d between the discharge electrodes (17, 18) of up to 14 mm, and a passive antenna (26) on the outer wall of the discharge vessel (12), with the shortest distance a between a discharge electrode (17, 18) and the floating antenna (26) of up to 7 mm.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

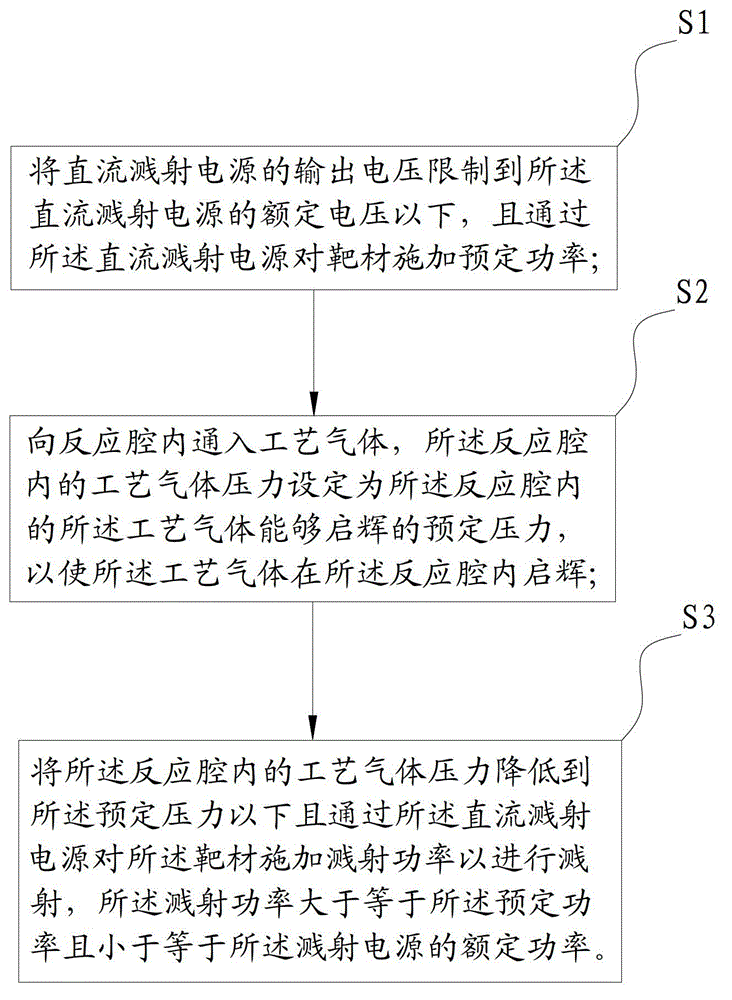

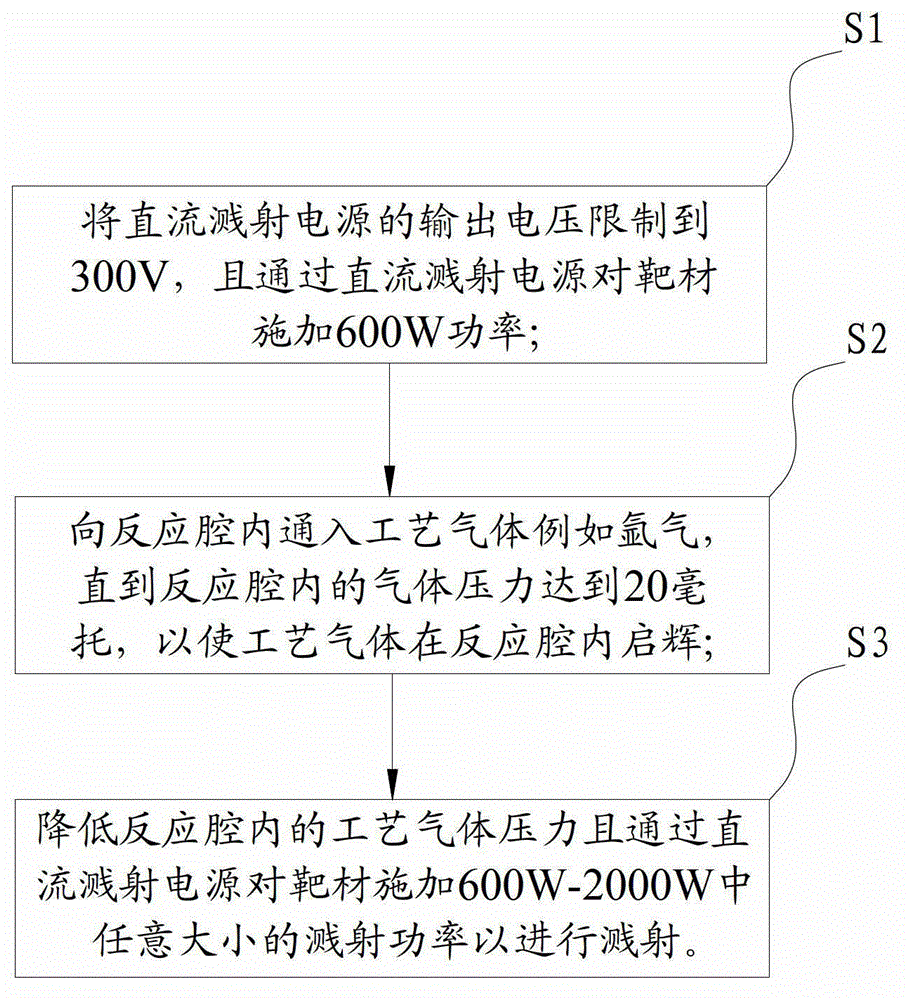

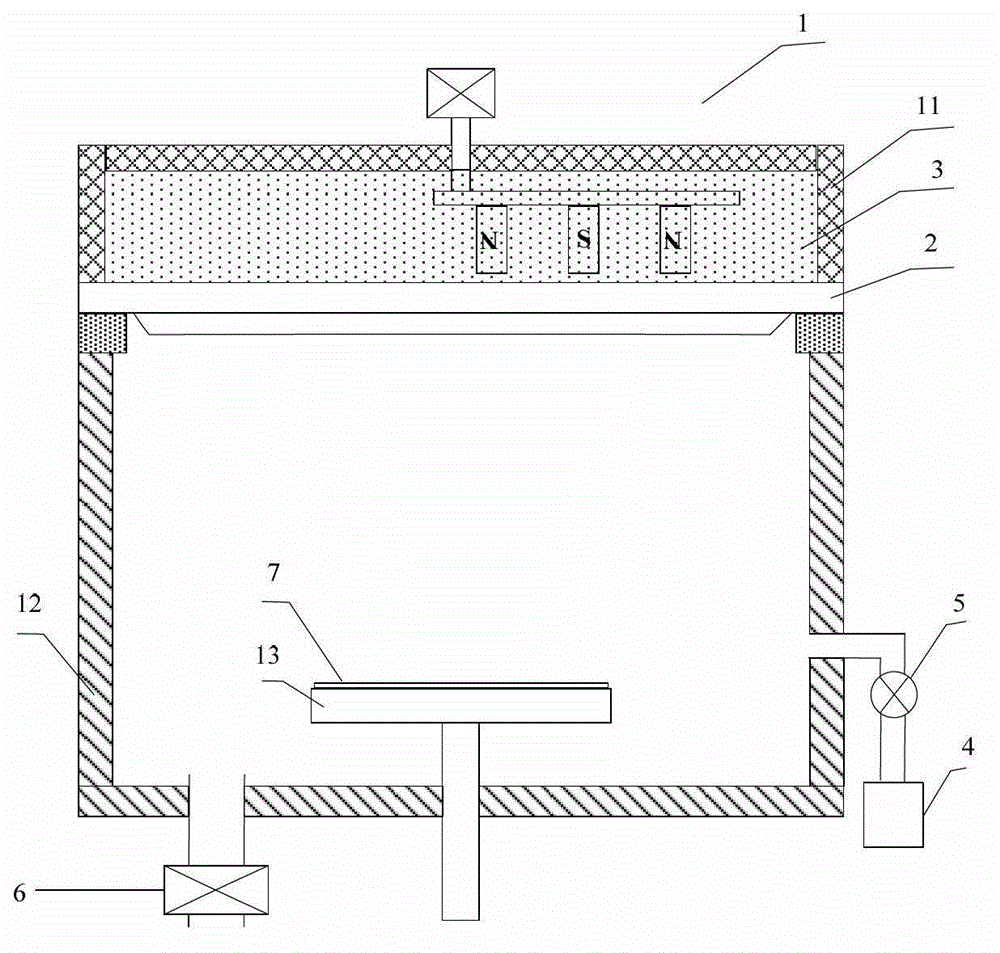

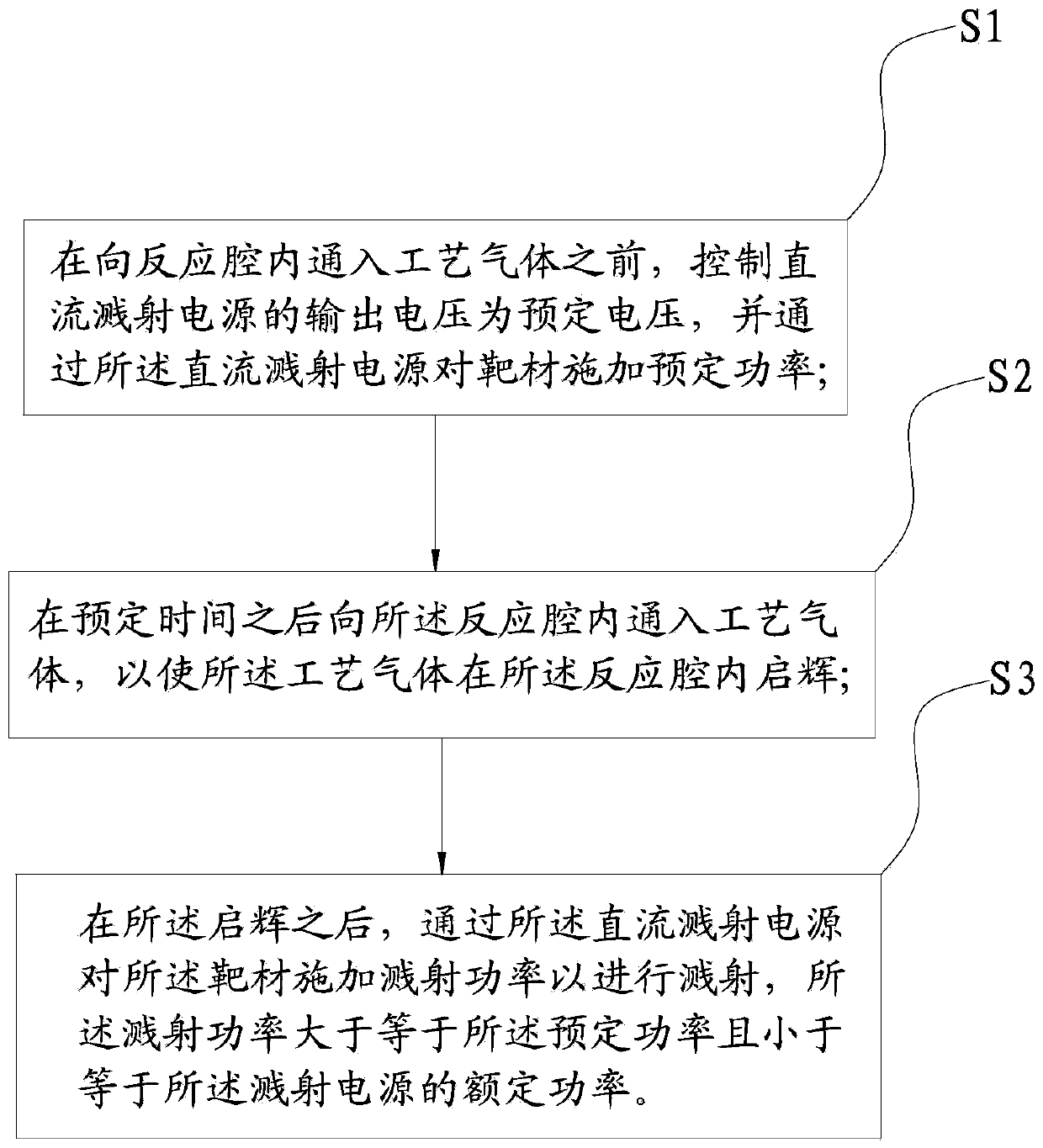

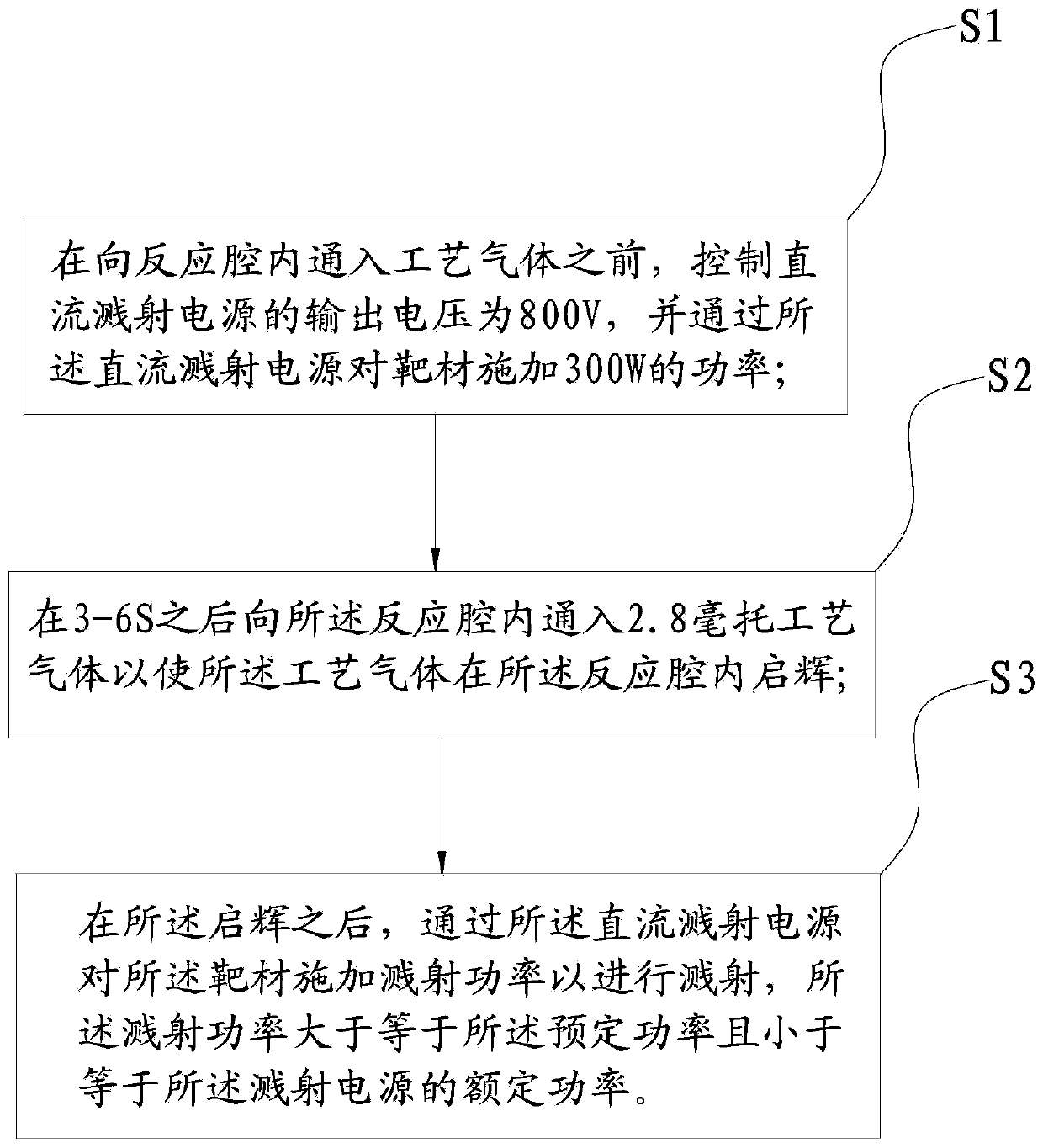

ITO thin film sputtering process and ITO thin film sputtering device

ActiveCN103938164AImprove deposition uniformityImprove uniformityVacuum evaporation coatingSputtering coatingSputteringPeak value

The invention discloses an ITO thin film sputtering process and an ITO thin film sputtering device. The ITO thin film sputtering process comprises steps of: 1) limiting the output voltage of a direct-current sputtering power supply to be lower than the nominal voltage of the direct-current sputtering power supply, and applying a preset power to a target material through the direct-current sputtering power supply; 2) feeding process gas into a reaction cavity, wherein the pressure of the process gas in the reaction cavity is set to be a preset pressure capable of glow starting of the process gas so that the process gas can be subjected to glow starting in the reaction cavity; and 3) lowering the pressure of the process gas in the reaction cavity to be lower than the preset pressure, applying a sputtering power to the target material through the direct-current sputtering power supply and sputtering, wherein the sputtering power is not less than the preset power and is not more than the rated power of the sputtering power supply. The ITO thin film sputtering process can lower the voltage peak value of glow starting.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

