High-pressure sodium lamp

A high-pressure sodium lamp and very high-frequency technology, applied in the field of lighting systems, can solve problems such as inability to realize new opportunities, and achieve good maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

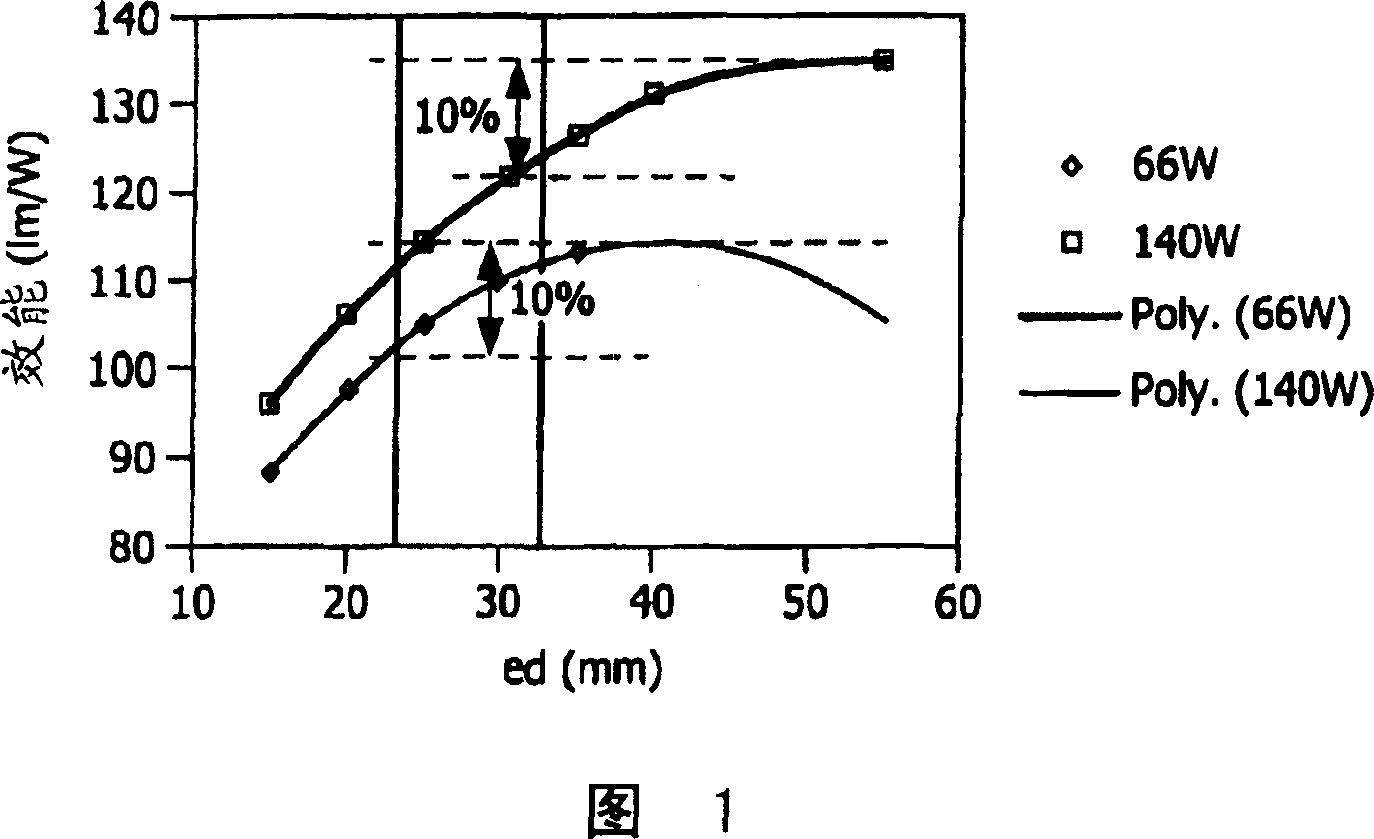

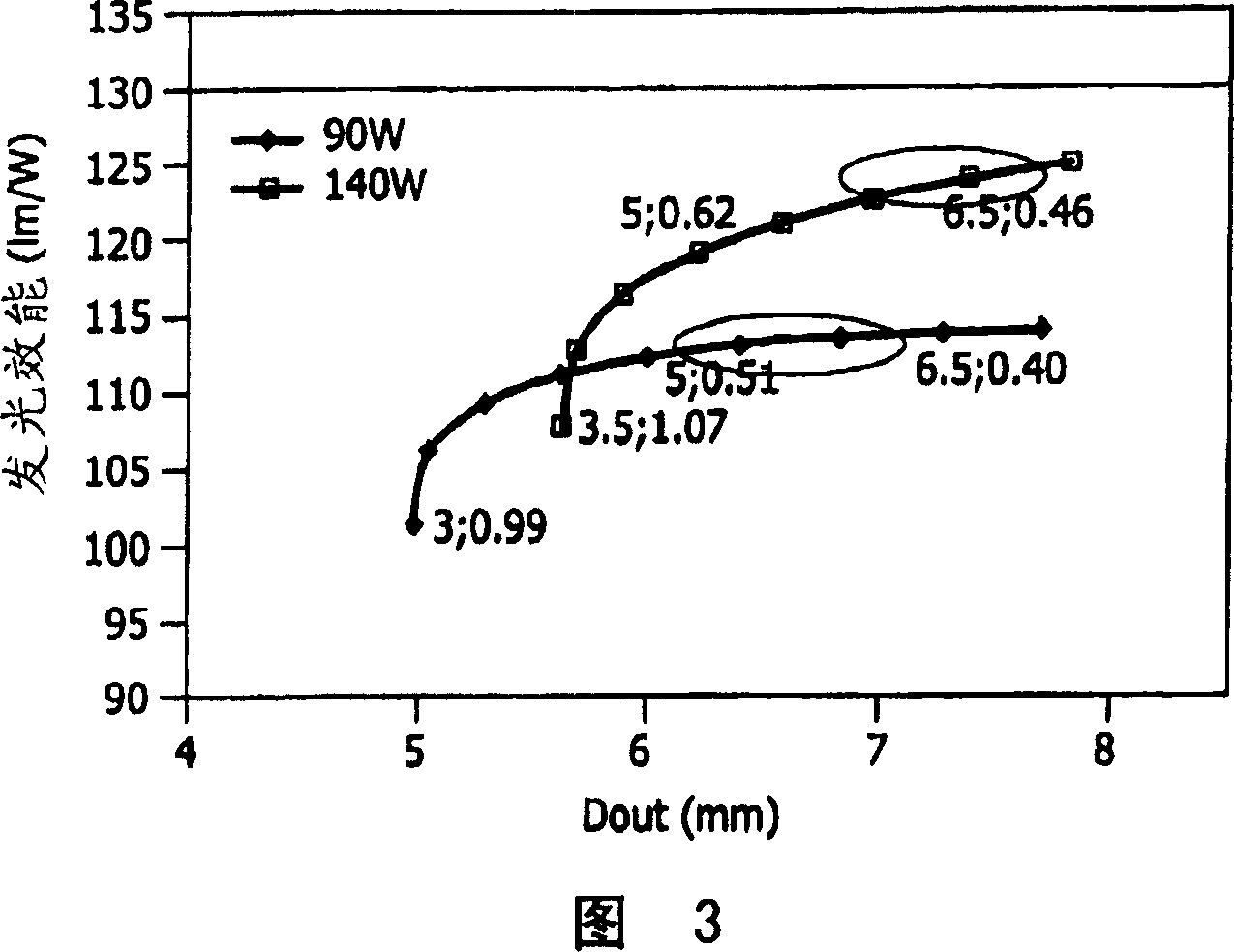

[0037] With electronic ballasts, the lamp voltage can be freely selected, as opposed to working with conventional CuFe ballasts. A shorter light source (shorter electrode distance) gives the possibility to more efficiently bundle the light emitted from the illuminant, resulting in a higher luminous flux on the illuminated surface.

