Multi-layer gradient high-temperature wear-resistant coating on surface of cutting tool and preparation method thereof

A cutting tool, high-temperature wear-resistant technology, applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems of low deposition rate, discharge stability and controllability, etc. The effect of reducing glow voltage, reducing arcing phenomenon, and increasing coating deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

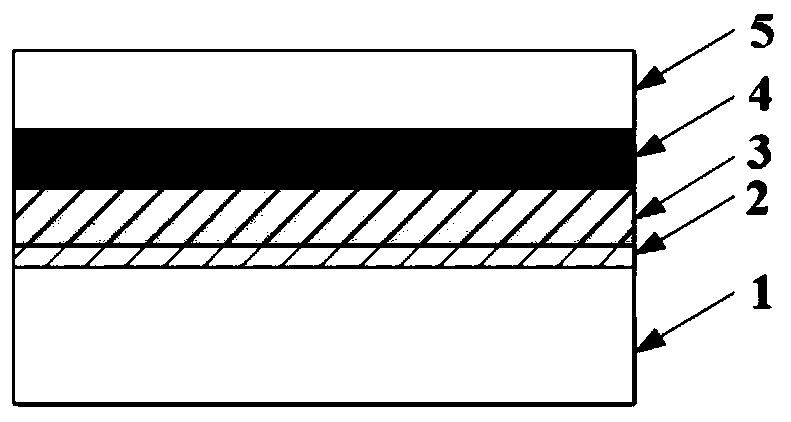

[0036] A method for preparing a multilayer high-temperature wear-resistant coating on the surface of a cutting tool, the steps of the method are as follows:

[0037] (1) Chemical scrubbing substrate 1: Use a cotton swab dipped in petroleum ether to scrub the surface of the sample to be plated with the prepared high-speed cutting tool substrate 1 to remove obvious grease and dust particles on the surface;

[0038] (2) Chemically clean substrate 1: use petroleum ether, acetone, and absolute ethanol to ultrasonically clean high-speed cutting tool substrate 1 for 30 minutes each;

[0039] (3) Heating and vacuuming: Install the clean cutting tool substrate 1 on the workpiece frame of the coating vacuum chamber of the high-power pulse magnetron sputtering equipment, set the heating temperature to 200°C, and the vacuum degree is less than or equal to 2×10 -3 Pa.

[0040] (4) Ion beam cleaning substrate 1: Introduce Ar gas into the coating vacuum chamber until the vacuum degree is 1....

Embodiment 2

[0052] A method for preparing a multilayer high-temperature wear-resistant coating on the surface of a cutting tool, the steps of the method are as follows:

[0053] (1) Chemical scrubbing substrate 1: Use a cotton swab dipped in petroleum ether to scrub the surface of the sample to be plated with the prepared high-speed cutting tool substrate 1 to remove obvious grease and dust particles on the surface;

[0054] (2) Chemically clean substrate 1: use petroleum ether, acetone, and absolute ethanol to ultrasonically clean high-speed cutting tool substrate 1 for 30 minutes each;

[0055] (3) Heating and vacuuming: Install the clean cutting tool substrate 1 on the workpiece frame of the coating vacuum chamber of the high-power pulse magnetron sputtering equipment, set the heating temperature to 200°C, and the vacuum degree is less than or equal to 2×10 -3 Pa.

[0056] (4) Ion beam cleaning substrate 1: Introduce Ar gas and keep the vacuum degree stable at 1.5×10 -2 Pa~5.0×10 -2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com