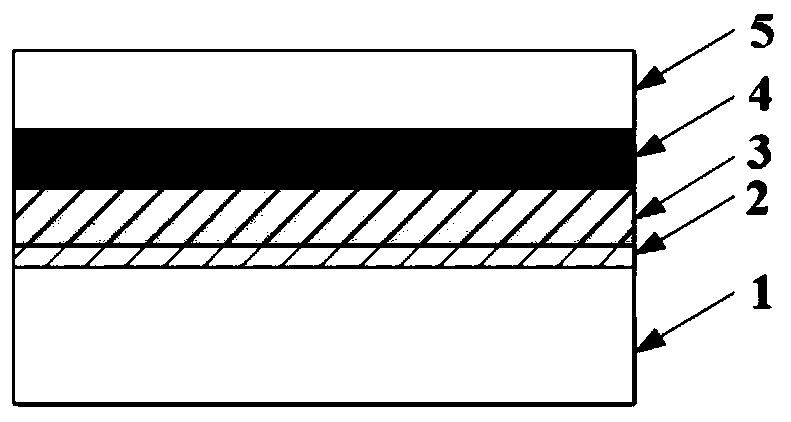

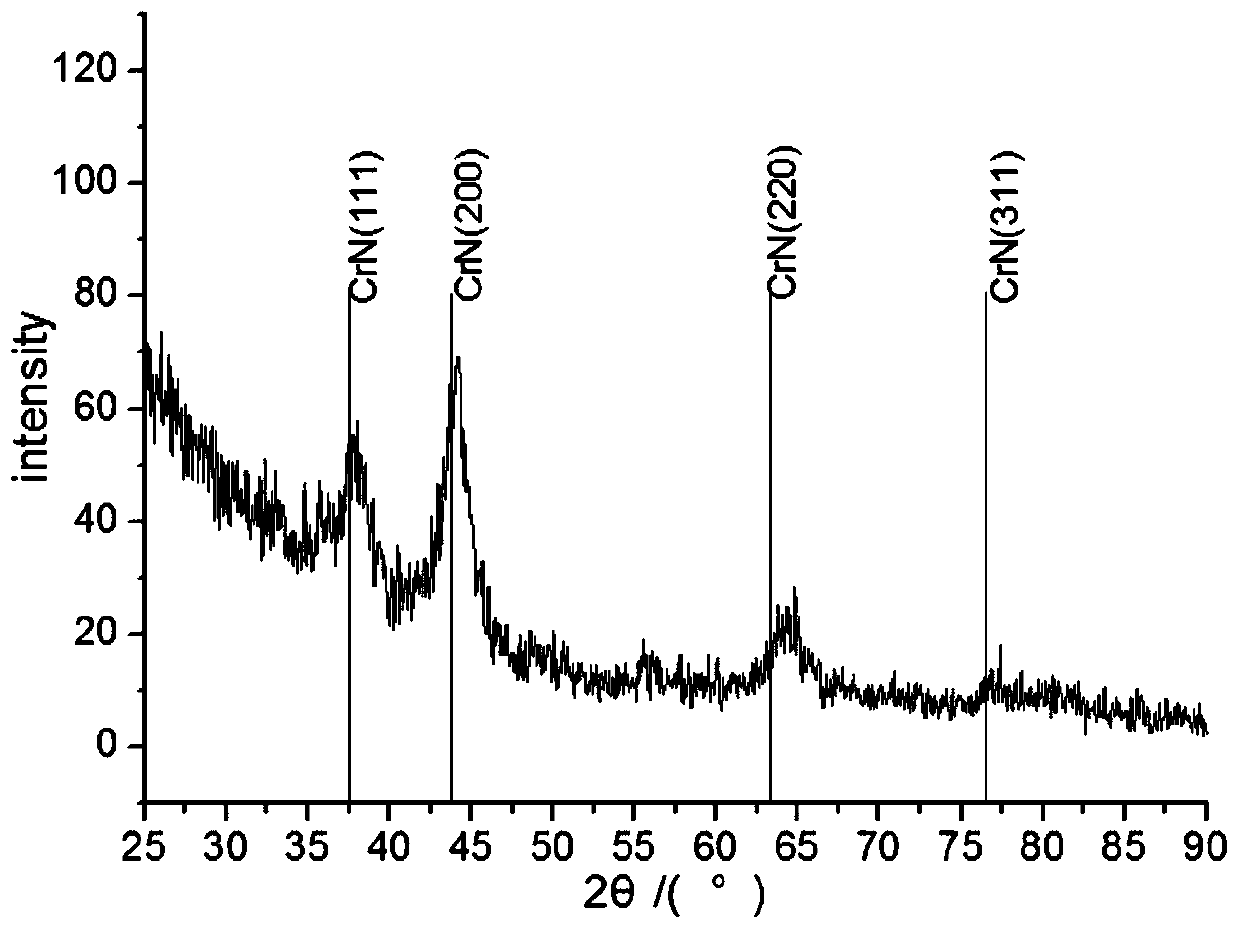

Multi-layer gradient high-temperature wear-resistant coating on surface of cutting tool and preparation method thereof

InactiveCN109735799AIncrease deposition rateEliminate discharge delayVacuum evaporation coatingSputtering coatingWear resistantHardness

The invention belongs to the field of high-speed cutting tool surface vacuum coating modification, and relates to a multi-layer gradient high-temperature wear-resistant coating on the surface of a cutting tool and a preparation method thereof. The coating consists of a Cr bombardment implant layer with a thickness of 5-15 nm, a Cr transition layer with a thickness of 1-2 micron, a CrN performancebearing layer with a thickness of 2-4 micron and an AlCrN hard core layer with a thickness of 5-15 micron which are sequentially attached to the surface of a matrix of the cutting tool; the coating isprepared through a HIPIMS and DCMS composite co-deposition technology. The coating has the advantages of high hardness, good adhesion property with the matrix and high temperature and wear resistance.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

ITO thin film sputtering process and ITO thin film sputtering apparatus

ActiveCN103966557AImprove performanceImprove deposition uniformityVacuum evaporation coatingSputtering coatingSputteringDirect current

The invention discloses an ITO thin film sputtering process and an ITO thin film sputtering apparatus. The method comprises the following steps: before introducing process gas into a reaction chamber, controlling output voltage of a direct current sputtering power source to be predetermined voltage and applying predetermined power on a target material by using the direct current sputtering power source; introducing the process gas into the reaction chamber after predetermined time so as to allow the process gas to realize glow starting in the reaction chamber; and after glow starting, applying sputtering power on the target material by using the direct current sputtering power source to implement sputtering, wherein the sputtering power is more than or equal to the predetermined power but less than or equal to the rated power of the sputtering power source. The ITO thin film sputtering process provided by the invention can greatly reduce glow starting voltage, mitigates bombardment of a GaN layer caused by too high particle energy at the moment of glow starting and effectively reduces damage to the GaN layer. Moreover, since no new mechanism is needed, stability is improved, adjustment of the process can be conveniently carried out, and thin film deposition uniformity is enhanced.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

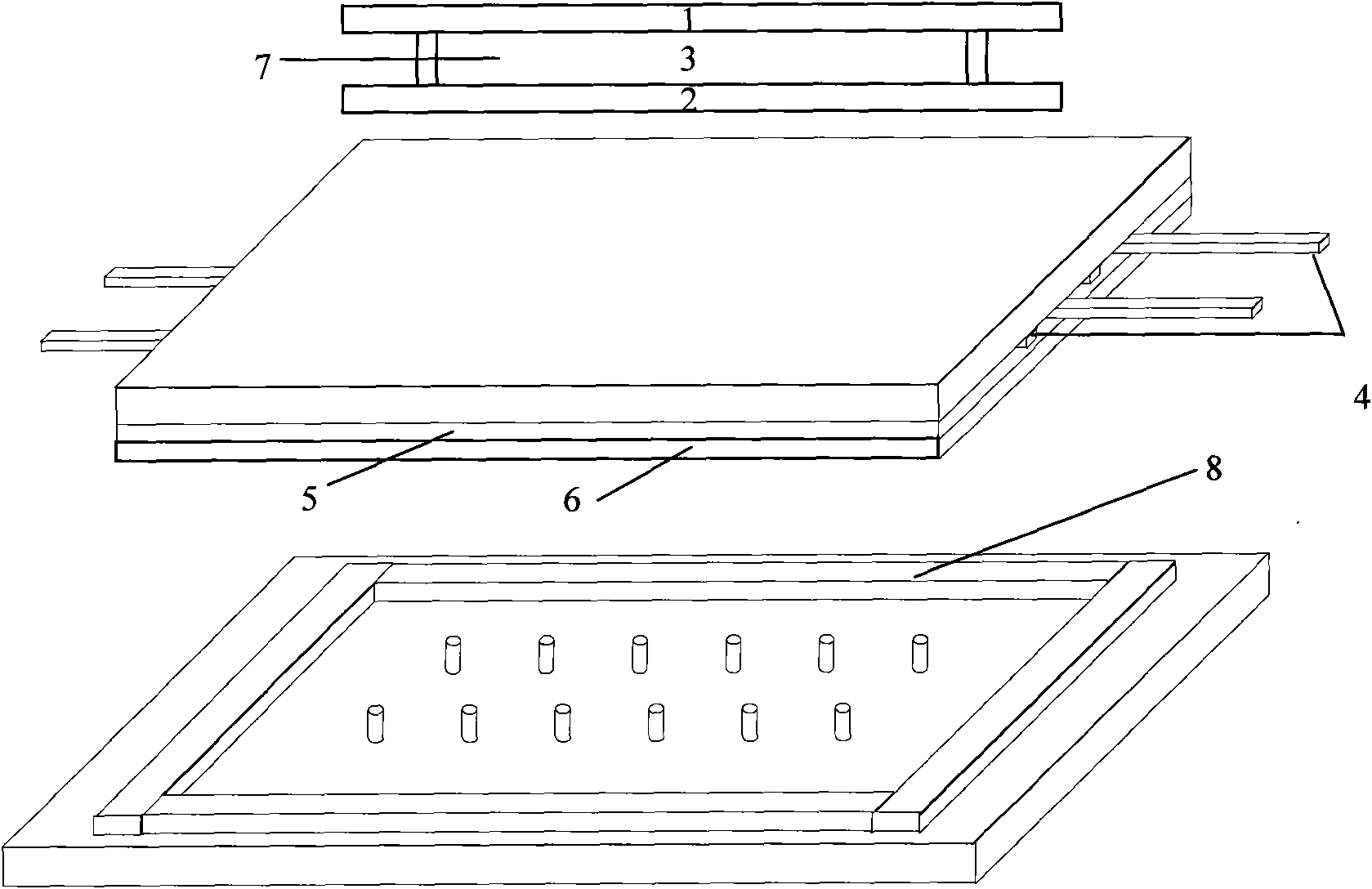

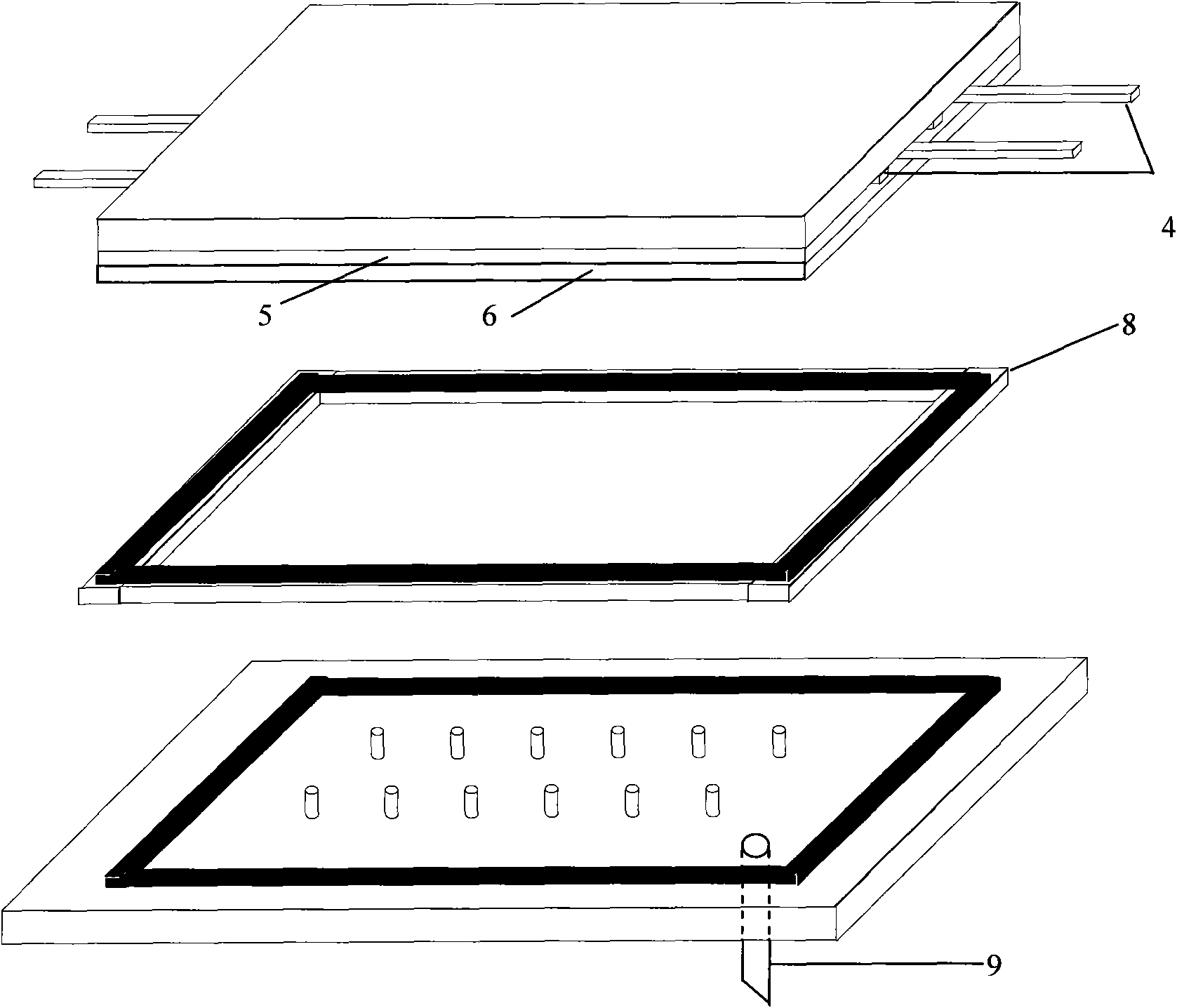

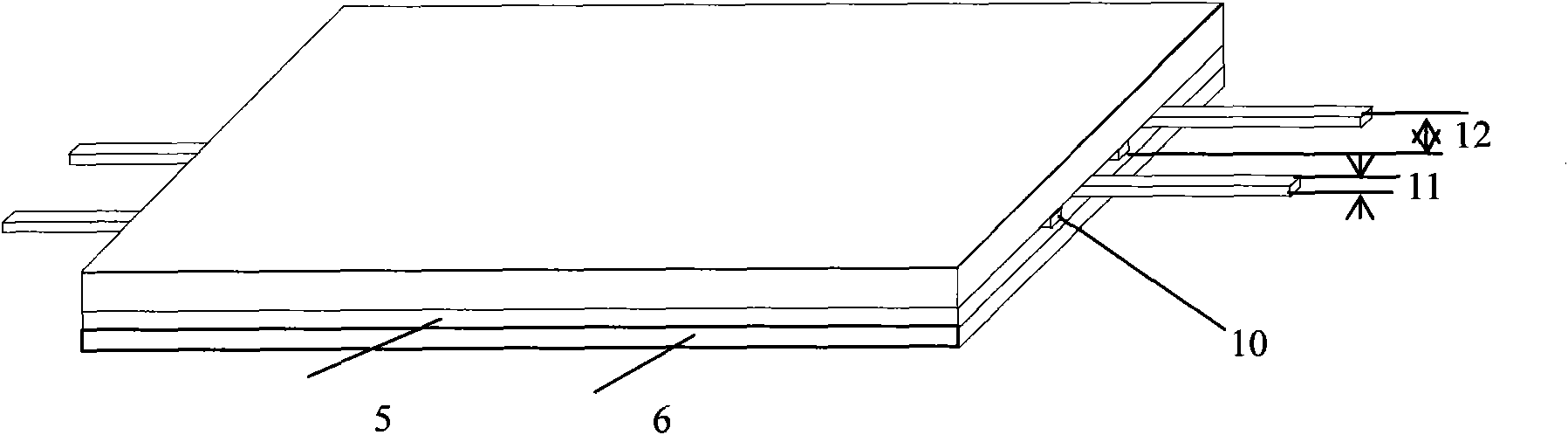

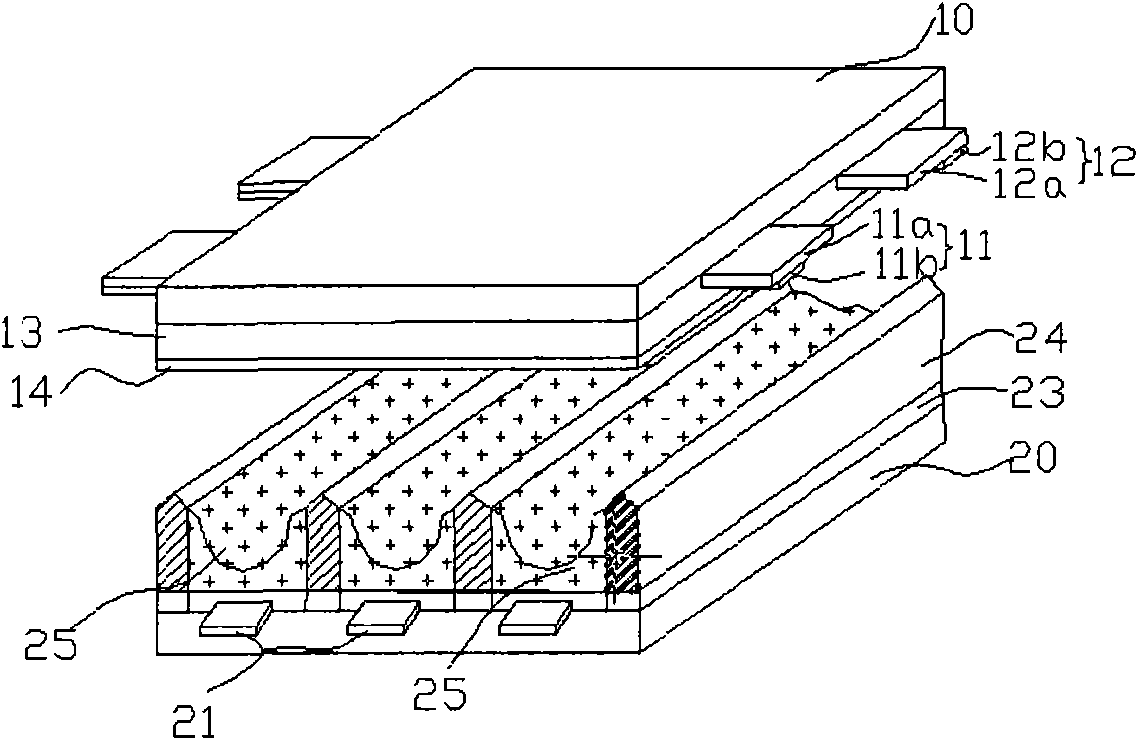

Novel plasma display panel

InactiveCN101719452AReduce ignition voltageHigh light efficiencySustain/scan electrodesAlternating current plasma display panelsEngineeringMetal electrodes