[0038] A consequence of the shorter electrode distance is a lower lamp voltage and thus a higher lamp current. Higher lamp currents lead to higher power losses in the ballast, which in turn leads to lower lamp efficacy (especially if mercury-rich amalgam is used to limit voltage drop). Optimum system efficacy is thus a compromise between lamp, ballast and luminaire efficacy.

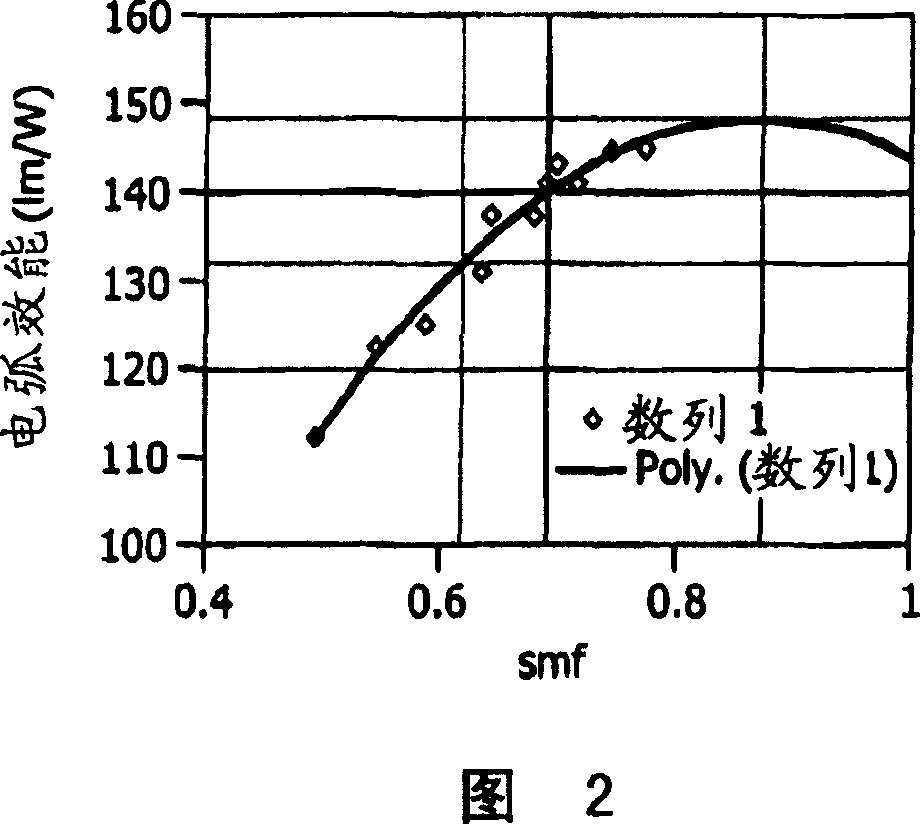

[0039] Therefore lower electrode distances (and thus higher lamp currents) combined with higher ballast efficiencies (>90%) are only possible when VHF ballasts are used. Losses in VHF ballasts are significantly lower than in conventional ballasts: 6 and 12 W at Vla=55 V for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com