Surface discharge electrode structure capable of lowering discharge voltage

A technology of surface discharge and electrode structure, which is applied to the parts, circuits, and electrical components of discharge tubes/lamps, and can solve the problem of high withstand voltage requirements for discharge drive circuit components, reduced operating reliability of drive circuit components, and discharge ignition voltage. and maintenance of high voltage to achieve the effect of improving work reliability, reducing ignition voltage, and reducing discharge voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

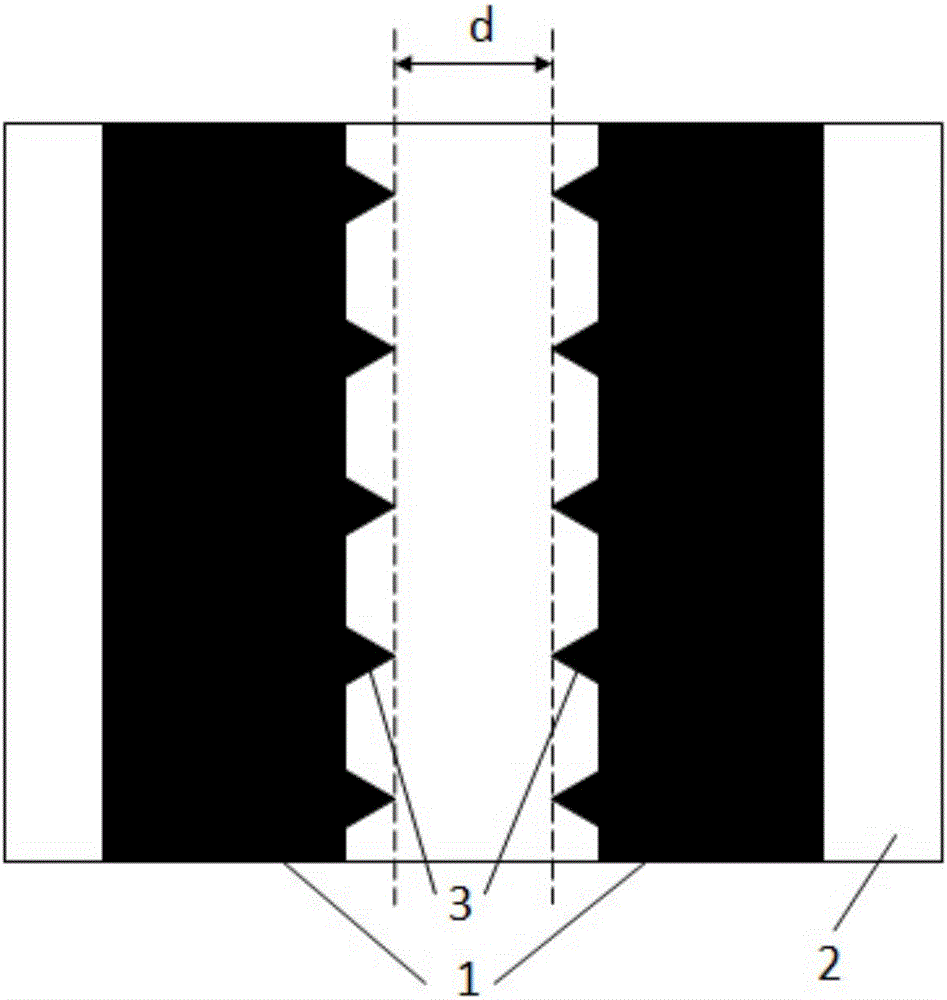

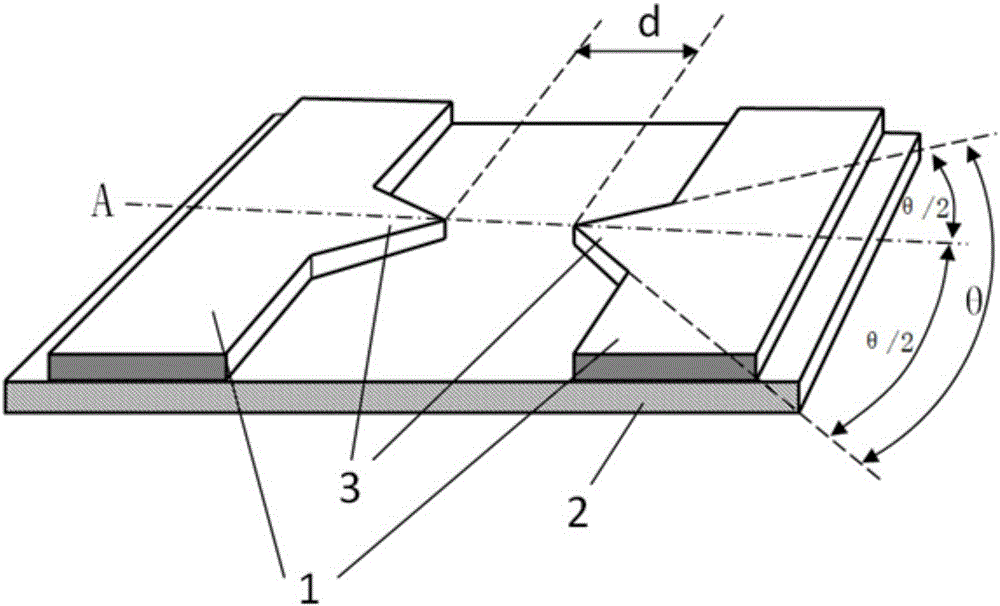

[0024] A surface discharge electrode structure capable of reducing the discharge voltage is used for direct current discharge, including a substrate 2, two discharge electrodes 1 symmetrically arranged on the substrate 2, and two discharge electrodes 1 on the opposite side walls of the two discharge electrodes 1 are respectively provided with A plurality of raised points 3, the pointed end of the raised points 3 is arranged on the opposite end of the discharge electrode 1, the raised points 3 arranged on the two discharge electrodes 1 are symmetrical, the pointed ends of the raised points 3 The shape end angle θ is 30°, and the protruding tip 3 is an isosceles triangle, and the base is on