The invention discloses a novel plasma display panel comprising a front substrate and a rear substrate in sealing connection with the front substrate, wherein the front substrate is provided with a discharge electrode comprising a sustaining electrode and a scanning electrode which are extended in parallel; and one of the sustaining electrode and the scanning electrode is a metal electrode, and the other one is a transparent electrode and a bus electrode located on the transparent electrode. The plasma display panel of the utility model is capable of achieving lower firing voltage and higher lighting effect on the substrate at the same time.

Owner:SICHUAN COC DISPLAY DEVICES

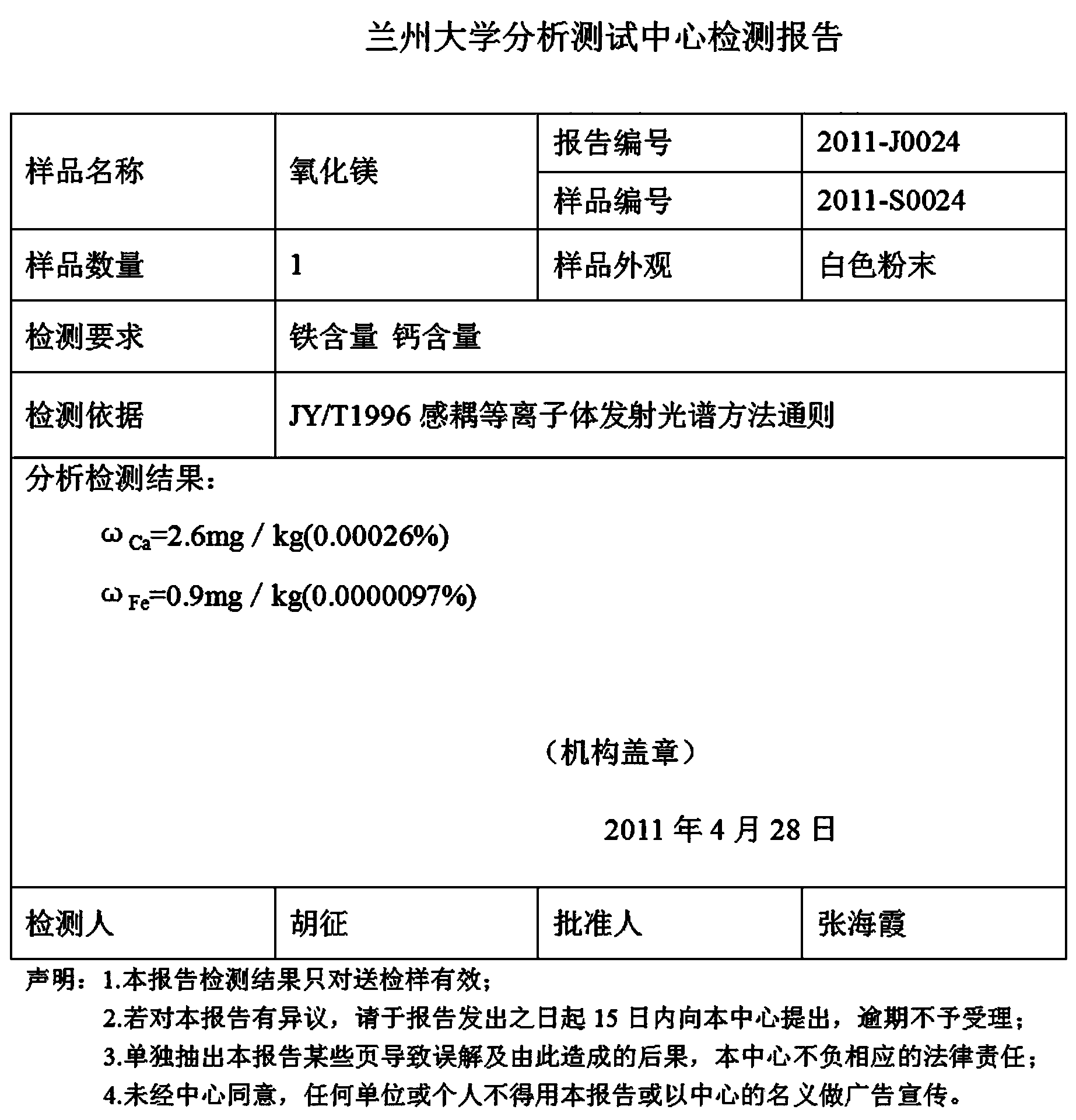

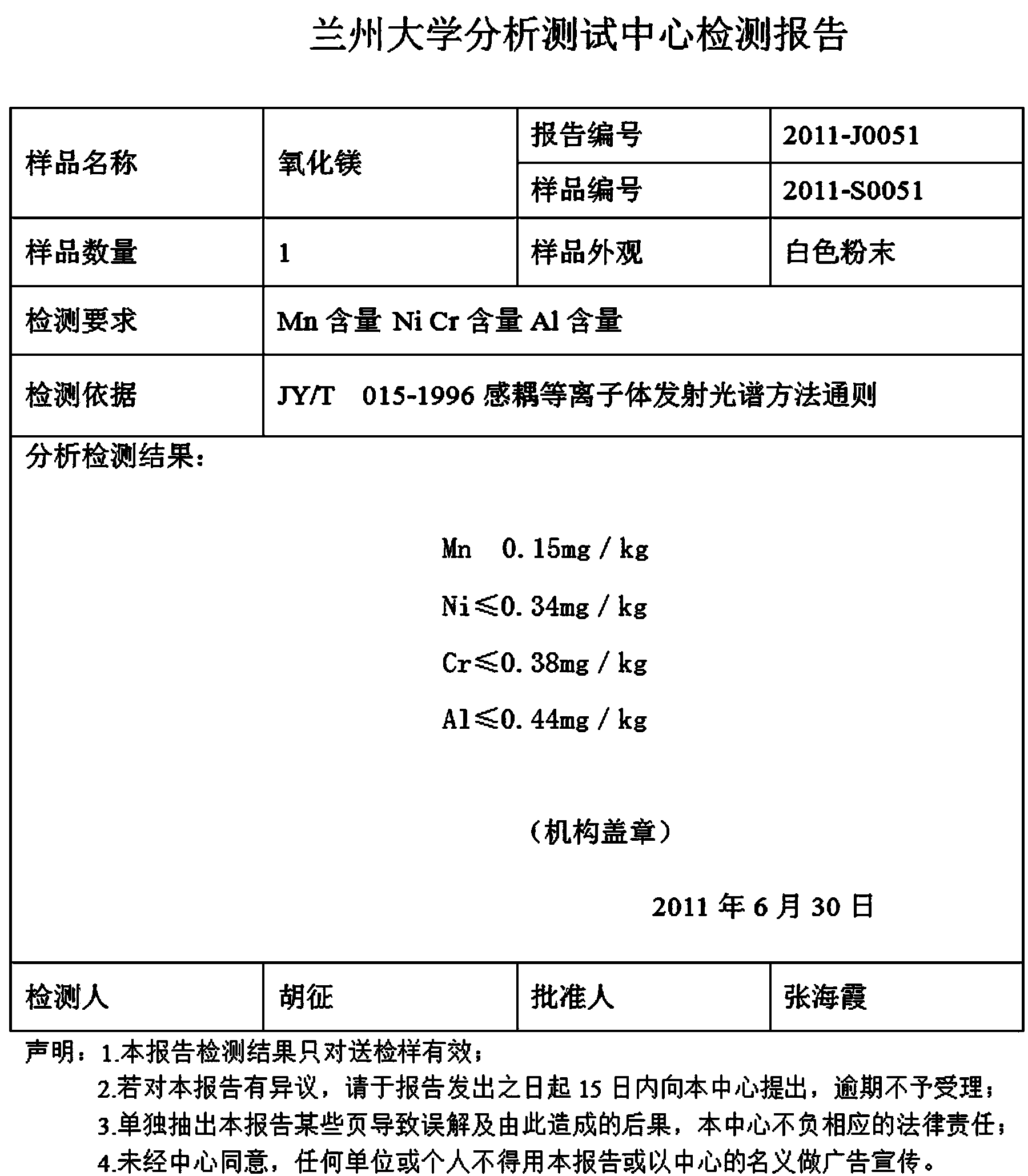

Preparation method of ultrapure magnesium oxide powder

ActiveCN103787376AExtend working lifeShock resistantMagnesiaMagnesium hydroxideOXALIC ACID DIHYDRATELiquid product

The invention discloses a preparation method of ultrapure magnesium oxide powder. The preparation method comprises the following steps of A. dissolving magnesium sulfate heptahydrate in pure water to prepare a magnesium sulfate solution and filtering to remove mechanical impurities and insoluble impurities; B. adding oxalic acid with continuously stirring, ageing repeatedly and carrying out suction filtration to remove calcium impurity; C. dropwise adding hydrogen peroxide into the solution with calcium removed with continuously stirring; D. adding a sodium hydroxide aqueous solution with continuously stirring; standing for stratification after reaction is completed, extracting a supernatant liquid, and removing impurities by a multi-stage precipitation and multi-stage filtration under a normal pressure; and E. putting the filtered clear liquid into a polytetrafluoroethylene reaction kettle, dropwise adding ammonium hydroxide with continuously stirring to obtain a pure magnesium hydroxide turbid liquid, separating a turbid liquid product through centrifugation, washing, filtering, drying, sintering for at least 5 h, and thus ultrapure magnesium oxide powder with a purity of 99.999% can be obtained.

Owner:GANSU KETE OPTICAL TECHNIC MATERIAL

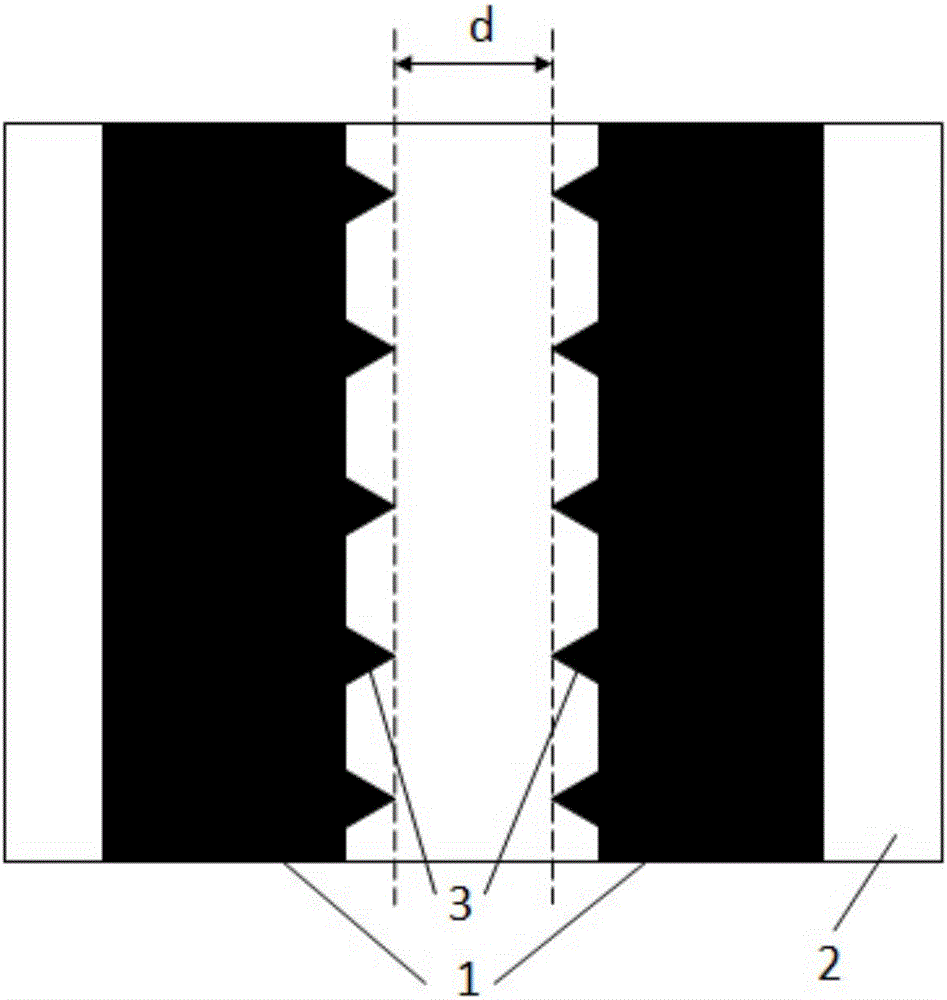

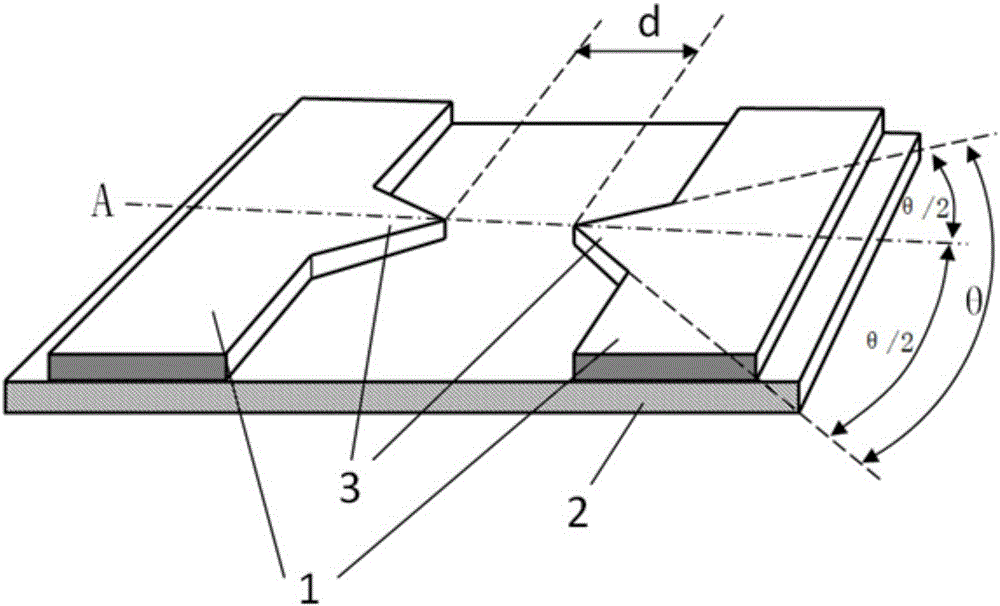

Surface discharge electrode structure capable of lowering discharge voltage

InactiveCN106373841AReduced withstand voltage requirementsReduce manufacturing costDischarge tube/lamp detailsState of artElectric discharge

The invention discloses a surface discharge electrode structure capable of lowering discharge voltage and belongs to the technical field of surface discharge. Specifically the invention relates to a direct current or alternating current surface discharge electrode structure so as to solve problems of overhigh firing voltage and maintaining voltage for electric discharge in technologies of the prior art. The surface discharge electrode structure comprises a substrate and two discharge electrodes symmetrically arranged on the substrate, wherein protruding tips are respectively arranged on side walls, facing toward each other, of the two discharge electrodes; the protruding tips are respectively arranged on ends, facing toward each other, of the discharge electrodes; the protruding tips arranged on the two discharge electrodes are symmetrical. While a discharge current is basically kept unchanged, firing voltage and maintaining voltage for surface electric discharge can be remarkably lowered via the surface discharge electrode structure.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

