A device and method for assisting radiofrequency glow discharge of a flat plate by an atmospheric pressure pulse

A technology of radio frequency glow discharge and pulse discharge, which is applied in the direction of discharge tubes, circuits, electrical components, etc., can solve the problems of unstable discharge, conversion, and increased energy consumption, and achieve the goals of increasing concentration, high concentration, and reducing ignition voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

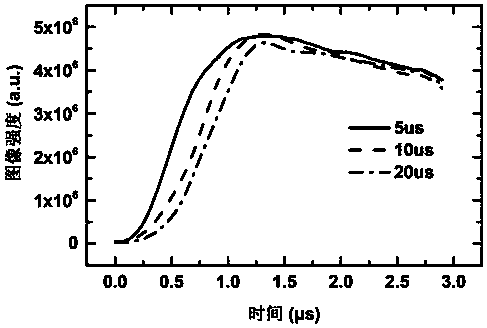

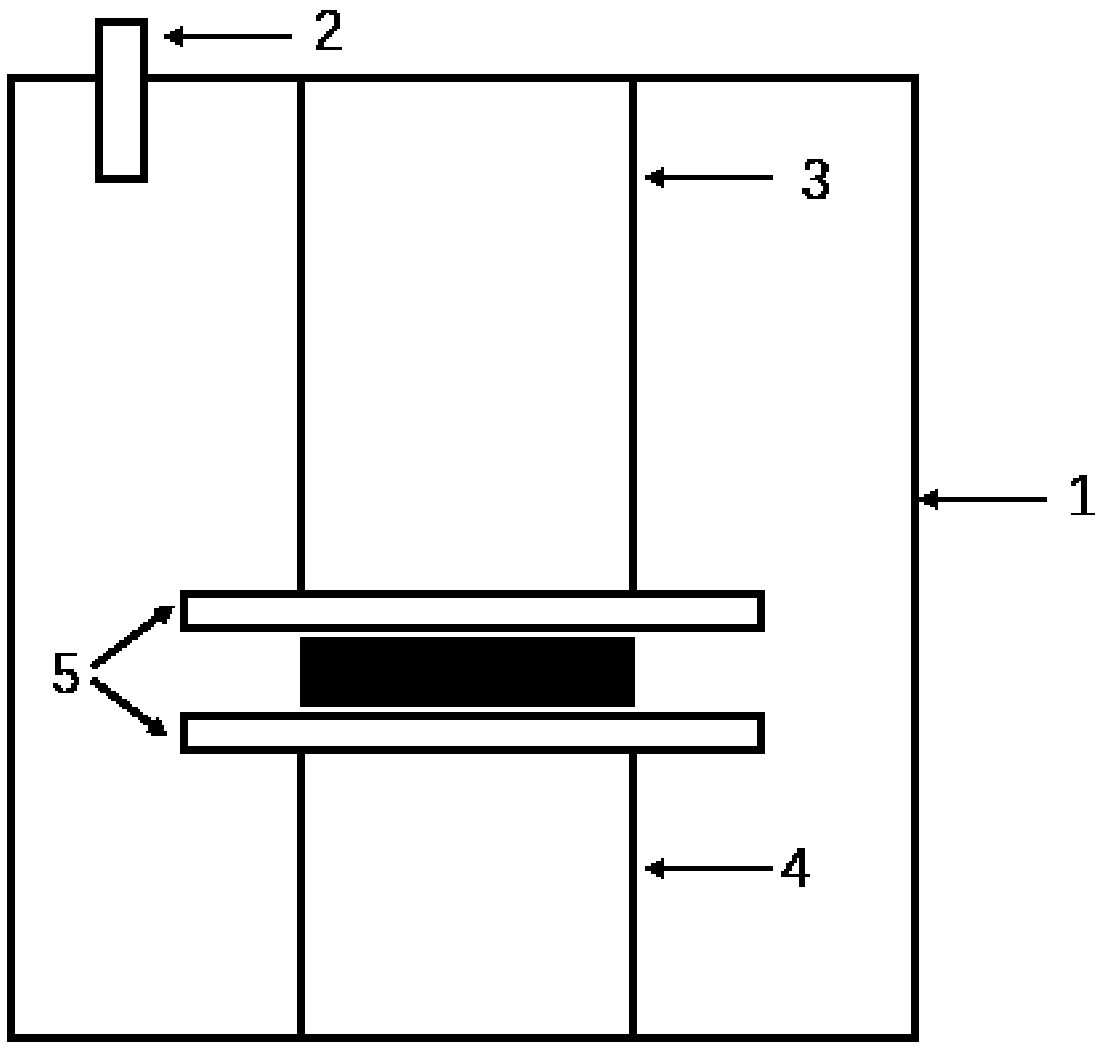

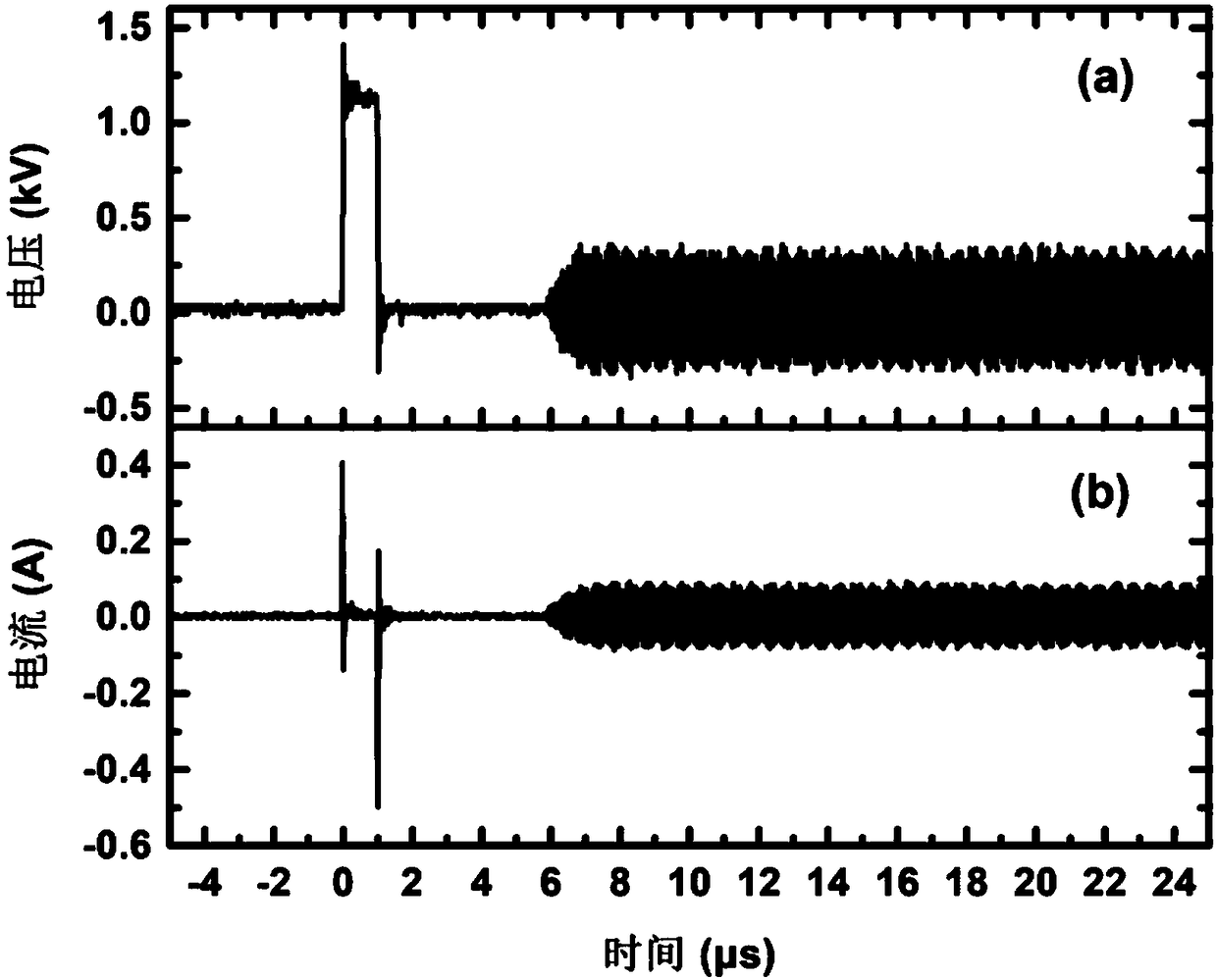

[0024] Such as figure 1 As shown, the present invention provides a device for assisting flat radio frequency glow discharge with pulse at normal pressure, which is a dielectric barrier discharge plasma reactor, which includes a discharge chamber 1 filled with discharge gas The top of the discharge chamber 1 is provided with an air inlet 2, and the discharge chamber 1 is provided with an upper electrode 3 connected to a high-voltage power supply and a lower electrode 4 connected to a radio frequency power supply, and a pair of electrodes is arranged between the upper electrode 3 and the lower electrode 4. The upper and lower dielectric plates 5 are connected to the upper electrode 3 , and the lower dielectric plates 5 are connected to the lower electrode 4 . The upper electrode 3 and the lower electrode 4 are metal cylindrical electrodes with a diameter of 20 mm. The material of the dielectric plate 5 is alumina ceramic sheet or quartz glass sheet, its size is 400mm×400mm×1mm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com