Vacuum ultraviolet flat light source

A technology of vacuum ultraviolet light and flat light source, applied in discharge lamps, cathode ray lamps/electronic injection lamps, electrical components, etc., to achieve the effects of increasing the intensity of ultraviolet light, improving luminous efficiency, and reducing ignition voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

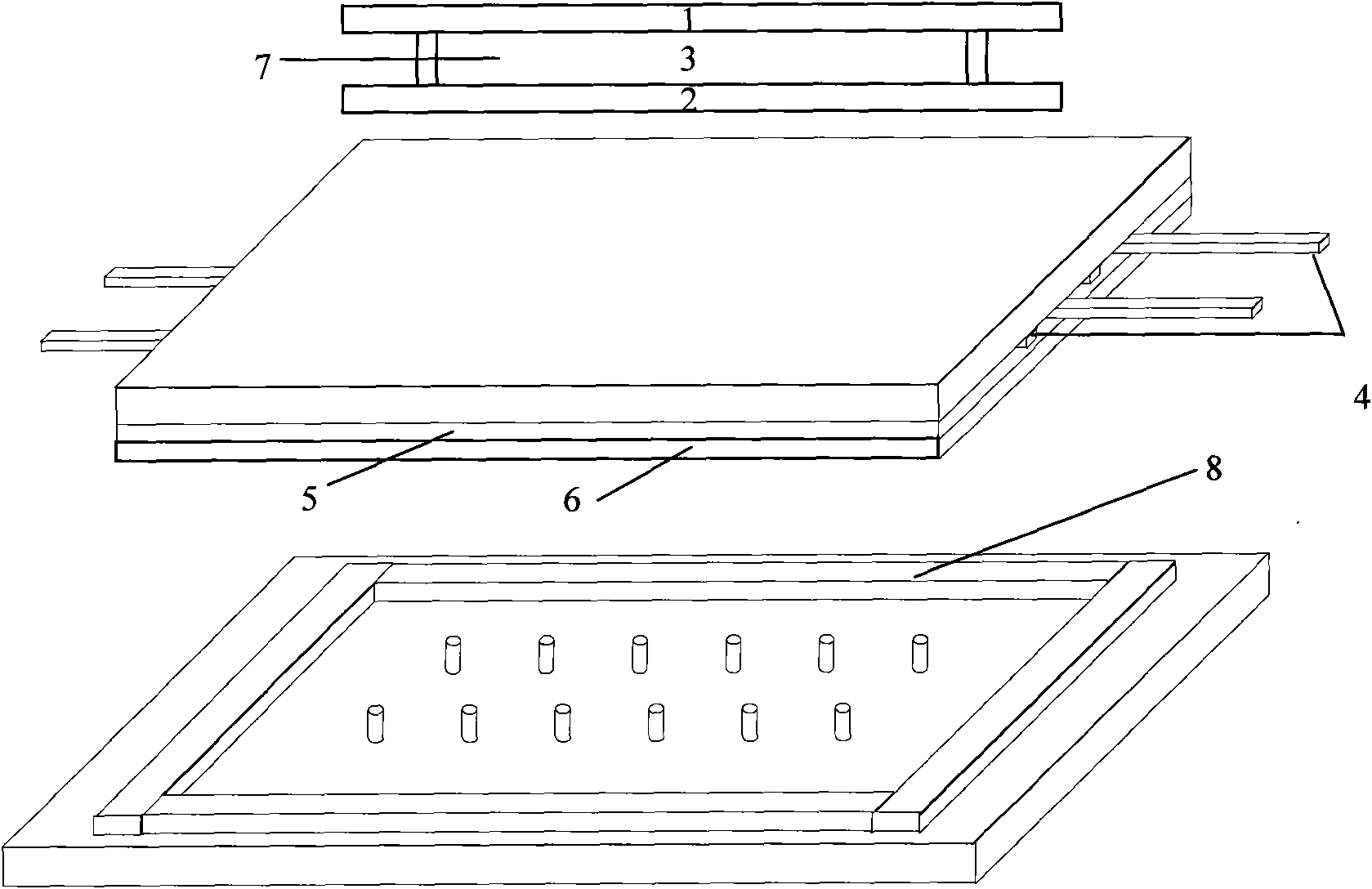

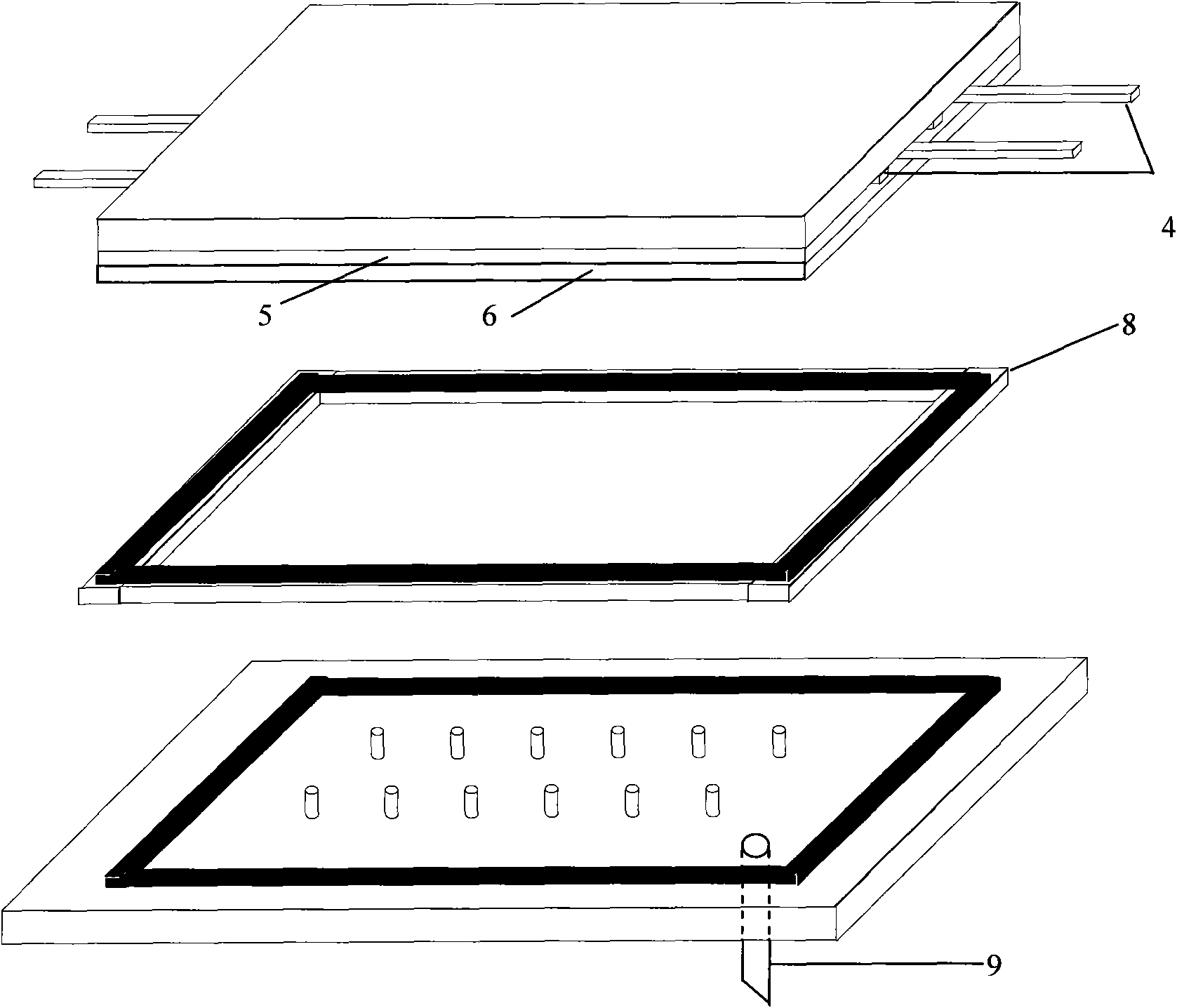

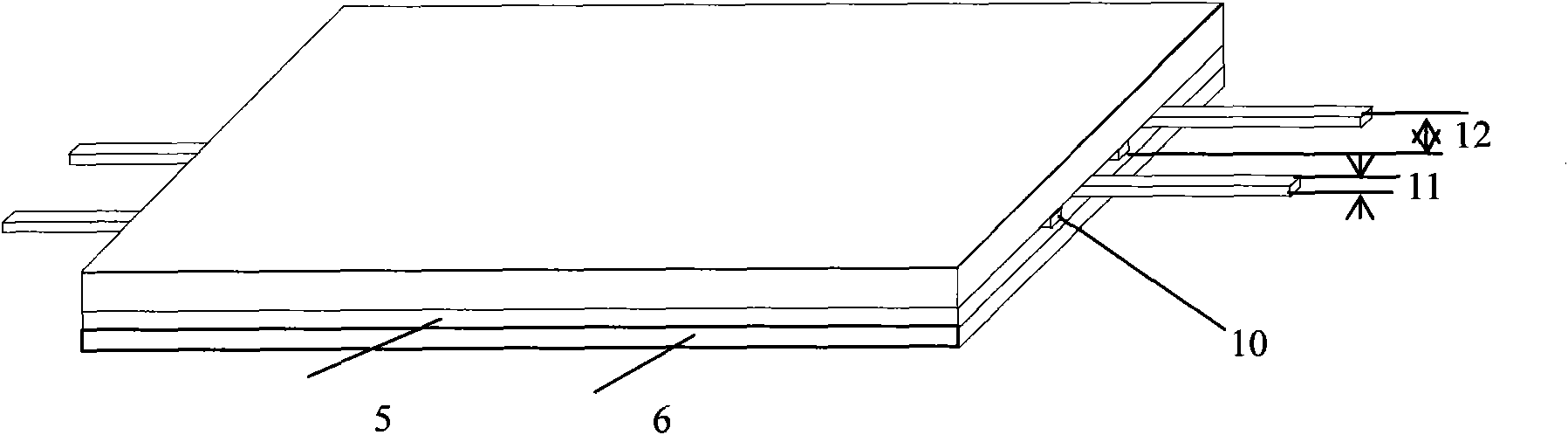

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] Such as Figure 1~6 As shown, a vacuum ultraviolet flat panel light source includes a front substrate 1 and a rear substrate 2, the front and rear substrates are made of quartz glass, and a discharge cavity 3 is provided between the front substrate 1 and the rear substrate 2, and the surface discharge method is adopted. A pair of parallel electrodes 4 are arranged on the front substrate, and are located in the discharge chamber, and a dielectric layer 5 is also arranged on the front substrate, and the paired electrodes are located between the front substrate and the dielectric layer, and on the dielectric layer A protective film 6 is provided, and the discharge cavity is filled with a working gas 7, which can be composed of a mixed gas of Ne and Xe gas, and the proportion of Xe gas is higher than or equal to 20%, or it can be composed of pure Xe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com