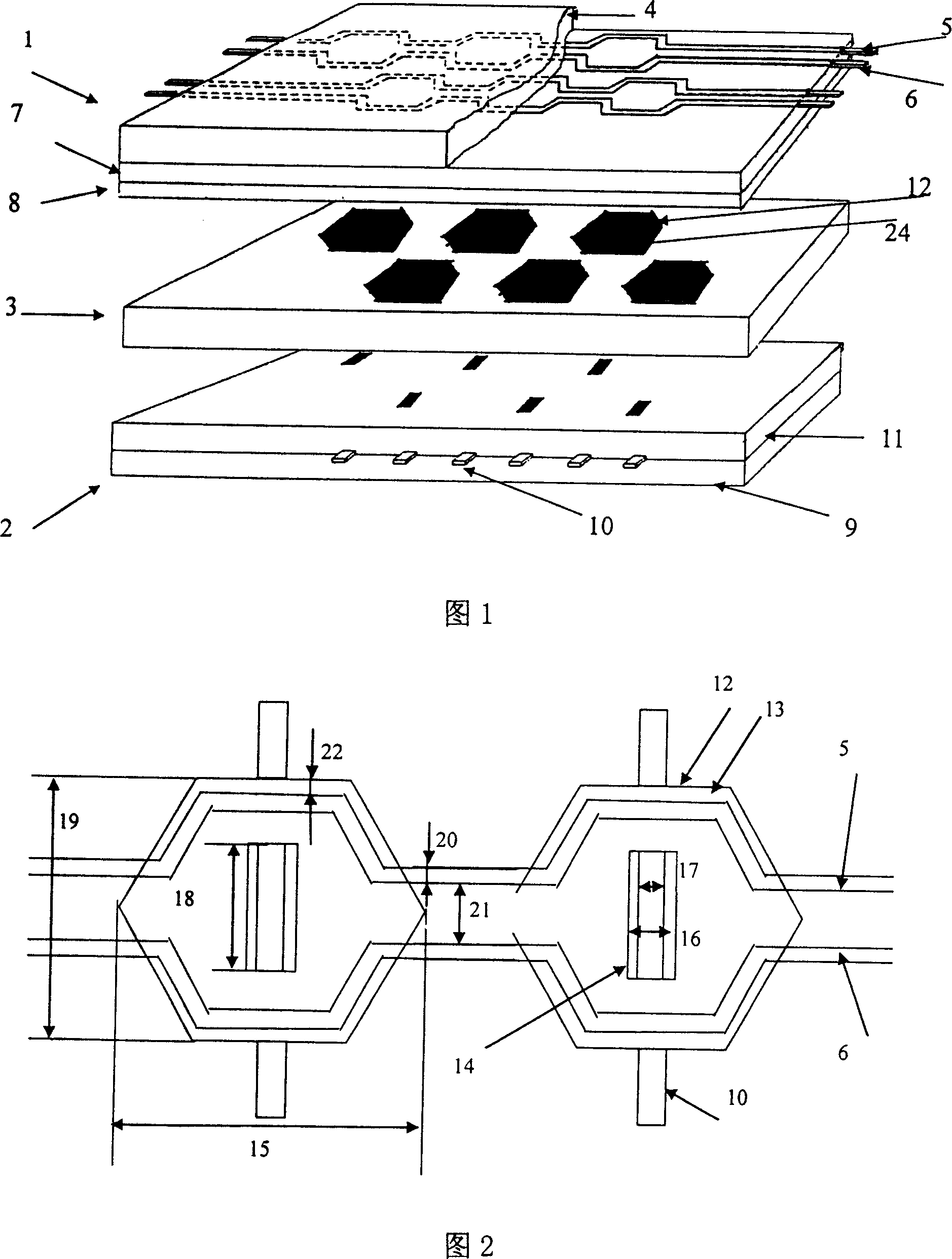

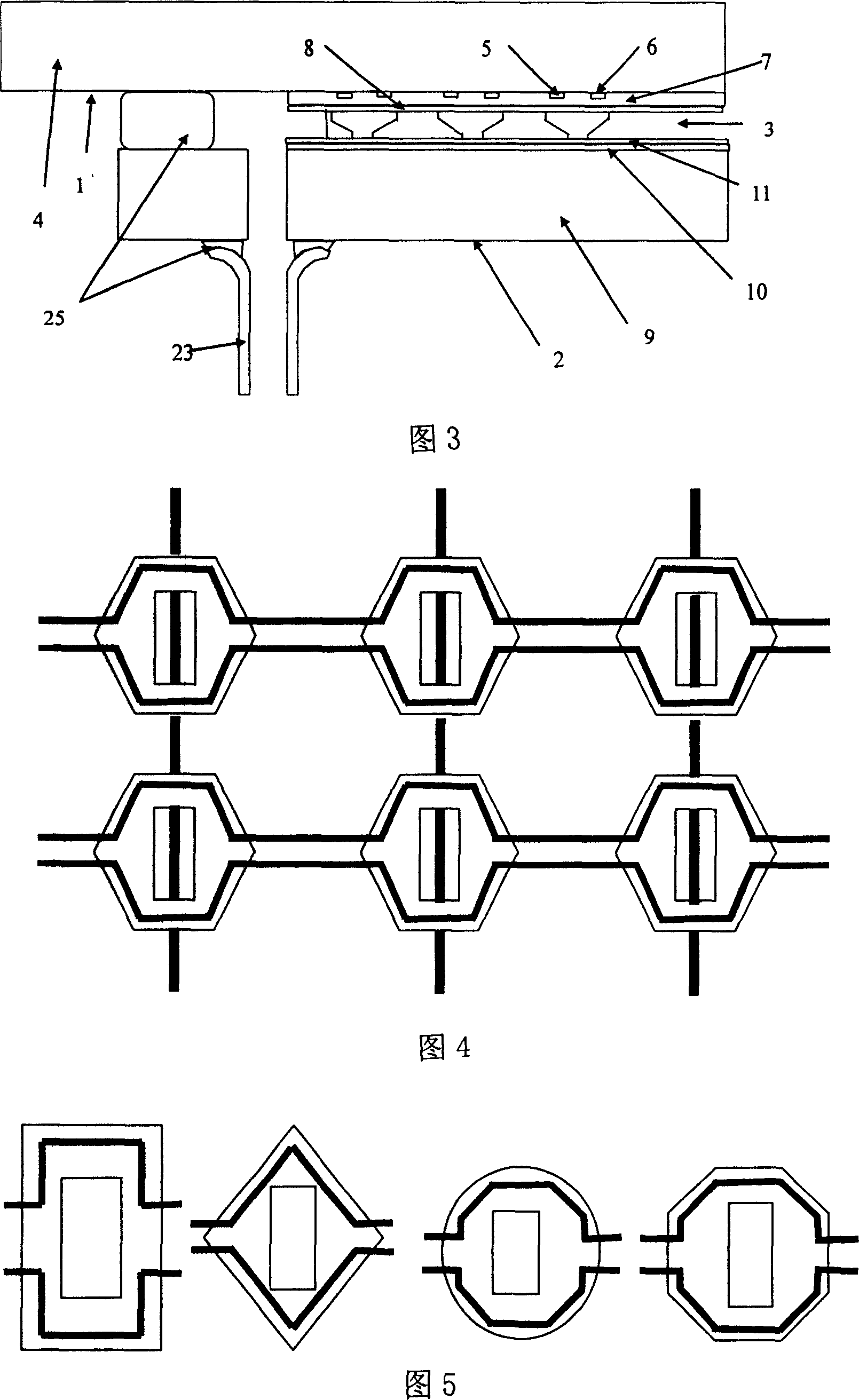

A surface discharge type aperture mask style plasma display plate with novel electrode structure

InactiveCN1963982ALong discharge pathImprove luminous efficiencySolid cathode detailsCold-cathode tubesOptoelectronicsPlasma display

Unlike to current shadow mask plasma display panel or discharge plasma display panel, this invention comprises: a front and back substrates, the conductive shadow mask between substrates for support, a couple of scanning and maintenance electrodes on the front substrate, and the addressing electrode on another substrate to form the discharge unit with the mesh hole of shadow mask. This invention can reduce power consumption.

Owner:NANJING HUAXIAN HIGH TECH CO LTD

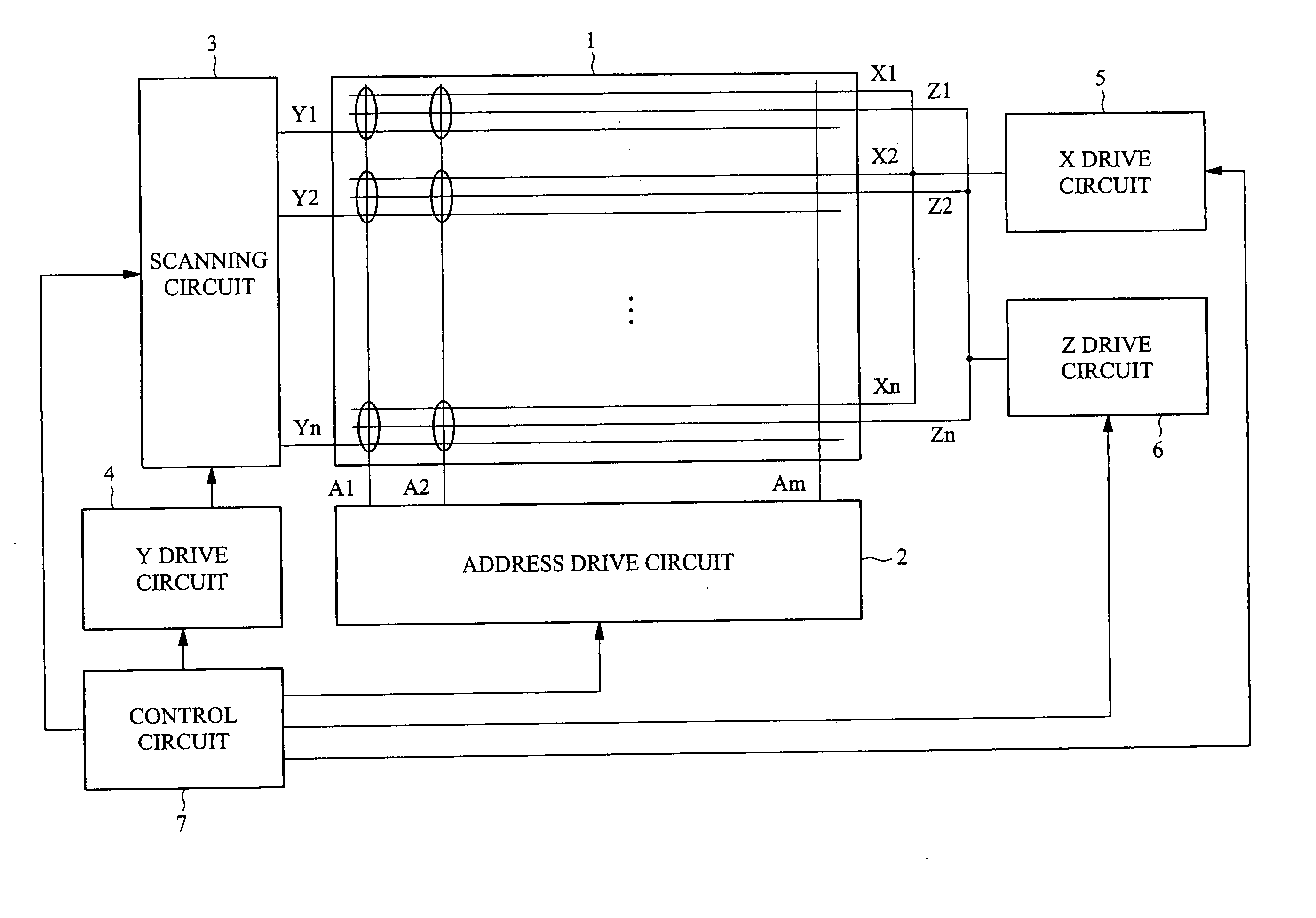

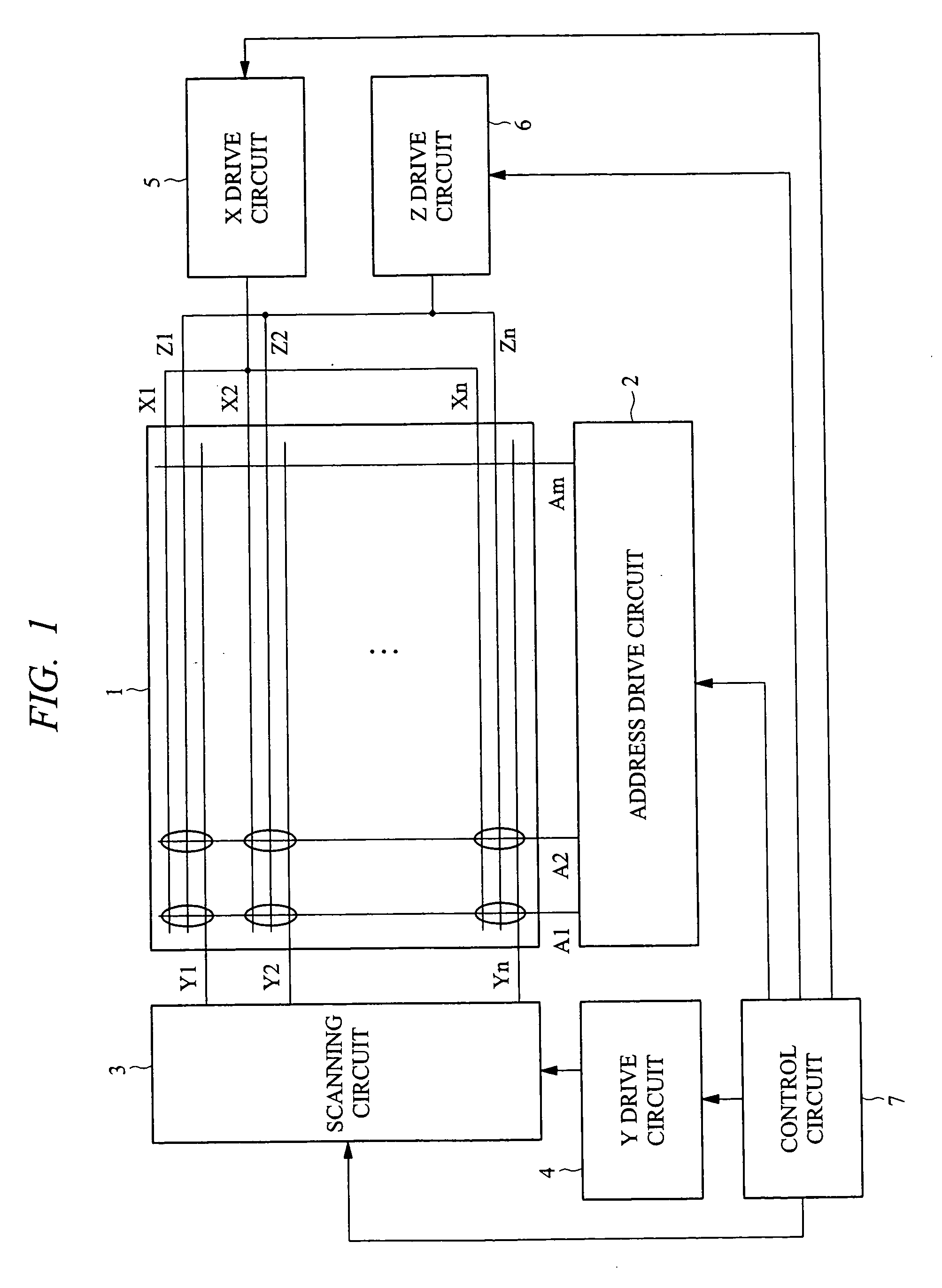

Plasma display panel and plasma display device

InactiveUS20060220998A1Increase brightnessReduce voltageAddress electrodesSustain/scan electrodesPhosphorUltraviolet

A plasma display panel in which firing voltages between any of electrodes are low can be realized. A plasma display panel has a first substrate and a second substrate. The first substrate has a group of laterally extending first electrodes for performing sustain discharge and a group of laterally extending second electrodes which can be independently driven, a group of third electrodes positioned between the first and second electrodes, a dielectric layer covering-them, a group of fourth electrodes extending vertically and provided on the dielectric layer, and a protective layer. The second substrate has barrier ribs provided in parallel to the fourth electrodes so as to divide at least the first to third electrodes in the extending directions, and phosphors for emitting light when excited by an ultraviolet ray.