the same level as the side of the discharge electrode. The discharge electrode 1 is made of metal material, and the substrate 2 is made of insulator material. The protruding tip 3 is set on the discharge electrode, under the same condition of the voltage and the distance d between the two disc...

Embodiment 2

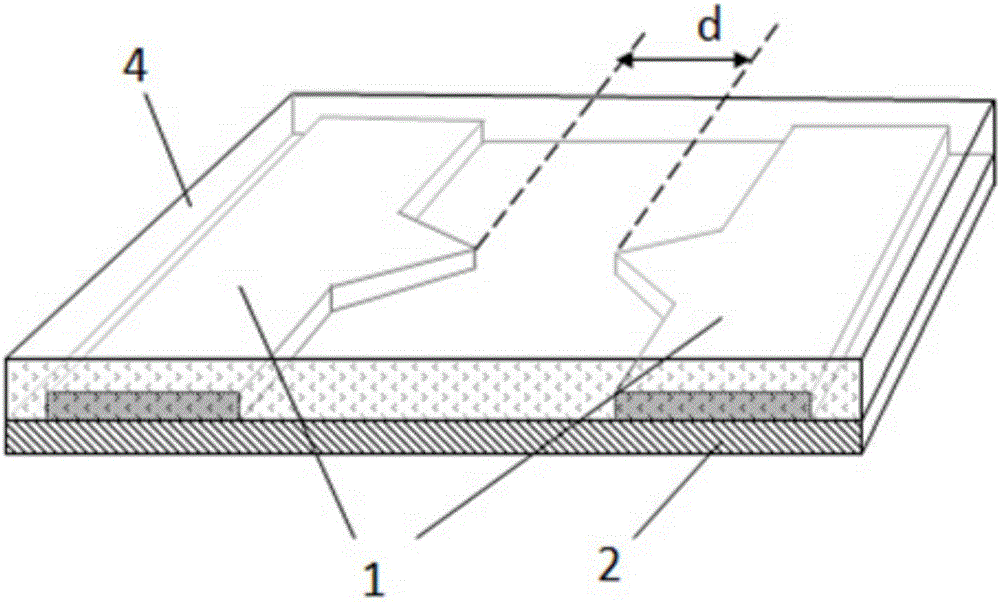

[0026] A surface discharge electrode structure capable of reducing the discharge voltage is used for AC discharge, including a substrate 2, two discharge electrodes 1 symmetrically arranged on the substrate 2, and two discharge electrodes 1 on the opposite side walls of the two discharge electrodes 1 are respectively provided with A plurality of protruding points 3, the pointed ends of the protruding points 3 are arranged on the opposite end of the discharge electrode 1, the protruding points 3 arranged on the two discharge electrodes 1 are symmetrical, the points of the protruding points 3 The angle θ is 30°, and the protruding tip 3 is an isosceles triangle, the base and the side of the discharge electrode are on the same horizontal plane, the discharge electrode 1 is a conductive material, the substrate 2 is an insulator material, the discharge electrode 1 and the substrate 2 The upper surface may be covered with a dielectric layer 4 (the covering dielectric layer may or may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com