Owner:FUJITSU HITACHI PLASMA DISPLAY LTD

Plasma panel display adopting mixed protection layer and preparation method of mixed protection layer

InactiveCN101826428AImprove featuresReduce ignition voltageTube/lamp screens manufactureDischarge tube luminescnet screensProportional controlOrganic solvent

The invention provides a plasma panel display adopting a mixed protection layer and a preparation method of the mixed protection layer, relating to the technical field of protection layers applied to plasma panel displays. In the invention, an Mg1-xZnxO crystal with Zn content being larger than 30 percent and smaller than 50 percent is used as a first source, an Mg1-xZnxO crystal with Zn content being larger than 0 percent and smaller than10 percent is used as a second source, the first source and the second source are mixed in a certain proportion to form a third source, the mixed proportion is controlled as follows: the first source occupies 50-70 percent of the total weight, the second source occupies 30-50 percent of the total weight, the third source is dispersed into a volatile organic solvent according to the proportion that the third source occupies 5-10 percent of the solvent weight, the third source is evenly dispersed into the solvent by ultrasonic treatment, the solvent is evenly sprayed on the surface of the prepared MgO film by adopting a spray pistol, and the mixed protection layer is formed on the surface of the MgO film when the organic solvent volatilizes. The plasma panel display adopting the mixed protection layer reduces the statistic response time and improves secondary electron emission characteristics.

Owner:SOUTHEAST UNIV

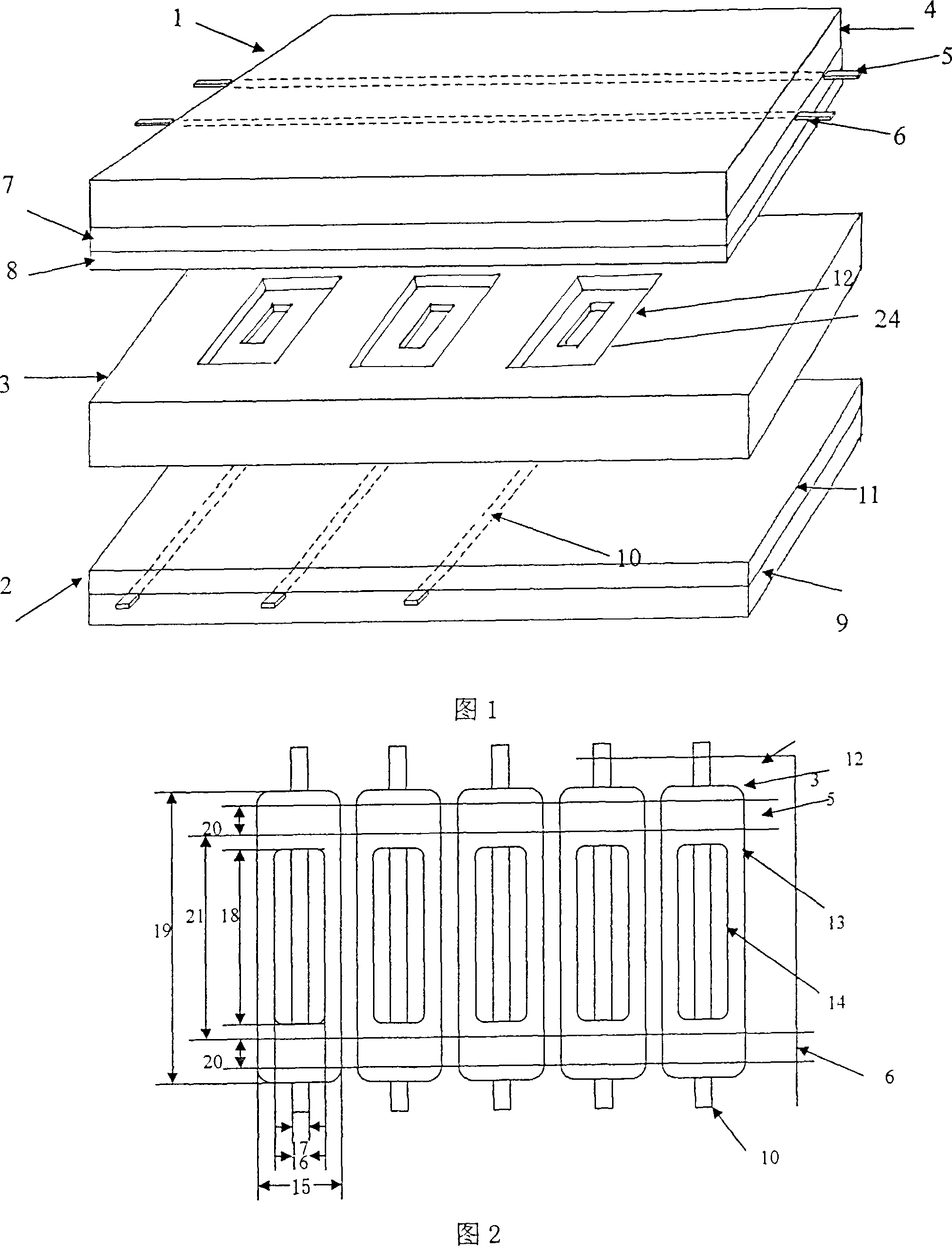

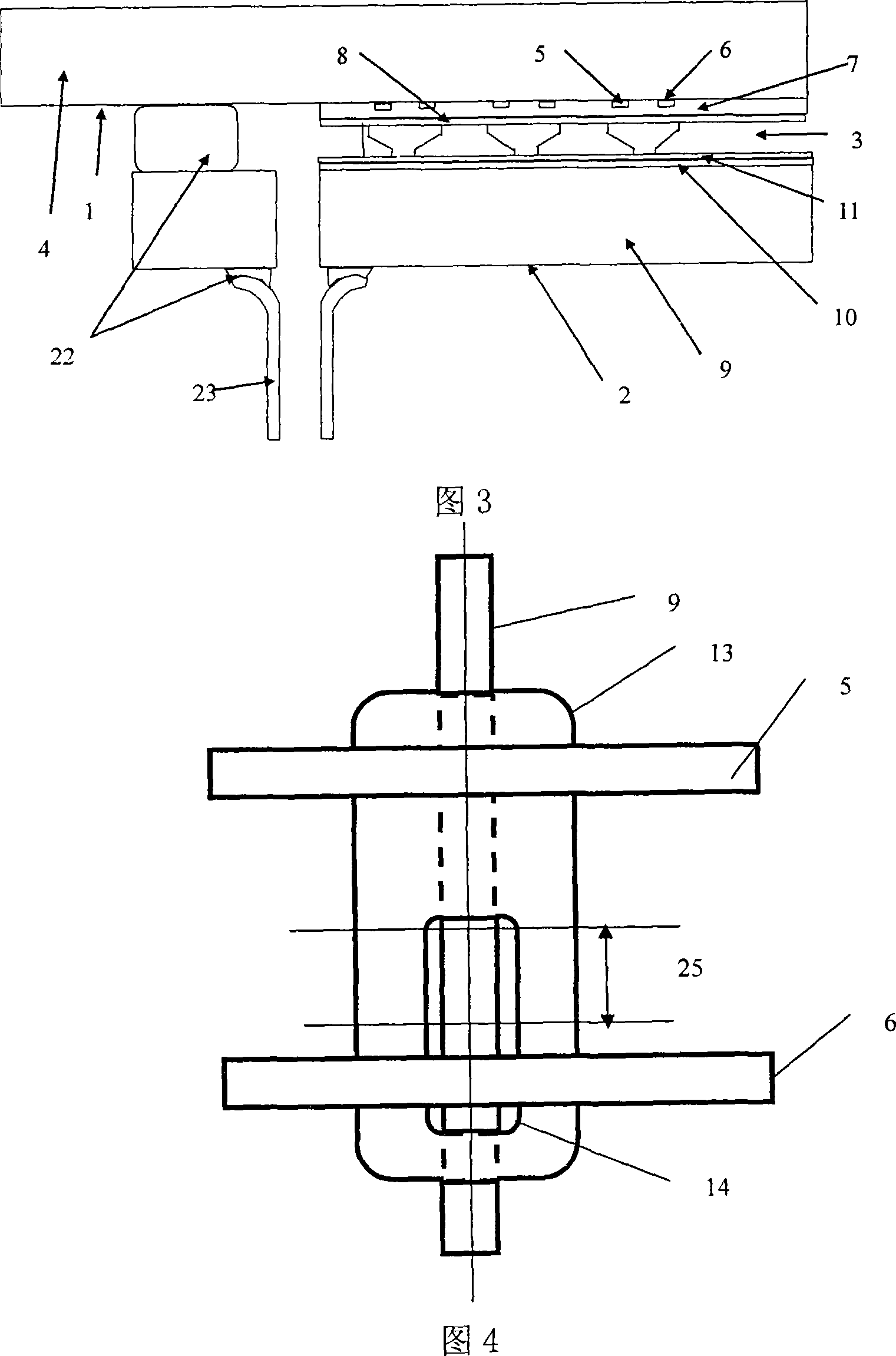

Commingle discharging shadow mask type plasma display panel and driving method thereof

InactiveCN101202192AReduce ignition voltageLong discharge pathStatic indicating devicesSolid cathode detailsDisplay boardBarrier preparation

The invention discloses a mixed discharging shadow mask plasma display board, aiming at the problems caused by a subtend discharging adopted by the existing shadow mask plasma display board and making use of the advantages of the barrier preparation of shadow mask. The display board comprises a front base board, a back base board and a conductive shadow mask which comprises a grid-hole array and is clamped between the front and back base boards to support the base boards. A group of scanning electrodes and maintaining electrodes which are arranged on the front base board, an address-searching electrode arranged on the back base board and the grid hole of the conductive shadow mask form a discharging unit. The invention also discloses a driving method with combined subtend discharging and surface discharging. The invention has the advantages that the fire voltage is low; the brightness and illumination efficiency are high; the power consumption is low.

Owner:NANJING HUAXIAN HIGH TECH CO LTD

Process and device for reducing the ignition voltage of plasmas operated using pulses of pulsed power

InactiveUS20020043336A1Low powerPrevent defective operating stateCellsLiquid surface applicatorsCharge carrierLong pulse

Process and device for reducing an ignition voltage of power pulses in plasmas operated in a pulsed manner with long pulse-off times. The process includes generating a power pulsed plasma at a pulse duty factor, the pulse duty factor being a ratio of pulse-on time to pulse-off time, and at least before the beginning of the pulse-on time of the power pulses, producing charge carriers using an additional plasma discharge at a lower power than that of the power pulses. The device includes a vacuum chamber including at least one pump system, an arrangement for producing plasma, the arrangement including at least one anode and at least one cathode, an energy source connected to the cathode and the anode which cab be pulsed in the frequency range of between approximately 10 Hz to approximately 1 MHz, and a mechanism for one of producing an additional plasma discharge.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

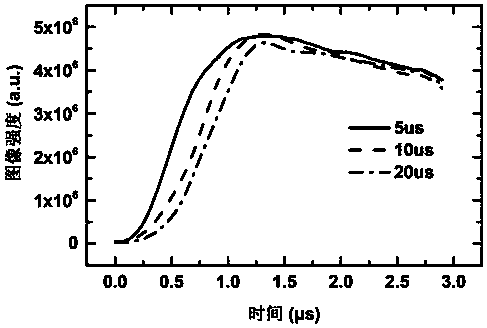

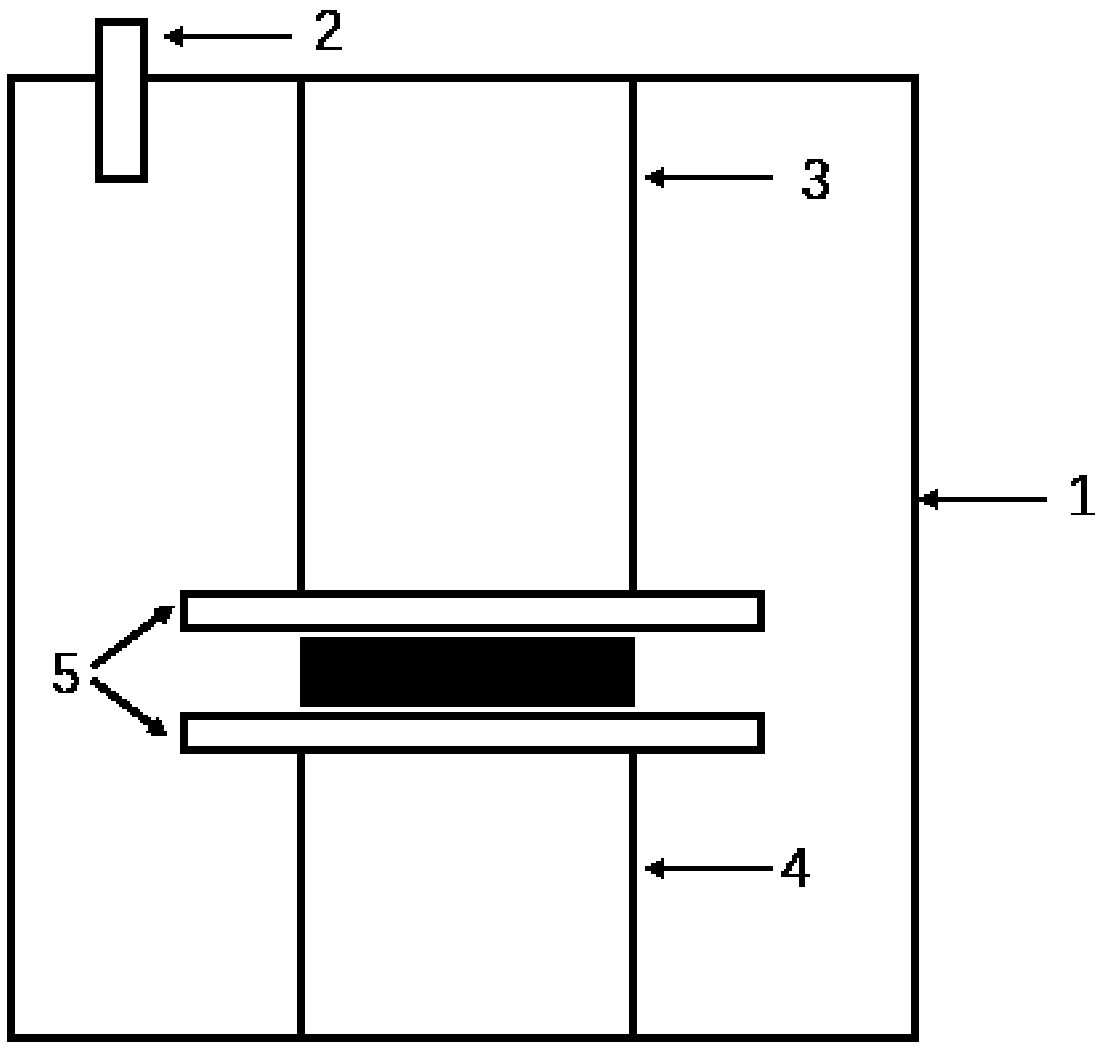

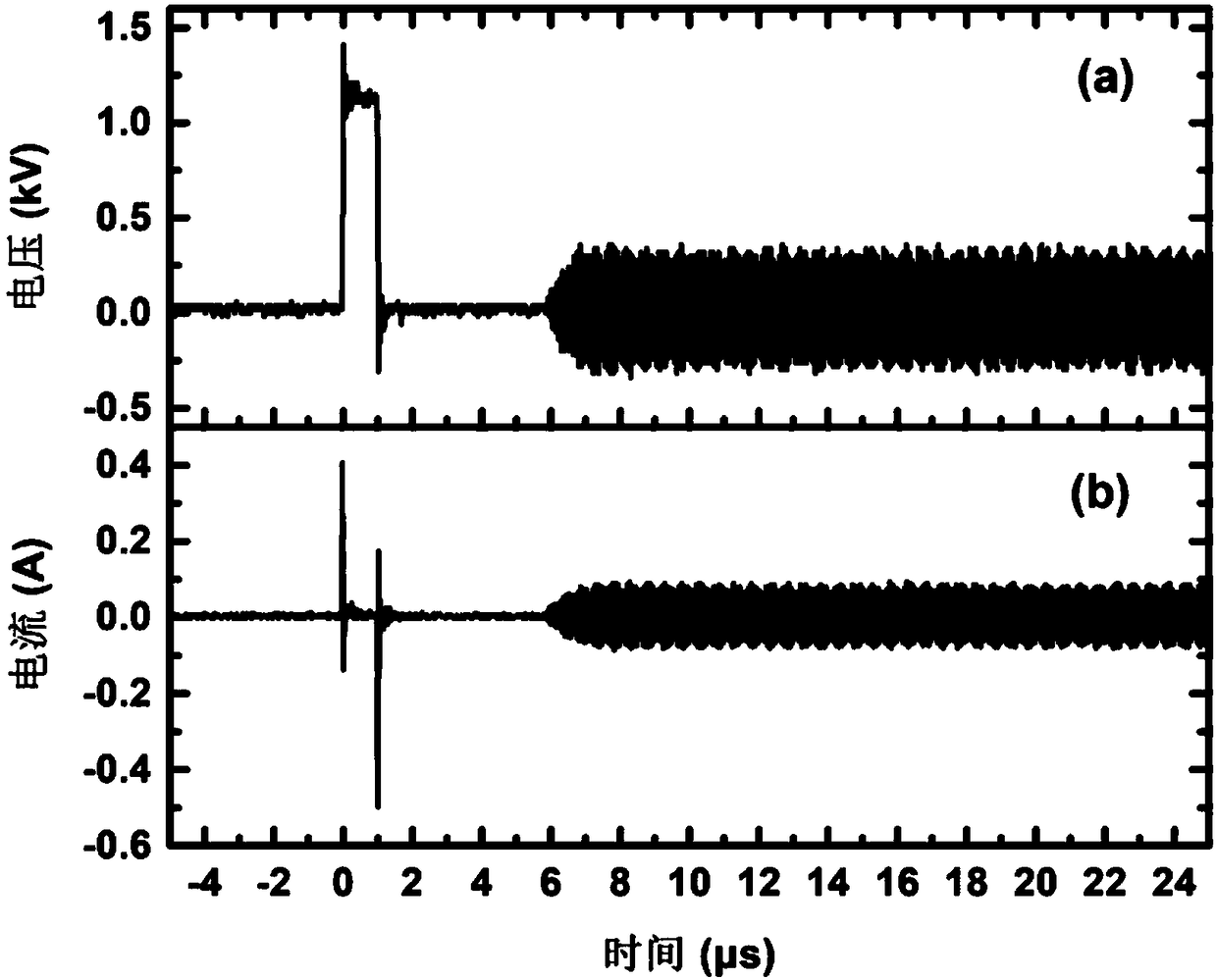

A device and method for assisting radiofrequency glow discharge of a flat plate by an atmospheric pressure pulse

InactiveCN109065433AShorten the glow timeHigh densityElectric discharge tubesDielectric plateEngineering

The invention discloses a device and method for assisting the RF glow discharge of a flat plate by an atmospheric pressure pulse. The device is a plasma discharge reactor, which comprises a dischargechamber filled with a discharge gas; An air inlet is arranged at the top of the discharge chamber, an upper electrode connected with a high-voltage power source and a lower electrode connected with aradio frequency power source are arranged in the discharge chamber, a pair of dielectric plates distributed up and down are arranged between the upper electrode and the lower electrode, the upper dielectric plate is connected with the upper electrode, and the lower dielectric plate is connected with the lower electrode. The method comprises the following steps: the discharge gas is introduced intothe discharge chamber from the air inlet, and the upper electrode is connected with a pulse power supply to form pulse discharge; after the pulse discharge is finished, pulse modulated RF alternatingcurrent flows through the lower electrode so as to generate RF discharge between the dielectric plates. The invention utilizes the active particles generated in the pulse discharge to assist the radio frequency discharge to start glow, reduces the glow time and the maintenance voltage of the glow time.

Owner:DONGHUA UNIV

Method for manufacturing rare earth aluminate substrate fluorescent powder

ActiveCN101182413ASynthesis temperature is lowReduce dosageLuminescent compositionsPhosphorRare earth

The invention provides a production method of aluminate matrix phosphor, comprising seven steps as follows: pretreatment of raw materials, mixing of wet method, primary high-temperature air synthesis, primary smashing and grading, secondary high-temperature reduction, secondary grading and surface coating; finally the aluminate phosphor product with the surface coated with MgO film can be prepared. The method of the invention completely combines the advantages of wet chemical method, solid-phase reaction method, and modern air smashing and grading technology; the use of pretreatment of the raw materials for synthesis and the mixing process of wet method improves the reaction activity of the raw materials for synthesis; at the same time, the combination of the high-temperature solid-phase method and the air grading technology can achieve the effective control over the central grain size and distribution of the phosphor; finally the phosphor product of high luminous efficiency, fine grain size and centralized distribution can be prepared; the invention has significant application prospects.

Owner:JIANGSU BREE OPTRONICS CO LTD

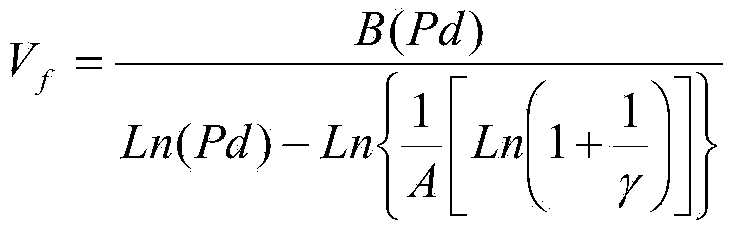

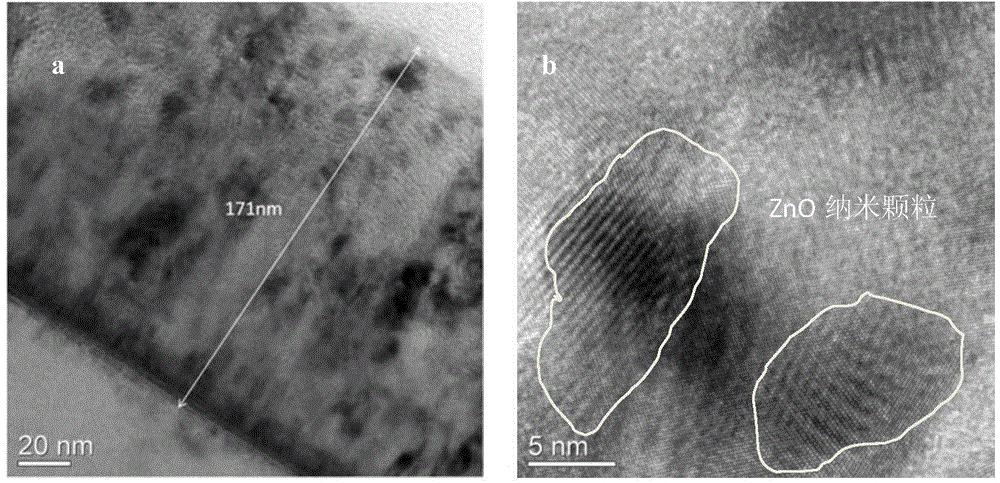

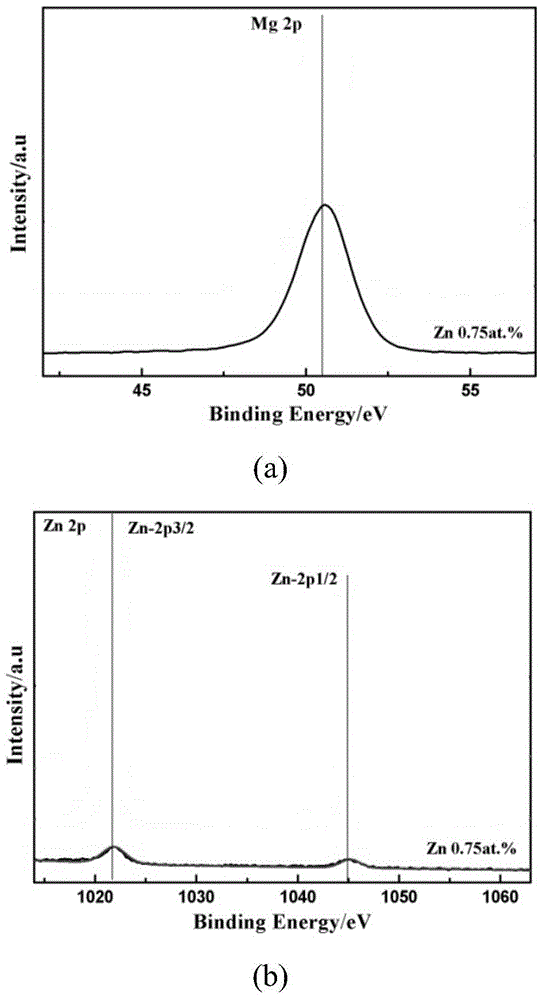

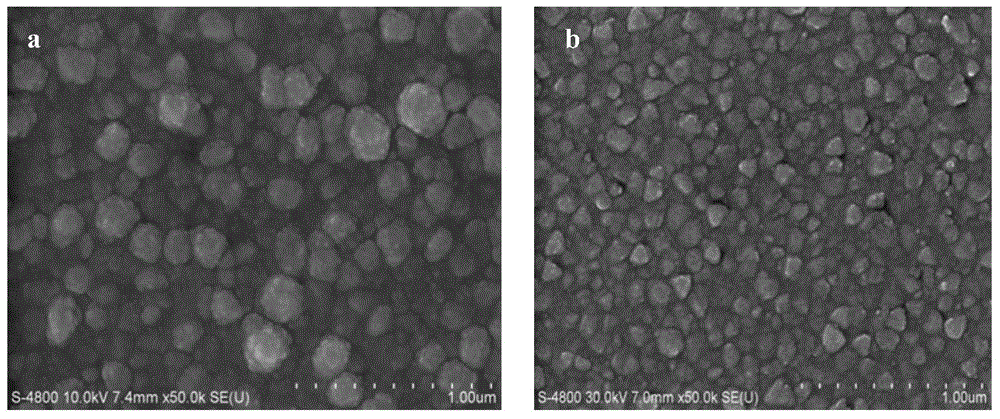

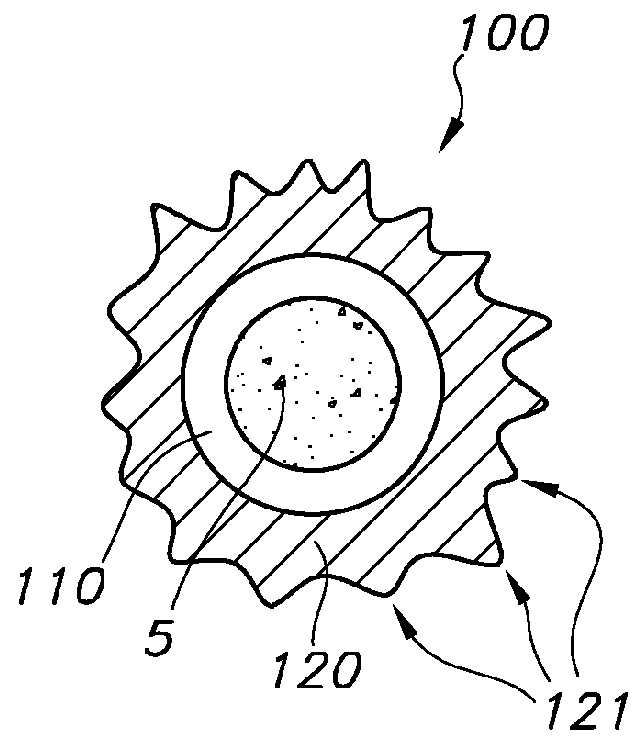

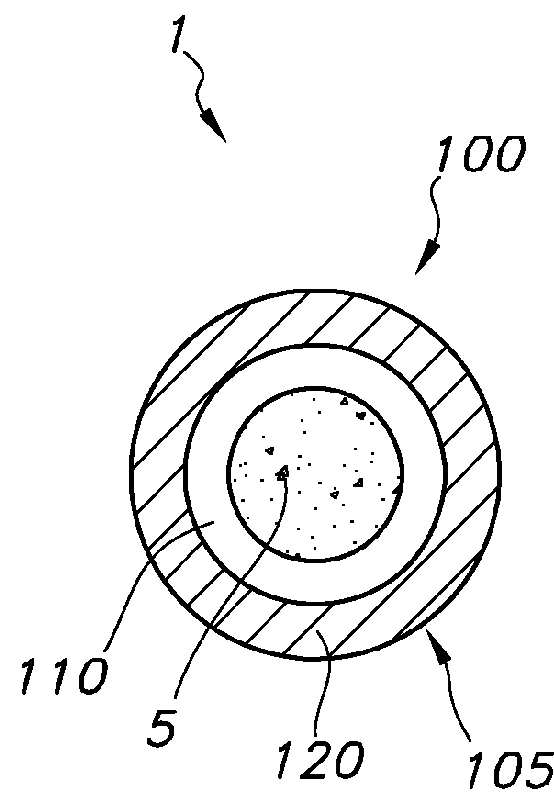

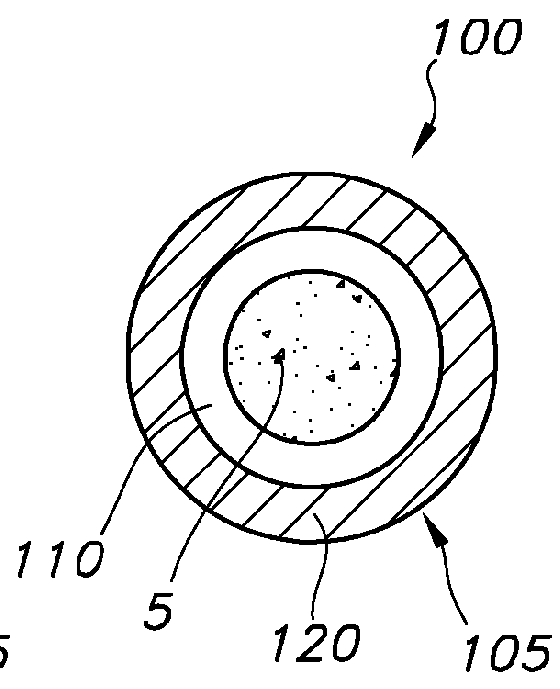

MgO/ ZnO composite dielectric protection film and preparation method thereof

ActiveCN104124123AImprove secondary electron emission coefficientIncrease roughnessAlternating current plasma display panelsCold cathode manufactureDielectricDisplay device

The invention discloses an MgO / ZnO composite dielectric protection film and a preparation method thereof. The composite dielectric protection film comprises a ZnO nanometer wire; an MgO film layer is arranged on the surface of the ZnO nanometer. According to the MgO / ZnO composite dielectric protection film and the preparation method, a ZnO seed crystal layer is arranged on a substrate and produces the ZnO nanometer wire, then the MgO film is arranged on the surface of the ZnO nanometer wire by a depositing manner, and thus the roughness of the surface of the composite dielectric protection film is improved, and as a result, the secondary electron emission coefficients of the composite dielectric protection film are increased; the dielectric protection film with high secondary electron emission coefficients can effectively lower down the firing voltage of a display, and thereby, the power consumption and cost of a PDP (Plasma Display Panel) display are decreased to some extent, and as a result, the service life of a device is prolonged, and the stability of working voltage of the display is improved.

Owner:宁波云涂科技有限公司

MgO/ ZnO composite medium protecting film and preparation method thereof

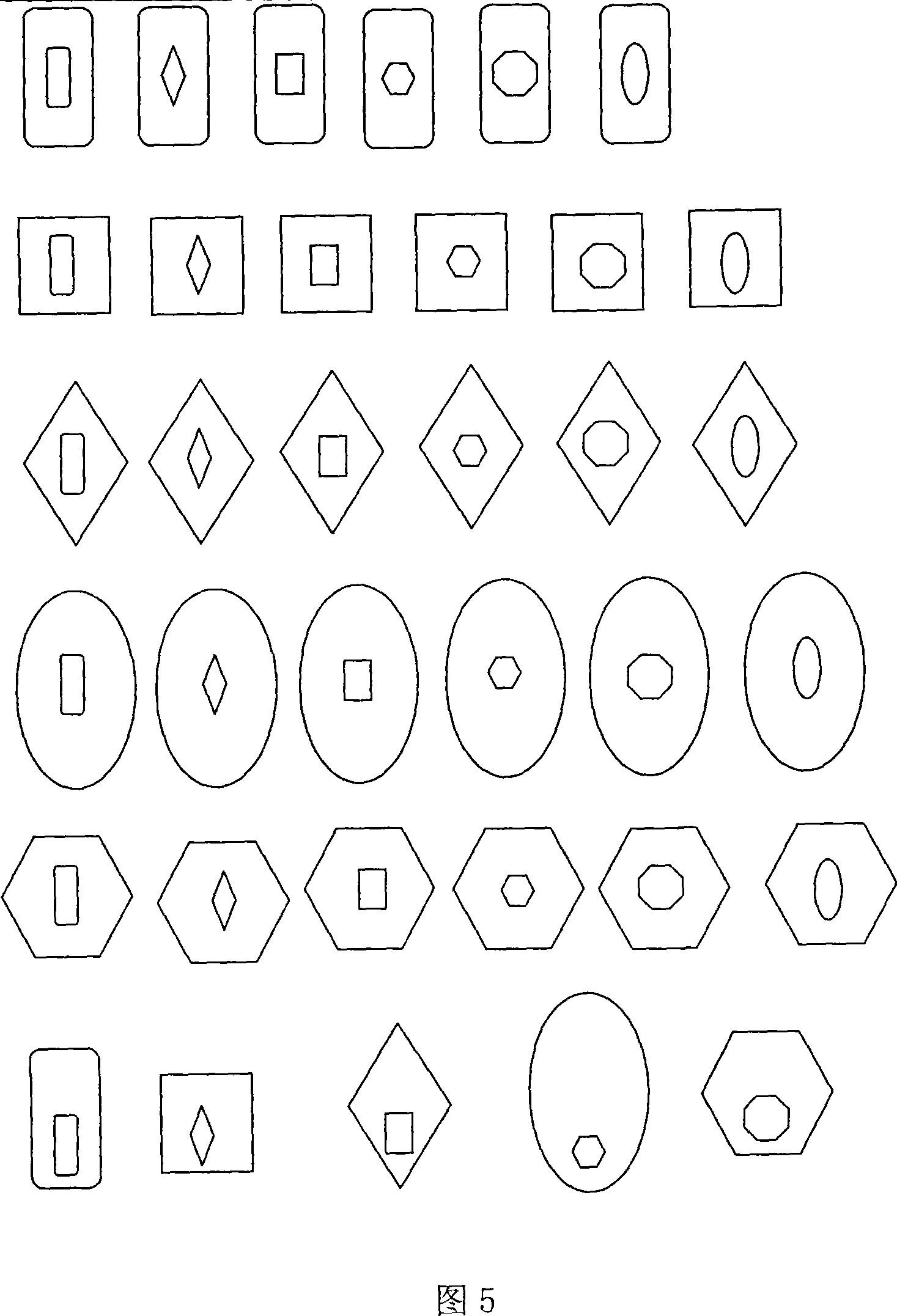

InactiveCN104599923AIncreased secondary electron emission coefficientReduce ignition voltageGas-filled discharge tubesCold cathode manufactureSecondary electronsVoltage

The invention discloses an MgO / ZnO composite medium protecting film and a preparation method thereof. The composite medium protecting film comprises an MgO film in which diffusely distributed ZnO particles are doped. According to the MgO / ZnO composite medium protecting film, the ZnO particles are doped in the MgO film, so that the shapes of the surface particles are changed from elliptic shapes into triangular shapes; the secondary electron emission coefficients of the composite medium protecting film are increased, the firing voltage of a display can be effectively reduced, and therefore, the power consumption and cost of a PDP display can be certainly reduced, the service life of a device can be prolonged, and the stability of the working voltage of a display device can be improved.

Owner:XI AN JIAOTONG UNIV

Vacuum ultraviolet flat light source

InactiveCN101540262ASuitable for different applicationsHigh strengthLamp detailsEngineeringAlternating current

The invention discloses a vacuum ultraviolet flat light source which comprises a front base plate and a rear base plate, wherein the front base plate is made of quartz glass, and a discharge cavity is arranged between the front base plate and the rear base plate; the front base plate is provided with paired parallel electrodes and adopts surface discharge, or the electrodes are arranged on the front base plate and the rear base plate, and an opposite type discharge mode is adopted; the surfaces of the electrodes are also provided with dielectric layers which are provided with protective films; the discharge cavity is filled with working gas with certain air pressure, and the working gas with certain air pressure can be formed by the mixed gas of Ne gas and Xe gas. When alternating-current pulses are brought between the electrodes, the working gas discharges, and 147nm and 172 nm vacuum-ultraviolet light is continuously generated under the action of keeping current pulses and sent to the outer surface of the vacuum ultraviolet flat light source, which needs to be processed, by the quartz base plates. The invention can generate a surface light source of the vacuum-ultraviolet light, thereby having superiority for processing surfaces with large areas; and the invention can generate single-surface and double-surface vacuum ultraviolet flat light sources, thereby being suitable for different application occasions.

Owner:SOUTHEAST UNIV

Plasma display panel without transparent electrode structure and methods for manufacturing upper substrate thereof

InactiveCN101685750AAvoid yellowingBarrier contactAlternating current plasma display panelsSolid cathode detailsSilver electrodeEvaporation

The invention discloses a plasma display panel without a transparent electrode structure, which comprises an upper substrate and a lower substrate sealed with the upper substrate, wherein the upper substrate is provided with a first magnesium oxide layer positioned on the surface of upper substrate glass, a silver electrode X and a silver electrode Y which are positioned on the surface of the magnesium oxide layer, a dielectric layer positioned on the surfaces of the silver electrode X and the silver electrode Y, and a second magnesium oxide layer positioned on the surface of the dielectric layer. The invention also discloses two methods for manufacturing the plasma display panel without the transparent electrode structure, namely an electron beam evaporation method and a magnetron sputtering method. The manufacturing cost is reduced and the brightness is increased.

Owner:四川世纪双虹显示器件份有限公司

Semi-closed constant-pressure dual-frequency large area glow discharge experimental device

The invention discloses a semi-closed constant-pressure dual-frequency large area glow discharge experimental device comprising a quartz glass cylinder, sealing plates, electrodes and a connecting post. The upper and lower sealing plates are connected and fixed through supporting columns and fixing bolts. The middle position between the upper and lower sealing plates is provided with the electrodes, and the electrodes are sealed through the quartz glass cylinder. The upper part of one side of the quartz glass cylinder is provided with a gas inlet, and different discharge gases are piped in through the gas inlet. The lower part of the other side of the quartz glass cylinder is provided with a gas outlet. The electrodes are connected with an external plasma power supply through the upper connecting post. The plasma ignition voltage can be significantly reduced, the device can be used for plasma discharge of toxic and hazardous gases because of the semi-closed environment, and the doubleelectrodes can be driven by dual power supplies of different frequency combinations so that large plasma density can be acquired and the range of application is wide.

Owner:QINGHAI NORMAL UNIV

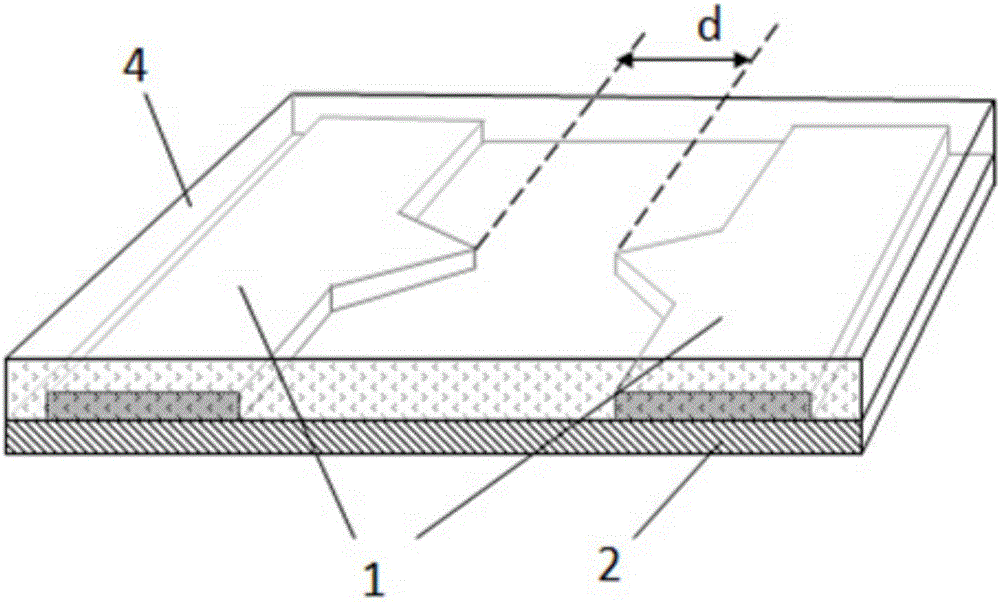

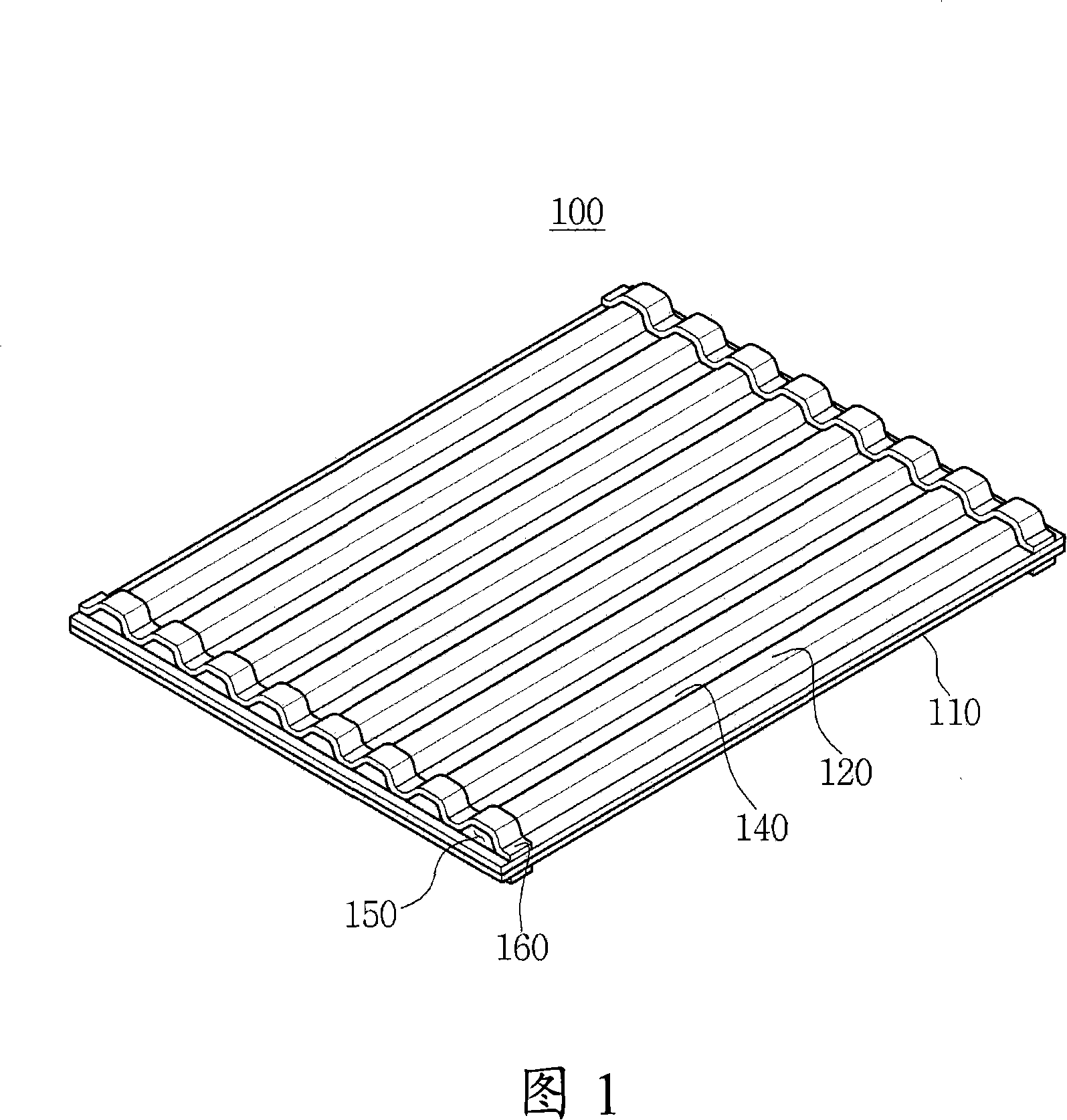

Surface light source device having secondary electron emission layer, method of manufacturing the same, and backlight unit having the same

InactiveCN101137256AReduce ignition voltageLow calorific valueGas-filled discharge tubesElectroluminescent light sourcesSputteringIon exchange

There is provided a substrate for a surface light source device, comprising a first secondary electron emission layer including crystalline magnesium oxide (MgO) powder on a surface of the substrate. There is also provided a surface light source device comprising a first substrate and a second substrate facing each other at a predetermined distance between which a discharge space is formed; and an electrode to apply a discharge voltage to the discharge space, wherein a first secondary electron emission layer including crystalline MgO powder is formed on a surface of at least one of the first substrate and the second substrate. Preferably, the crystalline MgO powder is obtained by grinding an MgO sputtering target. There is provided a backlight unit comprising a surface light source device including a discharge space formed between a first substrate and a second substrate, an electrode to apply a discharge voltage to the discharge space, and a first secondary electron emission layer including crystalline MgO powder on a surface of at least one of the first substrate and the second substrate; a case to receive the surface light source device; and an inverter to supply a discharge voltage to the electrode. Preferably, a second secondary electron emission layer ion-exchanged with a secondary electron emitting material is formed under a surface of the substrate.

Owner:SAMSUNG CORNING CO LTD

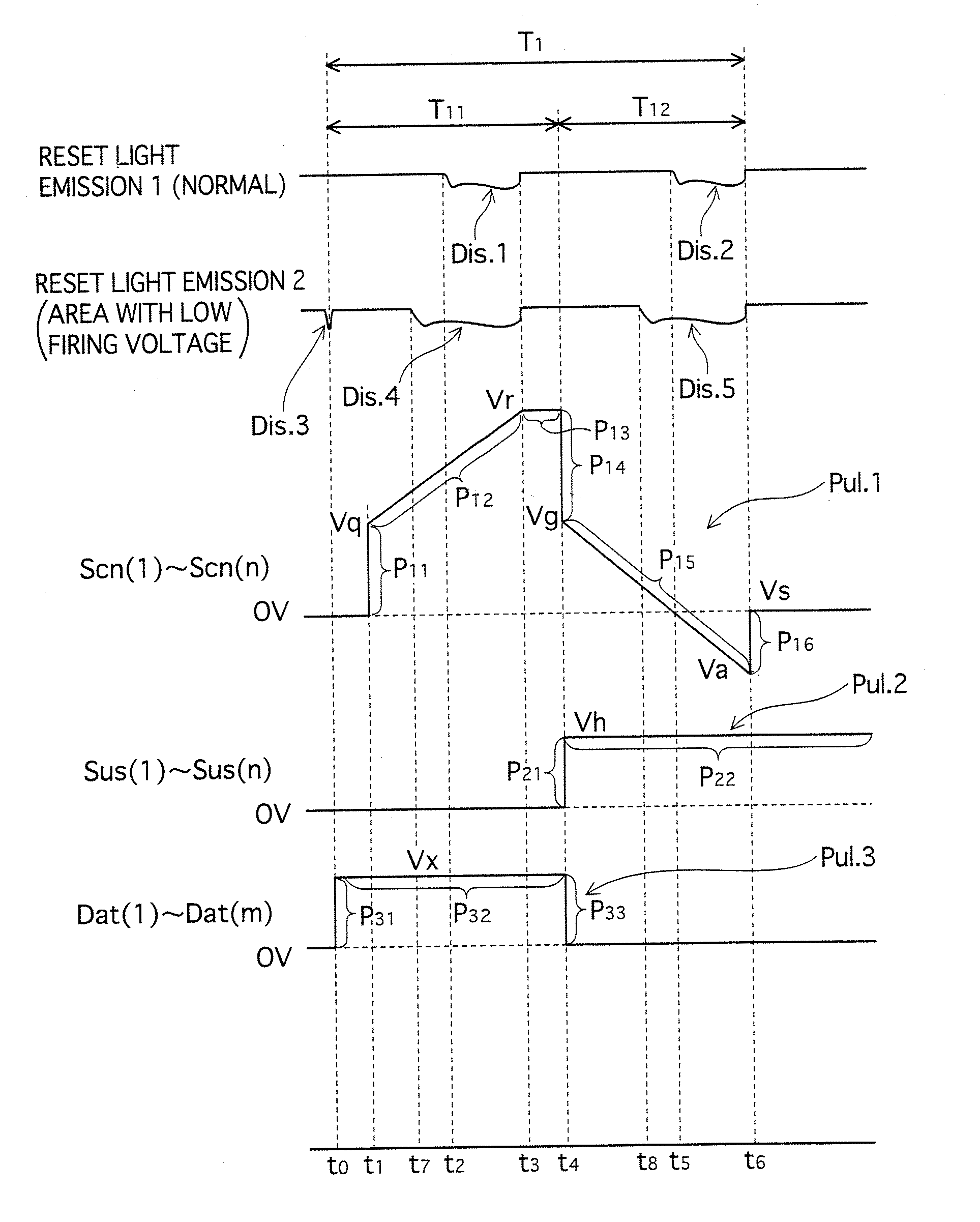

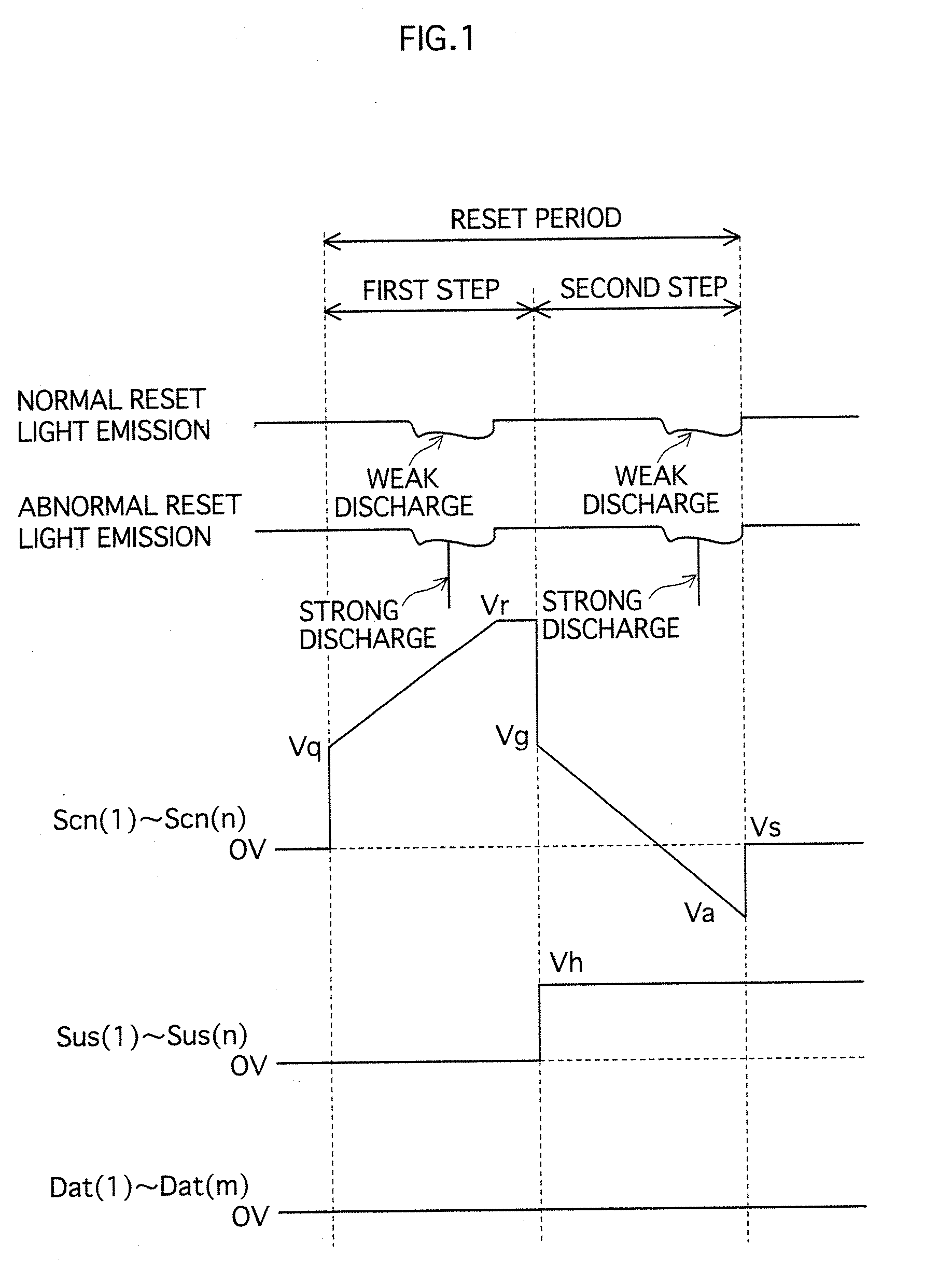

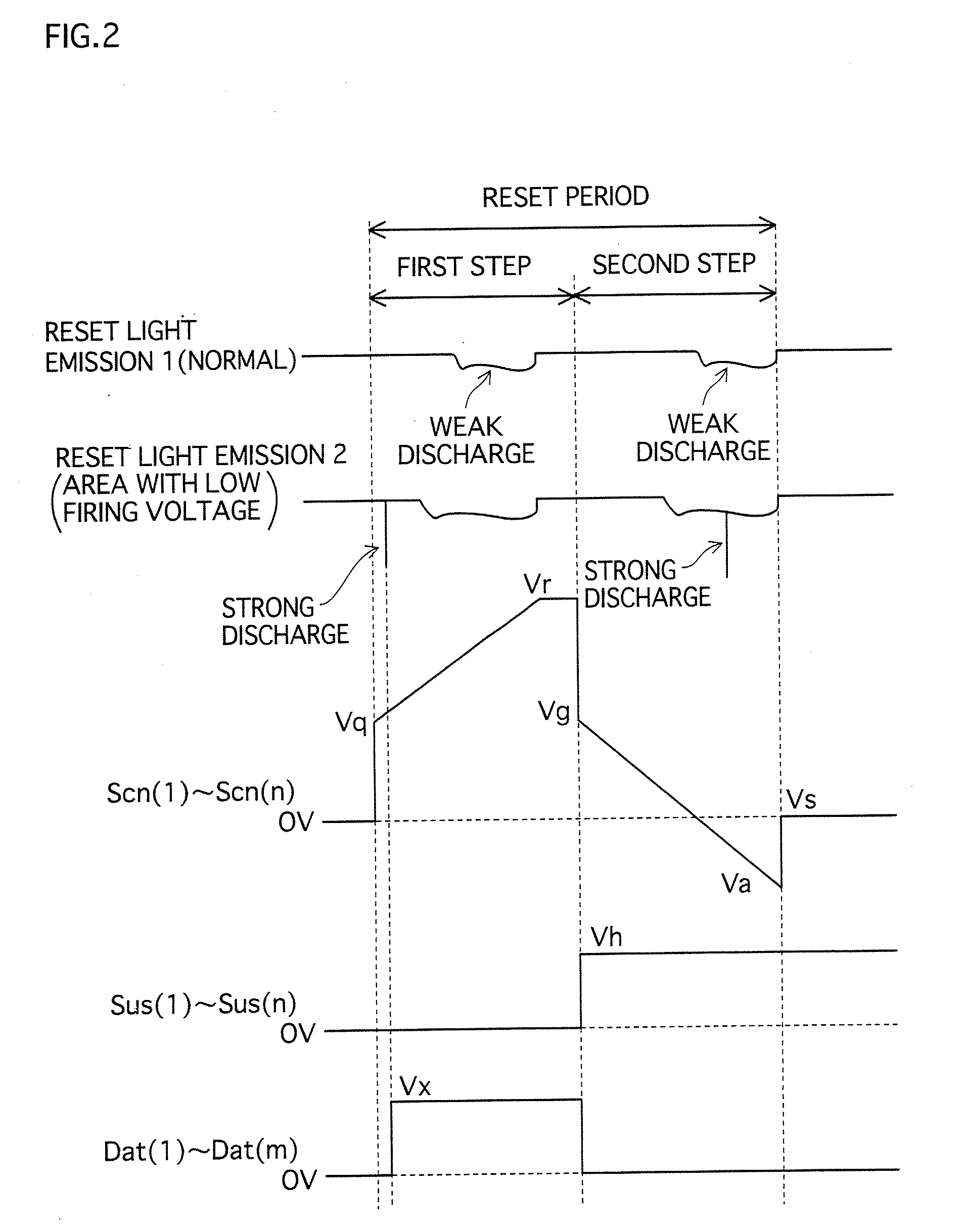

Plasma display panel device and drive method thereof

InactiveUS20090009436A1Reduce ignition voltageControl generationStatic indicating devicesPotential differenceEngineering

Provided are a PDP device and a drive method thereof which restrict the generation of an erroneous discharge in the all-cell reset period and to restrict the appearance of flickers in the areas with low grayscale levels even if some areas have a lower firing voltage than the other areas due to variation of a property in the panel surfaces or due to a long-term driving, or even if the voltage applied to the address electrode is increased with the pursuit of high definition.The pulse Pul.3 is applied to address electrodes Dat at timing t0 prior to timing t1 when the potential of the scan electrodes Scn is increased to Vq(V). In this drive method, voltage Vx(V) is applied to address electrodes Dat so that there is no potential difference between the scan electrodes Scn and the sustain electrodes Sus at timing t0 when discharge Dis.3 is generated. Accordingly, the discharge Dis.3, which is generated between the scan electrodes Scn and the sustain electrodes Sus due to reduction in the firing voltage, does not become a trigger for extending to the scan electrodes Scn to generate an erroneous discharge.

Owner:PANASONIC CORP

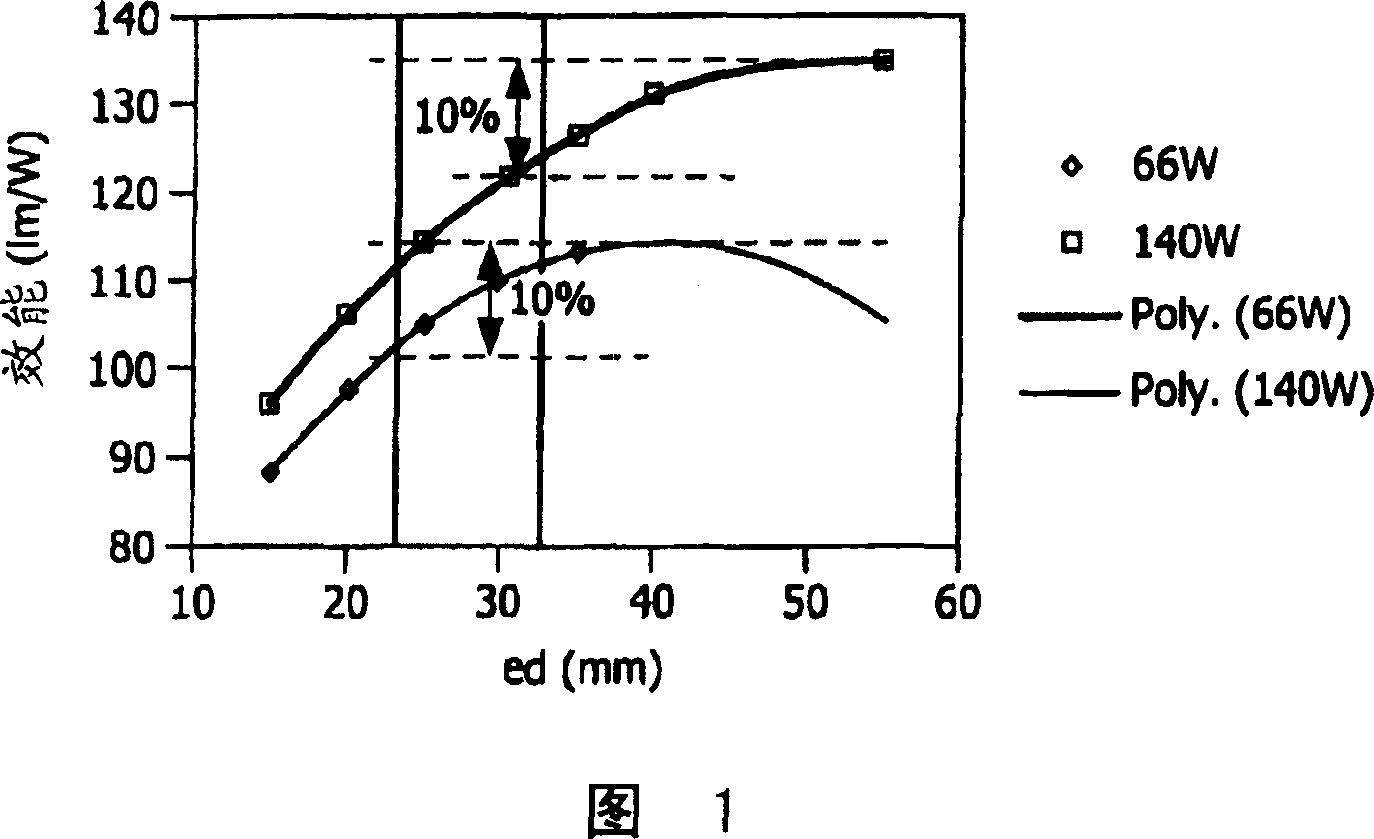

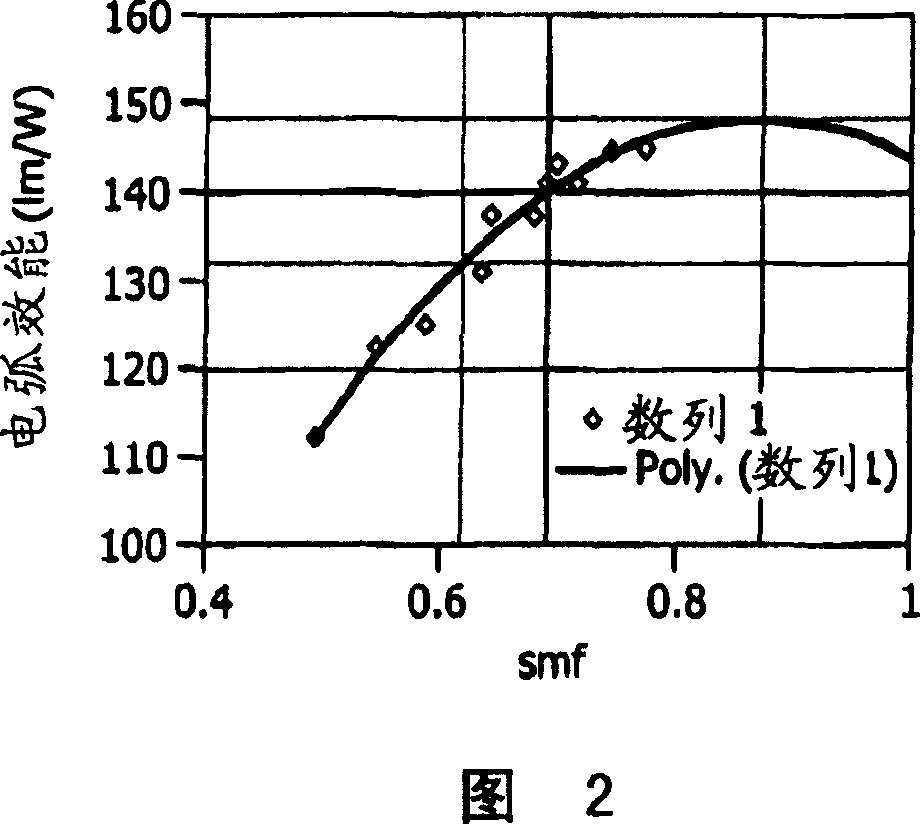

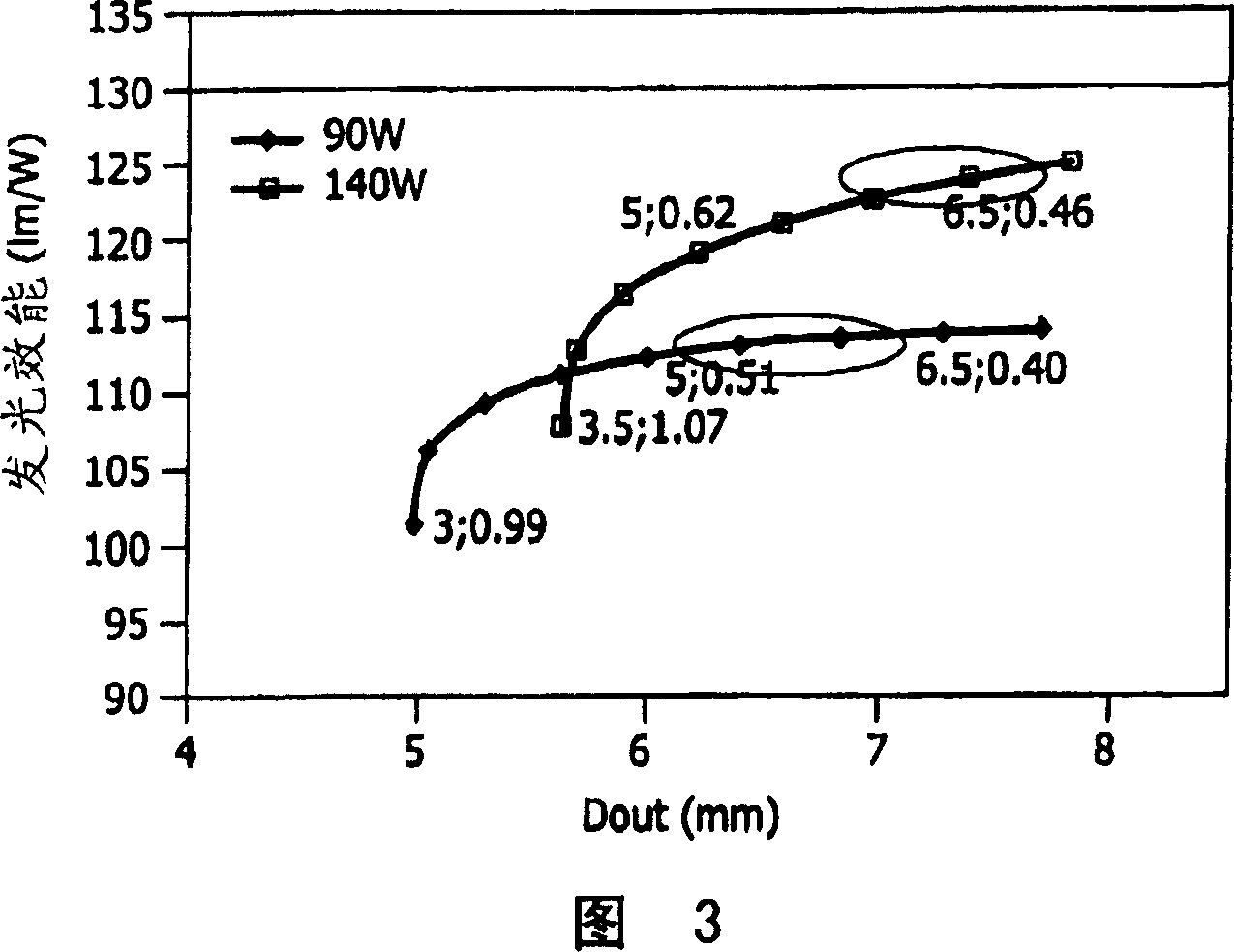

High-pressure sodium lamp

InactiveCN1947218AHigh wall temperatureHigh lamp efficacyElectric lighting sourcesGas discharge lampsVery high frequencyElectrode

The invention is related to high pressure sodium lamp having a nominal power Pla. The lamp, which is designed to be operated at a very high frequency (VHF), has a discharge tube with a ceramic wall and an internal vessel diameter Dint, which encloses a discharge space in which a pair of electrodes at a mutual electrode distance ed and a filling of Na-amalgam with a sodium mol fraction (smf). According to the invention the discharge tube has a ratio ed / Dint of at most 7, preferably between about 5.5 and 4.0.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Luminescent material particles comprising a coating and lighting unit comprising such luminescent material

InactiveUS9334442B2Good effectReduce ignition voltageLuminescent compositionsGas discharge lamp detailsEffect lightAlkaline earth oxides

The invention provides a a luminescent material comprising particles of UV-luminescent material having a coating, wherein the coating (a “multi-layer coating”) comprises a first coating layer and a second coating layer, wherein the first coating layer is between the luminescent material and the second coating layer, and wherein in a specific embodiment the second coating layer comprises an alkaline earth oxide, especially MgO. Further, the invention provides a lighting unit comprising such luminescent material.

Owner:SIGNIFY HLDG BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com